-

-

February 27, 2024 at 7:47 am

luna6362

SubscriberHi,I am using DPM and MRF to simulate the seperation of oil and R32 inside the compressor.

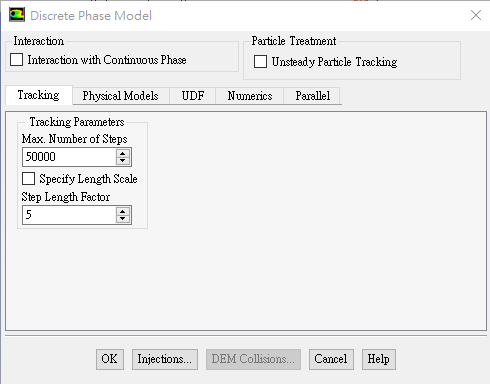

My setup in DPM shows in pic below.

I have some questions here.

(1) I have to know the mass flow rate at outlet to calculate the OCR of the comperssor(how much oil comes out from the compressor).

I know I can use Trajectory Sample Histograms to know the distributed of the particle's mass flow.

But it seems to assume the situation that all the particles have reached the outlet.

And the other problem of using Trajectory Sample Histograms is the plot doesn't have any units on it.

So can anyone give me some methods that I can get the mass flow rate on the outlet surface?

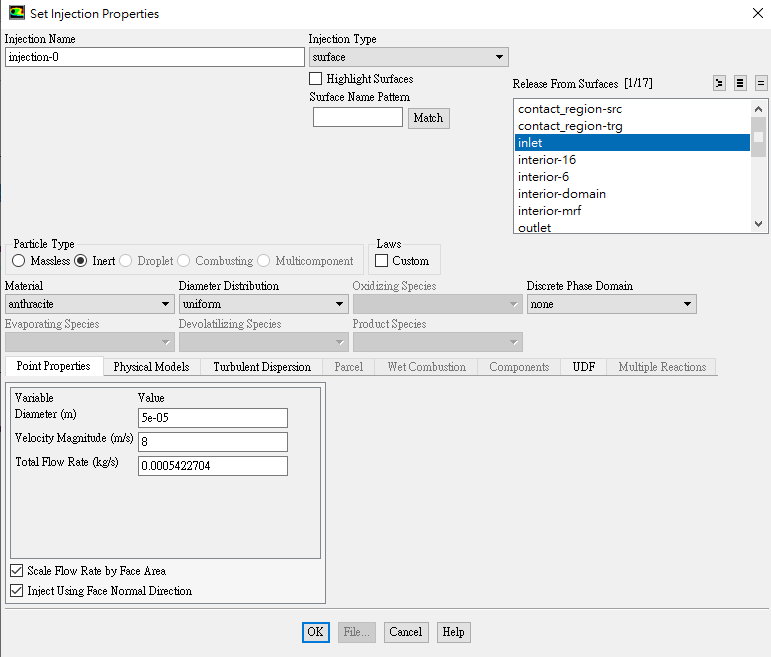

(2)If the velocity of R32 at the inlet is 8m/s(steady situation).

And I want the particle have same velocity inject into the compressor.

Is it right way that I set the Velocity magnitude of DPM to 8m/s?

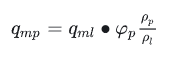

(3) I use this formula to calculate the Total Flow Rate setting of DPM.

qmp = the Total Flow Rate setting of DPM

qml = the Mass Flow rate of R32 when using pure R32 to simulate

φp = Particle Volume Fraction

ρp/ρl = solid-liquid density ratio

Is this formula right?

I find this formula on the internet but I can't find this formula in the guide of Ansys.

So I am not sure it is right to use.

Hope someone can give me some suggestions!

Thank you for reading my question.

-

February 27, 2024 at 10:21 am

Rob

Forum ModeratorSetting the parcel inlet velocity to the gas flow is correct. Scaling to surface area can make post processing a little more complicated (parcels aren't all the same mass) but is otherwise fine.

Look in the reports for "escaped mass" under DPM. However, with droplets in DPM they'll still bounce off walls so unless you set something otherwise there's a fairly good chance that all of the droplets/particles will reach the outlet.

No comment re the size equation. For a single injection size you set the mass flow that you want to include. Whether it's the correct mass isn't something I can judge.

-

February 28, 2024 at 11:23 am

luna6362

SubscriberHello Rob!Thank you for your reply.

I still have some questions.

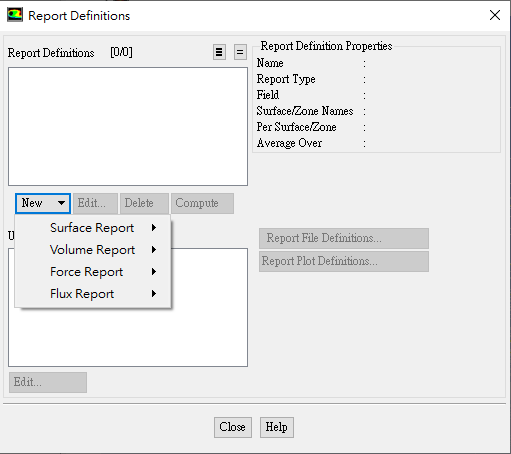

(1)Sorry I can’t find the reports in DPM that called “escaped mass”.

Could you please tell me where the function is? What should I set if I want to get the volume(the unit is kg/s)?

(I have set some wall to be in "trap",so in my case,the particle will not reach outlet for all.)

(2)So your meaning is the Total flow rate in the DPM setting is just very pure volume of the mass flow rate that I want the particle to be?

Don’t it need any complicated formula to swich?

Thank you again!

-

-

February 28, 2024 at 11:55 am

Rob

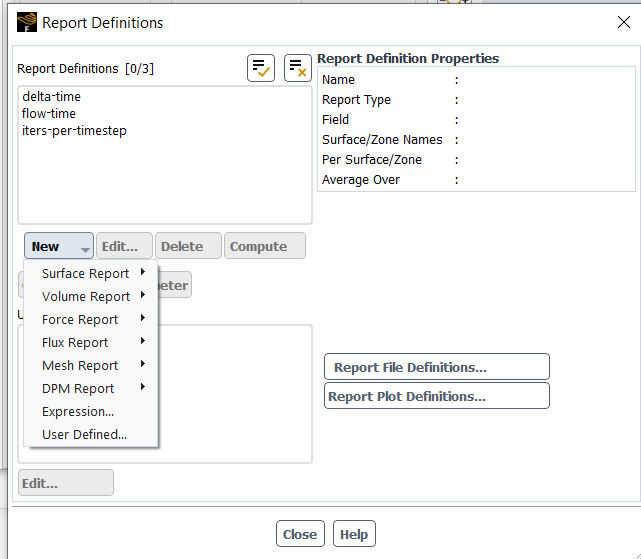

Forum ModeratorOnce the DPM model is on, look in Solution>Report Definition> New > DPM Reports.

Re the mass & volume. You're injecting a mass of parcels into the domain, not a volume of particles. Have read up on parcel theory, that should resolve the mass & volume confusion.

-

February 28, 2024 at 12:18 pm

luna6362

SubscriberThank you!

(1)I just open the Report Definition.And I am surely turn on the DPM model.

But I didn't see the DPM Reports????.

(2)I will go to read parcel theory.Thank you so much.

DPM model is so complicated than I thought.

One last qusetion about the Total Flow rate in DPM!

So if the mass flow of oil inject into the compressor is 0.0005412 kg/s.

The Total Flow rate in DPM is not so simplely set into 0.0005412kg/s?

-

February 28, 2024 at 12:59 pm

luna6362

SubscriberHello Rob!Sorry for disturbing you again.

I just found a statement on User guide said that it don't need to set the Total Flow Rate when I am running uncoupled calculations.

Is it correct?

-

February 28, 2024 at 2:27 pm

Rob

Forum ModeratorIf the mass of oil (spray) into the compressor is 0.0005412 kg/s then the DPM injection flow rate is 0.0005412 kg/s. The parcels will sort out so that each parcel is a fraction of that value: so for a surface injection with 10 facets (10 parcels) each parcel will be 0.00005412 kg/s assuming you don't scale by facet area or mess with the parcel settings.

Initialise the model, there's a chance some of the reports aren't active.

-

February 28, 2024 at 2:46 pm

luna6362

SubscriberI got it!! Acutually I selected scaled flow rate by face area before.

After reading your explain,I think I don't need to select it.

But I still can't choose DPM report.

Is it relative with running steady DPM case?

I don't want to run unsteady DPM case,because I think in my compressor case is unnessecery.

If I am wrong please correct me.Thank you so much.

-

-

February 28, 2024 at 3:43 pm

Rob

Forum ModeratorSteady looks OK here too. Run a couple of iterations and try again.

-

February 29, 2024 at 8:47 am

luna6362

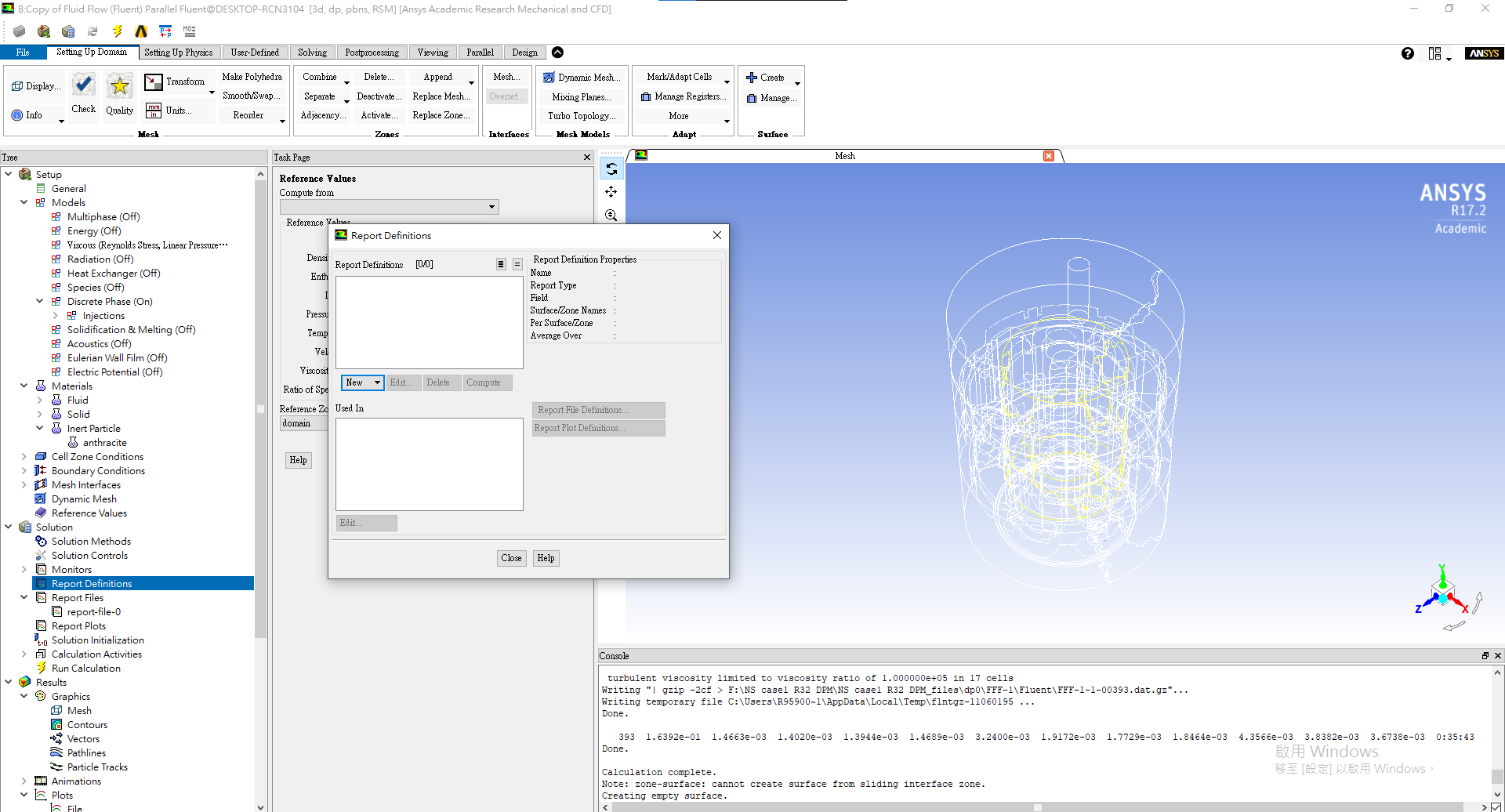

SubscriberIt have run 293 iterations but still can't use DPM report????

I found the other method to get the mass flow rate of outlet.

It called summary in DPM's reports of results.

But it is also unavalible untill I let DPM be unsteady.

But if I want unsteady DPM for steady flow cases, it ruled that I should turn on the interaction with continous phase.

But I don't want my DPM interact with continous phase.

What should I do? Thank you again.

-

-

February 29, 2024 at 11:41 am

Rob

Forum ModeratorAh, running on R17.2 isn't going to help. A lot of the DPM reports were added/improved in the 2020-2022 releases. R17 is around 8 years old now.

-

March 1, 2024 at 7:06 am

luna6362

SubscriberSo sad.????So I can just use summary to get the mass flow rate?

-

-

March 1, 2024 at 9:49 am

Rob

Forum ModeratorPretty much, or the DPM.out files. Updating is possibly your best option.

-

March 14, 2024 at 8:48 am

luna6362

SubscriberYes,I think updating is the best solution.????

I use "total flow rate/num tracked*escaped track" to calculate the mass flow rate of outlet in the end.

Doesn't very sure that this method is right or not.

Another question here.Sorry for disturbing you again.

I change different value of total flow rate,but the num of escaped track didn't have any difference.

Is this a regular result? Thank you so much always.

-

-

March 14, 2024 at 9:20 am

Rob

Forum ModeratorTracks are the parcels, remember we're not tracking each particle as there would be too many. Parcel theory is used to keep the compute overhead sensible.

-

March 14, 2024 at 9:42 am

luna6362

SubscriberYes I always remember this theory.So actually the total flow rate is only influence the streamline result?

-

-

March 14, 2024 at 10:26 am

Rob

Forum ModeratorMass flow will alter carrier flow (if coupled), if uncoupled it shouldn't do anything.

-

March 18, 2024 at 7:25 am

luna6362

SubscriberThat's a useful information to me.Thank you so much.

So if it is uncoupled in my case.

Is it okay to use this simple formula "total flow rate/num tracked*escaped track" to calculate the mass flow rate of outlet in the end?

I got this calculate method idea from this instruction.

https://ansys13.ansys.com/KnowledgeArticles/Phase-1/2058026/2058026.pdf

-

-

March 18, 2024 at 10:10 am

Rob

Forum ModeratorIf you've not used "scale by area" on the injection it's not a bad idea as all parcels will be the same mass. Equally, if that is the case, particles (parcels) injected is what goes in, and particles (parcels) escaped is what leaves - do you want the mass or fraction of mass on the outlet?

-

- The topic ‘How to know the mass flow rate at outlet surface when using DPM model?’ is closed to new replies.

-

4954

-

1639

-

1386

-

1242

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.