-

-

January 13, 2025 at 2:34 am

yaozutang

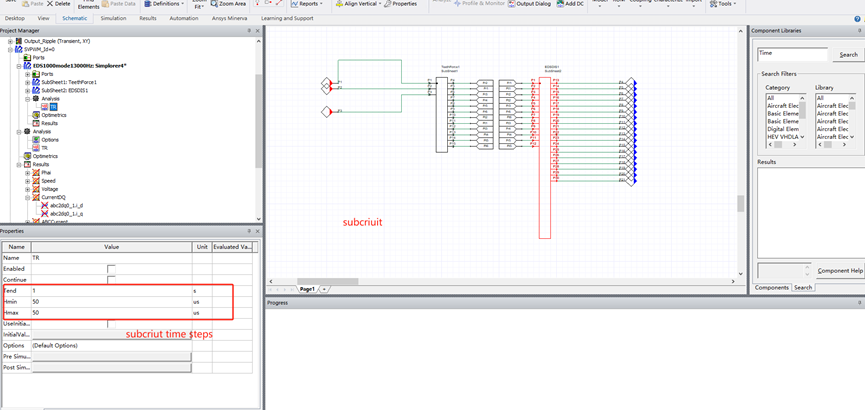

SubscriberI am currently doing a system-level NVH simulation of a motor under real-time control. The motor housing state space matrix simplified model (SPM) obtained from modal analysis is exported to Twin Builder and placed in a subcircuit to calculate the vibration of the motor measurement point.

The global step size is set to 1~10us, and the subcircuit step size is set to 50us, but the subcircuit step size does not take effect during actual operation, so the simplified model (SPM) calculates the motor displacement with the same step size. This results in a very long calculation time.

Therefore, I would like to ask, how can I set the simulation step size of the subcircuit to be inconsistent with the global simulation step size, so that the simulation speed becomes faster? -

March 19, 2025 at 2:55 pm

MirandaH

Ansys EmployeeSubcircuit usually follows the main design.

-

- You must be logged in to reply to this topic.

- How does Ansys Twin Builder implement different simulation steps for subcircuits

- Simulation of capacitor combining eddy currents with displacement currents

- Compute near field simulation with current

- HFSS: Using Q3D to solve the DC point

- Double-sided LIM external circuit error

- Ansys Resonance simulatioin error

-

3190

-

1024

-

962

-

858

-

798

© 2025 Copyright ANSYS, Inc. All rights reserved.