TAGGED: fluid-flow, inconsistency, mesh, mesh-sizing, rectangular

-

-

January 18, 2021 at 10:54 pm

B_Rahman

SubscriberJanuary 19, 2021 at 6:27 amKeyur Kanade

Ansys EmployeeAs ANSYS Staff, we can not download attachments. Please upload images using upload image functionality. nObviously coarser mesh will have different results than finer mesh. Please check theory guide for the same. nYou will first need to do mesh independent study. You need to have a mesh where results do not change further even if mesh is refined. Then check convergence criteria. Make sure that along with residuals, you also monitor key variables to confirm convergence. nRegards,nKeyurnHow to access Ansys Online Help DocumentnHow to show full resolution imagenGuidelines on the Student CommunitynHow to use Google to search within Ansys Student CommunitynJanuary 19, 2021 at 3:47 pmB_Rahman

SubscriberAs ANSYS Staff, we can not download attachments. Please upload images using upload image functionality. Obviously coarser mesh will have different results than finer mesh. Please check theory guide for the same. You will first need to do mesh independent study. You need to have a mesh where results do not change further even if mesh is refined. Then check convergence criteria. Make sure that along with residuals, you also monitor key variables to confirm convergence. Regards,KeyurHow to access Ansys Online Help DocumentHow to show full resolution imageGuidelines on the Student CommunityHow to use Google to search within Ansys Student Community/forum/discussion/comment/103615#Comment_103615

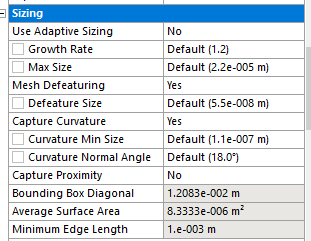

My apologies. I will get the pictures uploaded properly as follows. I understand that I need to keep running it at more and more refined meshes until the values doesn't change. Usually the trend I observe with Pressure drop is that it gradually comes closer and closer to the analytical prediction with more refined meshes. However the trend here was that it started with an ANSYS pressure drop close enough to the analytical value at a coarse mesh, but kept rising dramatically until over 12 million nodes where it suddenly rebounded back close to the analytical value. I am puzzled as to what could account for such dramatic fluctuations?n

n

January 19, 2021 at 4:50 pm

n

January 19, 2021 at 4:50 pmYasserSelima

SubscriberI am not able to explain the results. I am just wondering if you were using inflation or not? if yes, did you change the parameters?nJanuary 19, 2021 at 6:40 pmB_Rahman

SubscriberI am not able to explain the results. I am just wondering if you were using inflation or not? if yes, did you change the parameters?/forum/discussion/comment/103696#Comment_103696

All I changed was element size. I did not do anything to change the default inflation parameters.n n

January 19, 2021 at 7:03 pm

n

January 19, 2021 at 7:03 pmKarthik Remella

AdministratorYou are not changing your inflation layers here. But, you are changing the bulk mesh. nAlso, is this a turbulent flow? Which model are you using and what y+ values are you getting for each of the meshes? nThank you.nKarthiknJanuary 19, 2021 at 7:23 pmYasserSelima

SubscriberThank you for the reply. Can you share a photo of the velocity profile near the wall for different element size. The coarse one the fine one and 1 in between. I would appreciate if you do so. nJanuary 19, 2021 at 9:42 pmB_Rahman

SubscriberYou are not changing your inflation layers here. But, you are changing the bulk mesh. Also, is this a turbulent flow? Which model are you using and what y+ values are you getting for each of the meshes? Thank you.Karthik/forum/discussion/comment/103709#Comment_103709

Thanks for the reply @Kremella, . This is a laminar flow model. I don't understand what y+ values of meshes are? nJanuary 20, 2021 at 1:30 pmKarthik Remella

AdministratorIf this is a laminar flow, I take back my comment on Y+. It is only applicable for turbulent flow. nPlease consider changing the inflation layer settings. As you refine the bulk region of your flow domain, you might have to refine the inflation layer as well. On the mesh where you are not getting a good match between analytical and computational, please share a screenshot of the mesh resolution near the wall. I'm surmising that there is a jump near the wall that the affecting the results.nAlso, what is your inlet condition? nKarthiknJanuary 20, 2021 at 5:26 pmJanuary 21, 2021 at 9:35 amDrAmine

Ansys EmployeeIs this not related to your other post? What is the issue now here? Add more information about model settings etc. (and BC's).nJanuary 21, 2021 at 1:28 pmKarthik Remella

AdministratorJust to add here, how deep is your convergence for each case? Are you monitoring your residual as well as your parameter of interest (overall pressure drop)?nKarthiknJanuary 22, 2021 at 3:58 pmB_Rahman

SubscriberIs this not related to your other post? What is the issue now here? Add more information about model settings etc. (and BC's)./forum/discussion/comment/103855#Comment_103855

The other post was looking at why the analytical vs. ANSYS calculations are not matching up. This one is more so focused on the strange trend that is happening with the resulting pressure drop, as mesh size is lowered. The model settings and boundary conditions are the same as the previous post: /forum/discussion/22491/troubleshooting-different-results-for-different-mesh-on-exact-same-geometry-rectangular-channel#latestn, also including the no slip condition for the falls, and zero pressure at the outlet nJanuary 23, 2021 at 8:27 pmYasserSelima

SubscriberUse inflation near the walls, Mesh size are very large near the wall to capture physics. nJanuary 23, 2021 at 8:36 pmYasserSelima

SubscriberThere is pinned post, introducing boundary layer theory. I recommend you have a look at it. nViewing 14 reply threads- The topic ‘How do I account and solve for mesh convergence issues in ANSYS for rectangular channel?’ is closed to new replies.

Ansys Innovation SpaceTrending discussionsTop Contributors-

3492

-

1057

-

1051

-

965

-

942

Top Rated Tags© 2025 Copyright ANSYS, Inc. All rights reserved.

Ansys does not support the usage of unauthorized Ansys software. Please visit www.ansys.com to obtain an official distribution.

-