-

-

January 19, 2024 at 1:27 pm

henrique.geraissate

SubscriberHello Ansys community,

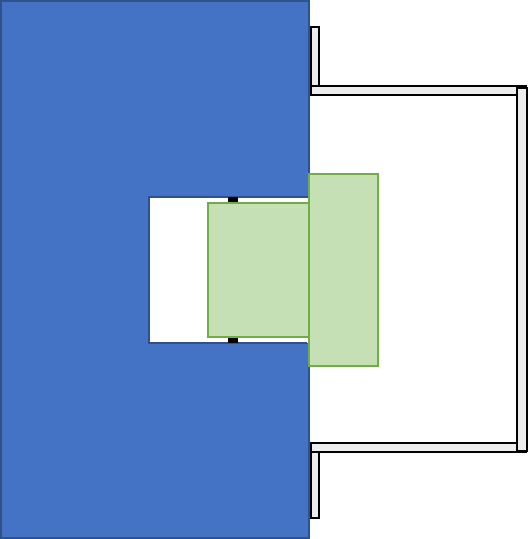

I am working on a project of a pressure cell, and more specifically on a safety device in case the cell fails. A very simplified sketch of the design is represented below:

The green part is screwed into the blue one and the gap between them is filled with water and pressurized up to 1 GPa. The thin greyed part is a safety cage that should catch the green plug in case the thread fails and the plug is ejected. The cage is also fixed to the cell by means of screws, but I would like to rely on the deformation of this cage to absorb the energy of the impact, and not on the screws.

The distance between green plug and cage is rather short, so I am considering that from the moment the plug is ejected until it reaches the cage there is no loss in energy. I am now trying to simulate only the cage, and the only information I have that could be used as an input is the plug kinetic energy.

So my question is: how to set this model up? I do have a strategy, but I am not sure if this makes sense or not:

- I am using fixed support on the "feet" of the cage.

- I am applying an arbitrary displacement on the region that would receive the impact, and setting the analysis to run in several substeps.

- for each substep, I evaluate the Total Strain Energy.

- If the total strain energy increases above the kinetic energy I have calculated for the plug, then I consider that all the impact was absorbed.

Does that make sense for you? Do you have a suggestion on another approach to this problem?

I have also other questions related to that, such as is it ok to use shell elements for the cage? Is the fixed support a good approach? How could I set the boundary conditions up in a better way?

I appreciate any comments and suggestions, and I am looking forward to hearing from you.

Thanks!

-

January 22, 2024 at 3:41 pm

dlooman

Ansys EmployeeThat method is a little unusual, but seems OK. A more typical method would be to estimate the velocity of the plug when it hits the cage. Then a transient analysis would be done starting with the plug touching the cage and having the calculated initial velocity. A slight improvement on your static method would be to apply the displacement to the back of the plug pressing against the cage through nonlinear contact. That way the force distribution on the cage is more natural. The applied displacement artificially constrains the cage deformation. A shell model of the cage is fine, but I don't see the advantage of using shells. Fixed supports at the cage attachment points seem fine.

-

February 1, 2024 at 12:09 pm

henrique.geraissate

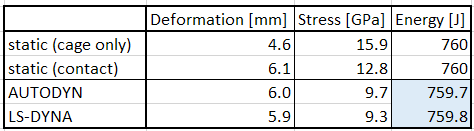

SubscriberHello Dave,Thank you for your answer.I have built three additional models with your suggestion: one static (with frictional contact between plug and cage, and displacement applied to the plug) and two explicit dynamics with different solvers (autodyn and ls-dyna), both with an estimated initial velocity. To avoid modelling the whole plug, which has a complex geometry, I am using only a cylinder with identical material properties, except for the density, which I have changed to get the same mass) and thus same energy for the explicit analysis).Comparing the 4 models, I am getting different results, specially between the implicit and explicit analyses. Please see the table below. It shows the deformation and stress results for the cage in the time step which the kinetic energy of the plug reaches the minimum (for explicit) or when total strain energy in the cage reaches the estimated initial energy of the plug (implicit). So the energy column for the explicit analyses shows “input” values, whereas for the static ones the values are extracted from the simulation.Also please ignore the absurdly high stress values. I am using linear materials and, although this is already an indication that design must be reviewed, I am more worried now in making the FE model right.I can see that both explicit solvers agree very well. Would you suggest a preferred one? If so, would mind explaining why?As for the static analyses, the one using contact definition gets closer to the explicit, but it required several tweaks in the settings to achieve convergence. What I don’t get is why the stress levels are so much higher, even with similar deformation.Now, the thing is.. I would like to rely in the cage deformation to absorb the impact energy, meaning I don’t mind at its going through plastic deformation. In fact, that’s exactly what I would expect to happen. But I guess that this behavior can only be captured with non-linear material properties, is that right?Also, I considered using shell model to allow an easier parametric study varying the cage thickness, for example.I’m sorry for the very long post. I hope you can find some time to answer it :)Best,Henrique -

February 1, 2024 at 5:36 pm

dlooman

Ansys EmployeeYou'll probably need a new post to get input on which is better LS-DYNA or AUTODYNE. I only support Mechanical. The Mechanical stresses are probably higher because they are more accurate. That's one of the advantages of implicit. Plasticity is definitely a nonlinearity.

-

February 2, 2024 at 9:33 am

henrique.geraissate

SubscriberHi Dave,

Thanks again. May I ask why the implicit analyses are more accurate in terms of stress results? I would guess that it may be related to the mesh, which accept only linear elements in the dynamic analyses if I understood correctly. Are there any other reasons?

-

February 2, 2024 at 1:55 pm

dlooman

Ansys EmployeeI believe it's because the elements have more integration points. That a recollection from a long time ago, but you could check the theory.

-

- The topic ‘How to evaluate absorbed energy in a static analysis’ is closed to new replies.

-

4683

-

1565

-

1386

-

1242

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.