-

-

August 9, 2019 at 2:25 pm

NTAKMAT

SubscriberHello guys,

I am trying to attach the spring between two solid bodies . when i run the model in transient analysis system it gives me the following message:

One or more MPC contact regions or remote boundary conditions may have conflicts with other applied boundary conditions or other contact or symmetry regions. This may reduce solution accuracy. Tip: You may graphically display FE Connections from the Solution Information Object for non-cyclic analysis. Refer to Troubleshooting in the Help System for more details.

I tried to create imprint faces where springs will be attached but still i get the same message. I have removed the boundary conditions(displacement ) on the face that spring is attached but i get high displacement.

I need your help on how i can model by putting the spring between two bodies or attach as body-ground without getting the message above.

-

August 10, 2019 at 12:52 am

peteroznewman

SubscriberIf you imprint a face on the solid to attach the spring, and the edges of that face don't touch any other face that has a boundary condition or load on it, then you will not get that message.

-

August 12, 2019 at 9:39 am

NTAKMAT

SubscriberHow can you prevent the edges of imprinted surface not to touch on other faces that have boundary conditions? Another question why, if i put the spring without other boundary conditions (usually fixed support), I get high deformations?

-

August 12, 2019 at 12:06 pm

NTAKMAT

SubscriberI need also a help on how to insert spring between two bodies and body to ground in ansys workbench by using apdl command.

spring have the following properties:

Stiffness: 34000 N/mm

damping: 12.5 N.s/mm

Length: 12 mm (body to body) and -350 mm (body to ground)

-

August 12, 2019 at 12:19 pm

peteroznewman

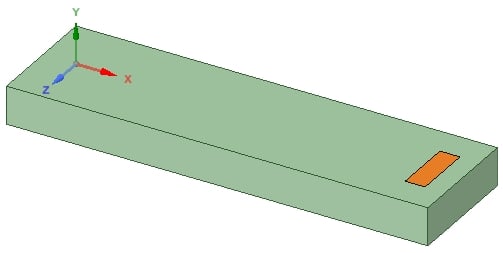

SubscriberHere is a beam with an imprinted orange face that doesn't touch any other face or edge.

This is usually unnecessary. The warning messages are very conservative and can often be ignored.

You don't need apdl to create a spring with those properties. You can do that in Mechanical.

If the two faces on the two bodies are 12 mm apart, then the spring will be that long automatically. If the faces are not 12 mm apart, you can move either the Mobile or the Reference Coordinate (X, Y, or Z) to a location to achieve the spring length you want.

If you have an answer to your question, please mark a post with Is Solution to mark the discussion as Solved, or ask a followup question.

-

August 13, 2019 at 7:42 am

NTAKMAT

SubscriberThank you for your kind reply, I did the same but the problem I am facing is: when I try to change the stiffness there is no change in the deflections of equivalent stresses. That why i was think that the spring is not properly attached to the bodies. I f you have an answer to that you can also tell me. Why changing the stiffness value doesn't change the results?

-

August 13, 2019 at 10:43 am

peteroznewman

SubscriberYou haven't shown your model so I don't know why.

If your model was a cantilever beam with a Displacement boundary condition at the end and the spring was also connected to the end, then changing the stiffness of the spring only changes the Reaction Force for the Displacement, and will not change the deformation or stress, which is dictated by the Displacement.

-

August 13, 2019 at 1:07 pm

-

August 13, 2019 at 9:28 pm

peteroznewman

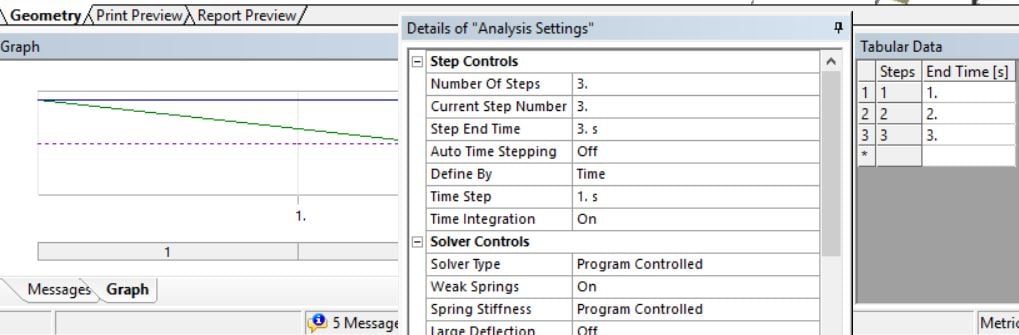

SubscriberOkay, but what is the load? What is the end time for the transient?

-

August 14, 2019 at 8:09 am

-

August 14, 2019 at 3:54 pm

peteroznewman

SubscriberWhat is the area of the face that the pressure is applied to?

I want to convert pressure to force by multiplying by the area.

Are these pressures applied in a Static Structural or Transient Structural model?

1 second is Quasi Static so using Transient Structural is more work than Static Structural.

-

August 15, 2019 at 6:46 am

NTAKMAT

Subscriberthe area is 100 mm2 (20x5 mm). The system analysis is transient structural

-

August 15, 2019 at 2:28 pm

peteroznewman

SubscriberA pressure of 1000 MPa acting on an area of 100 mm^2 creates a total force of 100,000 N.

That force on a single spring with a 34,0000 N/mm rate displaces 2.94 mm.

But there are many springs supporting that load, correct? If there are 4 springs, then the displacement is 1/4.

What is the mass of of all the parts?

What is the first natural frequency of the system?

If the first natural frequency is > 30 Hz, then a 3 second ramp up to 1500 N is definitely quasi-static.

-

August 16, 2019 at 8:35 am

NTAKMAT

SubscriberI didn't do modal analysis, I was interested only on varying the spring stiffness to see if there is any change. surprisingly i didn't see any change that is my question. I am asking my self why there is no change while it already known that it has to be a change. Try to put these data in a model a see if there is any change, and tell me why on my side there is no change. Thank you for always responding ontime.

-

August 16, 2019 at 11:43 am

peteroznewman

SubscriberModal analysis should always be done prior to solving a Transient Structural model. The natural frequencies provide useful information to help decide on time step sizes. Modal is also a useful diagnostic test on the connections in the model to see if the mode shapes behave as expected or if there is an error in the model. The Modal solution takes a lot less time than a Transient Structural.

It is often useful to run a Static Structural model as a diagnostic test of a model prior to a Transient Structural because like Modal, it solves in less time than the Transient Structural. In your case, you want to know why a change in spring stiffness doesn't show a change in deformation.

Please drop both a Modal and Static Structural analysis system onto the Model cell of your Transient Structural and solve them. From the Modal, you can answer the question about the first natural frequency of the system. After you solve the Static Structural, you can select that block in Workbench and right mouse click on the block to Duplicate. That will give you an independent block that you can change the spring stiffness without affecting the original model. Reply with the maximum deformation from each Static Structural model and the first natural frequency.

-

- The topic ‘How to attach spring to a solid body’ is closed to new replies.

- LPBF Simulation of dissimilar materials in ANSYS mechanical (Thermal Transient)

- Real Life Example of a non-symmetric eigenvalue problem

- How can the results of Pressures and Motions for all elements be obtained?

- BackGround Color

- Contact stiffness too big

- Element Birth and Death

- Python-Script to Export all Children of a Solution Tree

- Which equations and in what form are valid for defining excitations?

-

4597

-

1495

-

1386

-

1209

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.