TAGGED: ansys-cfd, ansys-fluent, simulation

-

-

July 11, 2024 at 6:54 pm

andrey.eng

SubscriberHello,

I am starting my studies in this field of fluid simulation. I would like to know where I can find study materials or tutorials that can show me the first steps to run this simulation. What physics should I use, what parameters should I configure. I would be very grateful for any help.

-

July 15, 2024 at 12:57 pm

Rob

Forum ModeratorStart with the physics of the absorption mechanism you want to model: ie what is the physical process? From there go through the basic training for geometry, mesh & solver. From there you'll know what's important, and what is available in the solver.

-

July 17, 2024 at 6:53 pm

andrey.eng

SubscriberThe phenomenon I want to study is the process of hydrogen desorption absorption in a metal alloy (powder). The process takes place in a pressure vessel.

Is there a tutorial that comes closest to this application?

-

July 18, 2024 at 11:14 am

Rob

Forum ModeratorMoving powder or a packed bed? What scale are you wanting to model? Ie a single grain using micro CT or a bulk model?

This is why I suggested working out/defining all of the physics of interest before looking at the basic training and learning materials. You can then pick bits out of the tutorials to work up to what you want to model.

-

July 18, 2024 at 12:42 pm

andrey.eng

SubscriberThe powder will remain inert inside the container. The scale is small, the pressure vessel has only 20 Nl. The hydrogen will be inserted into the vessel and the metal alloy will absorb it.

-

July 18, 2024 at 12:47 pm

Rob

Forum ModeratorOK, so what phenomena do you want to model? What do you want to learn from the results?

-

July 18, 2024 at 2:07 pm

andrey.eng

SubscriberI want to model the absorption rate of hydrogen in the metallic alloy, and also check the variation in internal pressure and temperature. I intend to analyze which conditions are most favorable for absorption.

-

July 19, 2024 at 9:59 am

Rob

Forum ModeratorIs absorption the rate limiting step, or getting the hydrogen to the middle of the packed bed? It's possible to model a lot of physics in Fluent, but you need models for this, and depending on what you need you will need to assign values to, or write, these models. Hence, all of the planning before going anywhere near a computer.

-

July 19, 2024 at 12:56 pm

andrey.eng

SubscriberI would like to analyze both things, both the absorption rate and the amount of hydrogen into the metal alloy medium.

-

July 19, 2024 at 1:03 pm

-

July 19, 2024 at 2:59 pm

Rob

Forum ModeratorIt's a way of doing it. Are you using porous media for the powder? What initial condition are you setting, how are you modelling hydrogen density and how are you absorbing the hydrogen onto the powder?

-

July 19, 2024 at 4:16 pm

andrey.eng

SubscriberSo, these are my doubts. What would be the best boundary conditions to represent this situation?

-

July 19, 2024 at 4:32 pm

Rob

Forum ModeratorIdeal gas and mass flow or pressure depending on what you know. It's not an easy problem, hence all my questions as I can't tell you what to model, only what buttons to use.

-

July 19, 2024 at 4:59 pm

andrey.eng

SubscriberI would like to work as a function of pressure, as it is an important parameter for the absorption of hydrogen in the metallic alloy. For example, I have the maximum refill pressure in the canister which is 10 bar, I know I cannot exceed this value, but I can look for a value that meets my needs. As for modeling the powder, I really don't know how to follow it. I also have data on the canister operating pressure.

-

July 19, 2024 at 5:02 pm

Rob

Forum ModeratorOK, so possibly a transient pressure profile for the boundary. Have a look at the mass source options in Fluent's cell zone conditions.

-

July 23, 2024 at 12:07 pm

andrey.eng

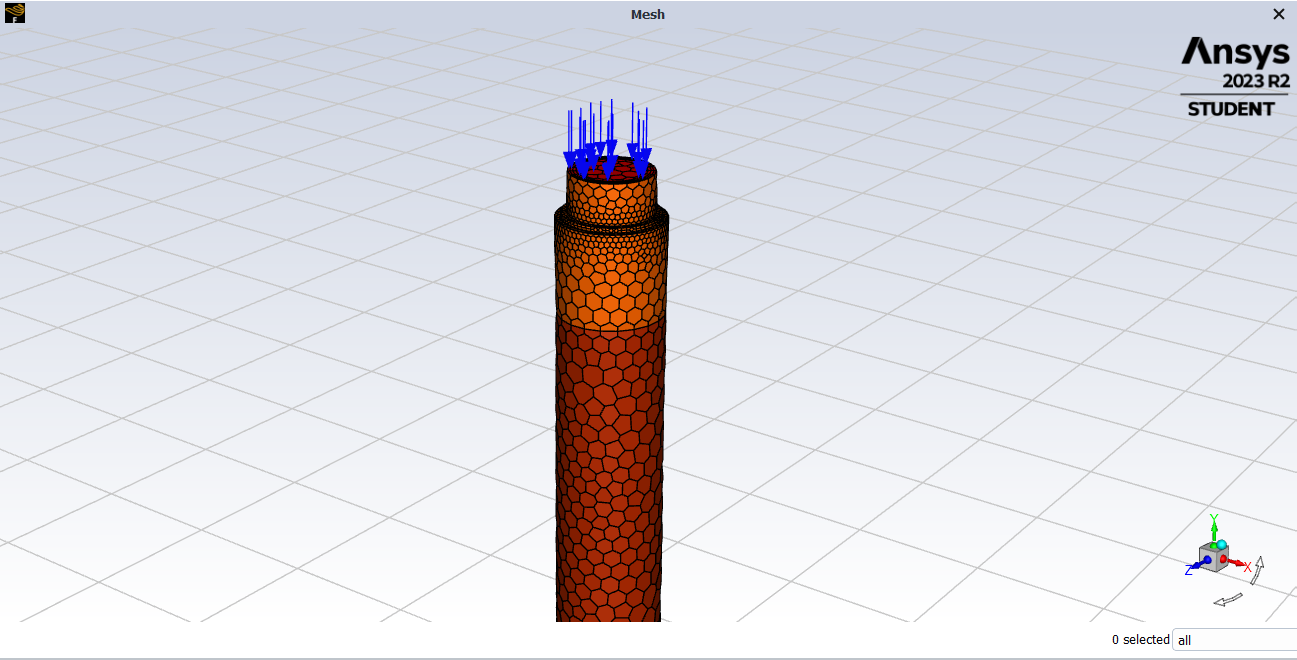

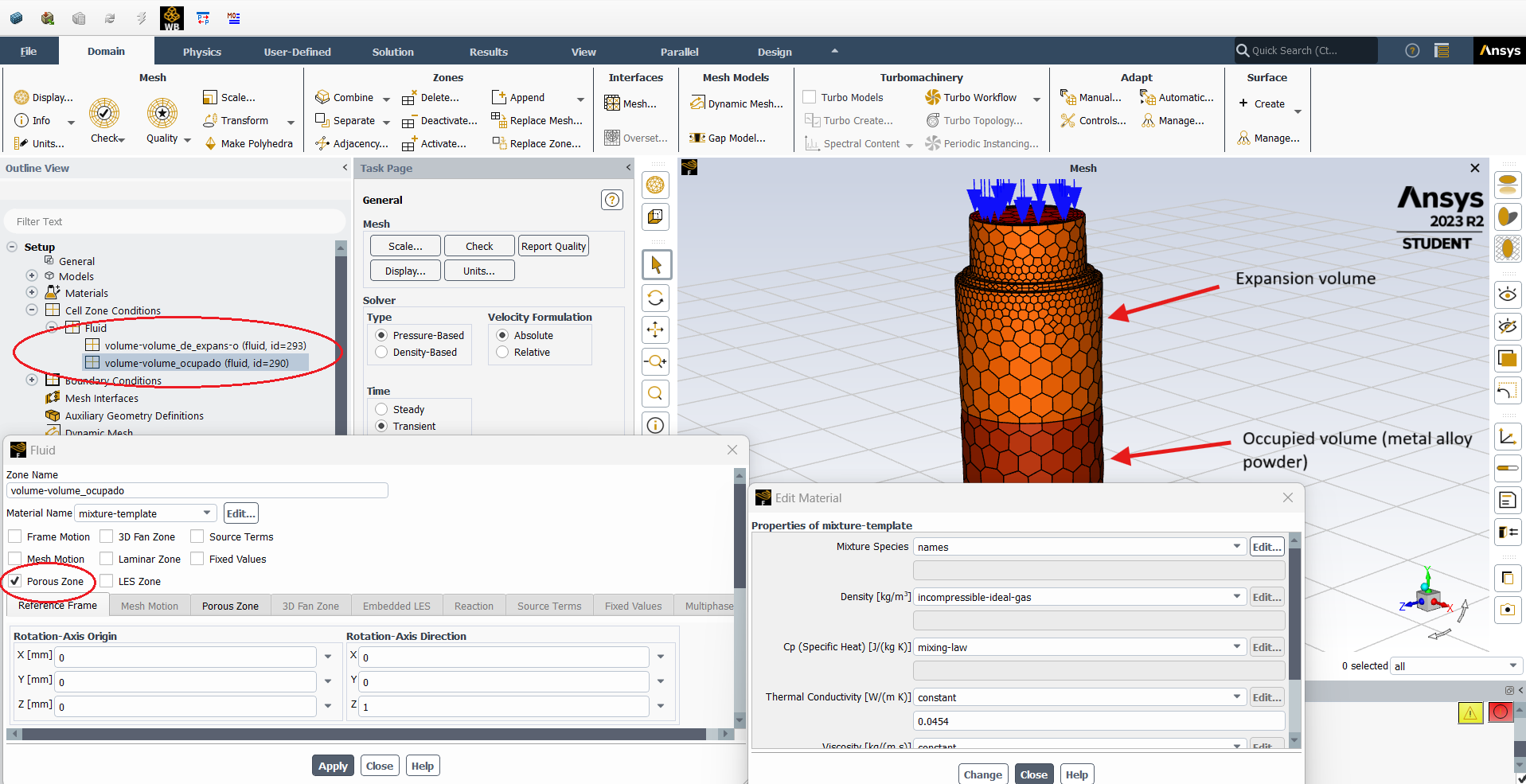

SubscriberRight, can I keep my model as it is in the image above? With the mesh divided into two parts.

-

July 24, 2024 at 12:28 pm

Rob

Forum ModeratorYes, you want the lower region regardless of how you include the absorper material.

-

July 26, 2024 at 12:41 pm

-

July 29, 2024 at 10:54 am

Rob

Forum ModeratorYou don't, as there's no flow in a solid region. Hence my comments regarding porous media.

-

July 30, 2024 at 4:22 pm

-

July 30, 2024 at 4:23 pm

andrey.eng

SubscriberI have the physical properties of the metallic alloy.

-

July 30, 2024 at 4:35 pm

Rob

Forum ModeratorThe resistance coefficients etc will depend on particle size etc - look for the Ergun Equation option in the manual (Porous Media). Absorption effects are going to be more interesting.

-

August 5, 2024 at 4:51 pm

andrey.eng

SubscriberHow do I represent the metallic alloy in a volume? For example, I need to configure one volume being hydrogen and another being the metal alloy, in "materials" do I need to configure a mixture? I want to show to the software that hydrogen will be absorbed by the metallic alloy and that the internal volume of material can undergo a possible expansion.

-

August 6, 2024 at 8:38 am

Rob

Forum ModeratorPlease read & action my previous comment. Unless you need a surface material for hydrogen I don't think you need the species models.

-

August 22, 2024 at 1:46 pm

andrey.eng

Subscriber -

August 23, 2024 at 2:03 pm

andrey.eng

SubscriberHello,

What would be the best approach to this type of problem Eulerian or Lagrangian?

-

August 23, 2024 at 2:20 pm

Rob

Forum ModeratorI'd use porous media, but otherwise Eulerian-Granular and read the bit on packed beds.

-

August 23, 2024 at 3:55 pm

andrey.eng

SubscriberRight, as I need to capture the hydrogen absorption phenomenon in the metal alloy, I need to activate the species model, right? The domain is divided into two parts, one containing hydrogen and the other containing the metallic alloy, in the volume of the alloy, I will configure it as a porous medium and in this medium I configure the alloy or hydrogen material?

-

August 23, 2024 at 4:16 pm

Rob

Forum ModeratorBoth zones will be hydrogen, but one zone will also be porous with a porosity and flow resistance coefficients.

I think you'll need species, and then there should be some surface reaction options for porous media: check as I'm not as familiar with that bit. There should be a m2 surface per m3 volume value.

-

- The topic ‘Hydrogen Absorption Simulation – Ansys Fluent’ is closed to new replies.

-

5014

-

1683

-

1387

-

1248

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.