TAGGED: -quasi-static, load-step, mechanical

-

-

November 20, 2024 at 8:52 am

mhannan

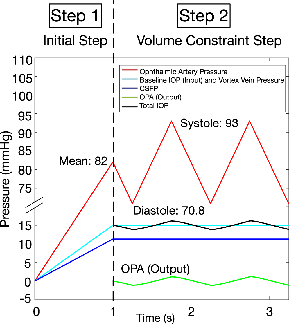

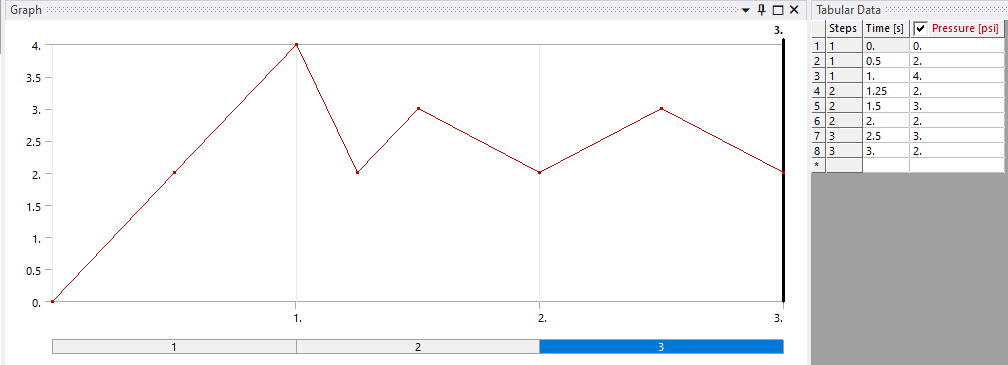

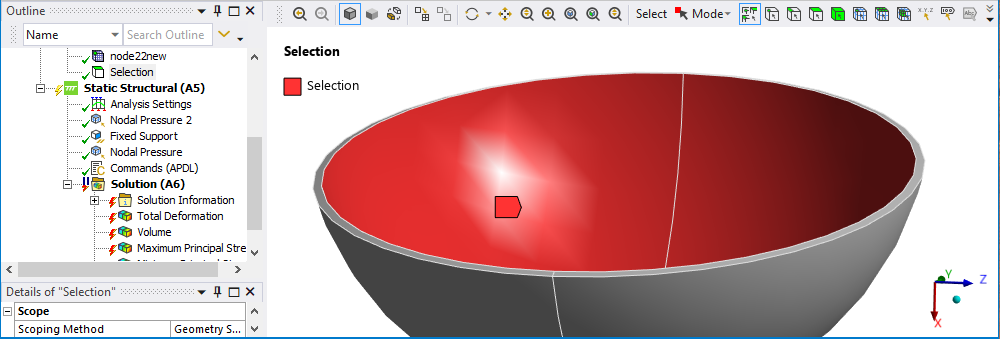

SubscriberHey, I am doing quasistatic analysis in static structural module of ansys. My whole load curve is for 3 second and it’s not linear or constant load for 3 second. The loads changes within a very short time like 1 have almost 30point of load in between 0 to 1 second. There are almost 137 points of load in the whole 3 sec curve and loads for all the 137 points are different.

How can I get result for the individual 137 points ??

This loads are my input pressure and how can I get output for the all individual point(input points of pressure vs time are generated from the graph by webplotvisualizer) in ansys static structural.

-

November 20, 2024 at 12:48 pm

peteroznewman

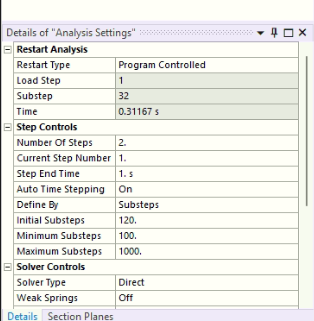

SubscriberIn Static Structural, under Analysis Settings, Step Controls, you can set the Number of Steps to 3 and set the Step End Time for each step to 1, 2 and 3 s.

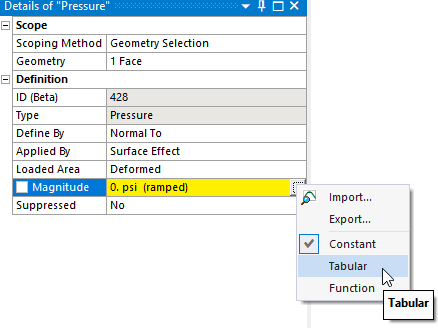

In the Pressure load, there is a pull down menu that allows you to select Tabular data input.

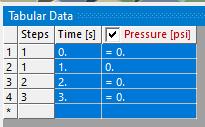

In the Tabular data window, click once in the blank cell to the left of Steps to select the whole table.

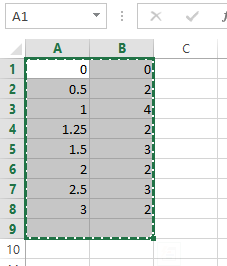

In Excel, copy the 2 columns and 137 rows of numbers plus one blank row at the bottom. In Mechanical, right click on that same blank cell in Tabular data and select Paste. My example shows 8 rows of data and I have selected 9 rows to copy.

You can do the same thing with just one Step. Just set the End time to 3 and copy paste the data in the same way and you will get the same load history.

Finally, you want to force the solver to take small enough time steps to not skip over any part of the load history. Under Analysis Settings, change Auto Time Stepping to On then Define By Time. Set the Initial and Maximum Time Step to a value smaller than the smallest time increment in your table. Set the Minimum Time Step to a value one tenth of that smallest time increment.

If you used one load step of 3 s you are done. If you used 3 load steps, you have to repeat the previous paragraph two more times for each load step.

-

November 25, 2024 at 9:01 am

mhannan

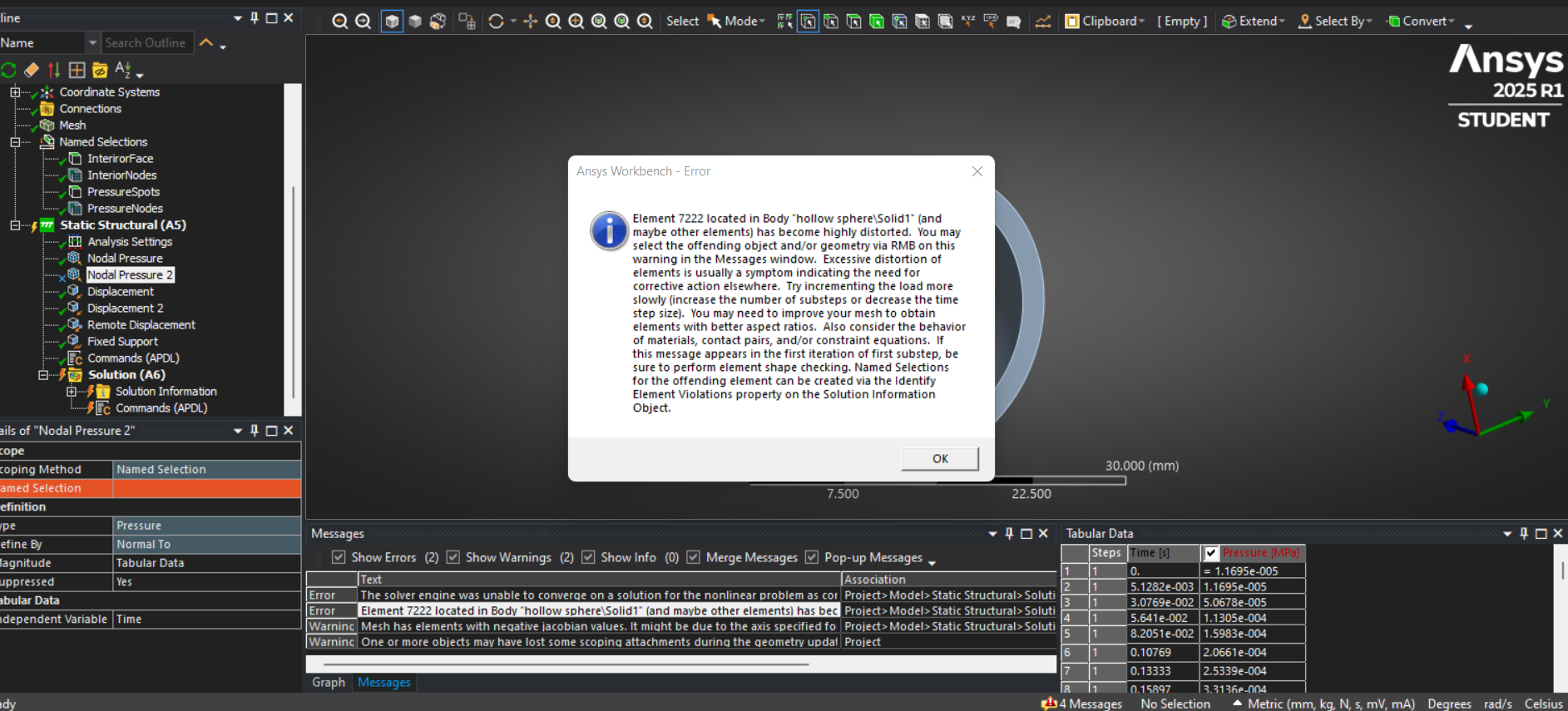

Subscriberhey, I tried your process and I faced errors:

error1: The unconverged solution (identified as Substep 999999) is output for analysis debug purposes. Results at this time should not be used for any other purpose.

error2: Element 10365 located in Body "for fsi - Copy|Sclera" (and maybe other elements) has become highly distorted. You may select the offending object and/or geometry via RMB on this warning in the Messages window. Excessive distortion of elements is usually a symptom indicating the need for corrective action elsewhere. Try incrementing the load more slowly (increase the number of substeps or decrease the time step size). You may need to improve your mesh to obtain elements with better aspect ratios. Also consider the behavior of materials, contact pairs, and/or constraint equations. If this message appears in the first iteration of first substep, be sure to perform element shape checking. Named Selections for the offending element can be created via the Identify Element Violations property on the Solution Information Object.

warning 1: The unconverged solution (identified as Substep 999999) is output for analysis debug purposes. Results at this time should not be used for any other purpose.

warning 2: Solver pivot warnings or errors have been encountered during the solution. This is usually a result of an ill conditioned matrix possibly due to unreasonable material properties, an under constrained model, or contact related issues. Check results carefully.

https://drive.google.com/file/d/1EHkE4lLSBiPs3Mqmd5lNLObQtBCc4mmJ/view?usp=sharing

-

November 28, 2024 at 9:34 pm

-

-

November 28, 2024 at 9:27 pm

peteroznewman

SubscriberThe process I provided was to import 127 rows of time history into the pressure load, you must follow a different process to obtain convergence.

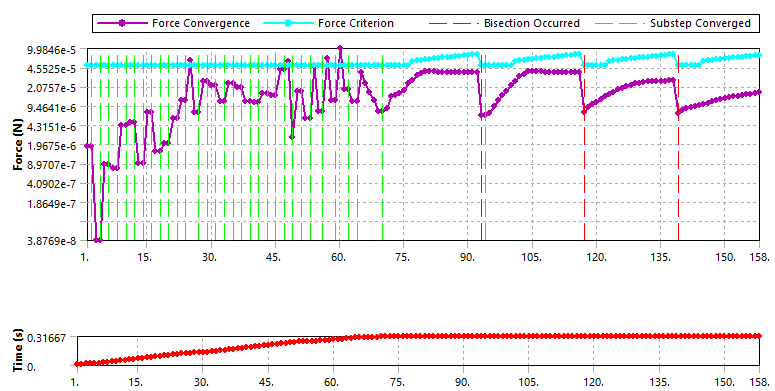

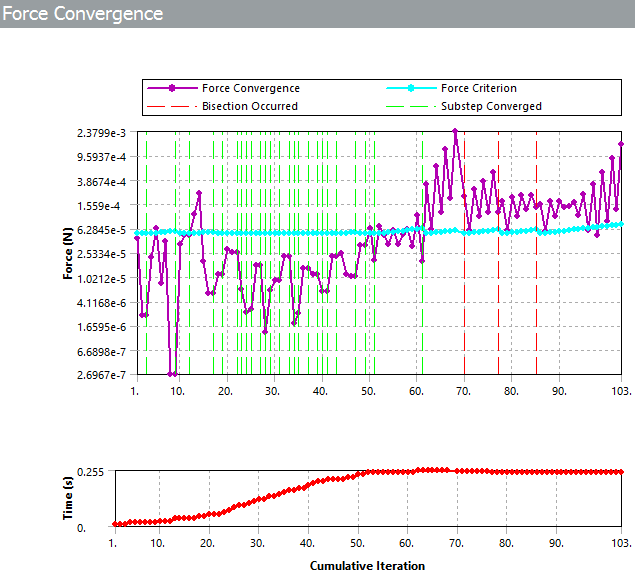

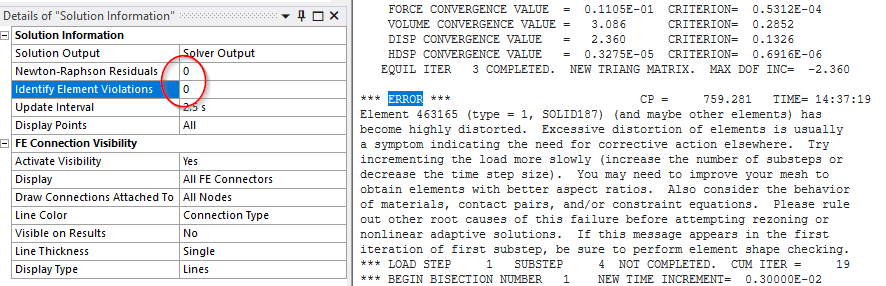

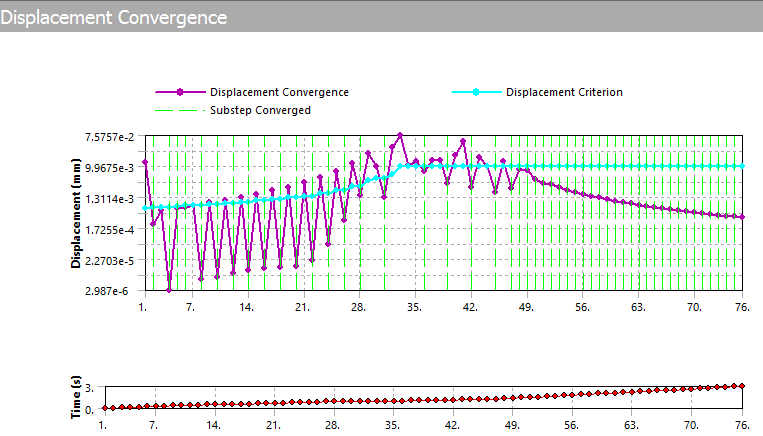

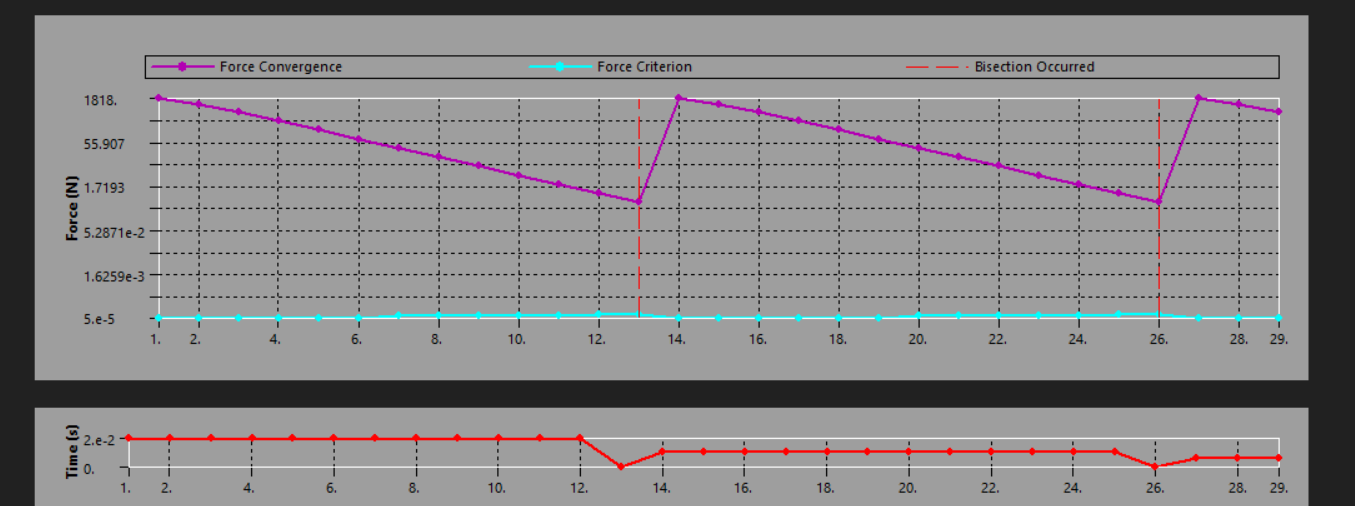

The highly distorted error message contains some good advice which you should follow. Try incrementing the load more slowly (increase the number of substeps or decrease the time step size). You know where to find that. It is helpful to first look at the Force Convergence plot under the Solution Information folder. The graph shows you what time the solver ran into problems converging. The graph also shows you how many times the automatic time stepping algorithm used bisection to reduce the time increment. You can also change the plot to show the size of the time increment vs time.

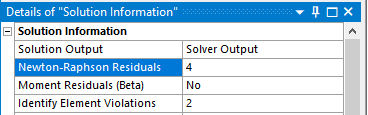

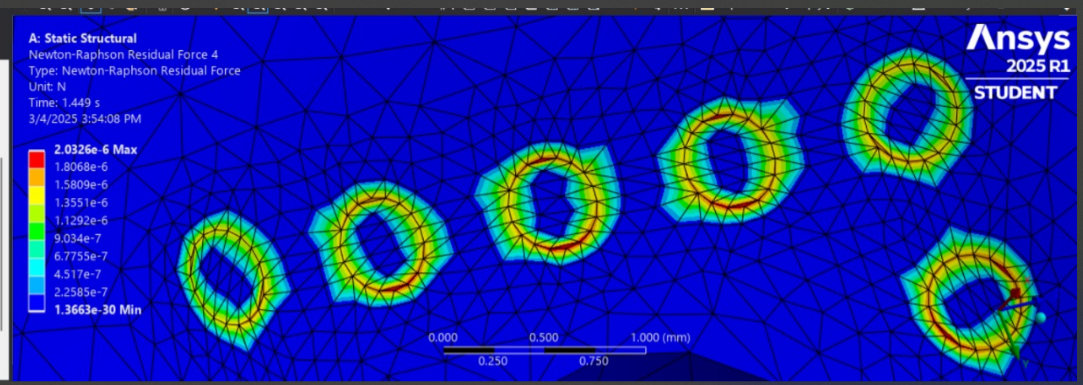

Another piece of advice in the error message mentions that you may need to improve the mesh. However, you need to know where on the mesh the solver is having difficulty converging. To see that, edit the Analysis Settings. Click on the Solution Information folder and on the line that says Newton-Raphson enter a number, say 3. This will make 3 contour plots under this folder that show you where on the mesh the force imbalance was largest for the last three iterations. If there are large elements there, you may need smaller elements or if the elements are of low quality, you may need to improve the shape.

-

December 1, 2024 at 7:58 am

mhannan

SubscriberRather than time step, I use step number and now the simulation converges, can you look into this???

I am also facing problems in implementing subroutine, can you tell me the process?https://drive.google.com/file/d/1g1vRm8BfO_--YiE75Kg3b2pGuTZTStO2/view?usp=drive_link

-

December 2, 2024 at 12:49 am

-

December 29, 2024 at 11:03 am

mhannan

SubscriberAs they are different object so I mesh the both body, can I get your mail where you can respond faster?

-

December 29, 2024 at 2:54 pm

peteroznewman

SubscriberI check here more frequently than I check my email, so it's faster to reply here.

In the model, you have two bodies that take up the same space, which is not a normal situation in reality. That looks like a mistake in the model.

-

January 3, 2025 at 5:56 pm

mhannan

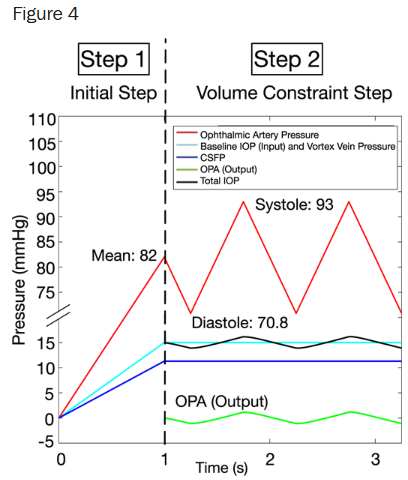

Subscriberif you see the part choroid, this part should change it’s volume overtime with the changing of pressure which are exerted by the 18 nodes by using nodal pressure. And the part called inside is actually vitrious body which is fully incompressible(So I modeled as water) when the choroid changes it’s volume, it’ll affect vitrious body and as it can’t change it’s volume it’ll create an opposite pressure to resist it’s volume deformity. I need to extract the pressure. Below part is the modeling of the opposite pressure which is named OPA in FEBio:

”To estimate the OPA in all models, a ‘‘volume constraint’’

was imposed on the inner limiting membrane and the

augmented Lagrangian was turned on. The tolerance and

penalty factor were set as 0.00001 and 0.001, respectively.

Those values were chosen because they maintained the

volume of the vitreous within 0.000001% during the cardiac

cycle. All pressure estimates (to maintain the volume of the

vitreous body constant) were extracted from the FEBio output

log file (.log) under the section ‘‘Volume Constraint’’ at each

converged step.”

here is the ipdated model

https://drive.google.com/drive/folders/19FQFr4y9Cpfm5TyeTlqGjdfvhFeVS1jQ?usp=sharing

Also please check me the APDL, and can yopu tell me how can insert effective permeability.

I need your help badly, please reply me soon.

thanks in advance. -

January 4, 2025 at 4:15 pm

peteroznewman

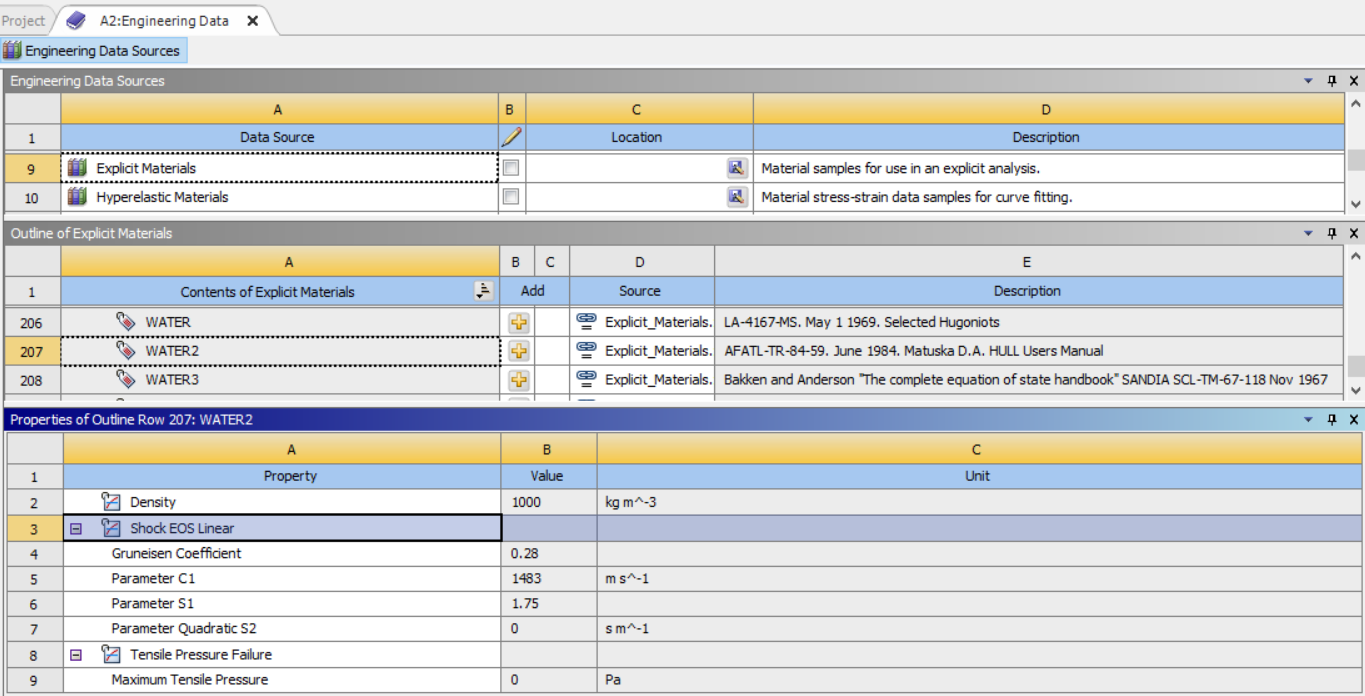

SubscriberYou have assigned the material WATER3, which was defined using Isotropic Elasticity, to the Inside body. This is a big mistake because WATER3 has a huge Shear Modulus, while real water has zero Shear Modulus. This will cause a large error in your results. Delete the Inside body and instead use the faces of the solid elements that define the inside cavity surface to create HSFLD242 elements.

HSFLD242 is used to model fluids that are fully enclosed by solids (containing vessels). The hydrostatic fluid element is well suited for calculating fluid volume and pressure for coupled problems involving fluid-solid interaction. The pressure in the fluid volume is assumed to be uniform (no pressure gradients). Hydrostatic fluid elements are overlaid on the faces of 3D solid or shell elements enclosing the fluid volume.

-

January 4, 2025 at 4:25 pm

peteroznewman

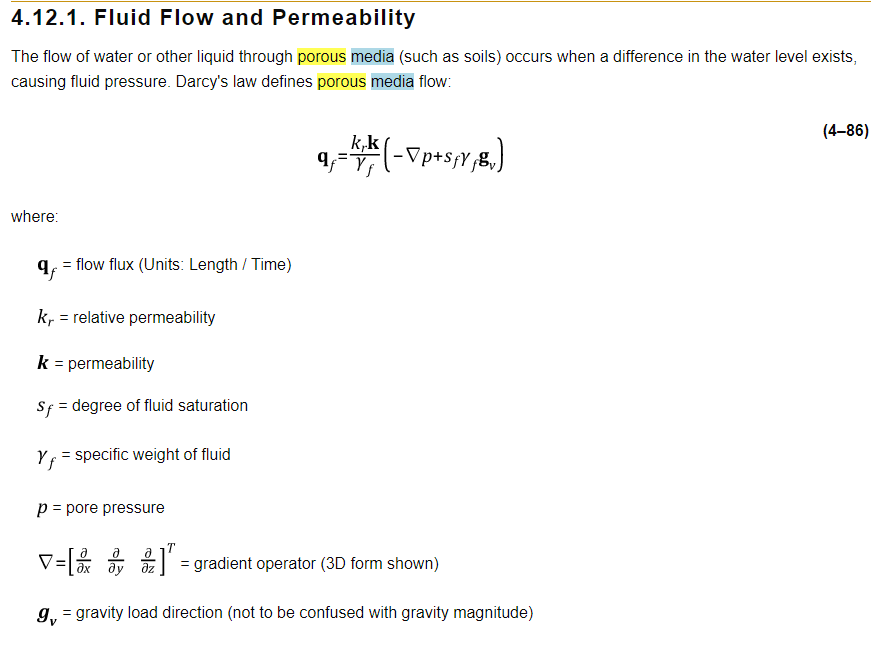

SubscriberYou ask about effective permeability, which is related to fluid flow through porous materials. You must use a different solver for that such as Fluent. Here is the Fluent tutorial on modelling flow though porus media.

Another environment to build porous models is Discovery. Here is the Discovery help page.

Here is the Discovery Porus media coefficient calculator.

There is a theory course on Flow through Porus Media.

-

January 5, 2025 at 5:45 am

mhannan

SubscriberActually I need to add volume constrains and make the body called inside fully incompressible so that it can’t change it’s volume overtime. As water is incompressible so I think it will work. Can you tell me how can I add volume constrains and get the pressure as a result. Do you think HSFLD242 will work in my case??

If this work then how will I incorporate it in my model?

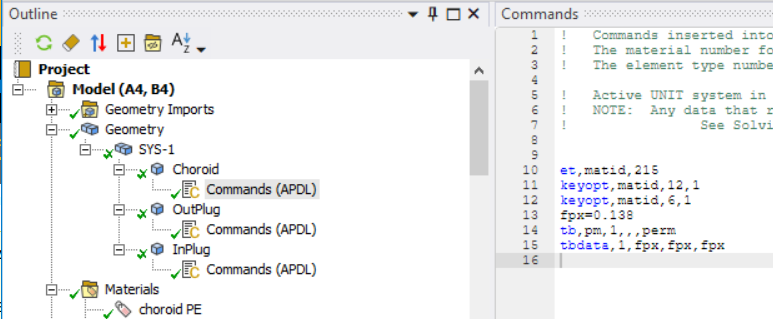

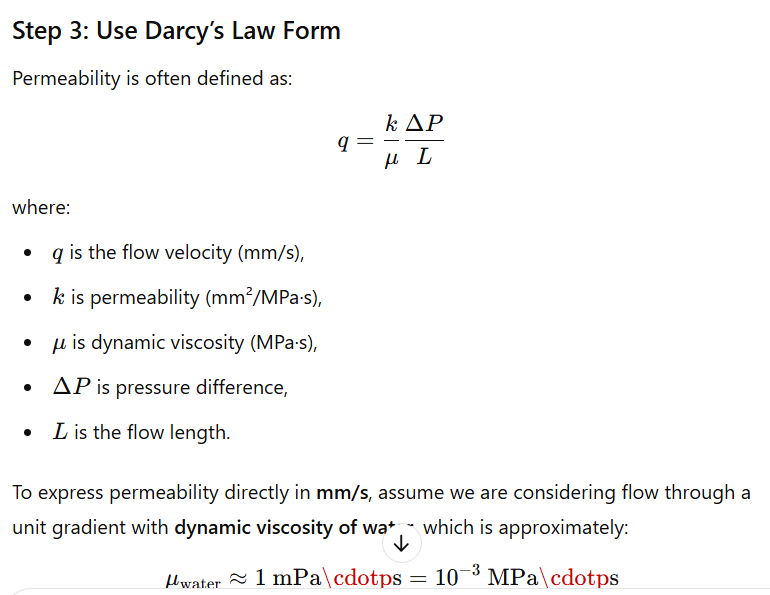

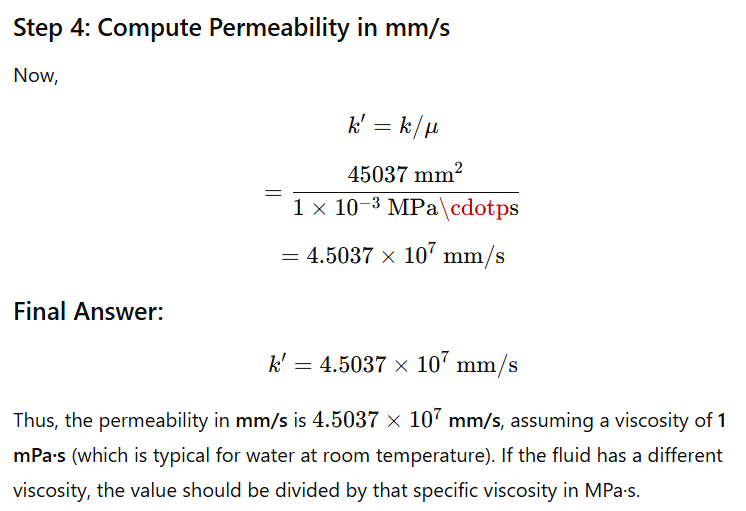

I have to define choroid’s material property as Biphasic, where the solid volume fraction is 0.55.

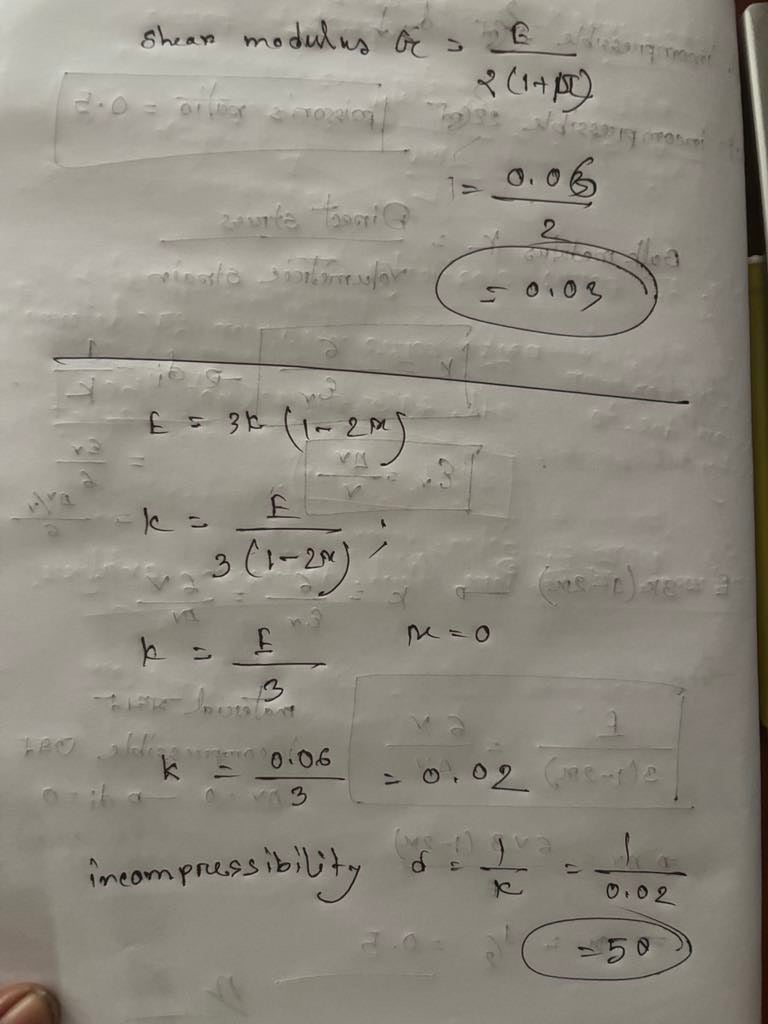

The solid portion is defined as Neo Hookian model with model parameter :

Elastic modulus = 0.06 MPa

Poisson’s ratio = 0

Permeability: 45037 mm2/MPa.s

How can I input this into ansys?

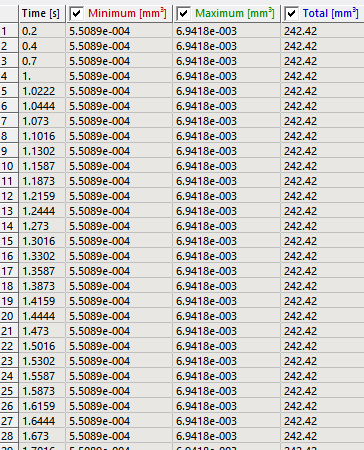

Also I need to measure the volume change of choroid but after applying nodal pressure(nodal pressure for modeling cilliary artery), there is no change of volume which I measure from “volume” result window. Below is the example: -

January 5, 2025 at 3:01 pm

peteroznewman

SubscriberThe HSFLD242 elements include a pressure node at the center to report the pressure in fluid and can be defined as fully incompressible using KEYOPT(6) which defines the hydrostatic fluid element compressibility:

Use KEYOPT(6) = 0 (default) to model the hydrostatic fluid element as compressible. You need to define a fluid material property (use the TB command with Lab= FLUID) to relate changes in fluid pressure to fluid volume.Use KEYOPT(6) = 1 or 2 to model the hydrostatic fluid element as incompressible. The fluid volume is kept constant, even as the solid enclosing the fluid undergoes large deformations. The fluid volume, however, can change when fluid mass is added to or taken out of the containing vessel; this is achieved by applying a fluid mass flow rate or by prescribing a non-zero hydrostatic pressure degree-of-freedom constraint at the pressure node. The fluid volume can also change when a temperature load is applied at the pressure node for a fluid with a non-zero coefficient of thermal expansion. When KEYOPT(6) = 1, the change in volume is accommodated by a change in fluid mass (mass flows into or out of the cavity). When KEYOPT(6) = 2, the change in volume is accommodated by a change in fluid density such that fluid mass is held constant. Read Chapter 15 for how to model hydrostatic fluid models.

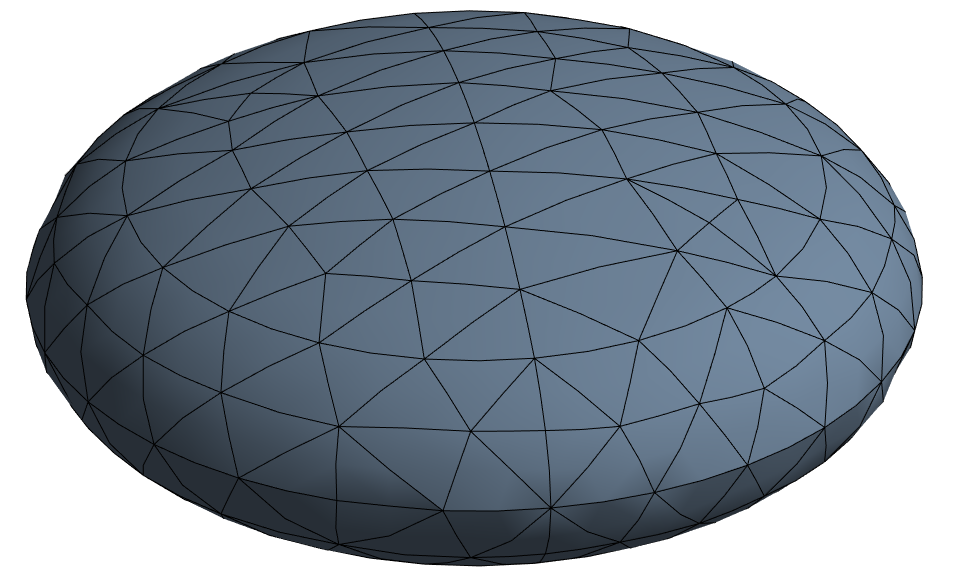

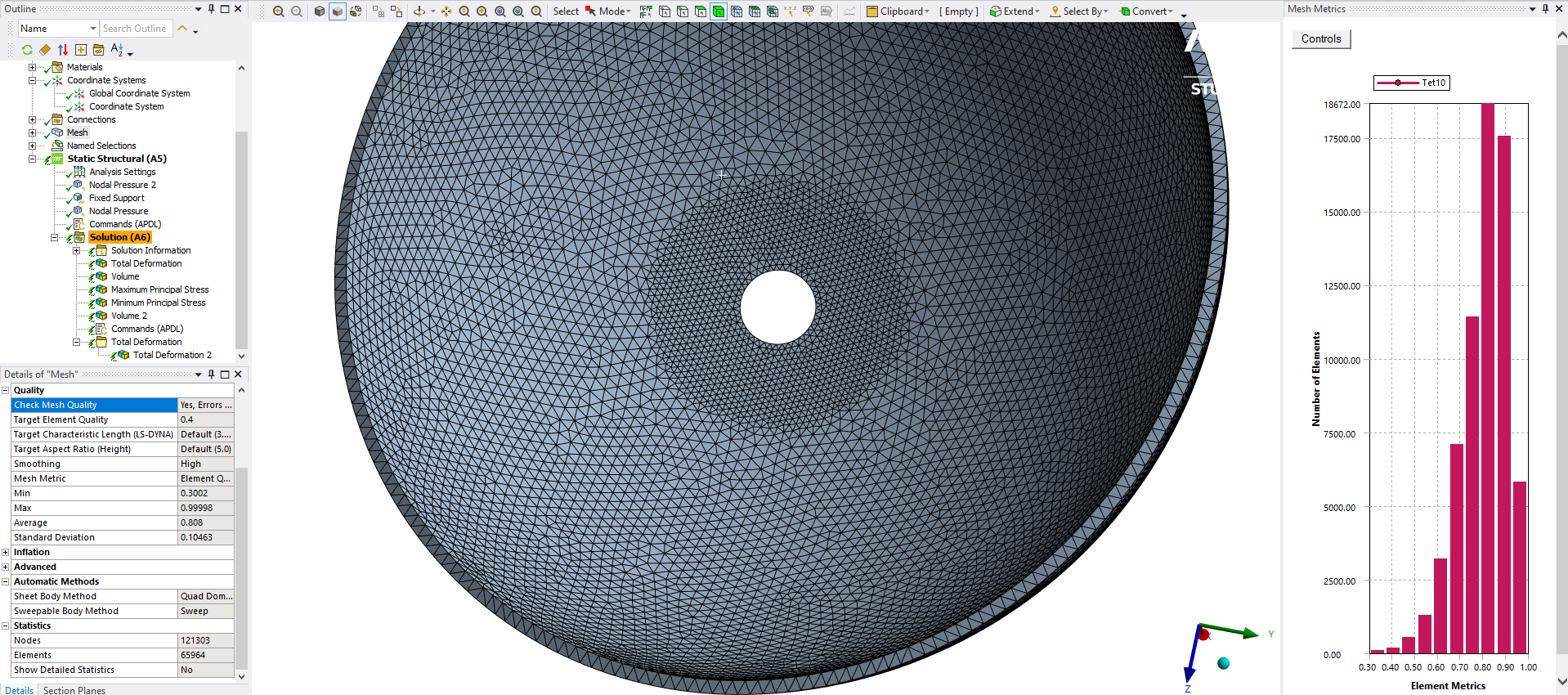

Note that HSFLD242 elements must have the shape of a pyramid, with the pressure node at the apex in the center of the cavity. That means the solid elements that define the enclosed volume must be either pyramid or hex elements. Your current mesh uses tetrahedral elements, which is incompatible with HSFLD242 elements. A significant effort would be required to achieve hex element meshing throughout your model. The benefits of using HSFLD242 elements is that it has a direct pressure output that is constant over the entire fluid volume and there is a fluid volume output.

If you mesh the solid Inside body with tetrahedral elements, assign a water property defined with orthotropic elastic material properties so you can set the Shear Modulus to practically zero. This discussion that has my definition of water that has a practically zero shear modulus. The benefit is the meshing is easy. You can create a stress ouput for hydrostatic stress, but it may vary throughout the volume.

-

January 5, 2025 at 3:54 pm

peteroznewman

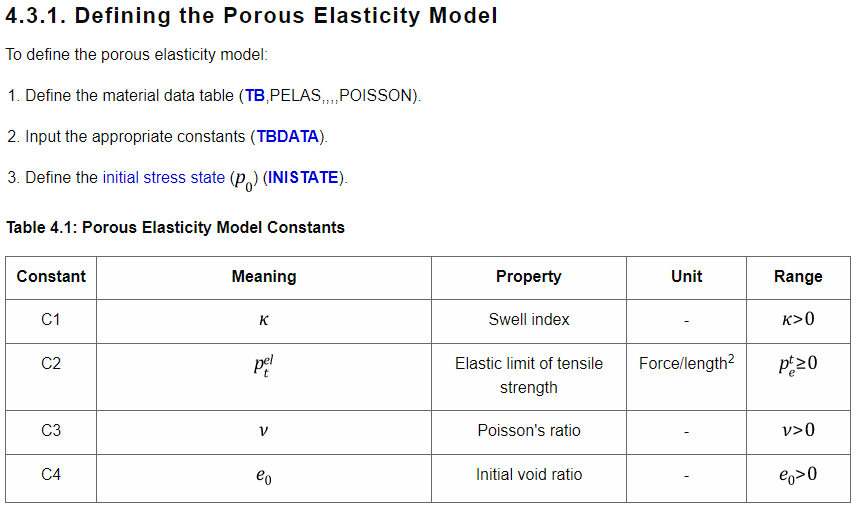

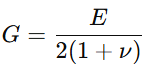

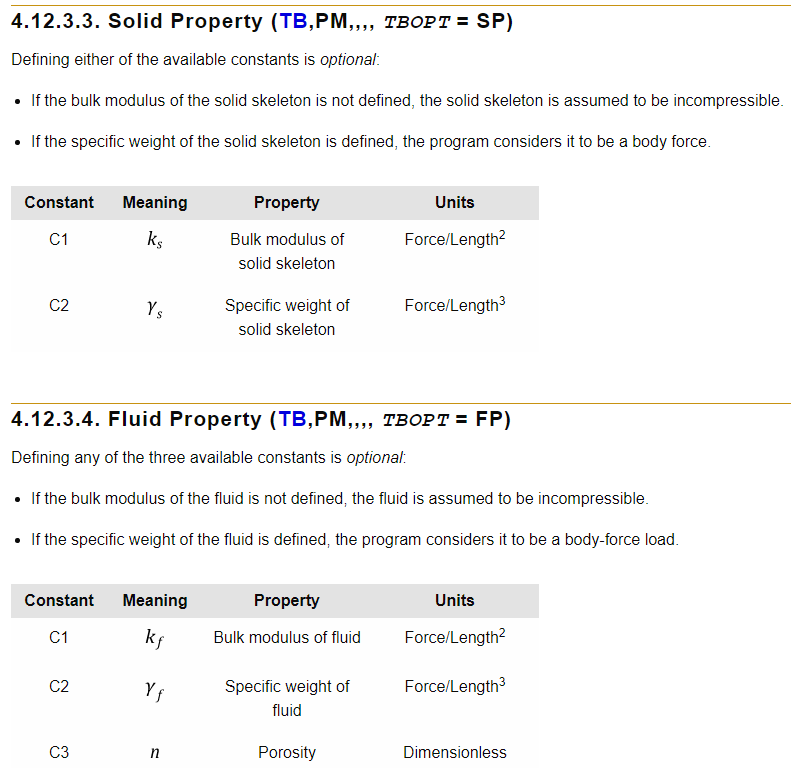

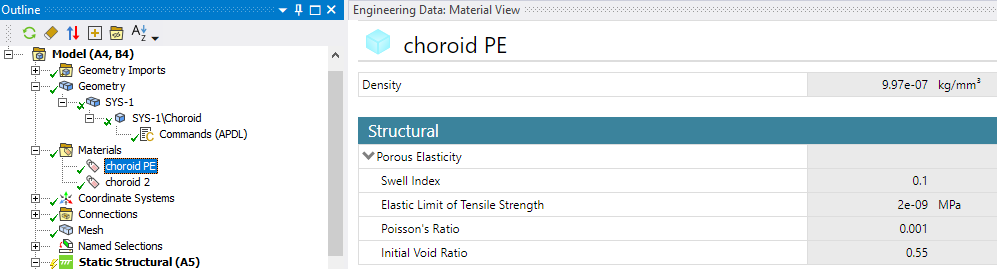

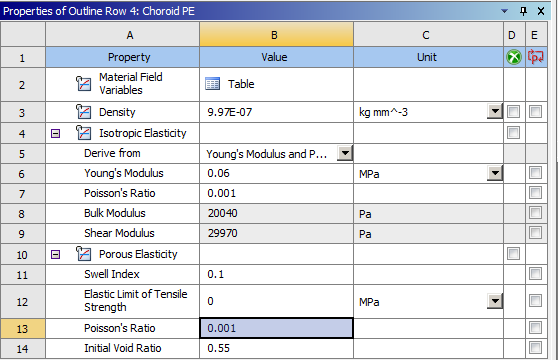

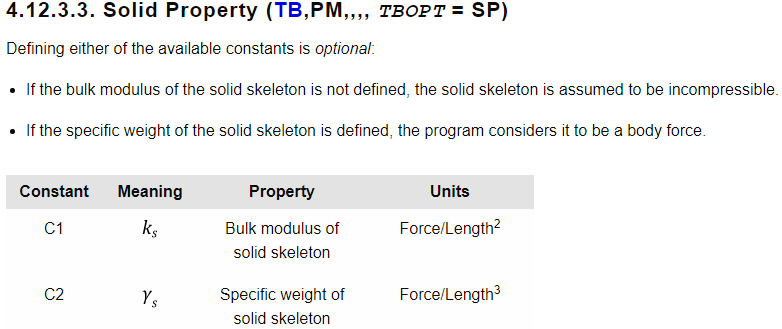

SubscriberThe last model you shared uses a Static Structural analysis, but since you want to include Coupled Pore-Fluid Diffusion and Structural Model of Porous Media, you might want to select the Coupled Field Static analysis from the toolbox. Read Chapter 2.12 to learn how to perform this type of analysis.

The material models supported in the coupled structural-pore-fluid-diffusion analysis include elasticity (isotropic, orthotropic and anisotropic), porous elasticity, Mohr Coulomb plasticity, Cam-clay plasticity, jointed rock plasticity, extended Drucker-Prager and Drucker-Prager-based concrete plasticity.

Porous elasticity material can be defined with an Initial void ratio, which would be 0.45 to give you a solid volume fraction of 0.55

Note that Hyperelastic material models are not on the list of material that support pore-fluid diffusion. I don’t know where you want the pore-fluid diffusion to act, but you have used Hyperelastic materials such as Yeoh for Piamater and Duramater, Mooney-Revlin for Sclera and Neo-Hookean for Choroid. However, I find in Engineering Data, it does not complain if I add Porous Elasticity to a Neo-Hookean material, but maybe they just haven’t put all the error checking in that is required. For many illegal combinations, Engineering Data will use a strike-though font so highlight illegal combinations in material properties.

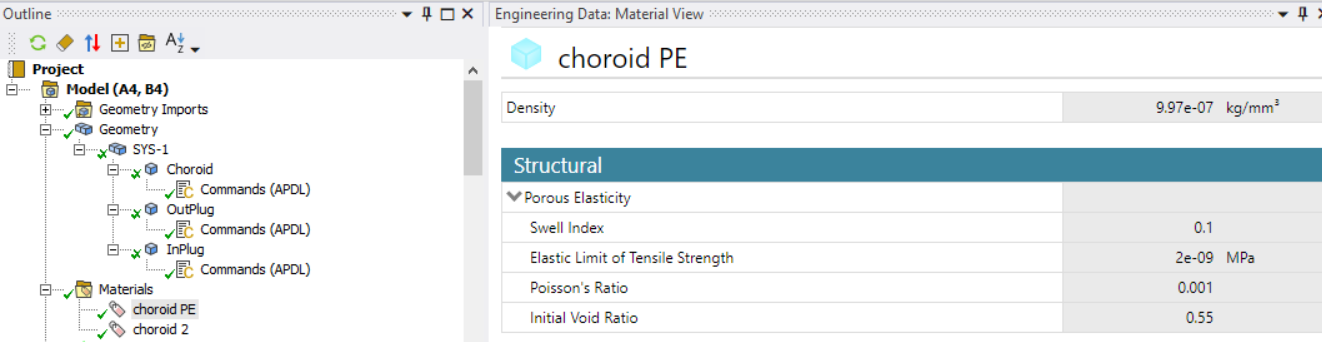

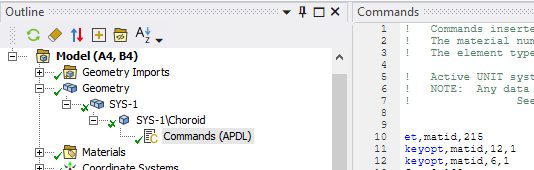

Note that you must mesh the bodies that will have permeability with the correct element type that supports coupled pore pressure analysis such as CPT217.

There are two Verification Test models of coupled pore-pressure deformations. One is a 2D model VM260. VM264 is a 3D model using CPT217. I see they use Analysis Type of Static (ANTYPE,0) so maybe you don’t have to use ANTYPE,SOIL which was mentioned in 2.12 above.

In the last model you sent, I see the volume changes in Step 1, but not in Steps 2 and 3. Maybe when you get a model that includes pore-fluid diffusion, you will see a volume change.

-

-

January 10, 2025 at 5:34 pm

mhannan

SubscriberI think the pressure which I was applying through nodes aren't working, I have experimented on a simplified model. How to handle this issue?

-

January 10, 2025 at 11:42 pm

peteroznewman

SubscriberYou have a very complex model that uses many types of material properties and is a coupled physics type of model. I suggest you build competence in each component of this complex model by analyzing many much simpler test models and you indicate above that you have already started to look at a simplified model. Please describe in detail that simplifed model, what result you obtained and why you think it is wrong.

The ideal simple test model is one which has an analytical solution so you can show that your model result matches the analytical model. The ideal simple test model may have geometry very different than your eyeball anatomy. The verification model VM264 is a simple cylinder.

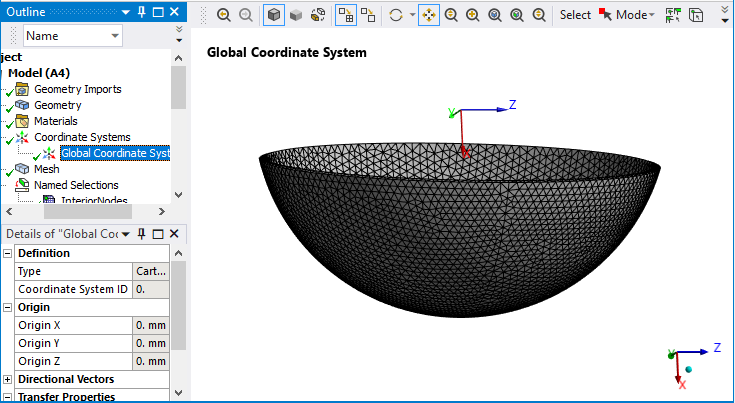

Another simple test model is a volume of water inside a non-porus elastic (or hyperelastic) enclosure with a constant wall thickness. Use a simple geometry such as a sphere and show that you can apply pressure to one face and have the other faces expand out while the volume of water remains constant. I would use symmetry to make the boundary conditions simple. Use SpaceClaim to create a sphere at the origin, then create 3 planes at the origin and slice the body to leave a 1/8 model, keeping the solid on positive side of the origin. Make a plane at the tangent to the sphere on the X axis. Sketch a circle on that plane. Project that circle onto the surface of the sphere to create a face to apply pressure. Due to symmetry, that will be like pushing on both sides of the full sphere.

What other component of the full model can you think of to break out into a simple test model?

-

January 15, 2025 at 12:11 pm

mhannan

Subscriberhere I uploaded a simplified model where I use water as orthotropic solid and CPT217 but couldn't understand why this is not converging.

Is this okay inserting CPT217?

https://drive.google.com/drive/folders/1tNCgeLdl58NlKD706NXF2LGBPWbiu9-b?usp=sharing -

January 15, 2025 at 10:48 pm

peteroznewman

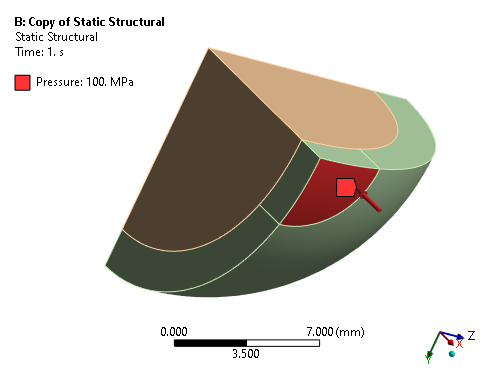

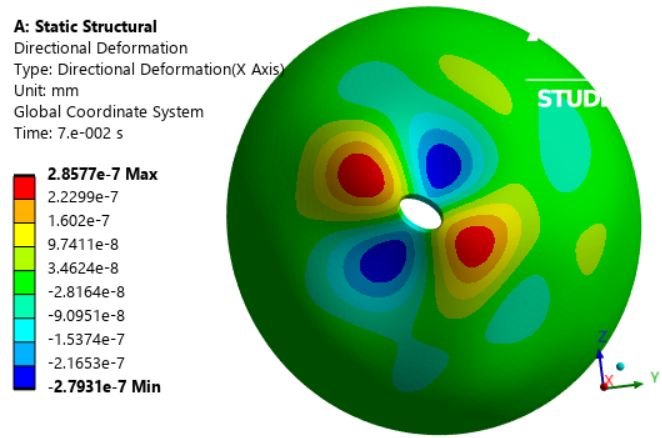

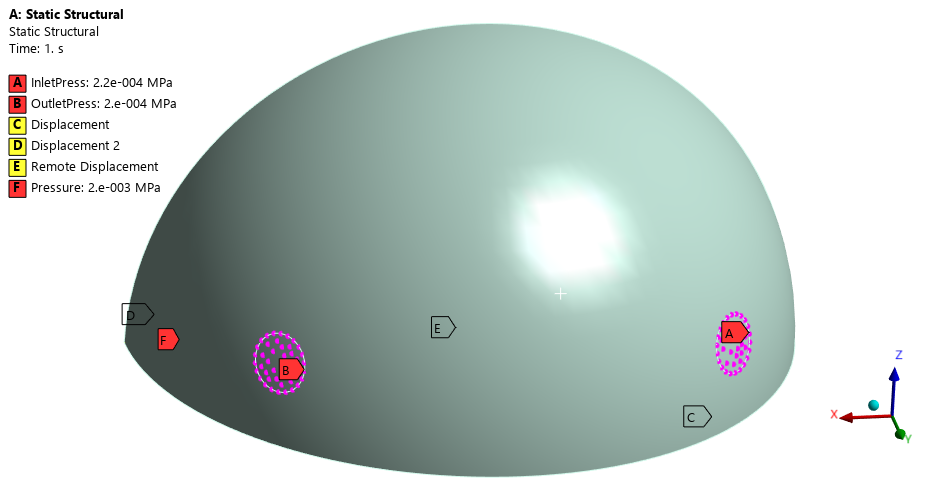

SubscriberI downloaded your file and made a few changes to make it to show the pressure on a circle imprinted on opposite sides of the hollow sphere with a water center. One problem with your model is it has no connection to ground. I followed the directions I gave above to create 3 planes of symmetry and have a 1/8 model. I also deleted the Porous Elasticity from the choroid material.

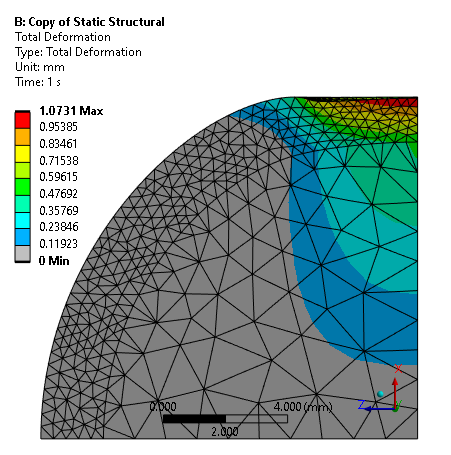

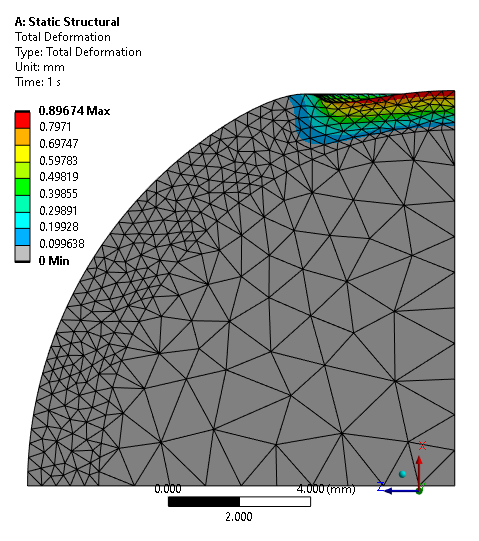

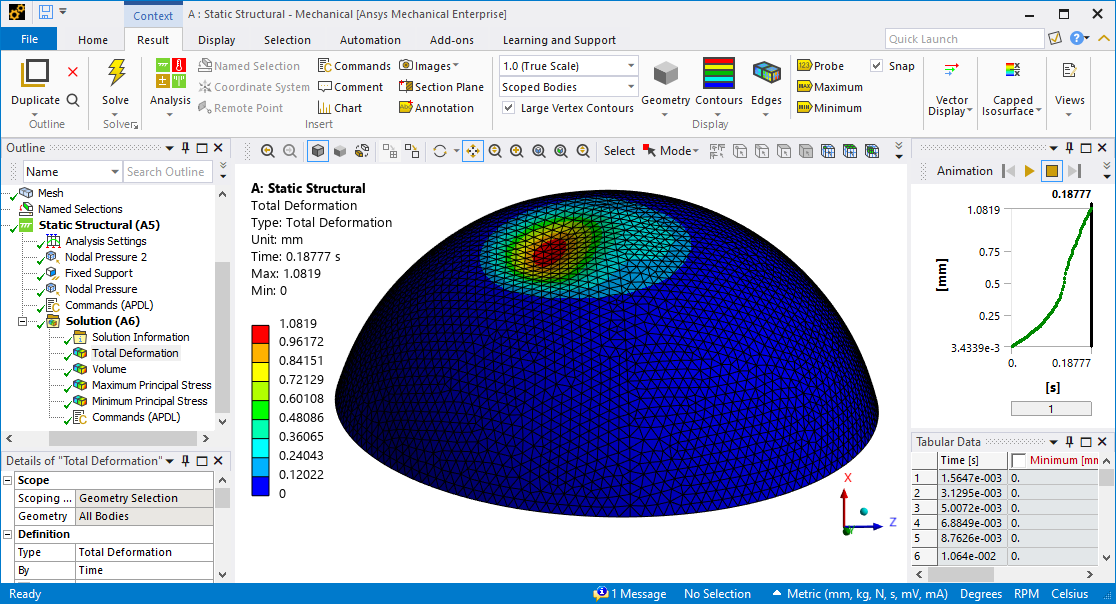

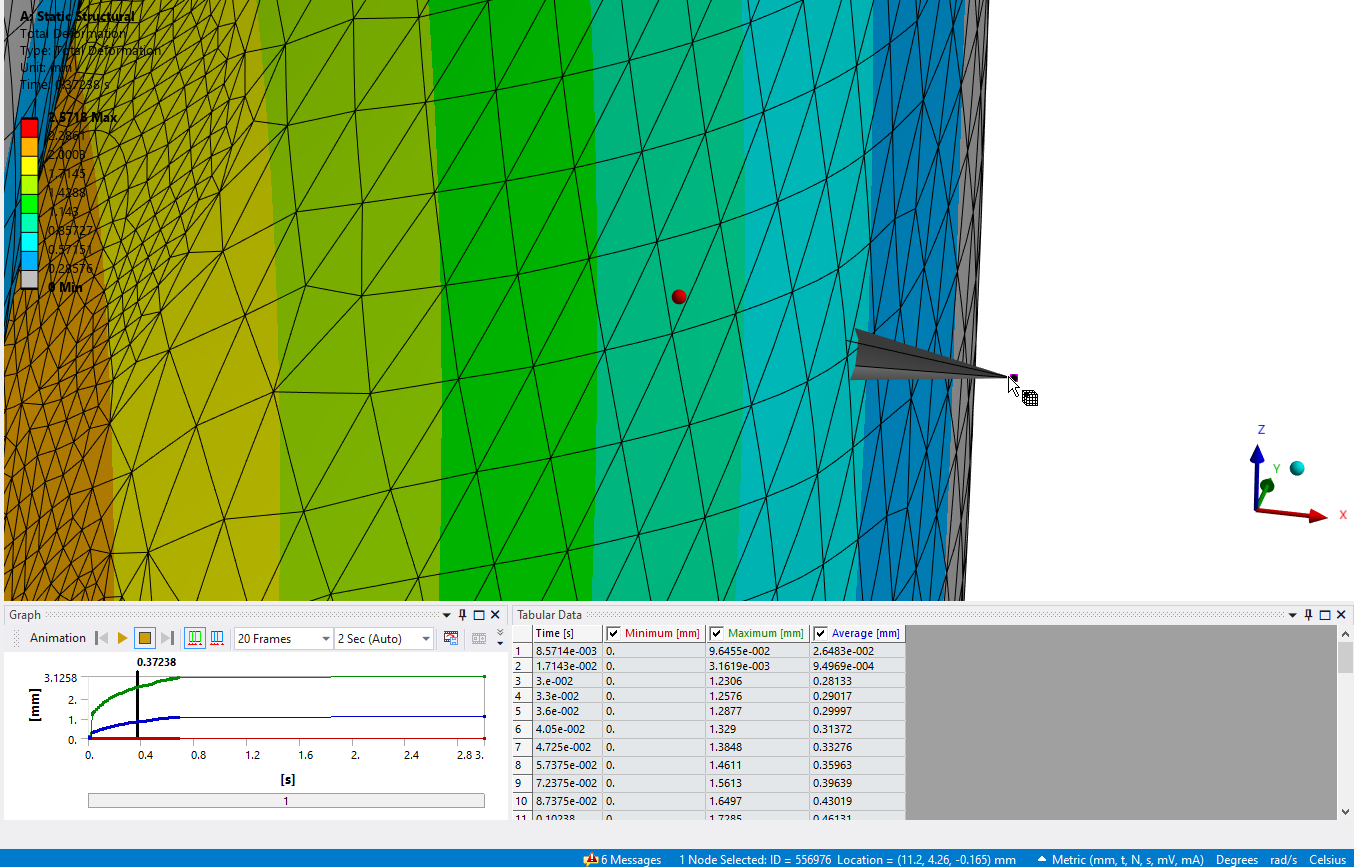

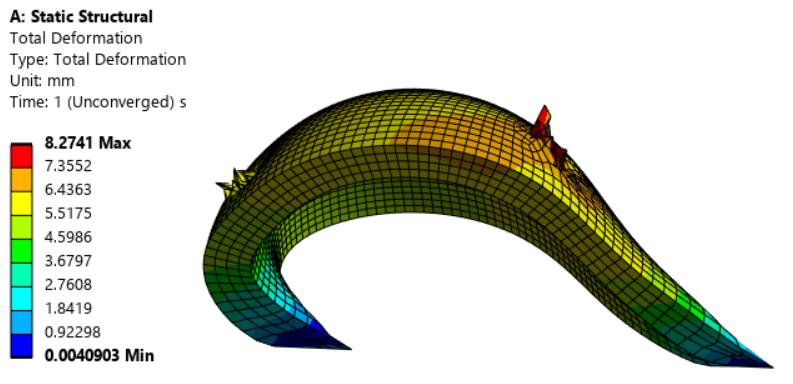

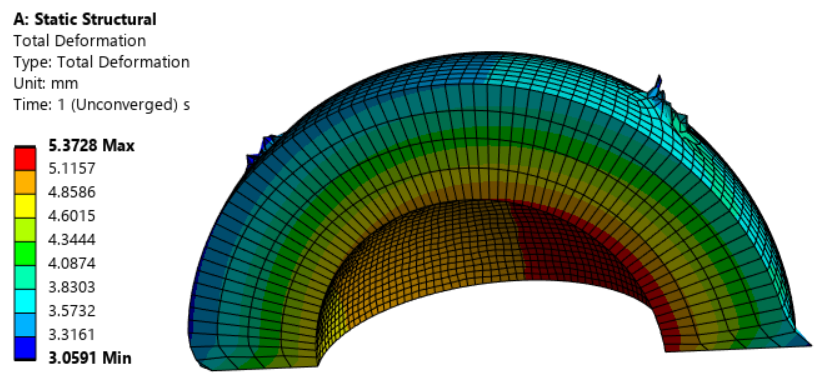

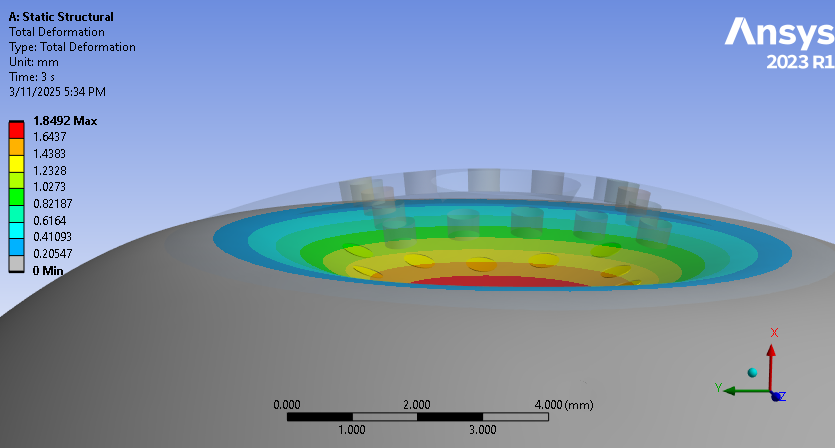

The deformation plot below is shown with a display scale factor of 1 True Scale. You can see that the top of the interior cavity has flattened out somewhat.

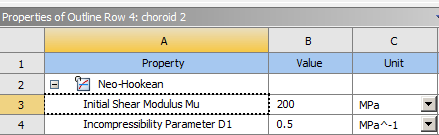

In the “B” model shown above, I created a material choroid 2 and used vastly higher Initial Shear Modulus so I could use vastly higher pressure to see some deformation and check the constant volume of the water.

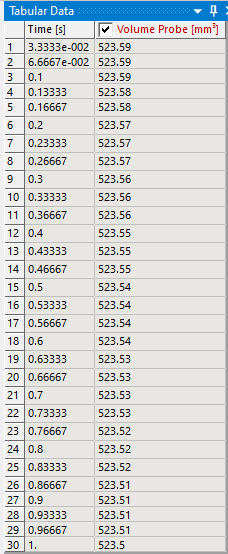

You can see that the water is holding a fairly constant volume with a Poisson’s Ratio of 0.49.

The “A” model has the original stiffness of choroid, but it can only solve up to a small pressure of 0.05 MPa.

The display scale factor shown below is 1.0 True Scale. See how the thickness of the low stiffness choriod has been squashed down.I solved this model in ANSYS 2023 R2. You won’t be able to open my model as you are using ANSYS 2020 R1 unless you upgrade to the latest version.

-

January 17, 2025 at 6:37 am

adib.aktab999

SubscriberHey I am from this new account.

Does the porus elasticity working??

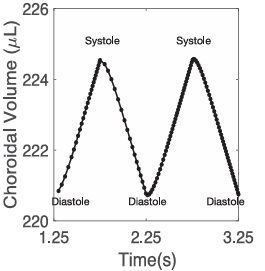

I have added CPT217 on the hollow sphere which is choroid and it has to change it’s volume overtime. The volume change should be in a range of (1-2mm^3) by using this pressure.

Material property for choroid is below

Solid volume fraction: 0.55

Solid matrix:

Neo-Hookean

Elastic modulus= 0.06 MPa

Poisson’s ratio= 0

Permeability: 45037 mm2/MPa.s

Basically I am looking for the volume change overtime for the choroid to validate my model which should be like this:

and also please share me the file. -

January 18, 2025 at 11:17 am

adib.aktab999

Subscriber -

January 18, 2025 at 7:37 pm

peteroznewman

SubscriberHere is a link to an Ansys 2024 R2 archive of the 1/8 model of a non-porus hyperelastic solid spherical shell enclosing a volume of water represented by an orthotropic material with a pressure applied to a circular face on the shell. I built that to observe the deformation of the sphere with pressure applied on opposite sides of the sphere, but in a 1/8 model.

You could try modifying the above model by replacing the orthotropic water elements with HSFLD242 elements, though this will require some APDL code that I cannot help you with. I read that HSFLD242 elements are compatible with a quadratic tet mesh, though the figure shows it connecting to a quadratic hex element. However, after you delete the water elements (and water solid body), it is simple to mesh the choroid solid body with hex elements.

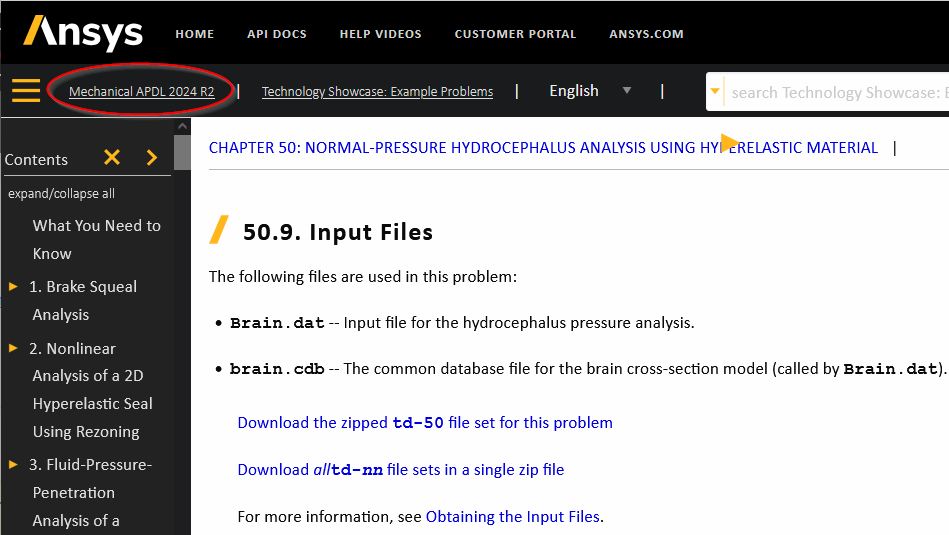

I recommend you study the Technology Showcase Example Problem Chapter 50: Normal-Pressure Hydrocephalus Analysis Using Hyperelastic Material.

This example uses porous elasticity with a neo-hookean hyperelastic material. Maybe you can apply what you learn to the 1/8 spherical shell model by adding porous elasticity and changing the elements to CPT217. -

January 19, 2025 at 4:48 pm

peteroznewman

SubscriberI learned how to use HSFLD242 elements to represent an incompressible fluid and show how the result is very different to using the orthotropic material to represent water. Read this discussion:

I recommend you use this method for your study.

-

January 21, 2025 at 6:10 pm

peteroznewman

SubscriberI recommend you study the Technology Showcase Example Problem Chapter 50: Normal-Pressure Hydrocephalus Analysis Using Hyperelastic Material.

This example uses porous elasticity with a neo-hookean hyperelastic material. Maybe you can apply what you learn to the 1/8 spherical shell model by adding porous elasticity and changing the elements to CPT216 or CPT217 depending on whether you mesh the choroid with quadratic hex or tet elements respectively.Note: the Input files for all the 2025 R1 Example Problems are empty zip files! You must change the version to 2024 R2 to get zip files with the promised input files.

-

January 21, 2025 at 6:14 pm

adib.aktab999

SubscriberCan you share me 2024R2 version, because it's not available rn on Ansys website.

-

January 21, 2025 at 7:00 pm

peteroznewman

SubscriberI expect these files can be opened in older or newer versions of ANSYS.

https://ansyshelp.ansys.com/public/Views/Secured/Doc_Assets/v242/MAPDL_showcase/td-50.zip

-

January 26, 2025 at 4:53 pm

adib.aktab999

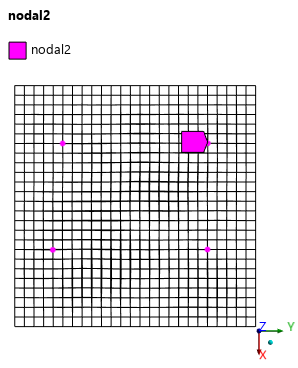

SubscriberHey I was trying to understand the nodal loading, so I use nodal loading on a cubic model. But it doesn't show any deformation I donnow what is the reason can you give me insight?

https://drive.google.com/file/d/1P1NIQ5X8pQUIpkkZLDCFCiGwXqPwkNcH/view?usp=sharing -

January 27, 2025 at 2:02 am

peteroznewman

SubscriberThe Command object under the solid body Part1 defines the permability of the Porous Medium using a TB, PM command. A number in that command defines permeability in a certian unit system, but you have not included a comment telling me what unit system I must solve in for that number to be correctly interpreted. Always put a comment in the command to define what units to use to interpret the numbers in the command.

You have not used a Command object to change the Element Type for the mesh to use ET, 217 which is required to use TB, PM.

The solution fails with an error because Element Type 186 does not support TB, PM

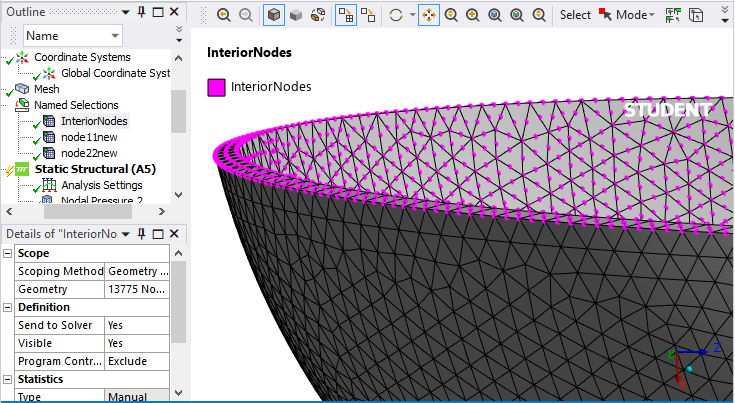

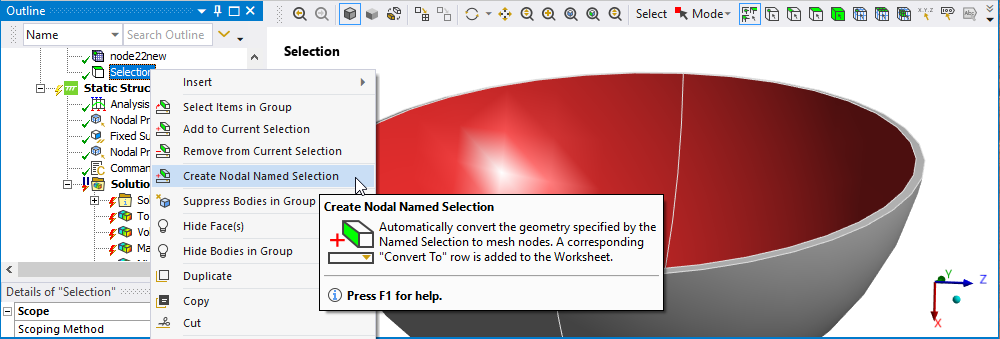

If you suppress the Command under Part1, the model will solve, but zero deformation is the result because you have not used Nodal Pressure correctly. You have only selected one node on the face of the element.

When applying a Nodal Pressure load in Ansys Mechanical, it's important to understand that the load is applied to element faces. For a nodal pressure to be created, all nodes of a given element face, including midside nodes, must be included in the node-based named selection. If you apply a nodal pressure to just one node on the face of a cube meshed with solid186 elements, it would not create an elemental face pressure unless all nodes defining that face are included [1].

URL: [1] https://ansyshelp.ansys.com/public/Views/Secured/corp/v251/en/wb_sim/ds_Nodal_Pressure.html -

February 1, 2025 at 4:03 pm

adib.aktab999

SubscriberHey can you please tell me, how can I incorporate HSFLD242 element in my model. I can't find it helpful from your discussion. I have to denote vitrous body as water(HSFLD242) and choroid as CPT217. I will apply nodal pressure on choroid and vitrous body generate repulsive pressure due to incompressibility and the choroid volume will change with pressure.You have said, "However, after you delete the water elements (and water solid body), it is simple to mesh the choroid solid body with hex elements."If I delete water element, then how can I select water? But for my model it is difficult to incoparate, how can I incorporate HSFLD242??Do I have to do tetrahedral meshing for HSFLD242?? I have trier sweep meshing after compressing water solid but it isn't working and same for CPT217.

I have studied chapter 50 but that was cpt212 with neo hookian.-

February 1, 2025 at 7:51 pm

peteroznewman

SubscriberIn my January 19 reply, I provided a link to a discussion that demonstrates how to incorporate HSFLD242 elements. While that model uses Hex elements, you can get the same result with Tet elements. Either kind of element will work. Here is a link to an ANSYS 2024 R2 archive with the models shown in that discussion. https://jmp.sh/zc0UG7Le

Once you delete the water elements, the inner face of the choroid can be used to fill that interior with HSFLD242 elements, which behave like an incompressible fluid.

-

-

February 1, 2025 at 5:14 pm

adib.aktab999

SubscriberHow to select internodal nodes of a whole surface??

https://drive.google.com/drive/folders/19FQFr4y9Cpfm5TyeTlqGjdfvhFeVS1jQ?usp=sharing

Many many thanks in advance for your help.-

February 1, 2025 at 9:41 pm

peteroznewman

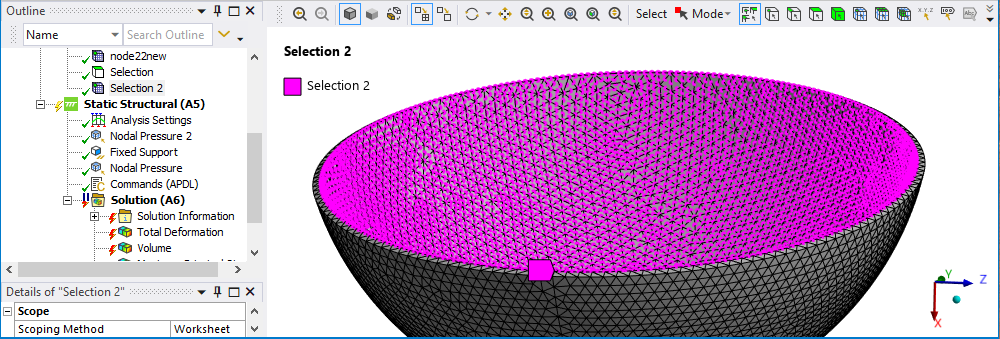

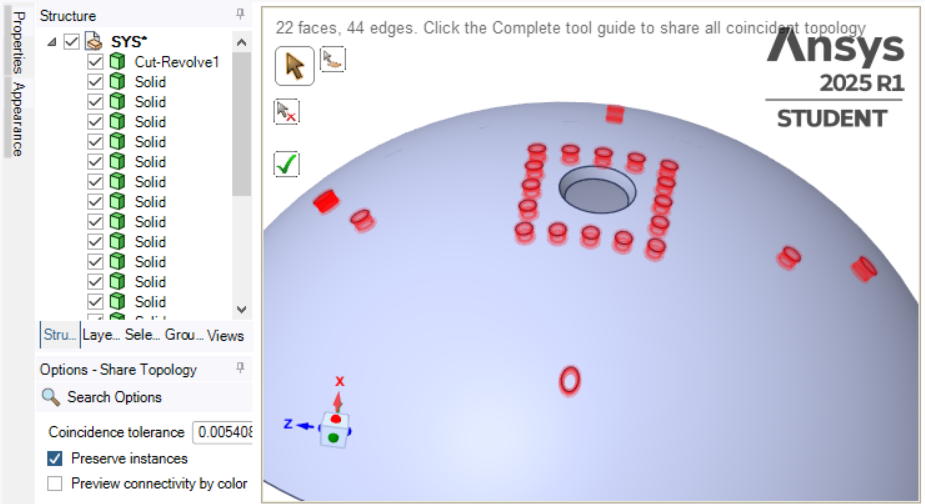

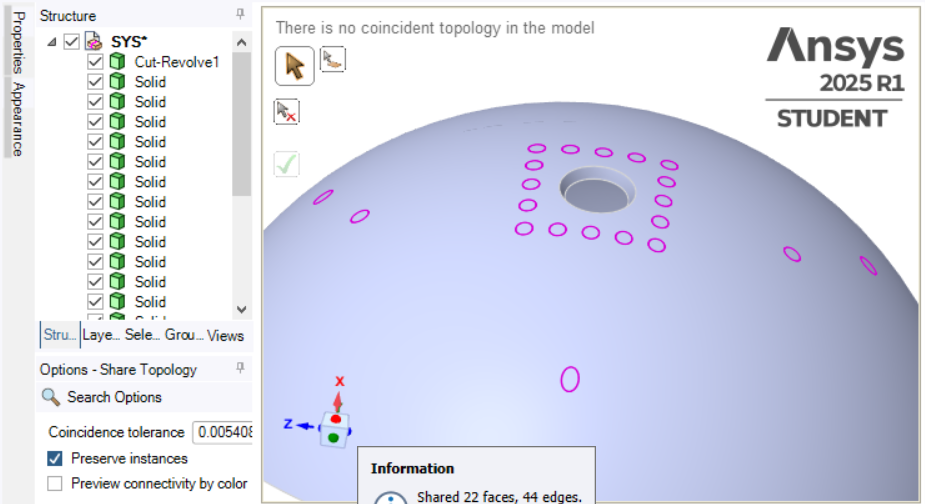

SubscriberYour hollow sphere geometry is corrupt. I fixed it in this repaired version which shows how to select the InteriorNodes. Your corrupt solid had no interior face.

You can use this example model to get the HSFLD242 elements working. https://jmp.sh/9j8my5y6

-

-

February 1, 2025 at 9:18 pm

adib.aktab999

SubscriberAs my choroid model will be porus hyperelastic which I intended to use CPT217, do I have to use "keyopt,matid,6,1" this code under choroid's geometry option?

-

February 1, 2025 at 9:42 pm

peteroznewman

SubscriberYou don't have to use any keyopts but this one is well know to help convergence in hyperelastic materials. Look up CPT217 in the Mechanical APDL Element Reference and see what keyopts are defined for this element.

-

-

February 1, 2025 at 10:45 pm

adib.aktab999

SubscriberHello Peter, when I am using the element it's not convergong. Can you look into the model?

Is my nodal pressure working??https://drive.google.com/drive/folders/19FQFr4y9Cpfm5TyeTlqGjdfvhFeVS1jQ?usp=sharing-

February 2, 2025 at 2:29 am

peteroznewman

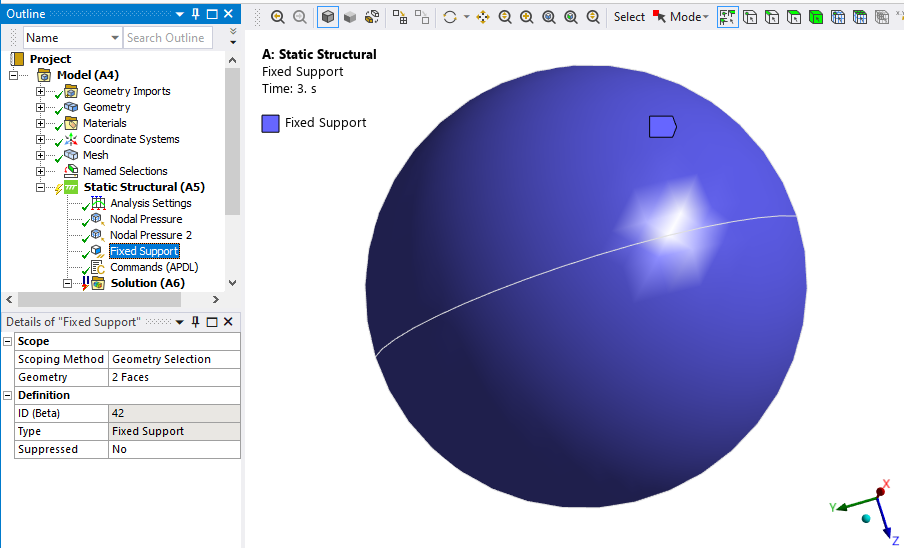

SubscriberI looked at your model. The Fixed Support is covering the entire outer surface. That means none of those nodes can move!

That means the effect of these nodal pressures is exactly zero!

I suggest you move the Fixed support to the thin bottom edge of the hemisphere.

I have the Student license on my personal laptop. The Student license has a limit of 128,000 nodes or elements. Your model has more than that so I would have to remesh to get below that limit. The problem is you are applying a nodal pressure so if I remesh, the Nodal Named Selections become broken. It would be better if you imprint the areas you want to apply the pressure to on the face in SpaceClaim. That way it will not be lost during remeshing.

If you want me to look at convergence issues, please keep your mesh below the 128,000 node limit. One way to cut down on the node count is to cut the model in half and use a Symmetry boundary condition on the cut face.

-

-

February 2, 2025 at 9:51 am

adib.aktab999

SubscriberFrom the previous file I have shared, whenever I changed the fixed support, it runs and it gives deformation not actually what I expected. Whenever I changed meshing to share with you and ran the model it is not converging. I shared the model can you look into it?

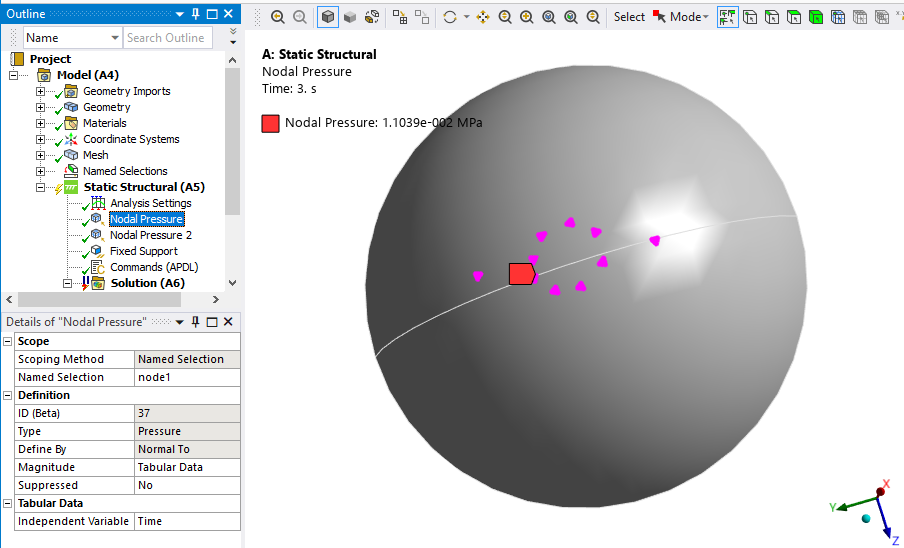

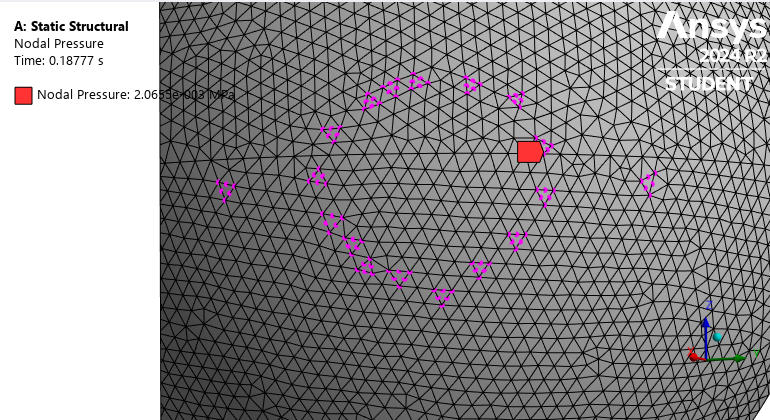

1. Is the nodal pressure applying properly??

2. Is the selecting pressure node for HSFLD242, okay or not. If not can you tell why?https://drive.google.com/drive/folders/19FQFr4y9Cpfm5TyeTlqGjdfvhFeVS1jQ?usp=sharing -

February 2, 2025 at 12:12 pm

peteroznewman

SubscriberOn the HSFLD242 elements, why did you include the narrow rim face of the hemisphere as InteriorNodes? Is there water on that face? I would exclude that face in the next model. It’s fine for now, especially since those nodes are fixed.

You put the HSFLD Node 8022 at the Global Origin. That means the water volume will have a conical top from that point down to the InteriorNodes. Is that what you want? It’s okay to leave that there for now because you will eventually have more geometry on the -X side of the origin, just be aware of the conical top if you request a report on the fluid volume.

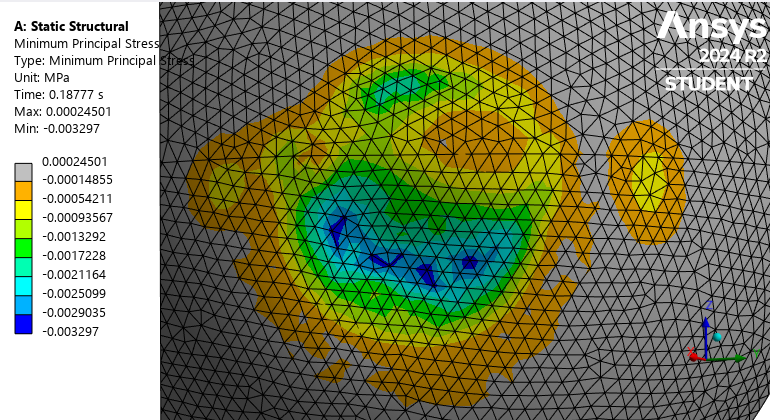

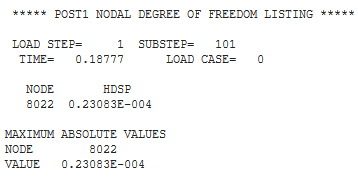

I set the Analysis to solve only step 1 and set the End Time to 0.18777 and got convergence. You can see that Nodal Pressue is causing deformation.

The Nodal pressure is causing compressive stress.

When you turn on Auto Time Stepping, you should make the maximum number of substeps a large number like 1000. I tried changing from the Iterative solver to the Direct solver and the time went down slightly from 9:29 to 9:11. I always use Direct unless I have a large model and the solution solves out-of-core.

The HDFLS242 pressure node reported the pressure in the Solution Output. This number is in MPa due to the Units being set to mm.

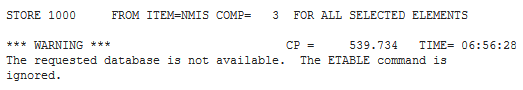

Your ETABLE command is not working.

Keep in mind that I am solving on ANSYS 2024 R2 while you are solving on 2020 R1 so your results may differ slightly from mine.

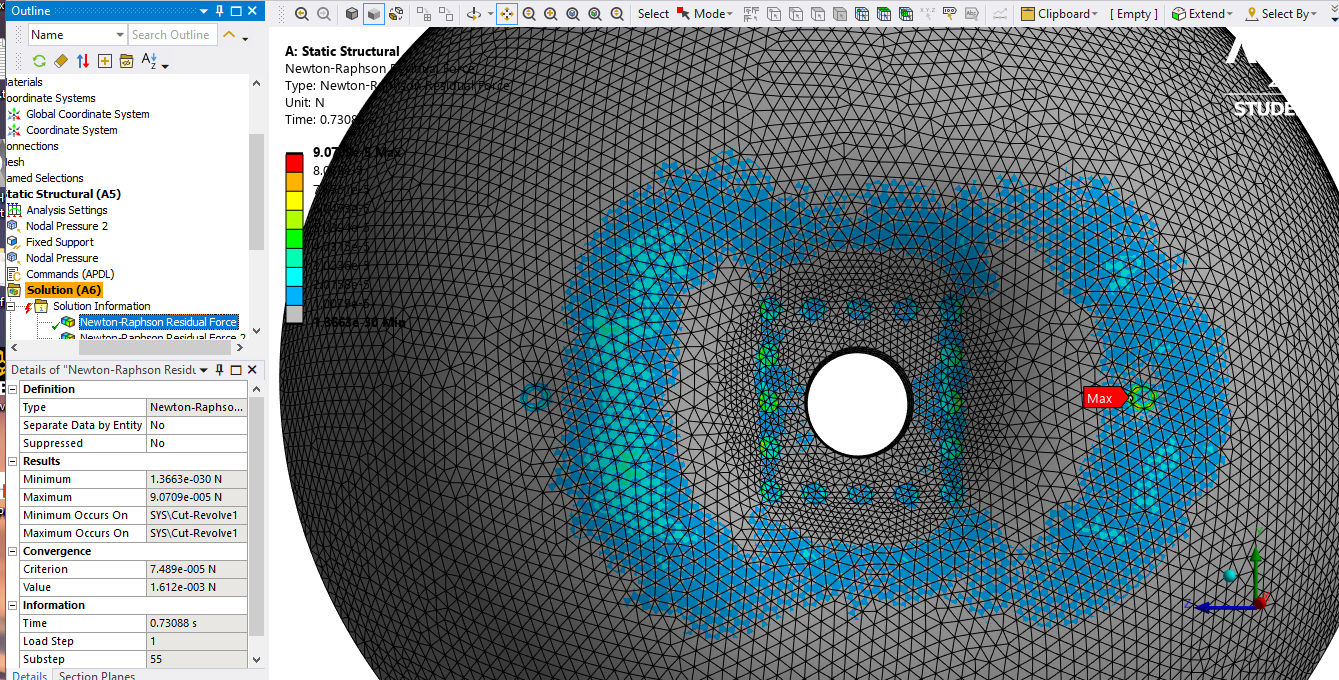

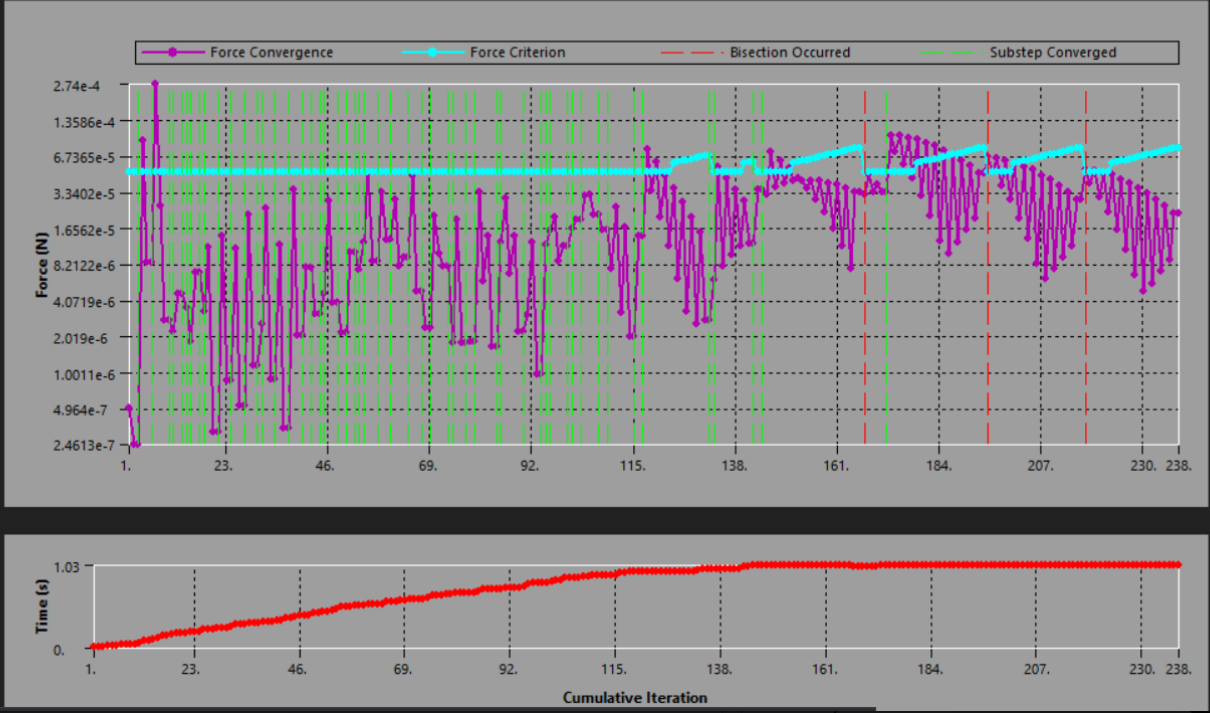

The next step is to change the end time to 1 and see if convergence continues. Looking at the Force Convergence, we see there is a problem and Interupt the solution.

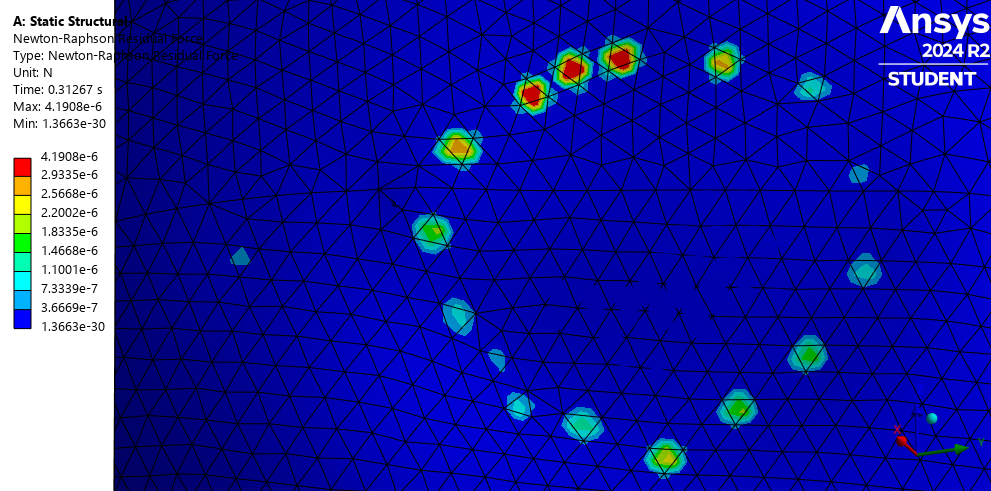

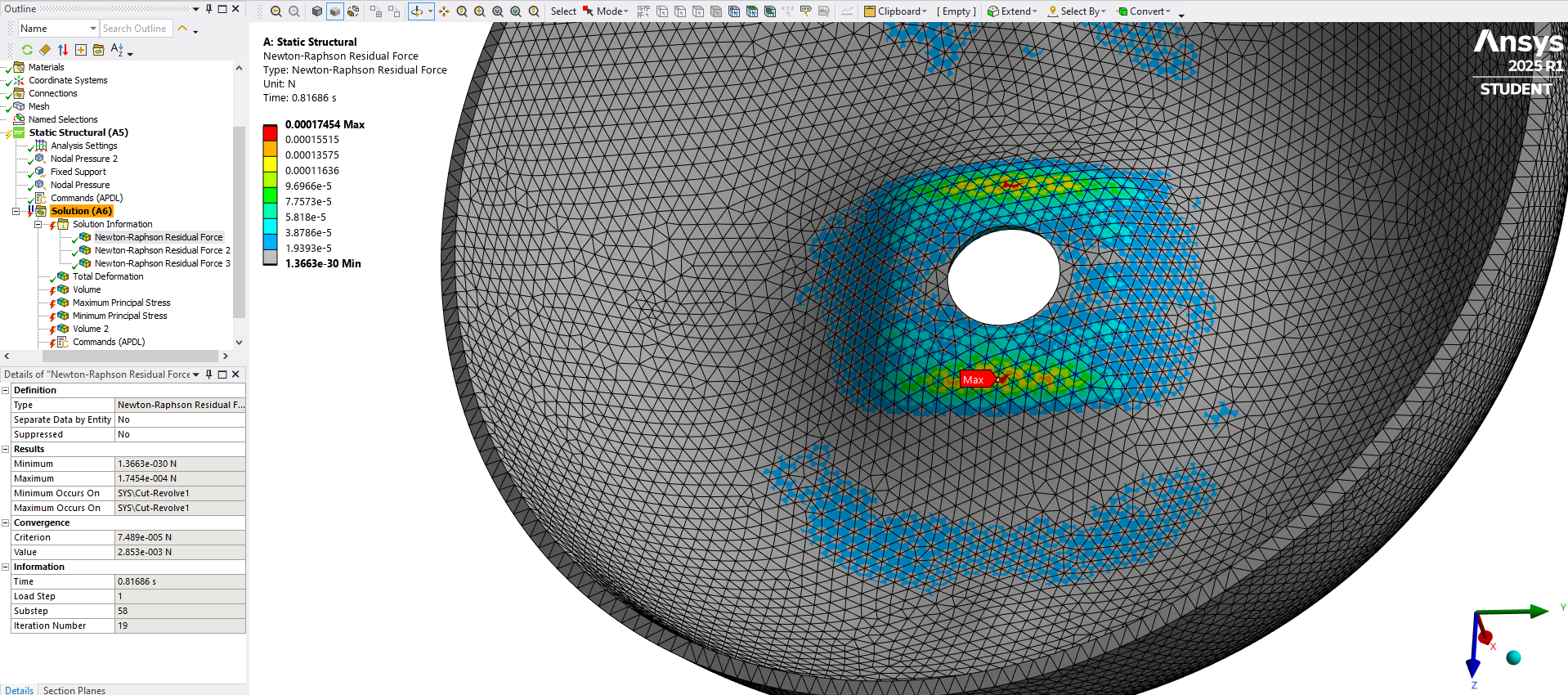

Notice that that the purple line goes horizontal, so it is unlikely to converge and after each bisection, it is not getting closer. This means it is time to look at the N-R residual plot, which you can only see if you put a number in the Newton-Raphson Residuals line of the Solution Information folder.

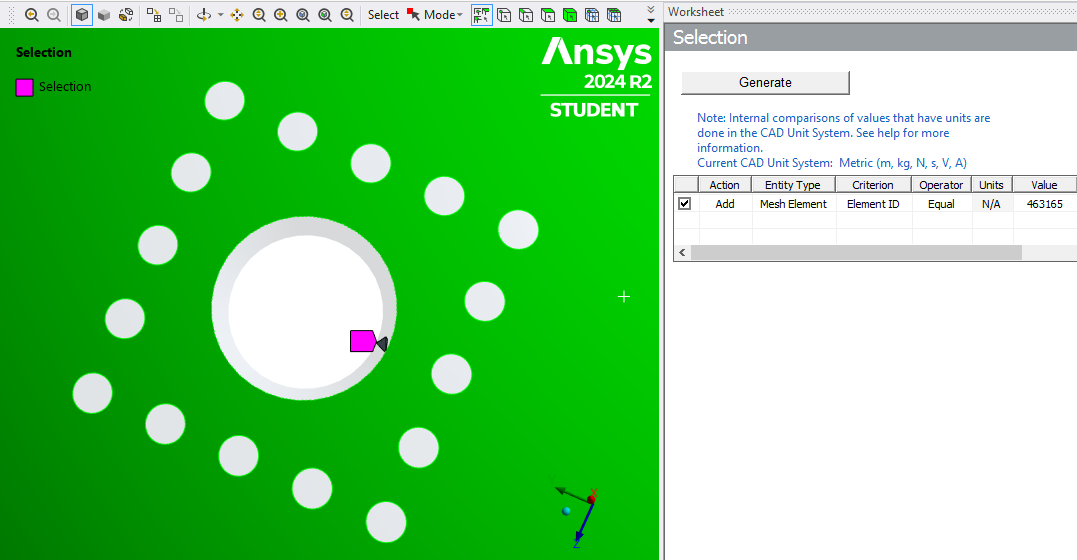

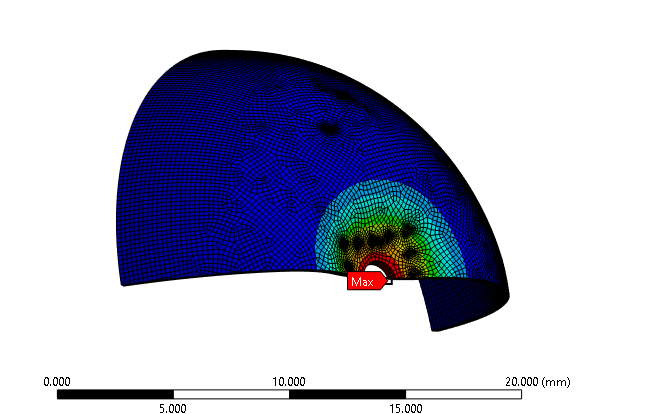

The reason the solver can't converge is because of a force imbalance in the elements colored red, yellow or orange below.

The corrective action is to apply a mesh control to use smaller elements around these regions. This is why you should stop using Nodal Named Selections for applying pressure and imprint a face on the geometry for each pressure location you want. That way, after a problem like this, you can simply apply a sizing mesh control, remesh and start solving again.

-

February 2, 2025 at 1:18 pm

adib.aktab999

Subscriber"why did you include the narrow rim face of the hemisphere as InteriorNodes?" I have done this because I couldn't select the whole interior face as nodes through box select when I am trying this some nodes remain unselected. Selecting individual nodes are frustrating.

still it's not converging.

I have added material's property newly by engineering data to solve ETABLE problem.-

February 2, 2025 at 1:47 pm

peteroznewman

Subscriber

-

-

February 2, 2025 at 1:21 pm

adib.aktab999

SubscriberThanks for your detailed help, I am working on it and let you know what’s happening. The last time when it's converged before decreasing mesh size, I noticed there wasn't any volume change.

-

February 2, 2025 at 1:53 pm

peteroznewman

SubscriberThe Neo-Hookean material has a small Incompressibility Parameter D1 so it is nearly incompressible. Since such a tiny area of your model has a pressure applied, the volume change might only be measured beyond the 5th digit. I created a 1/8 model with a sphere with a radius of 12 mm of that material and applied a 0.01 MPa pressure to the surface of the sphere. The surface was compressed in about 1.1 mm radially and the volume change of the1/8 solid went from 900 mm^3 to 677 mm^3.

-

-

February 2, 2025 at 1:58 pm

adib.aktab999

SubscriberMay be after introducing CPT217, it will improve because the paper I want replicate the property for the choroid:

Material property for choroid is below

Solid volume fraction: 0.55

Solid matrix:

Neo-Hookean

Elastic modulus= 0.06 MPa

Poisson’s ratio= 0

Permeability: 45037 mm2/MPa.s

They got 2-3mm^3 volume change, so to validate my model I have to get the same value or close to the paper's value. -

February 2, 2025 at 2:20 pm

peteroznewman

SubscriberI built the 1/8 spherical ball model of your Neo-Hookean material. Reread my previous reply where I put in the details.

-

February 9, 2025 at 5:52 pm

adib.aktab999

Subscriber"Your hollow sphere geometry is corrupt. I fixed it in this repaired version which shows how to select the InteriorNodes. Your corrupt solid had no interior face."

I can select interior nodes by using your node selction method in my model that I lastly shared. Isn't these are the normal nodes?

is interior nodes are different than normal nodes?

The model you have shared also not running in my 2025R1 -

February 10, 2025 at 7:22 pm

adib.aktab999

SubscriberHello peter, I have tried with your model with imprinted face but no progress,

https://drive.google.com/file/d/13lBcVeNdG1kwlxgAYbdgsC2NRqJQ1ROf/view?usp=drive_link

this is the model I have tried recently can you please look into it??

-

February 10, 2025 at 8:10 pm

peteroznewman

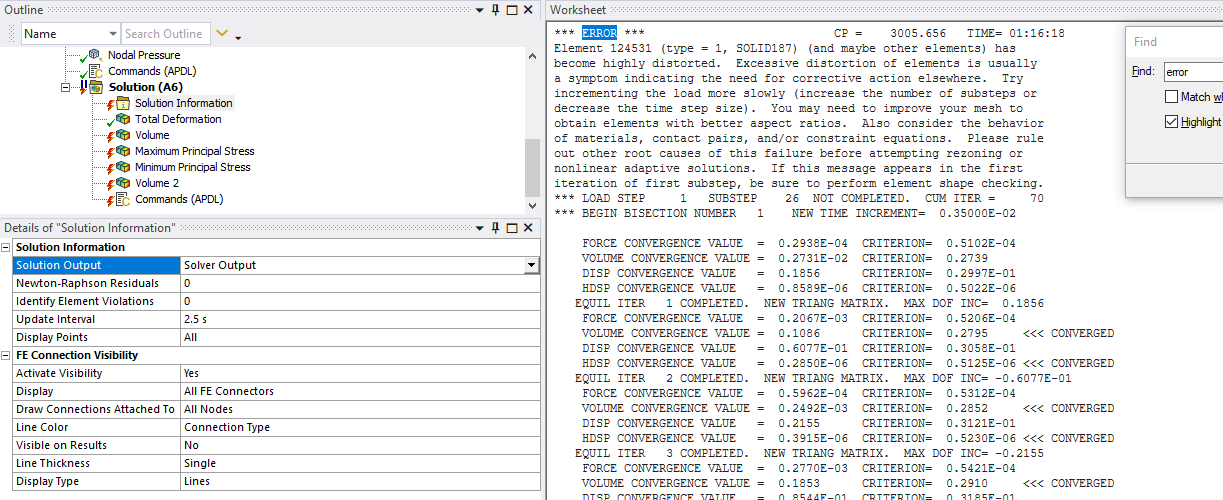

SubscriberI opened your model linked above and under the Solution Information folder, began reading the Solver Output. You must get in the habit of reading this file. At the top of the file, you can type Ctrl-F and a search bar opens, type Error and advance to the first error in the listing which is this:

*** WARNING *** CP = 4.562 TIME= 00:40:48

There are 4 HSFLD241 or HSFLD242 elements with pressure node 34840 that have negative volume. This can occur either when the element nodes

are numbered in clockwise manner or when the element face shared with the underlying solid or shell element is not facing the pressure node.

Check the element definition to make sure that the nodes are numbered in counterclockwise direction; otherwise, if the element face is not

facing the pressure node, no action is needed. The elements are saved in internal component _HSFLD348400.

*** ERROR *** CP = 4.859 TIME= 00:40:48

Element 17148 has negative Jacobian values at 3 integration points and the ratio of the part represented by the integration points to the

element volume reaches 1.27503432. Please modify the mesh before solving again.

*** ERROR *** CP = 4.859 TIME= 00:40:48

Element 17148 (SOLID186) is turning inside out.You have to fix this error for the solver to continue.

You will also find information such as this:

*** WARNING *** CP = 2.469 TIME= 00:40:47

The sparse solver must be used if any current technology elements with u-P formulation or MPC184 elements using Lagrangian multiplier are

included in the model. The equation solver option has been switched to the sparse solver.You requested the Iterative solver, but that doesn't work on your model, you must use Direct and the program has automatically switched your solver selection.

-

February 11, 2025 at 9:33 am

adib.aktab999

SubscriberThere aren't enough resource to solve this issue of my model that I provided by drive. I have applied nodal pressure 1 at +x direction(choroid's outer surface) and nodal pressure 2 at -x direction(choroid's inner surface).I have tried inreasing stiffness but nothing happened, same errors. May be imprinted face solve the issue for my model.

Btw I have tried to run your model also by changing imprinted faces' mesh size, no progress till now. -

February 12, 2025 at 4:01 pm

adib.aktab999

SubscriberWhen I am using your model it shows error, I am thinling using pressure on element face rather than using nodal pressure because it’s not converging at all.

When I am applying nodal pressure at your model where you imprint face that’s also gives error. The HSFLD242 file gives following error when I am using pressure at element face, the errors are below:***** MAPDL SOLVE COMMAND *****

*** WARNING *** CP = 0.609 TIME= 21:55:45

Element shape checking is currently inactive. Issue SHPP,ON or

SHPP,WARN to reactivate, if desired.

*** ERROR *** CP = 0.609 TIME= 21:55:45

Element 1234 has an undefined node number 0.

*** ERROR *** CP = 0.609 TIME= 21:55:45

Element 1235 has an undefined node number 0.

*** ERROR *** CP = 0.609 TIME= 21:55:45

The model data was checked and there were errors found.

Please check output or errors file (

F:\Thesis\_ProjectScratch\ScrDA77\file0.err ) for messages.

NUMBER OF WARNING MESSAGES ENCOUNTERED= 1

NUMBER OF ERROR MESSAGES ENCOUNTERED= 3 -

February 12, 2025 at 8:08 pm

peteroznewman

SubscriberUse File Archive and put the HSFLD .wbpz file on your drive and link below, I will take a look.

-

February 13, 2025 at 8:22 pm

adib.aktab999

SubscriberHello Peter, many many thanks for your continuous help.

Can you help me to provide some resource, how to imprint face on the object? I have ran the simulation with imprinted face and it is working without error.

Another question, I have to applied nodal pressure on the both surface. When I am imprinting face on both side of choroid and applied pressure on the both side. The side in which I applied HSFLD242, will make any problem?? -

February 18, 2025 at 4:43 pm

adib.aktab999

SubscriberHello Peter, can you help me to know how can I imprint face on the object.

-

February 18, 2025 at 7:17 pm

peteroznewman

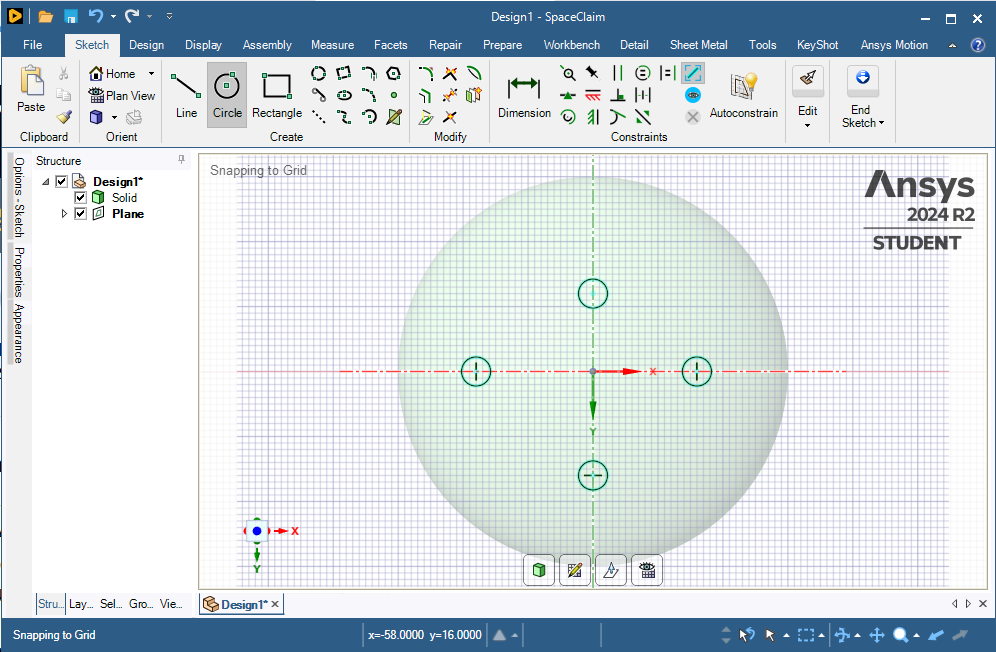

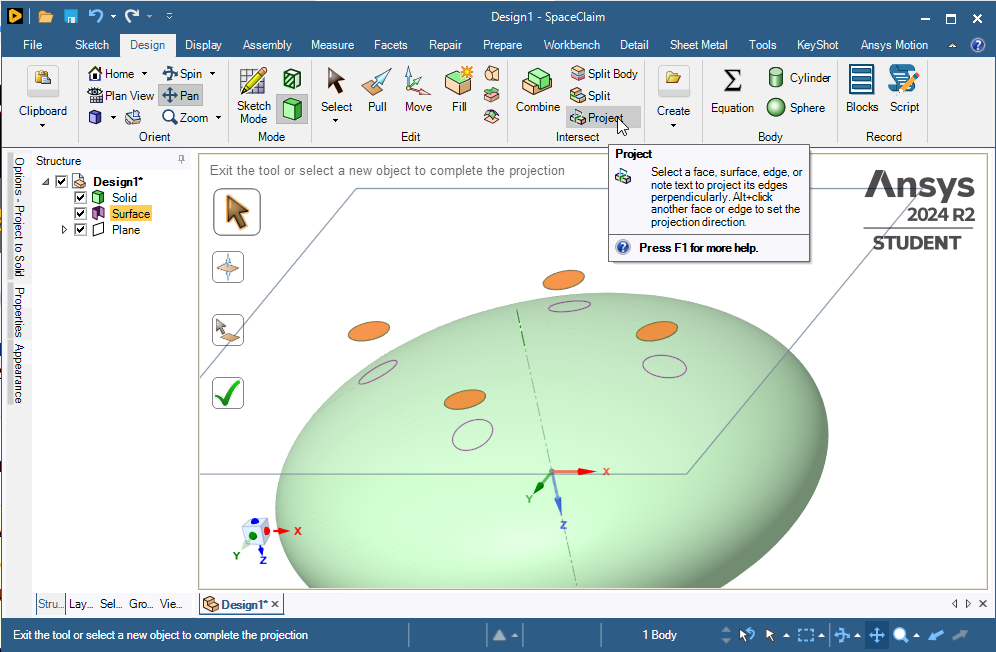

SubscriberIn SpaceClaim, create a plane using an axis. In the example below, I used the Z axis. Use the Move Tool to move the plane above the shape.

Select the Plane and start a Sketch, draw the shapes you want to imprint. I used circles.

Use the Project tool to imprint the circles onto the face of the solid.

If you want a more accurate shape, make the plane tangent to the surface so there is less distortion of the shape as it projects onto a curved face.

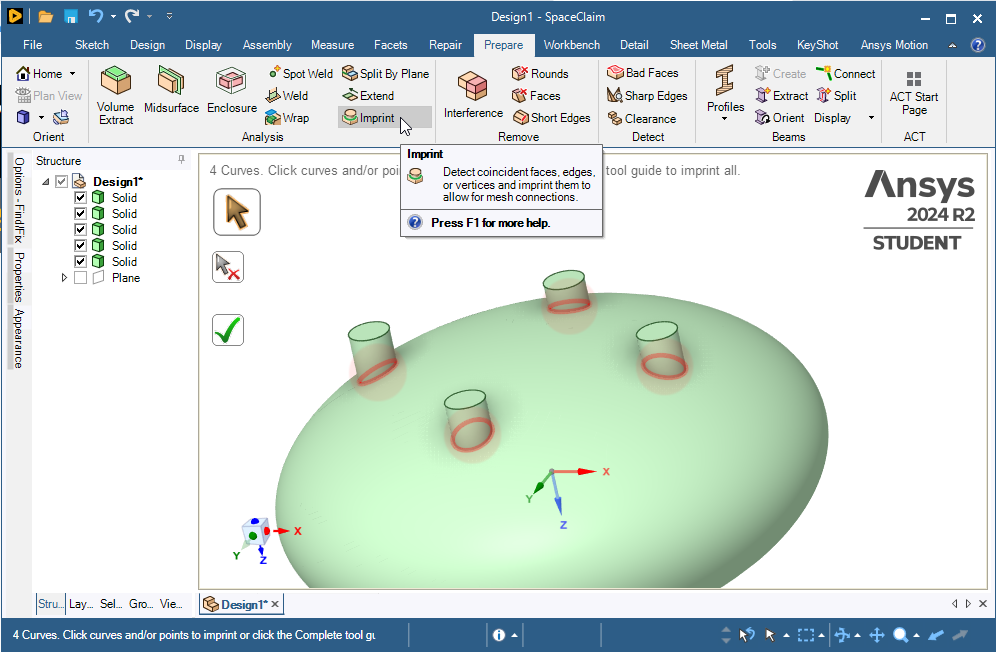

Another way is to pull the faces of the circles into solid bodies while the main solid is hidden to avoid merging into one new solid. Then on the Prepare tab use the Imprint button.

-

February 19, 2025 at 9:44 pm

adib.aktab999

SubscriberHello Peter, can you please look into my file?? I have imprinted face and applied load but it’s not converging. On the below model, I applied normal pressure on imprinted face but this isn’t converging. Please take a look on this first, I have run it on 2020R1.

https://drive.google.com/file/d/1e-bLDJUydJJAMF80ViRdr3Jhpcklk-uM/view?usp=sharing

-

February 21, 2025 at 12:28 am

peteroznewman

SubscriberI downloaded the 8 GB file but I have not had a chance to look at it yet because I have been travelling today and tomorrow.

-

February 22, 2025 at 9:09 pm

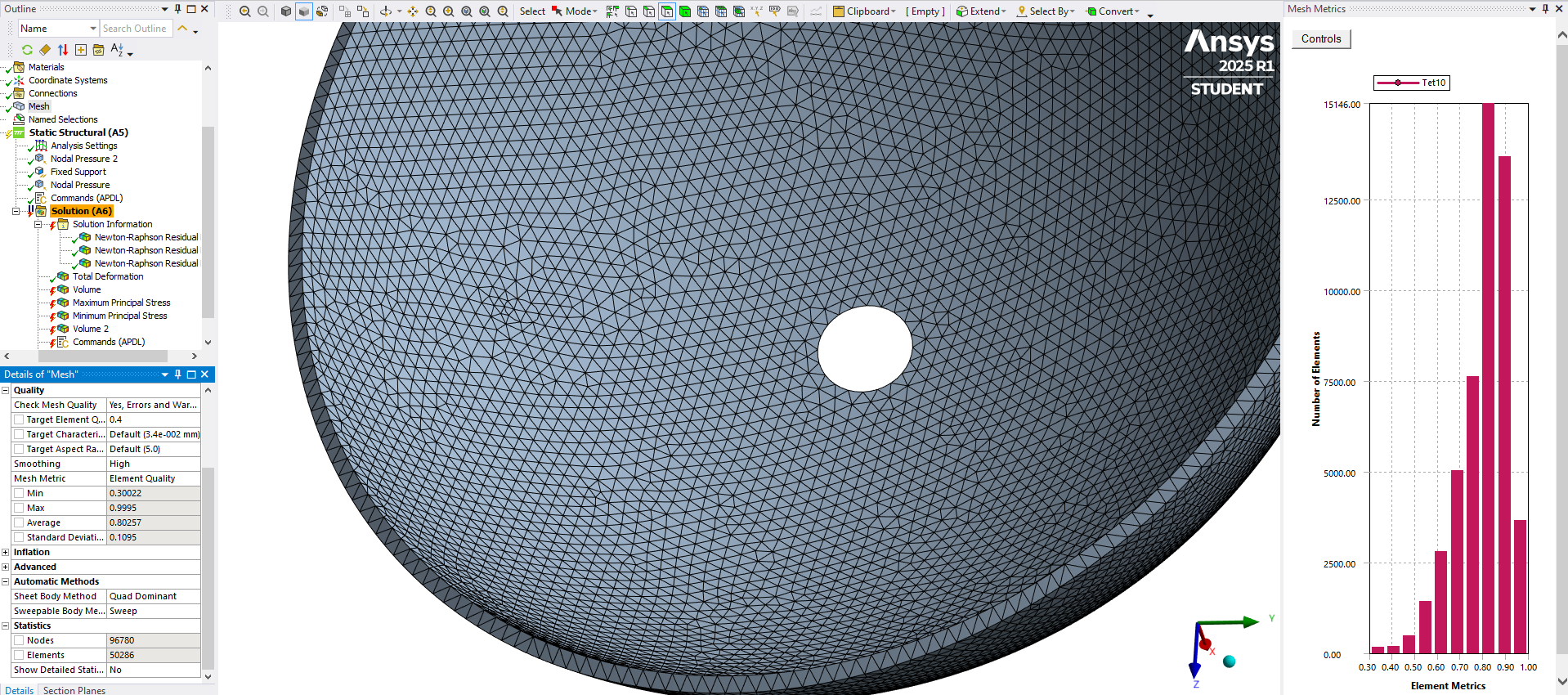

peteroznewman

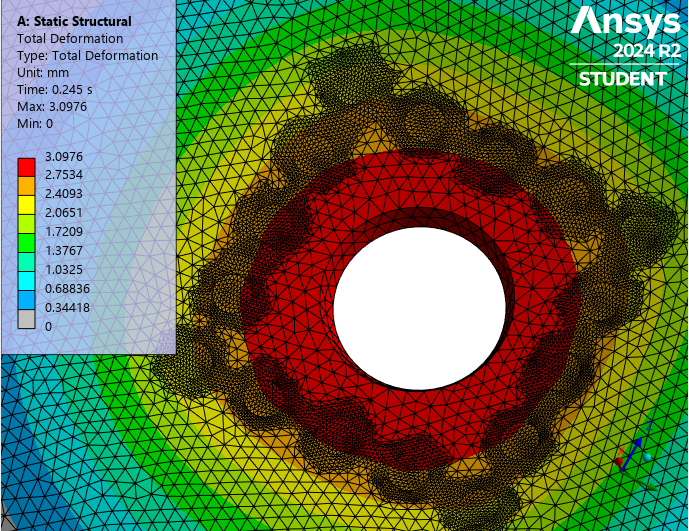

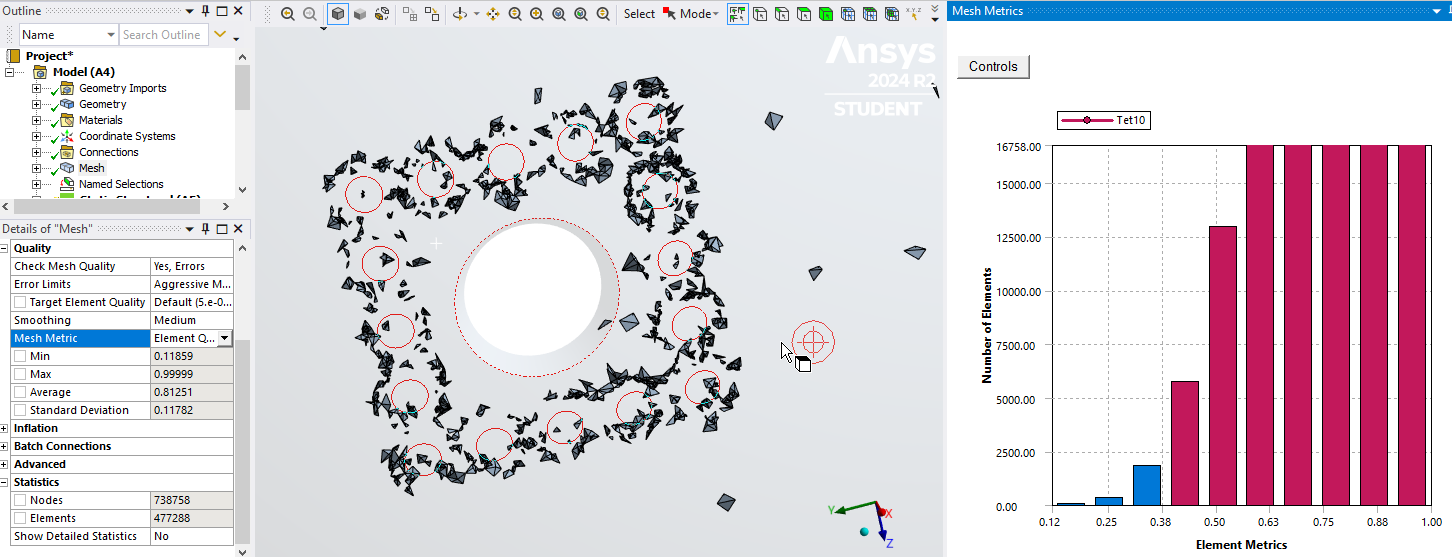

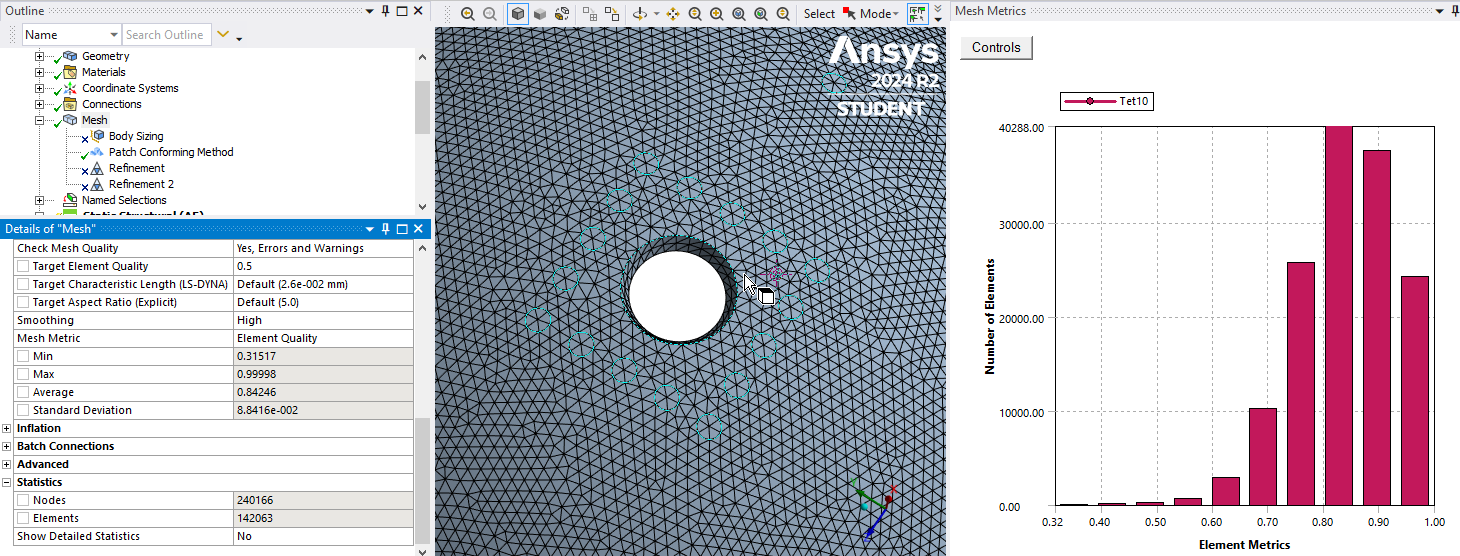

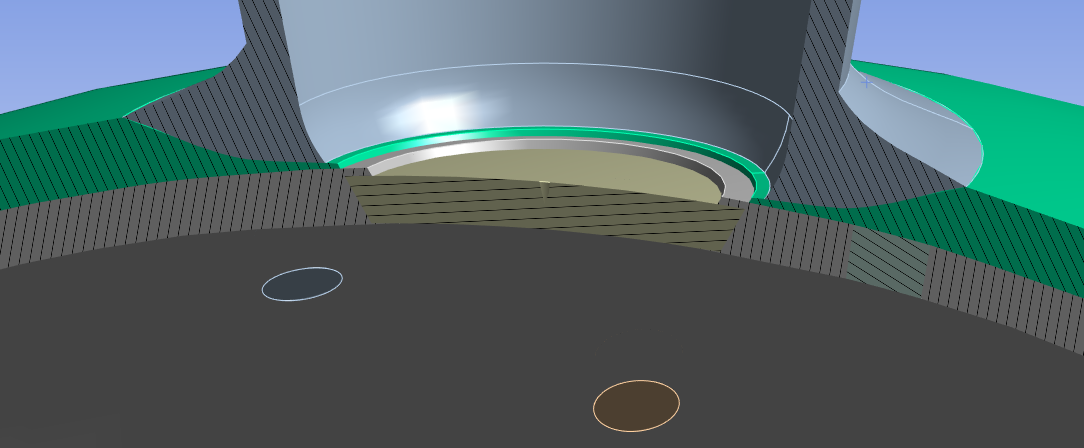

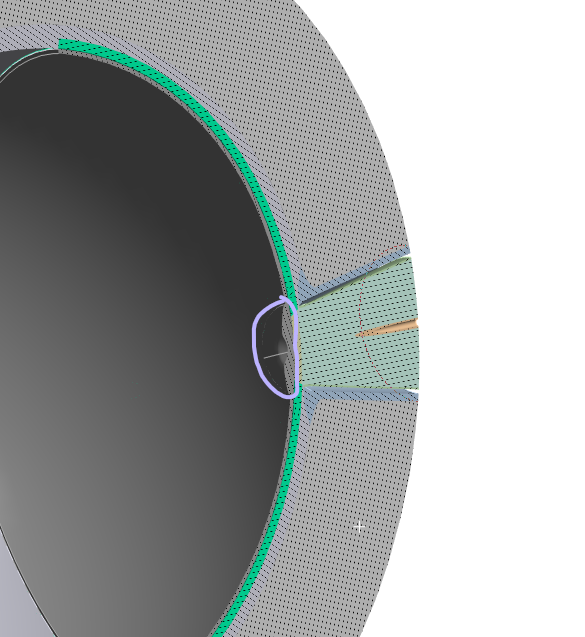

SubscriberI opened the file above and see a finer mesh around the imprinted faces where you are applying load.

Unfortunately, the mesh quality is poor with the worst element having a 0.12 element quality.

By changing the mesh parameters, I can get the mininimum element quality up to 0.32 which might help with the distorted element error and there are only 1/3 of the nodes in my better quality mesh so it will solve 3 times faster.

I see that the model converged up to t=0.255 s

I previously showed you how to look for the error in the Solver Output under the Solution Information folder, did you look at that?

I also told you to put a non-zero number into the Newton-Raphson Residuals and Identify Element Violations. You left them at zero, which means I have to do some work to look at where the deformed element is in the mesh. However, I see you have done that in the next post below so I won't bother to look at this element in this model and will instead download a later model.

-

-

-

February 20, 2025 at 9:10 am

adib.aktab999

SubscriberHello Peter, I have applied pressure due to long duration, I have extended from 3sec to 5sec in the imprinted face but the model isn’t converging.

I also applied extended pressure on element face. But

”warning: Mesh has elements with negative jacobian values. It might be due to the axis specified for a General Axisymmetric object under Symmetry folder is cutting through the body. Please check the results carefully.”

”Error: Element 1650 located in Body “SYS\Cut-Revolve1” (and maybe other elements) has become highly distorted. You may select the offending object and/or geometry via RMB on this warning in the Messages window. Excessive distortion of elements is usually a symptom indicating the need for corrective action elsewhere. Try incrementing the load more slowly (increase the number of substeps or decrease the time step size). You may need to improve your mesh to obtain elements with better aspect ratios. Also consider the behavior of materials, contact pairs, and/or constraint equations. If this message appears in the first iteration of first substep, be sure to perform element shape checking. Named Selections for the offending element can be created via the Identify Element Violations property on the Solution Information Object.”

these has popped out.

Below the drive link, I have tried element face pressure and extended duration. I have run this on 2025R1.

https://drive.google.com/file/d/1ZzhAkvBq5qAn09-SQJflOXERAnlJ3aXh/view?usp=sharing

How to solve this problem??

Just anyway it needs to converge by applying force on the imprinted face or element face.

I ran a simulation with imprinted face and extended time with some changes which is on the run, I will let you know what happens.-

February 22, 2025 at 10:56 pm

peteroznewman

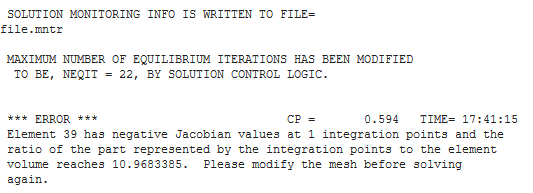

SubscriberThis model is a non-starter. It generates an error before it even tries to converge.

A negative Jacobian is forbidden which is why you have to remesh before solving again.

You are having better results with the imprinted faces where you get convergence for a number of substeps. Keep doing that, stop doing these Nodal Selections, they are not helping.

-

-

February 20, 2025 at 1:47 pm

adib.aktab999

SubscriberI ran a simulation with imprinted face and extended time in 2020R1.

https://buetedu-my.sharepoint.com/:u:/g/personal/1918024_bme_buet_ac_bd/Eb4kU-205FdLofPQgAYgd-UBzDvW3BpPLKBe3GD3KRt5gw?e=YuGvao-

February 22, 2025 at 10:37 pm

peteroznewman

SubscriberI would repeat the comments I made above on Feb 22 at 9:09 PM except you have a different element ID for the error. Why aren't you entering non-zero values here??? I wish I could see the N-R Residual plots, that would tell you where the solver is having problems converging. I can't solve this model as it is too large for the Student license.

This element has a high element quality > 0.75 which means that further improvements in element shape may not help. I recommend you add a Keyopt(6)=1 to the elements on the choroid body, which may help. You do that by putting the following APDL code under the SYS/Cut-Revolve1 body.

keyop,matid,6,1

Good Luck!

-

February 23, 2025 at 4:23 pm

peteroznewman

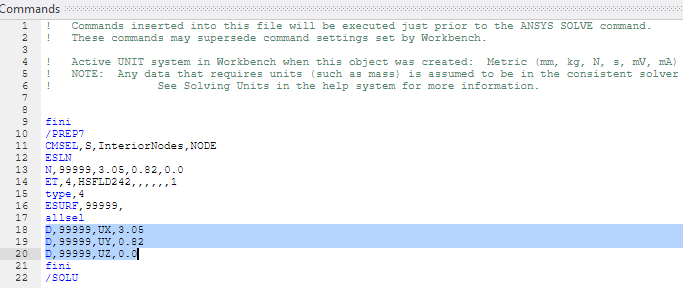

SubscriberLook at the Total Deformation plot and you will find there is a problem with node 556976 which is listed at the bottom of the screen. This is the node you used in the Command object for the HSFLD242 elements.

fini

/PREP7

CMSEL,S,InteriorNodes,NODE

ESLN

N,556976,0,0,0

ET,4,HSFLD242,,,,,,1

type,4

ESURF,556976,

allsel

D,556976,UX,0

D,556976,UY,0

D,556976,UZ,0

fini

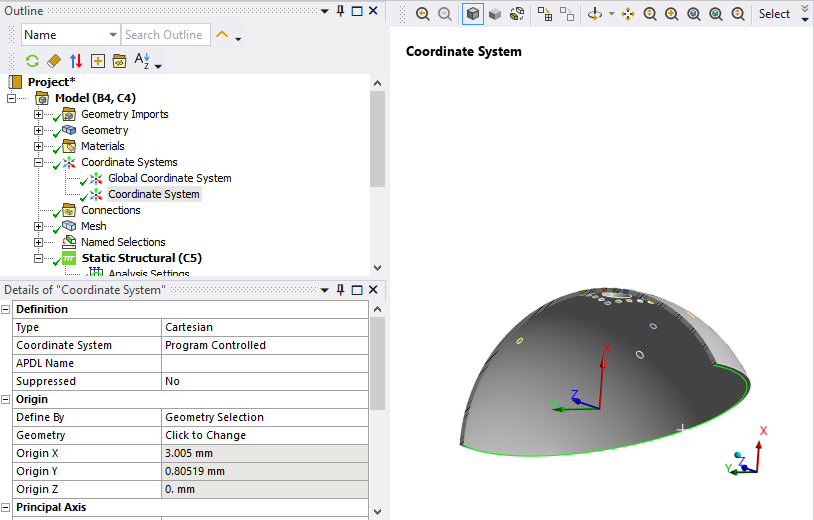

/SOLUYou should move that node to be at the coordinates of the center of the fixed surface (3.05,0.82,0.0) and you should use a node number outside the range of nodes in the mesh such as 9999999.

-

February 23, 2025 at 10:36 pm

peteroznewman

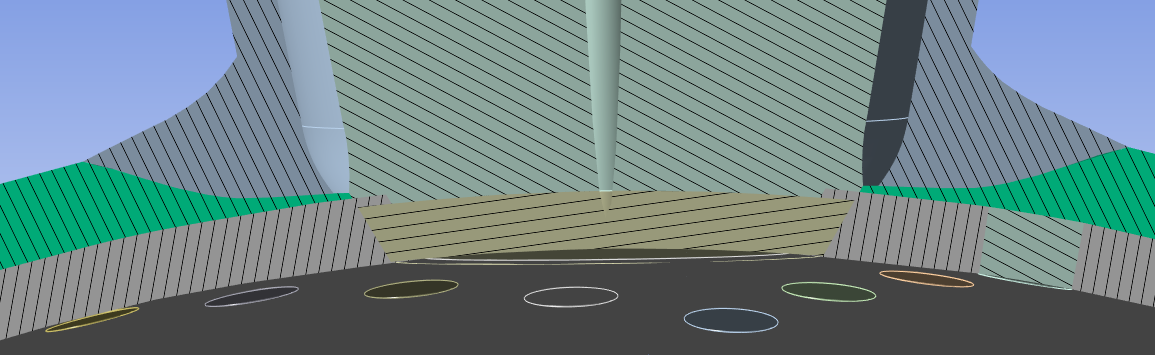

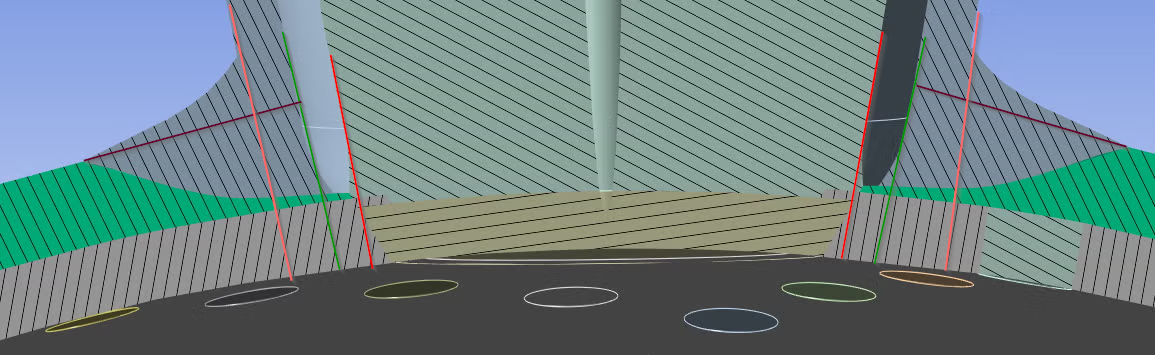

SubscriberI remeshed with a coarse mesh to keep under the Student limit of 128,000 nodes and have fairly good element quality > 0.30 and the node count is only up to 98,000 so I have some room to refine the mesh.

I fixed the defects you had in the coordinates and numbering of the fluid node. This time the solution did not have any highly distorted element error and it solved further than your model with the defects. I turned on the N-R Residual plot and now I see where the mesh is having difficulty converging.

Here I put a Sizing Sphere of Influence mesh control to cut the element size in half around the problem area while keeping the node count below 128,000.

Below you can see where on the mesh the next problem area is for convergence.

-

February 24, 2025 at 9:03 pm

adib.aktab999

SubscriberHello Peter, Thanks for your help.

I need to incorporate it in my main model soon. How can I solve this meshing problem??

I have ran the simulation with changed co-ordinate system, I will try to find the mesh errors from newton residuals. Can you suggest me a way to fix this and incorporate it in the main model? -

February 24, 2025 at 11:17 pm

adib.aktab999

SubscriberSame errors arises after changing mesh and co-ordinate number

-

-

-

February 25, 2025 at 12:20 am

peteroznewman

SubscriberI have shown you two iterations through the process, now you must iterate multiple times through the process. You might succeed with tet elements, you might need to mesh with hex elements that sweep through the thickness. You might benefit from using Inflation layers around the pressure edges. You might benefit from using linear element order instead of quadratic element order.

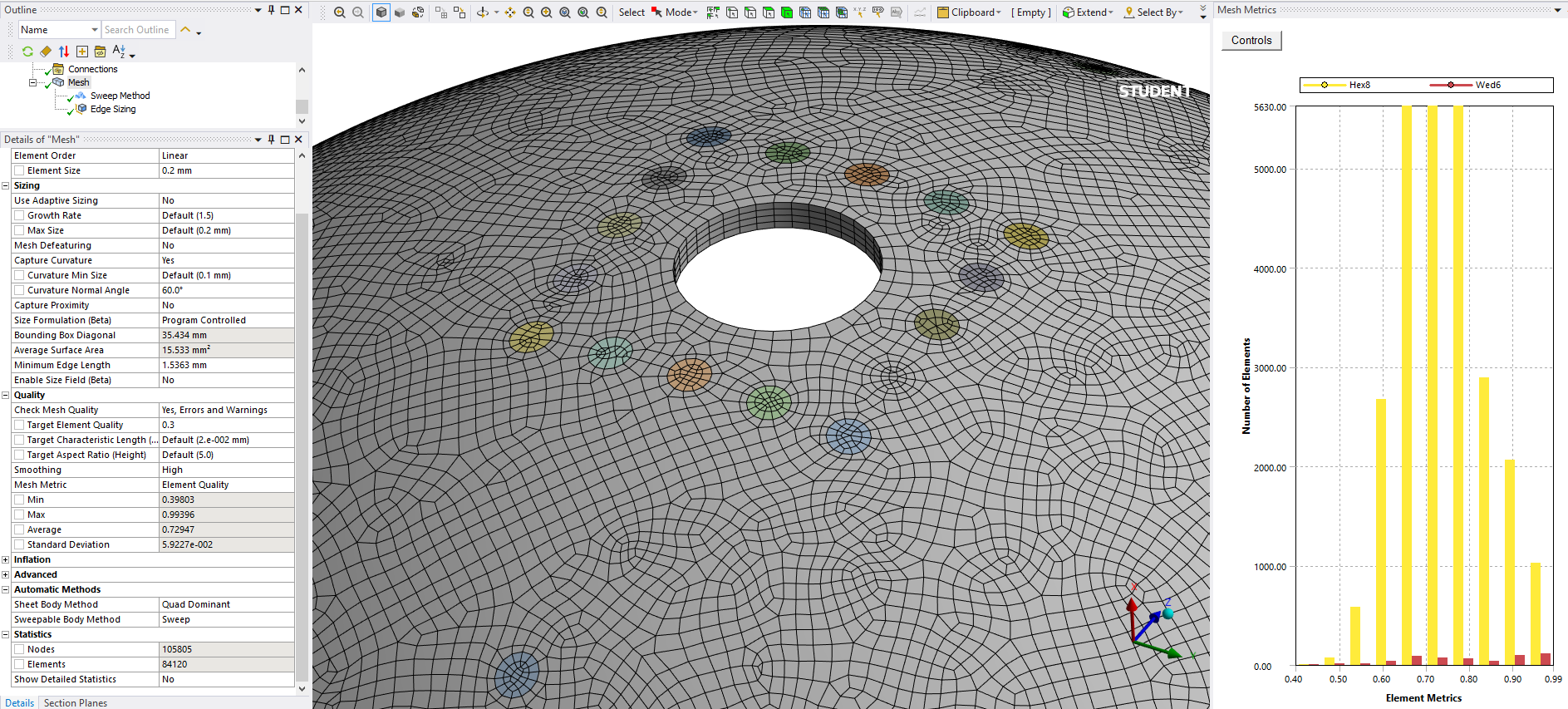

Here is a 99% hex mesh with 4 linear elements through the thickness and a minimum element quality of 0.4 that might work well. I did that in Ansys 2025 R1 and here is the link to the archive.

If you have difficulty getting a simple model to converge, it is unlikely that a more complicated model will converge more easily. Building the main model will be a long and difficult task. It may take months or even years to develop all the skills needed to get an acceptable solution with the main model.

Good luck!

-

March 2, 2025 at 10:37 pm

adib.aktab999

SubscriberHello, peter I am facing problem regarding geometry imprinting. I have successfully imprint face but when I have it made object into surface. How can I solve this issue?

https://drive.google.com/file/d/1qx108vpDPLMKMJvEm5G7dnumslXqRT3K/view?usp=drive_link

-

March 3, 2025 at 12:34 am

peteroznewman

SubscriberDid you look at my version done in Ansys 2025 R1? Here is the link to the archive.

You have to start with the solid model. I can’t use the file you uploaded because you have lost the solid Choroid. When you get a surface for one of the imprinted faces, you have to use the Pull tool, Up To the inner surface to make a solid cylinder. Then you have to use the Combine tool to subtract that solid from the Choroid solid to make a hole through the wall thickness and have a plug to fill that hole. Then you use the Share button to have the mesh keep the bodies connected.

Here is a video to help you out. https://youtu.be/0eCHjQlNbnU

-

March 3, 2025 at 11:09 am

adib.aktab999

SubscriberI have applied nodal pressure on your model with better mesh but it also not converged and the following error has popped out:

*** ERROR *** CP = 4.828 TIME= 00:06:46

Element type 4 is not the same shape as HSFLD242. Switching to a

different shape is not allowed while elements of type 4 exist. -

March 3, 2025 at 12:55 pm

peteroznewman

SubscriberDid the hex mesh converge to a higher pressure than the tet mesh?

-

March 3, 2025 at 12:58 pm

adib.aktab999

SubscriberNo, Peter. The error has popped out at the initial. Simulation didn’t start.

But I have tried face meshing and refinement and some experimental mesh setup to improve quality on a imprinted faced model. I have applied tet mesh and I saw that model converge till 1.065s where other were terminated at 0.265s-

March 3, 2025 at 6:02 pm

peteroznewman

SubscriberYou should fix that error.

-

March 3, 2025 at 6:22 pm

adib.aktab999

SubscriberThe error has popped out, when I use your hex meshed model!

Can you give me little hint on it??

-

-

-

March 3, 2025 at 11:29 pm

peteroznewman

SubscriberI don't know how to fix that error without looking at your model in detail. Please send a link.

-

March 4, 2025 at 12:18 am

adib.aktab999

Subscriberhttps://drive.google.com/file/d/1DQK0xrvnSeHRIYmikhnvOP48JxWdsPN4/view?usp=drive_link

This is the model I have tried using your meshing,

https://drive.google.com/file/d/1fzlySdZvv01K897z-kXqy9xJm4g-C9P_/view?usp=drive_link

Here I implement using finer meshing on imprinted faces. -

March 4, 2025 at 12:52 am

peteroznewman

SubscriberYou have to learn some troubleshooting strategies. I opened the model with the hex mesh and got the error that you got. Then I suppressed the Command Objects that caused the error and tried to solve. I found that you forgot to add a Fixed Support. After I added that, I solved and looked at the solver output. Guess what, element type 4 has already been used, that is why you can't use it again for the fluid elements.

The next available element ID is 24. Try using that instead and you will get this after you unsuppress the Command Objects and solve.

-

March 4, 2025 at 3:11 pm

adib.aktab999

SubscriberI have applied element type 24 on your model and it shows error. It is telling to make the mesh better that is may be arising from using (0,0,0) co ordinate system. And the solution isn't converging for non linear solution.

Anyway to imprint hex on the model the space claim technique isn’t working for all the faces.

-

-

March 4, 2025 at 3:28 pm

peteroznewman

SubscriberIt would be better if you show the exact text of the error. What do you mean by using (0,0,0) coordinate system?

What do you mean the SpaceClaim technique isn't working for all the faces?

-

March 4, 2025 at 5:29 pm

adib.aktab999

Subscriberhttps://drive.google.com/file/d/1yo0Iv3nFE03bUuKVMgJ9SlyFwux6KJ1u/view?usp=drive_link

Here is the model, you can look into it.

-

March 4, 2025 at 5:42 pm

peteroznewman

SubscriberWhy did you go back to the old 0,0,0 coordinates for the Node for the HSFLD242 elements when I provided better values in a previous model?

-

March 4, 2025 at 5:52 pm

adib.aktab999

SubscriberIf you see the Force convergence curve you can see the threshold is lower and any of the substep is converging in your model. I will try this with (3.05,0.82,0.0) and let you know what has happened. with using the co ordinate system still the convergence is far away from threshold convergence value. After changing the co ordinate system it shows:

But if you see my model which I posted on “March 4, 2025 at 12:18 am” with drive link, that simulation is converging till 1.4 sec almost and the error:

”The solver engine was unable to converge on a solution for the nonlinear problem as constrained. Please see the Troubleshooting section of the Help System for more information.” I have seen the raphson residual

popped out and terminate.

Actually using your technique in space claim after I select pull option and select the surface and then I select the another surface then hits the enter but it isn’t creating holes. Below is the model where I have tried:https://drive.google.com/file/d/1Lfaw90Da0Xx1DCx33OM7DRjEUw_leUNQ/view?usp=drive_link

-

March 5, 2025 at 1:29 am

peteroznewman

SubscriberHere again is the video to help you out. https://youtu.be/0eCHjQlNbnU. Study it closely.

You make solid plugs from the surfaces using Pull (No Merge), then you use the Combine tool to subtract the solid plugs from the main solid to make a hole, which includes deleting the interference solid that was created during the Combine operation. One refinement is to use the Options for the Combine tool and uncheck Keep cutter, then you don't have to delete the interference solid.

Looking at your Surface imprinting file, you are missing one surface.

-

March 5, 2025 at 10:46 pm

-

March 5, 2025 at 10:48 pm

adib.aktab999

SubscriberCan you help me to understand how can you use co-ordinate value in the code?

-

March 5, 2025 at 11:00 pm

peteroznewman

Subscriber-

March 6, 2025 at 12:34 am

adib.aktab999

SubscriberCan you please look into the model, I do not understand how to converge this model. I am literally frustrated.

https://drive.google.com/file/d/1Q0ZAYA-YKbMTmjt5uxwzGQTmKq_VZgBf/view?usp=drive_link

-

-

March 6, 2025 at 1:46 am

peteroznewman

Subscriber-

March 6, 2025 at 2:19 am

adib.aktab999

SubscriberHello Peter, lot of thanks for your continuous help. I have used the share option and try to mesh it as you have shown but still it isn't converging some weird errors popped up. Can you look into it:

https://drive.google.com/file/d/1_T4y5jC42tXOctd7KTnfbNEQ0l-DheVX/view?usp=drive_link -

March 6, 2025 at 11:39 am

adib.aktab999

SubscriberI have observed that the poor mesh has seen on the faces where the imprinted face is distorted. is this the reason of the error:

"Some of the elements on the problematic bodies can't meet the specified target metrics. Please check the elements and try changing the mesh size settings to achieve the needed mesh quality."

Do you think that for this reason my model isn't converging??

When I ran the simulation these error has popped out at the initial and solution is terminated:

"*** ERROR *** CP = 27.609 TIME= 17:28:39

An unexpected error has occurred on MPI rank 0 in the MPI software used

by Distributed ANSYS. Distributed ANSYS is unable to recover and will

terminate. Please send the data leading to this operation to your

technical support provider, as this will allow ANSYS, Inc to improve

the program."

"*** FATAL *** CP = 27.609 TIME= 17:28:39

MPI error code = 741412367 which translates to:

Unknown error class, error stack:

internal_Allreduce(1398)...................:

MPI_Allreduce(sendbuf=00000230A92CB710, recvbuf=00000230A8E55270,

count=292426, MPI_DOUBLE, MPI_SUM, MPI_COMM_WORLD) failed

MPIR_Allreduce(336)........................:

MPIDI_Allreduce_intra_composition_beta(793):

MPIDI_NM_mpi_allreduce(147)................:

MPIR_Allreduce_intra_auto(58)..............:

MPIR_Allreduce_intra_recursive_doubling(48): Unable to allocate"-

March 6, 2025 at 2:25 pm

peter.newman

SubscriberI got a similar error. You can improve the mesh quality and I think you will still get this error.

FORCE CONVERGENCE VALUE = 0.5361E-05 CRITERION= 0.5000E-04

Writing NEWTON-RAPHSON residual forces to file: file.nr001

ERROR: Worker process(es) with rank(s) 3 have encountered a FATAL error.

The information below was gathered from the file*.out output file(s).

Please review the worker process output file(s) listed below for more

details on this error.

Worker Process Output File .\file3.out:

*** FATAL *** CP = 1.734 TIME= 22:29:28

MPI error code = 135443726 which translates to:

Unknown error class, error stack:

PMPI_Waitany(287): MPI_Waitany(count=4, req_array=000000625FDF5700,

index=000000625FDF5C98, status=000000625FDF5B00) failed

PMPI_Waitany(270):

(unknown)(): Unknown error class.Notice however that the FORCE CONVERGENCE value is now a small number 0.536E-5 instead of that huge number the first time you ran this.

Under the Solve Settings, on the Home tab, if I uncheck Distributed and request 1 core, I get a different error.

*** ERROR *** CP = 0.828 TIME= 09:26:05

An unexpected error ( SIG$SEGV ) has occurred… MAPDL internal data

has been corrupted. MAPDL is unable to recover and will terminate.

Previously saved files are unaffected. Please send the data leading

to this operation to your technical support provider, as this will

allow ANSYS, Inc to improve the program.I suggest you open a new discussion to get help on this error.

-

-

-

March 6, 2025 at 9:10 am

adib.aktab999

SubscriberHello Peter. Have you looked into my model, I just need to figure it out, soon??

-

March 6, 2025 at 2:56 pm

adib.aktab999

SubscriberWhy this error is coming?? Due to interaction of complex elements??

what do you suggest to solve this error?? I haven't enough time to fix, can you suggest any other method. I need your help badly.

-

-

March 6, 2025 at 4:19 pm

peter.newman

SubscriberI don’t know why this error is being generated. I am not an Ansys Employee. I participate on this forum because I find some of the discussions interesting. I reply to the ones where my knowledge may be helpful and in the process, I may learn something new. That has been true of your discussion.

There is something seriously broken in this archive. When things are not going well on a complex model, retreat to a simpler model and get that working first. If you want to persue the hex meshed version of your model, go back to my model I built that used 3 planes of symmetry on a hollow sphere with a single imprinted face.

You have another model that converged past step 1 so you can make progress by building a better mesh on that. I can help with that. Is that version saved in an older version of Ansys?

-

March 7, 2025 at 10:18 am

adib.aktab999

SubscriberHello peter, I have improved mesh and after 1.278 it terminates. can you look into the model, is there anything to do?

https://drive.google.com/file/d/15WTuDmm1-3m9baNzV71hyOKGM4r_jEg2/view?usp=drive_link

-

-

March 7, 2025 at 7:19 pm

adib.aktab999

SubscriberHello peter, my workstation has 2023R1, the problem creating plug on the geometry. I have attached 2 files, can you look into these. If this can possible I can run the simulation on my workstation.https://drive.google.com/drive/folders/1kz6xzUFFog8qJucy0nNCk6JmW7xRwdgD?usp=sharing

-

March 7, 2025 at 7:33 pm

peter.newman

SubscriberI found two mistakes in the file in the 10:18 AM reply. The trival mistake is you have two Fixed Support on the same face. This doesn’t matter, it has no effect on the solution.

The other mistake is you applied a non-zero displacement to Node 99999. Why did you do that? You are supposed to hold that fixed where it is. You should look up the D command in the Mechanical APDL Command Reference.

Here is what you have:

The D command instructs the solver to move that node by those values. That is not what you want. All three values should be 0.0. I don’t know what effect that has on the solution. Maybe it causes the internal fluid to develop a pressure? You would have to do some research. In any case, I think the correct value is 0.0 for the displacement of Node 99999.

Note, that if your mesh has more than 99998 nodes, you will need to renumber this node. Change the node to 999999 and make sure that your mesh has fewer than 1 million nodes so you won’t get a collision.

-

March 8, 2025 at 9:13 am

adib.aktab999

SubscriberCan you suggest anything regarding this?

-

-

March 7, 2025 at 11:03 pm

adib.aktab999

Subscriberhttps://youtu.be/OZbKnxKTd_0?si=Nv-GFFto7taZfjuS

No luck in converging. SHould I apply pressure using remote point??

Or should I work on material property?

what do you suggest? Should I decrease the force amount ??

should I change element property?? -

March 8, 2025 at 2:35 pm

peteroznewman

SubscriberYour model is converging up to the pressure when it stops converging. On the imprinted version (not shared plugs), after I changed the D commands to 0.0, it converged up to 1 second when Nodal Pressure 2 was 6.74e-4 MPa and Nodal Pressure was 3.888e-3 MPa. If you make step 1 end below those pressures, and don’t exceed those limits in steps 2, 3, 4, that is one way to go.

If you replaced pressure with Remote Points, you would have to convert pressure to force or displacement.

What physically do those pressures represent? If they represent contact with a structure, then pressure is an inaccurate representation because the stiffness of the structure making contact is not in the model. It would be more accurate to add that structure to the model.

If you changed the material model or its parameters, that could make convergence easier, but then you wouldn’t be simulating the material you should be using. Where did you get these material properties?

There are solvers that do not have any convergence requirement: Explicit Dynamics which includes LS-DYNA. The model changes from being a Static Structural model to a dynamics model. The solver works by taking extremely tiny time steps which are calculated from the time it takes a compression wave travelling at the speed of sound in the material to cross the smallest element. You would exchange all the problems of achieving static equilibrium at each substep with the problems of an Explicit Dynamics solution. The main problem is the computation could start taking tens or hundreds of hours to compute.

Changing to an explicit dynamics solver would be like starting over. You can’t use APDL commands anymore because you are no longer using the MAPDL solver. You need to mesh the fluid. You can't afford the computation time to apply the pressure over 5 seconds. If you apply the pressure over 0.5 seconds, it will only take 1/10 of the time to solve. If you apply the pressure over 0.05 seconds, it will only take 1/100 of the time to solve, but the faster you ramp up the pressure, the more inertia forces become a significant force in the simulation and the more the deformation deviates from the static equilibrium.

-

March 8, 2025 at 2:55 pm

adib.aktab999

SubscriberThese pressures represent artery pressure by nodal pressure and vein pressure by nodal pressure 2. Artery pressure represents the entry of the blood and vein pressure represents exit of the blood pressure. My choroid is biphasic which author simulate in FEBio but I am trying to implement it in Ansys because of the meshing issues. Artery entry and vortex output happen through choroid's wall. Therese is sclera and retina on the surface of choroid. I can share the full model with you. I have tried to change material property and increase stiffness and compressibility parameter too. I can share the whole with you. Do you want to look into my model??

-

March 8, 2025 at 2:58 pm

peteroznewman

SubscriberWhy don't you mesh in Ansys, and export the mesh to FEBio and solve it there?

-

March 8, 2025 at 3:01 pm

adib.aktab999

SubscriberFEBio isn't that much compatible to handle a complex geometry like ours, Ansys is more compatible. I have tried FEBio but it's not working.

-

March 8, 2025 at 3:14 pm

peteroznewman

SubscriberYes, you mesh the complex geometry in Ansys, export the mesh to a file, then import that mesh into FEBio.

-

March 8, 2025 at 7:59 pm

adib.aktab999

SubscriberYes I can do this. But I am implementing this using ansys.

-

-

-

March 8, 2025 at 3:08 pm

peteroznewman

SubscriberSo do those pressures cause a force to be created on the dome? If you were to model the artery as a tube that connected to the dome, the pressure on the artery walls would obviously stretch the artery and slightly increase the diameter, but the choroid is like a reservoir and the artery pressure causes the fluid to flow through the porous material from the artery to the vein. You haven't got results for the porous material in Ansys yet. Is that something you want to work on?

-

March 8, 2025 at 3:17 pm

adib.aktab999

SubscriberAre you suggesting to use porus material like CPT217 or using FSI. I haven't enough time for FSI. I have to show results on 17March. So I haven't enough time to use FSI. Do you think using porosity can help the model to converge?? What do you suggest??

Also I need to measure the volume change of choroid but after applying nodal pressure(nodal pressure for modeling cilliary artery)

-

March 8, 2025 at 3:27 pm

peteroznewman

SubscriberI suggest you draw a Free Body Diagram of the arteries, choroid and veins. Does the choroid porous material have a non-porous membrane that keeps the blood contained? In simple terms, say a tube is anchored to ground at the free end with an internal pressure P1 at that side, and it is attached to a sphere that causes a pressure drop of dP and there is tube on the opposite side to drain the fluid with a pressure P2 where dD = P1 - P2. How does the free body diagram look for that system?

-

March 8, 2025 at 3:34 pm

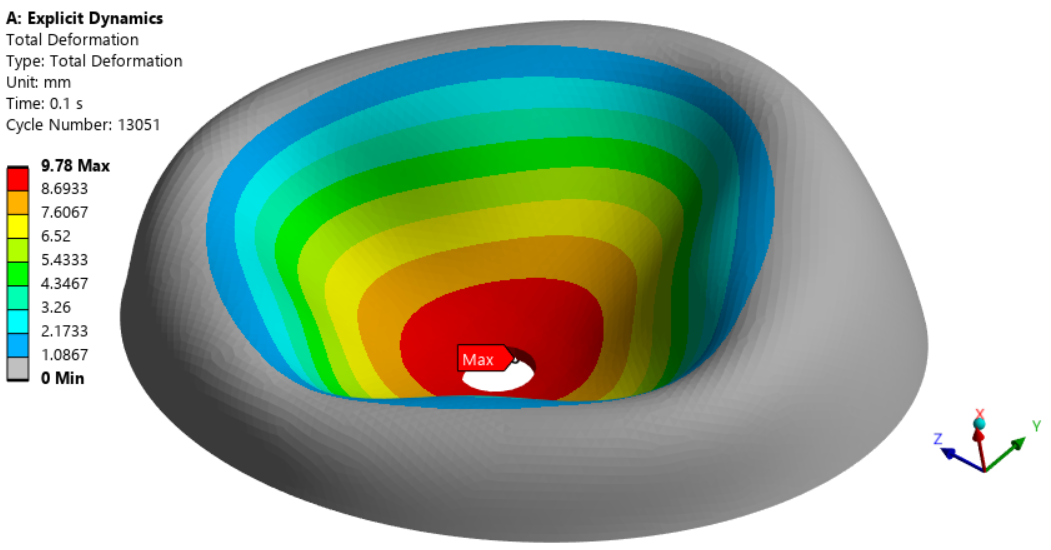

peteroznewman

SubscriberHere is what an Explicit Dynamics solution looks like. In 0.1 seconds, artery pressure ramps up to 1e-3 MPa and vein pressure ramps up to 2e-4 MPa. There is no internal fluid in this model to prevent collapse of the choroid. This solved in 12 minutes.

LS-DYNA probably has a good element to model the water to prevent this collapse.

-

March 8, 2025 at 3:40 pm

adib.aktab999

SubscriberAuthor mainly used nodal pressure to mimic the artery input and vein output. Due to the change of pressure the choroid’s volume change. Author mainly used sphere to simulate this problem. I can add artery and vein pipes to do fsi or pressure difference but if I change the geometry I haven’t enough time to do it. LS Dyna can be used to solve this issue?? If so how can I model water??

-

March 8, 2025 at 3:42 pm

adib.aktab999

SubscriberHere is the paper.

-

March 8, 2025 at 3:46 pm

adib.aktab999

Subscriberhttps://doi.org/10.1167/iovs.17-23454

-

March 8, 2025 at 5:17 pm

peteroznewman

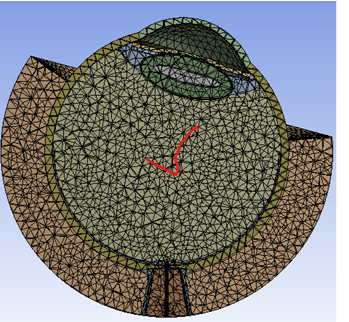

SubscriberFrom the paper, the authors built the mesh using one of the Ansys meshing programs: ICEM which is commonly used for CFD models and is good at creating a mostly hex mesh. I did that using Mechancial meshing with the SpaceClaim shared plugs.

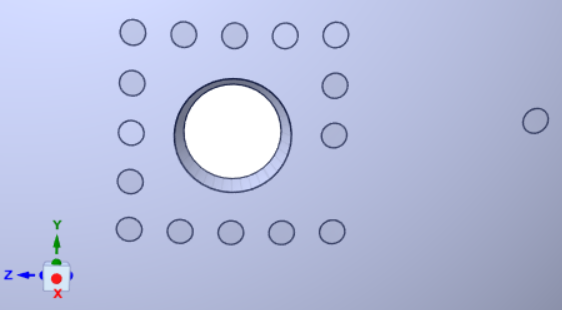

The reconstructed model was then discretized into a hexahedron-dominant mesh with 67,584 eight-node hexahedra and 3024 six-node pentahedra using ICEM CFD (ANSYS, Inc., Canonsburg, PA, USA; Fig. 1). The mesh density was numerically validated through a convergence test. No symmetry conditions were applied.

-

March 8, 2025 at 5:35 pm

peteroznewman

SubscriberFrom the paper, the inside of the eyeball has an IOP of 15 mmHg or a 0.002 MPa pressure. Shouldn’t that be applied to either 1) all the Interior Nodes or better still 2) the HSFLD242 node as a load in Step 1?

You can define the initial state of the hydrostatic fluid by defining initial pressure (input via the IC command with

Lab= HDSP) at the pressure node 999999

-

-

-

March 8, 2025 at 3:50 pm

peteroznewman

SubscriberANSYS Engineering Data Sources for Explicit Material includes three WATER models using Shock EOS (Equation of State) material models. You would mesh the inside of the sphere (using Share button first) and apply this material. You can solve either using LS-DYNA or Explicit Dyanamics.

I don’t know about using a Porous media in LS-DYNA or Explicit Dynamics. That would be something new to learn, but I just recently looked at Porus media in the Demo problem I found for you and wrote about in an old reply.

-

March 8, 2025 at 3:54 pm

adib.aktab999

SubscriberAs eye has a sophisticated structure, do you think that LSDyna will give good result on this?? The demo you have sighed was for CPT212. Should I add neo hookean model from engineering data and use APDL code about CPT217 on the the geometry module and give a run on static structural. Does that help??

Is it possible to do quasi static analysis on LS dyna??

Should I change to LSDyna?? -

March 8, 2025 at 5:01 pm

peteroznewman

SubscriberYou can do a Static analysis in LS-DYNA, but it will use the implicit solver that requires convergence.

You can do a Quasi-Static analysis in the explicit solver in LS-DYNA, which is what I was describing above. It is solving the dynamics equations over a long time scale so the inertia forces remain insignificant.

I think an important step is to understand how the pressure forces act in what the authors describe as a biphasic material with a solid phase (connective tissue) and a fluid phase (blood). This is what Ansys calls a Porus Media material. Have you built a simple Ansys model to observe the expansion of the PM volume as the pressure is ramped up? Are you able to do that in a simple model in FEBio?

-

March 8, 2025 at 5:58 pm

adib.aktab999

SubscriberAs far as I understood from FEBio, when choroid is assaigned as biphasic it's like choroid Think of the choroid as a **sponge** (bread) soaked in blood (milk). Pressures at arteries/veins act like **pouring/draining milk**, causing the sponge to swell/shrink.

?si=46FIZcK5ZYTy9ZoT From the video you can understood more clearly. So basically the force is applied on the fluid phase as far as I understood. Is this possible to implement by Ansys static structural?? -

March 8, 2025 at 7:10 pm

peteroznewman

SubscriberIn Mechanical APDL, the pressure in the fluid phase of porous media is typically created due to fluid flow driven by a pressure gradient. According to Darcy’s law, which defines the flow of fluids through porous media, the flow occurs when there is a difference in fluid pressure levels. This pressure difference causes the fluid to move through the porous medium, and the flow rate can be calculated based on the permeability of the medium and the viscosity of the fluid [3]. URL: [3] https://ansyshelp.ansys.com/public/account/secured?returnurl=/Views/Secured/corp/v251/en/ans_mat/elemdatatblpor.html

-

March 8, 2025 at 7:35 pm

peteroznewman

SubscriberScroll up in the replies to your March 8, 2025 at 3:01 pm post then scroll down and look at my replies. You will find I made some replies in-line under an older post to group my reply to your post. This makes them easy to miss compared with always replying to the bottom of this chain. Following up on the question of if IOP should be specified on the interior nodes, here is the code in the APDL snippet, notice the IC command to impose the 0.002 MPa of IOP on the Interior nodes.

fini

/PREP7

CMSEL,S,InteriorNodes,NODE

ESLN

N,999999,0.0,0.0,0.0

ET,4,HSFLD242,,,,,,1

type,4

ESURF,999999,

allsel

D,999999,UX,0.0

D,999999,UY,0.0

D,999999,UZ,0.0

IC,999999,HDSP,0.002

fini

/SOLUHere is the result:

The IOP causes the dome to buckle into a mode shape, but it quickly fails to converge. It looks like the some stiffer material is needed around that hole.

-

March 8, 2025 at 7:40 pm

adib.aktab999

SubscriberThe example problem you have recommened for permeability works like the biphasic material. When I have used the code for cpt212 in my model it shows:

*** ERROR *** CP = 4.453 TIME= 01:03:14Element type 285 does not support TB,PM.*** ERROR *** CP = 4.703 TIME= 01:03:14The step data was checked and there were errors found.Please check output or errors file ( C:\Users\BMELab\AppData\Local\Temp\test onchoroid.tmp1\_ProjectScratch\Scr9FBA\file0.err ) for messages.*** NOTE *** CP = 4.750 TIME= 01:03:14The Solution Control Option is only valid for single field structural,single field thermal, single field diffusion, coupledthermal-diffusion analyses and coupled-field analyses with structuraldegrees of freedom. The SOLCONTROL,ON command (if present) has beende-activated.*** NOTE *** CP = 4.750 TIME= 01:03:14The RESCONTROL command does not support fluid analyses. The RESCONTROLcommand settings have been de-activated.*** NOTE *** CP = 4.750 TIME= 01:03:14This nonlinear analysis defaults to using the full Newton-Raphsonsolution procedure. This can be modified using the NROPT command.

here is the code:et,5,212keyopt,5,3,2 ! Plane strainkeyopt,5,12,1 ! Pressure degree of freedom enabledfpx=4.8e-8tb,pm,1,,,permtbdata,1,fpx,fpx,fpxtb,pm,1,,,biottbdata,1,1.0 -

March 8, 2025 at 7:56 pm

adib.aktab999

SubscriberPeter Do I need to use the model with shared plug to do this analysis?

I have tried in my 2023 version but I don't know why the intersection isn't worked. I have done this in my laptop in 2025r1.

How can I resolve this ?

this link is added on "March 7, 2025 at 7:19 pm" comment.

I can do ICEM CFD meshing and trying to use the CPT217 on the choroid.

I am thinking of using stiffer material on the hole's around. -

March 8, 2025 at 8:09 pm

adib.aktab999

Subscriber"I suggest you draw a Free Body Diagram of the arteries, choroid and veins. Does the choroid porous material have a non-porous membrane that keeps the blood contained? In simple terms, say a tube is anchored to ground at the free end with an internal pressure P1 at that side, and it is attached to a sphere that causes a pressure drop of dP and there is tube on the opposite side to drain the fluid with a pressure P2 where dD = P1 - P2. How does the free body diagram look for that system?"

Extremely sorry to not following the answer. It will work but this causes time if you see my geometry, I have to modify multiple parts of my geometry to do this.

https://drive.google.com/file/d/1FXBLUxVTrg8Wmys81NzzB7NoZGgvsFpB/view?usp=drive_link -

March 8, 2025 at 8:21 pm

peteroznewman

SubscriberLook at the element shapes in the Ansys Help Mechanical APDL Element Reference.

CPT217 is a quadratic tet element.

CPT216 is a quadratic hex element

CPT215 is a linear hex element that can also be used on linear tet elements.

CPT212 is for 2D problems. You are doing a 3D problem and you meshed with Solid285, which is a linear tet element.

You have to mesh with the same element shape and element order if you want to convert the element to a different type.

-

March 8, 2025 at 10:06 pm

adib.aktab999

SubscriberHere I changed the code and the error has popped out:

*** WARNING *** CP = 60.438 TIME= 04:02:50There is not enough memory for the Distributed Sparse Matrix Solver toproceed in the in-core memory mode. The Distributed Sparse MatrixSolver will now restart using the out-of-core memory mode.*** WARNING *** CP = 60.656 TIME= 04:02:50There is not enough memory for the Distributed Sparse Matrix Solver toproceed in the in-core memory mode. The Distributed Sparse MatrixSolver will now restart using the out-of-core memory mode.*** WARNING *** CP = 60.891 TIME= 04:02:51There is not enough memory for the Distributed Sparse Matrix Solver toproceed in the in-core memory mode. The Distributed Sparse MatrixSolver will now restart using the out-of-core memory mode.*** ERROR *** CP = 61.578 TIME= 04:02:51There is not enough memory for the Distributed Sparse Matrix Solver toproceed. This is likely due to the use of pivoting while factoringthe matrix. Please increase the virtual memory on your system and/orincrease the work space memory and rerun the solver. Alternatively,using the DSPOPTION command to switch to a different memory modeand/or to specify additional memory for the solver may also help. Thememory currently allocated for the Distributed Sparse Matrix Solversolver = 130 MB.

Here is the code:

et,24,217 ! Plane strain

keyopt,24,12,1 ! Pressure degree of freedom enabled

fpx=0.138

tb,pm,24,,,perm

tbdata,1,fpx,fpx,fpx

tb,pm,24,,,biot

tbdata,1,1.0

Hey man, do you think that the plugged geometry will work?? If so I will try that and can do hexa mesh by ICEMCFD.

I saw you have tried, Can you share the file??

I couldn't understand why couldn't I create plug in ansys 2023R1. -

March 9, 2025 at 12:33 am

peteroznewman

SubscriberWould you like to have a video meeting where you can share your screen and I can see what you are doing wrong in SpaceClaim? What time zone are you in? I am in Eastern Standard Time. Do you have a zoom account? If not we can use Google Meet? I am available tomorrow.

-

March 9, 2025 at 1:16 pm

adib.aktab999

SubscriberLet me know when is the time.

-

March 9, 2025 at 1:48 pm

adib.aktab999

SubscriberWhen I am trying to use the combine tools it gives a error massege which says "Unable to intersect"

-

-

March 9, 2025 at 8:06 am

adib.aktab999

SubscriberI have zoom and meet both and I am also free today. Just let me know. You can do at your mornings when it will be afternoon here. just let me know.

-

March 9, 2025 at 2:09 pm

peteroznewman

SubscriberIt’s just past 10 AM in Eastern time zone. Put a meeting link in your reply and a time for me to join. Make the meeting time at least 15 minutes from when you post to allow time for delays in seeing replies. I can join anytime in the next 2 hours.

-

March 9, 2025 at 2:40 pm

adib.aktab999

Subscriberhey Peter I am free, I am giving you the link. You can join:

https://meet.google.com/ezj-fntv-hve

-

-

March 9, 2025 at 5:08 pm

adib.aktab999

Subscriber”A solver pivot warning or error has been detected in the UX degree of freedom of node 12971 located in Solid. This is usually a result of an ill conditioned matrix possibly due to unreasonable material properties, an under constrained model, or contact related issues. Check results carefully. You may select the offending object and/or geometry via RMB on this warning in the Messages window.”

Why this error popped out??

I have used displacement option too but still it is coming??

"I have unsuppress the command for fluid material and ran the simulation still error is coming:*** ERROR *** CP = 9.438 TIME= 23:09:19

There are 12 small equation solver pivot terms (e.g., at the PRES

degree of freedom of node 13514). Please check for an insufficiently

constrained model. -

March 9, 2025 at 10:36 pm

peteroznewman

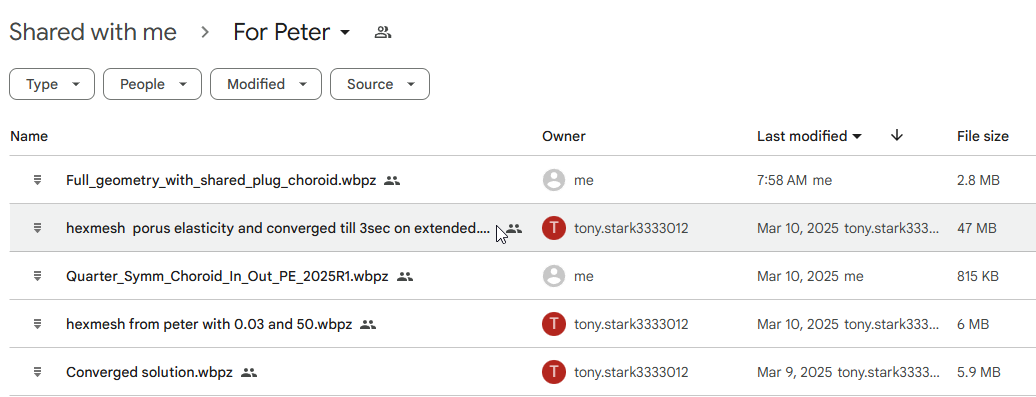

SubscriberI installed 2023 R1 on my desktop computer and made a hexmesh on the choroid body with plugs and shared topology.

Look for this file hexmesh on choroid 2023 R1.wbpz in the For Peter folder along with the solve.out file.