TAGGED: ansys-fluent, dpm, fluid-flow, multiphase, udf

-

-

July 21, 2021 at 12:24 am

Anadi_Mondal

SubscriberHello,

How to get deposition(droplets) mass flux (kg/s*m^2)from ANSYS if I use Discrete Phase Model and Eulerian Wall Film Model to simulate annular flow in a pipe?

If I inject droplets using injections ,a part of droplets will be deposited on the liquid film . I want to get this deposition mass flux on liquid film from ANSYS. Will you give any idea to get this?

Regards,

Anadi

July 21, 2021 at 6:55 amAmine Ben Hadj Ali

Ansys EmployeeThere is a variable called wall impinging mass flux. Without using EWF you might rely on Accretion rate.

July 21, 2021 at 7:13 pmJuly 22, 2021 at 6:06 amAmine Ben Hadj Ali

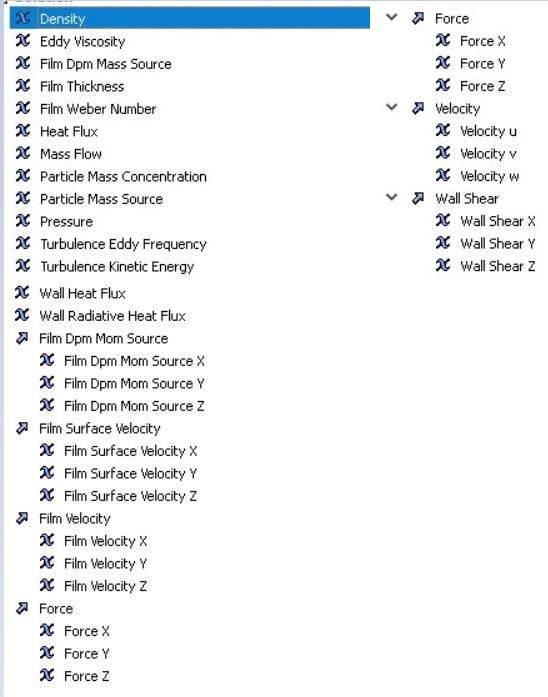

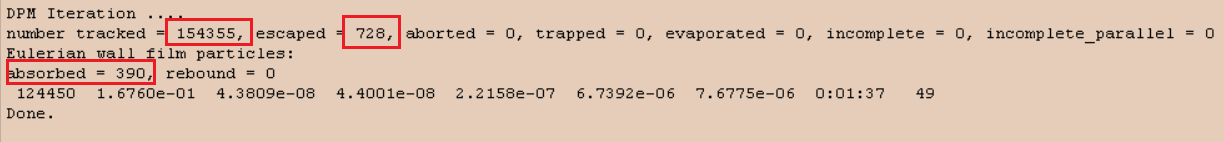

Ansys EmployeeHi as the question was related to Fluent I was commenting on what you can select under Fluent. First check that variable there and then we can talk about why it is not appearing in CFD-Post (which is another Ansys Product). Film DPM Mass Source should be the right naming there.

July 27, 2021 at 2:41 amAnadi_Mondal

Subscriber

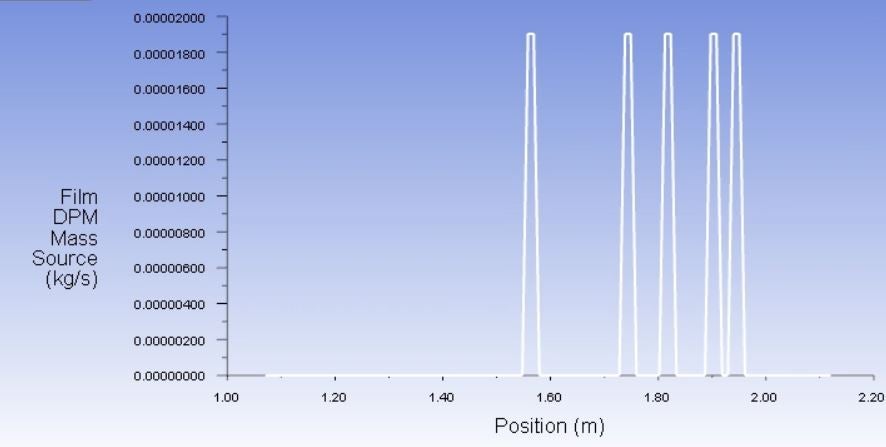

I am getting the Film DPM Mass Source like below image. But, I am expecting a continuous increasing trend curve from inlet of the tube to outlet. As same heat flux is applied at the wall ,the dpm mass source should have an increasing trend towards outlet. Here I am getting some spikes of same length only.

What might be the reason of getting some spikes only? I am using Discrete Phase Model and Eulerian Wall Film Model to simulate annular flow in a pipe

Regards Anadi

July 27, 2021 at 7:40 amAmine Ben Hadj Ali

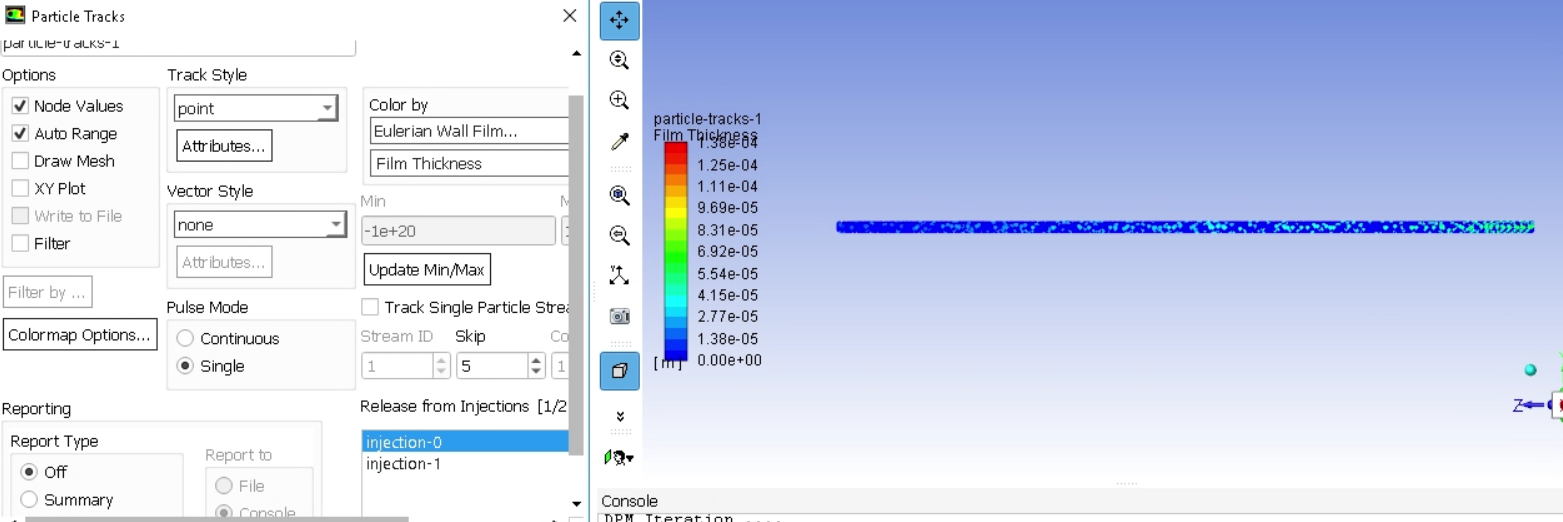

Ansys EmployeeI cannot judge it as I do not have details about where the droplet are impinging on the film. Display particle Tracks + Film to see if the peaks make a sense or not-.

July 27, 2021 at 9:47 pmJuly 28, 2021 at 6:13 amAmine Ben Hadj Ali

Ansys EmployeeOkay: I recommend always to rely on Fluent Post-Processing in these DPM cases. Looks like a plug of droplets are coming from inlet to outlet and not much being deposited on the walls.

Best to do a DPM summary in Fluent to understand the fates of the particles.

July 28, 2021 at 7:08 amAnadi_Mondal

Subscriber

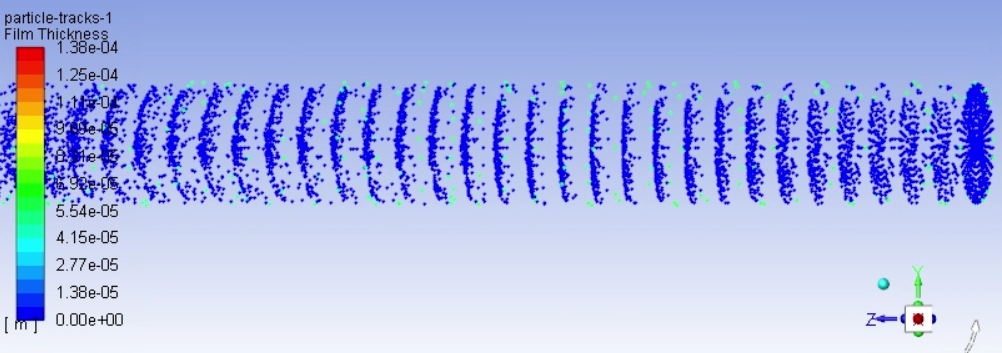

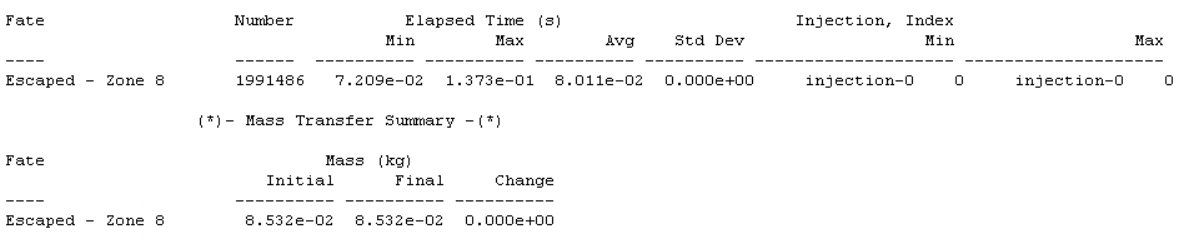

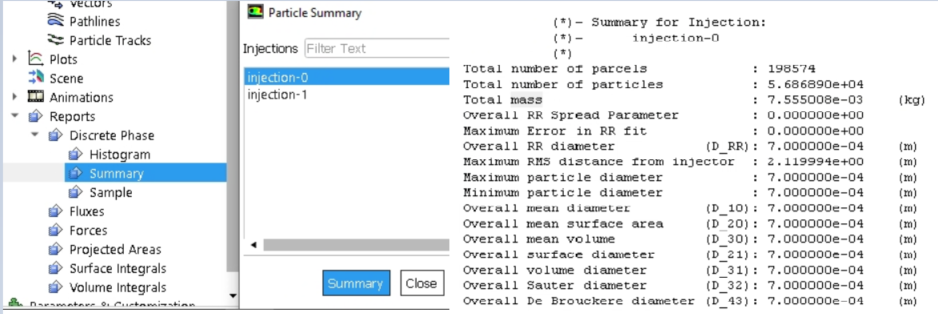

Here is the DPM summary. I think you are correct, not much particles are deposited on the film/wall. If can be happen due to droplet size, high vapor velocity etc . Still, I am expecting a continuous increasing trend graph, not only some spikes. Could you suggest anything(changes in parameters/ settings) to get a continuous graph?

Regards Anadi

July 28, 2021 at 10:38 amRob

Forum ModeratorIf you're firing droplets down a straight pipe why would they hit the walls?

July 28, 2021 at 6:05 pmAnadi_Mondal

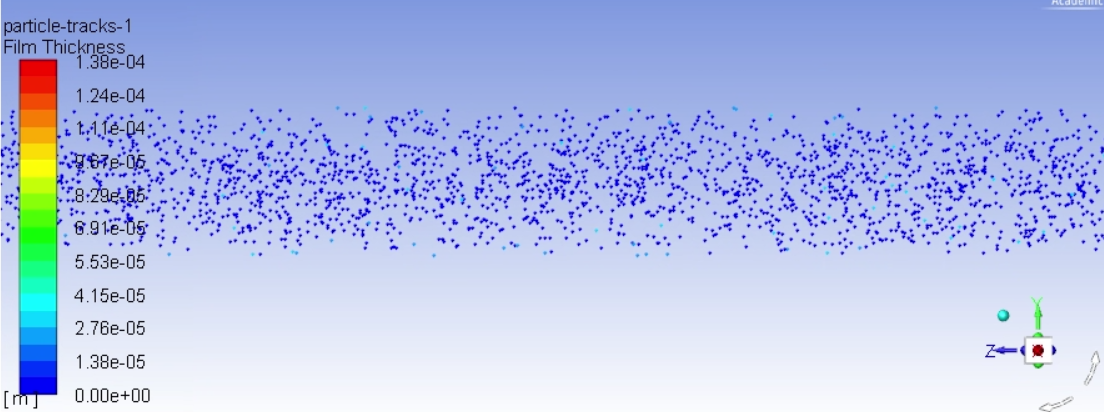

Subscriber& There will be very less droplet deposition near the injection surface but deposition should increase towards the outlet(away from injection surface). Droplets have random velocity away from injection surface(please see the attached image). So, the probability to touch the liquid film/film wall should increase, means more deposition.

If above assumption is wrong , then how can I inject droplets in the tube to simulate core( vapor is continuous phase and liquid droplets are discrete phase) of annular flow.? If the droplets touch the liquid film formed on the wall by EWF , it should be trapped there.

Here I am thinking to simulate 'liquid film' by EWF and 'core '( continuous vapor phase and discrete liquid droplet phase) by DPM to simulate annular flow in a pipe.

Moreover, It's a vertical tube and flow is going upward.

Zoom in view (little away from injection surface)

Regards

Anadi

Regards

Anadi

July 29, 2021 at 6:48 amAmine Ben Hadj Ali

Ansys EmployeeIs all about the injection direction and physics: heavy droplets might settle down. Lightweight will travel with the flow. Estimate the Stokes Number and judge the droplet behavior. You are getting what you are inputting into the Fluent. You might also need to account for more dispersion (turbulent) as well as Lift Force. For Lift you require a fluid lift force.

Random velocity fluctuation is not a warranty that you will get more droplets deposited.

July 29, 2021 at 8:25 amRob

Forum ModeratorAnd heavy droplets will only settle if gravity is on.

August 2, 2021 at 7:27 pmAugust 3, 2021 at 7:27 amAmine Ben Hadj Ali

Ansys EmployeeOthers are still in the domain not associated with a "final" fate. DPM Extended Summary can provide more insights. Accessible from TUI under /report. Cheers.

August 3, 2021 at 6:45 pmAnadi_Mondal

Subscriber

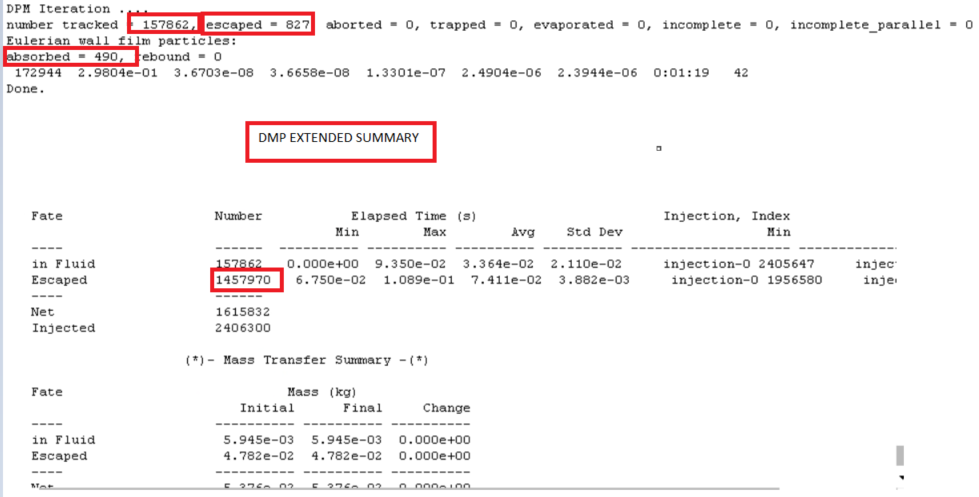

Here is the extended summary. From DPM iteration, I see escaped particles are 827, but in extended summary escaped particles are 1457970. What's the difference between these two?

Here, The number of 'Number tracked 'and in Fluid particles is same.

I decreased the particles diameter and see more particles are being absorbed on the wall film because particles having small diameter are more influenced by turbulence. But, still did not get any continuous upward graph .As deposition mass flux should increase from the injection surface to outlet, I am expecting a continuous graph. But, getting some discrete spikes only.

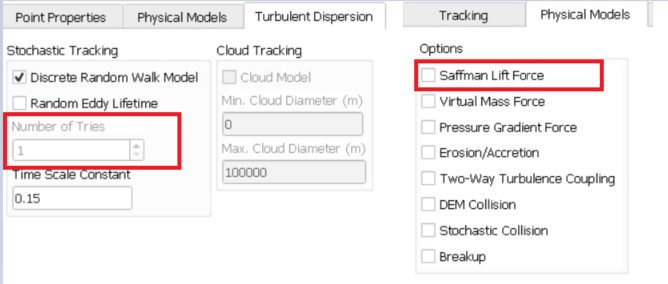

In a previous comment you told me ''You might also need to account for more dispersion (turbulent) as well as Lift Force''. Did you mean to increase the number of Tries under Turbulence Dispersion(left side image)?Again, I see number of tries option is 'inactive'. and by default it's 1. Should I turn on Saffman Lift Force under DPM physical model?

Regards

Anadi

Regards

Anadi

August 4, 2021 at 7:07 amAnadi_Mondal

Subscriber

I should add this info with previous question.

I see that if I click 'unsteady particle tracking ' in DPM model, number of tries in RWM is inactive. Is there any way to increase turbulent dispersion even after selecting 'unsteady particle tracking' in DPM?

Anadi

August 4, 2021 at 7:23 amAmine Ben Hadj Ali

Ansys EmployeePlease use the recent version to avoid any corrected issues with DPM summaries.

August 4, 2021 at 7:25 amAmine Ben Hadj Ali

Ansys EmployeeDefault for transient to have a single try.

August 10, 2021 at 1:04 amAnadi_Mondal

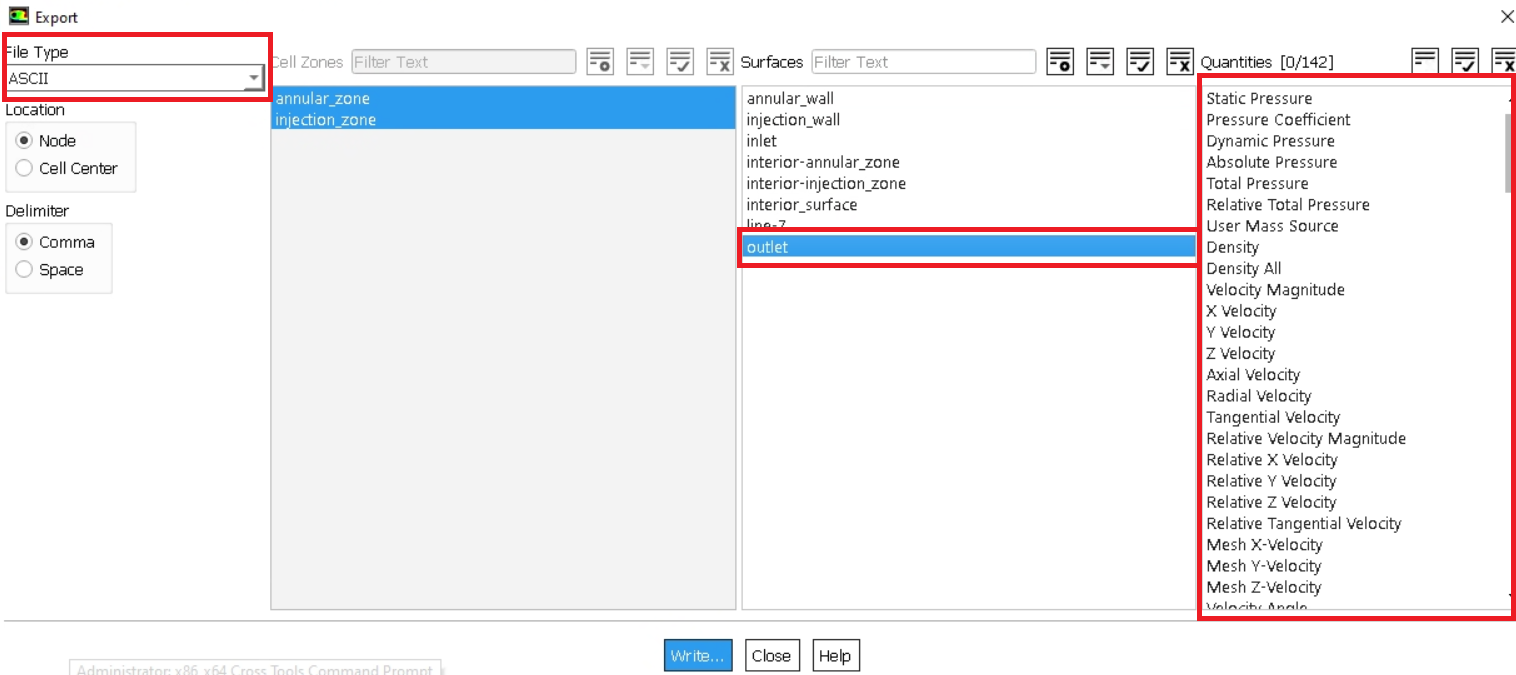

SubscriberDear & As I am getting very less droplet deposition, I am planning to change the droplet injection method. Currently I am using only the axial velocity of droplets to inject droplets. Maybe this is the reason to have very less droplets deposition on film. Now, I am planning to use an injection file which will include both axial and radial velocity to inject droplets . So I am planning to use two models (one for the development of outlet profile of droplets and use this droplets profile as an injection file to inject droplets from the inlet of the main model(second model)). The format for droplet injection file is(( x y z x-vel y-vel z-vel diameter temperature mass-flow-rate )) . After finishing first simulation , I am searching for droplets profile at outlet , I see no variable for droplets. File export Solution Data . I select the surface 'outlets', but all the variables are for continuous phase (vapor). How to get all variables required for injection file for discrete phase( position of parcel, velocity of parcel, diameter, temperature, mass flow) ?

Regards Anadi

August 10, 2021 at 7:13 amAnadi_Mondal

SubscriberHello This should be added with previous post.

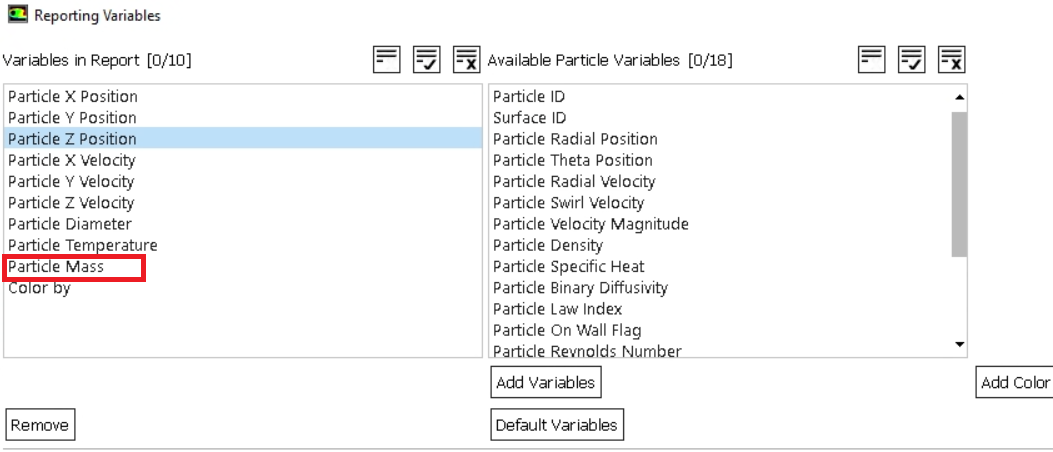

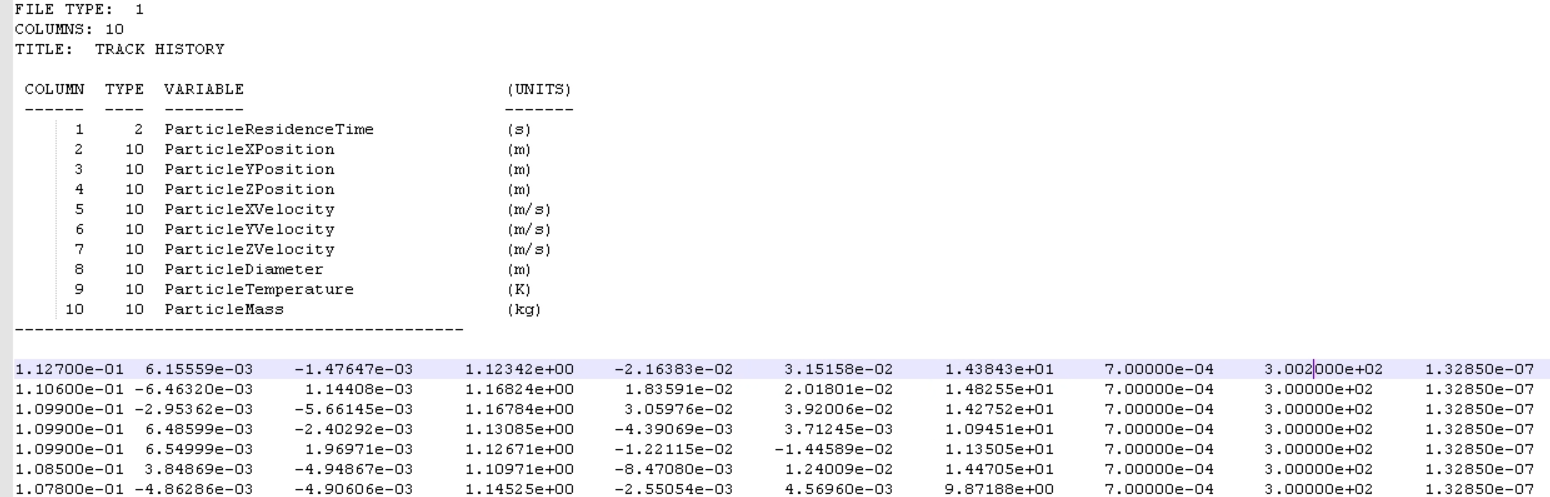

I have just read the topic ''24.7.4. Reporting of Current Positions for Unsteady Tracking'' from Ansys user guide and export a file "Time X-Position Y-Position Z-Position X-Velocity Y-Velocity Z-Velocity diameter temperature Particle Mass" . But I need (( x y z x-vel y-vel z-vel diameter temperature mass-flow-rate )) info at OUTLET(outlet flow condition) . How to get these variables at outlet?

Moreover , for injection file I need "mass flow"(kg/s) , but in the variable field I have 'particle mass'(kg). How to get flow rate? Will this flow rate I get from outlet or this is the flow rate I need to define during injection to get outlet profile?

Regards Anadi

August 10, 2021 at 11:27 amAmine Ben Hadj Ali

Ansys EmployeeBetter to do a sampling file along the boundary and use that file as injection file.

August 10, 2021 at 3:52 pmAnadi_Mondal

Subscriber

Sorry, I did not catch you. Would you add few more words about the idea & process of 'sampling file along the boundary(for my case boundary is outlet)' for the purpose of preparing a injection file?

Regards Anadi

August 10, 2021 at 5:43 pmAnadi_Mondal

Subscriber

August 11, 2021 at 12:35 amAnadi_Mondal

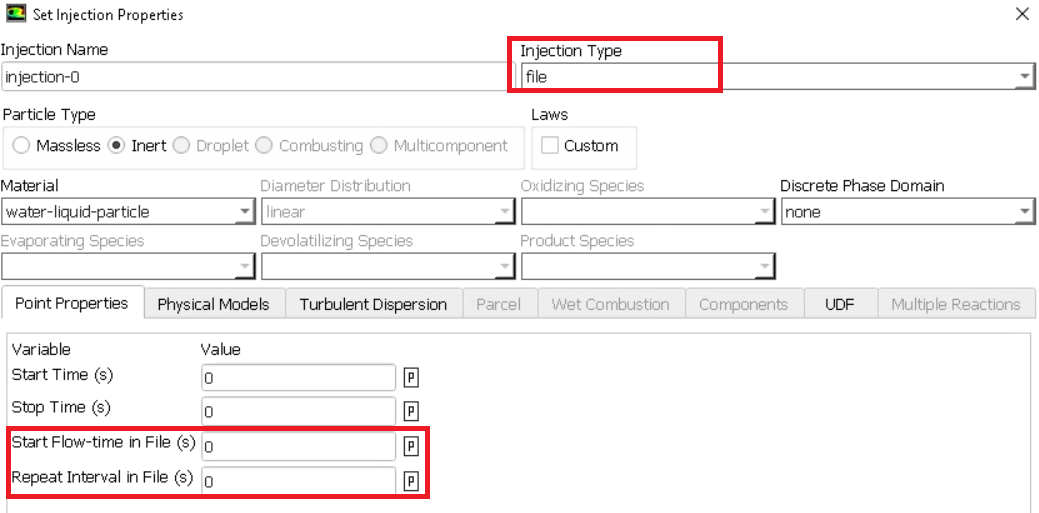

SubscriberHello I did some more research on sampling file .From online and Ansys user guide(24.7.8. Sampling of Trajectories) I came to know about extracting a .dpm file. But ,I did not get any clue about these questions-

1) I am using unsteady particle tracking case. How long(time steps) I should take to create sampling file? If I wait (time between start and stop time) longer period, huge data will be stored in .dpm file.

2) Should I use this (.dpm) file to inject particles for second model or I need to rename the .dpm (outlet.dpm)file as .inj (injection.inj) format?

3)I know about the start time and stop time ,but would you tell me about 'Start Flow-time' in file and' Repeat Interval in File'?

Regards Anadi

August 11, 2021 at 6:12 amAmine Ben Hadj Ali

Ansys Employee1/How long: that is your input. Usually transient injection file is required to mimic a real transient feed.

2/You do not need to do anything

3/Do not change: these fields are required if you really want to mimic a transient feed which will start after a certain flow time elapsed (and might be repeated-recycled)

What is the motivation now: do you want to track the injection during a certain time interval and to re-introduce that later in another simulation but at the same boundary condition?

Please be concise in your description as I am starting getting lost in this long thread.

August 11, 2021 at 6:40 amAnadi_Mondal

Subscriber

Motivation: I am planning to do two simulations( one for inlet development mode and another is the main model). I want to do inlet development model just to extract the droplet profile at outlet which(sampling file) will be used as an injection file at the inlet of main model to inject droplets at the same boundary condition.

1/How long: For example I want to do inlet development model for 0.5s(simulation time). Do I need to save droplet profile (sampling profile) at outlet for whole 0.5s? If I save droplet profile data for whole 0.5s , the outlet.dpm file size will be large.

Or Should I save the droplet profile after a certain time interval during inlet development model and use that file for injecting droplet in main model.

Thank you for your valuable time.

Anadi

August 11, 2021 at 6:58 amAmine Ben Hadj Ali

Ansys Employee1/Is the inlet of the second simulation corresponding to the outlet of the first simulation?

2/Yes you need to do that. You might reduce the data via Data Reduction under DPM Histogram but first please answer to 1/

Are you rather worring about the mass of droplets leaving the outlet you want to inject in simulation 2 or you need additionaly to maintain the right particle positions across the boundary?

August 11, 2021 at 7:12 amAnadi_Mondal

Subscriber

1/ Yes

2/So I need to save data for whole simulation time(0.5s) of inlet development model . Could you give little details of data reduction using DPM Histogram? I just save the droplet profile for 0.0045s and it's 1686KB. So, for 0.5s it will be around 190MB.

As I am getting less droplet deposition , I am thinking to consider axial and radial velocity of droplets together. Before this I was using only one model and injecting droplets using only axial velocity. So I am worrying about the velocity of droplets.

Anadi

August 11, 2021 at 12:28 pmAmine Ben Hadj Ali

Ansys Employee1/Then the strategy is correct

2/That part is well documented in the user's Guide.

Now it does depend on what you want in your second run: to consider the history of particle track say that at flow time x a parcel with ID y is coming with velocity u v w and diameter etc.. OR you say I do not care and you use a sort of steady state injection file.

August 12, 2021 at 3:46 amAnadi_Mondal

Subscriber

1/ In the user guide manual I see '24.7.9. Histogram Reporting of Samples', but here is no discussion about reduction of data(sample). Would you tell me the topic to read in user manual for data reduction?

Actually , I am using 'Transient' and 'Unsteady particle Tracking' case. My final goal is to use the DEVELOPED PROFILE at the outlet of inlet development model as new boundary condition for droplets injection in the main model.

2/ Is there any way to save the DEVELOPED PROFILE for DPM at outlet like saving velocity PROFILE at outlet for continuous phase ( File write profile)?

Or doing a sampling is the only way to make an injection file ?

3/ Sampling file in transient case means using the droplets history at outlet of inlet development model as inlet in main model. Here I am REPEATING droplet history not using DEVELOPED PROFILE. Am I sure?

4/ Which one is better, repeating droplets history(sampling) or using the DEVELOPED PROFILE from inlet development model as outlet as inlet for main model?

Regards Anadi

August 12, 2021 at 9:27 amRob

Forum ModeratorThe ASCII data is for flow field values. You need to look in the Reports=> DPM Summary to create a file for the outlet. That'll tell you size, flight time, velocity etc of any particles hitting that plane.

August 13, 2021 at 2:01 amAnadi_Mondal

Subscriber

Here is the summary of injection-0 I get in the console window after Reports Summaryinjection-0 Summary . Here I did not get any option to select boundary surface (OUTLET) ,also did not get any PROFILE for position, velocity, mass flow at OUTLET. I don't think I can use this summary(below) to prepare an injection file that will be used to inject droplets in the main model. Is there any way to get the droplets profile(position, velocity, mass flow) at OUTLET and use that info to make an injection file for main model?

Regards Anadi

August 13, 2021 at 8:28 amRob

Forum ModeratorTry Sample, one of those creates a file that is more-or-less the same as an injection.

August 14, 2021 at 7:57 amAnadi_Mondal

Subscriber

Actually, I was discussing withabout sampling. I am using 'Transient' and 'Unsteady particle Tracking' cases. My final goal is to use the DEVELOPED PROFILE at the outlet of the inlet development model as the new boundary condition for droplets injection in the main model.

I think sampling means repeating a droplet history from one model to another. Like repeating the droplet history of the inlet development model at the outlet as an input of main model. As this is an unsteady case, the outlet.dpm file would be large in size. So, another issue is how to concise that file to use as an injection to another model as the size of this file would be around 200MB.

For example, my total simulation time for the inlet development model is 0.5s, but there is no droplet passing through the outlet till 0.08s. So, if I use this particle history as an input of the main model means there will be no droplets in the main model until 0.08s. But it's not true. If I can use the outlet profile instead of the particle history of the inlet development model as an input of the main model then the problem will be solved.

In the annular flow, the vapor core is consists of a continuous vapor phase and discrete droplets, and these droplets have axial as well as radial velocity. I want to simulate these droplets at the beginning of the annular flow. If I use particle history then for a certain period(0.08s) in the main model there will be no droplets.

If my case would be a steady case, I did not experience this issue. Just use the steady particle history from the outlet of the inlet development model as an inlet of the main model. This file is easy to use.

Would you give an idea to overcome this issue for the transient cases?

Regards Anadi

August 16, 2021 at 12:45 pmRob

Forum ModeratorSampling will get you an output file that's similar to an injection file to add particles to a new model, or for additional post-processing in Fluent or something else. As the particles don't reach that surface until 0.08s there is no data until that point. So, you'll need to manually adjust the file, wait, or set the solver time to 0.08s when you start the run.

August 16, 2021 at 5:35 pmAnadi_Mondal

Subscriber

1/Will you comment on file size? As I am running an unsteady case, the file size would be more than 200MB during the inlet development model. Is there any problem to use this large file as an injection file in the main model?

2/Do I need to make any changes(header, zone, etc) to use the injection file obtained from the inlet development model in the main model as an injection file?

Regards Anadi

August 18, 2021 at 2:32 pmAnadi_Mondal

Subscriber

Will you comment on the above question?

Anadi

August 19, 2021 at 10:49 amRob

Forum ModeratorThe file format is covered in the manual, I can't remember off hand if there are any changes needed.

200MB shouldn't be an issue for the solver, but keep an eye on what's happening as it may be a problem for your computer.

Viewing 38 reply threads- The topic ‘How to get droplet deposition mass flux ?’ is closed to new replies.

Innovation SpaceTrending discussionsTop Contributors-

4838

-

1587

-

1386

-

1242

-

1021

Top Rated Tags© 2026 Copyright ANSYS, Inc. All rights reserved.

Ansys does not support the usage of unauthorized Ansys software. Please visit www.ansys.com to obtain an official distribution.

-