-

-

August 2, 2025 at 11:31 am

nitkum221

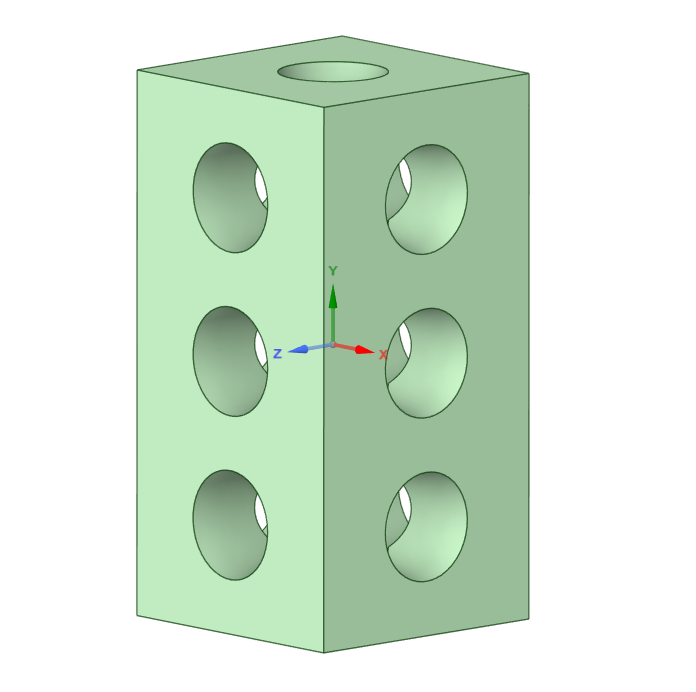

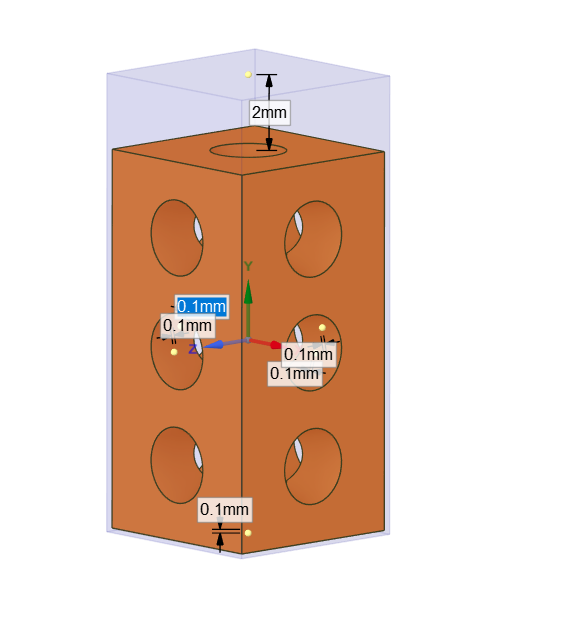

SubscriberI am currently working on a simulation involving laminar fluid flow and heat transfer analysis through a porous structure. To achieve this, I have designed an enclosure around a porous model. The working fluid is water, and the solid material is titanium.

However, I am facing an issue in ANSYS Fluent: I am unable to assign separate material properties for the fluid and the solid. In the Cell Zone Conditions, it only shows a single body, and I cannot apply materials separately for the fluid and solid domains.

Could you please guide me on:

How to assign fluid and solid material properties separately?

Whether the parameters I’ve used are appropriate for performing this simulation?

I have shared the design and Fluent setup files via Google Drive (link attached).

https://drive.google.com/file/d/1xNZeHOtbwjATooSGIUaqPnOo6Fk2m0TN/view?usp=sharing

Simulation Parameters

A) Models

Energy: On

Viscous: Laminar

B) Materials

Fluid: Water

Solid (Wall): Titanium

C) Cell Zone Conditions

Issue: Only a single body appears — cannot assign separate solid material

D) Velocity Inlet

Velocity Specification Method: Magnitude, Normal to Boundary

Reference Frame: Absolute

Velocity Magnitude: 0.0001 m/s

Initial Gauge Pressure: 0 Pa

E) Pressure Outlet

Reference Frame: Absolute

Gauge Pressure: 0 Pa

Pressure Profile Method: 1

Backflow Direction Specification Method: Normal to Boundary

Backflow Pressure Specification: Total Pressure

F) Wall Conditions

Boundary: Stationary Wall

Shear Condition: No Slip

Wall Definition: Same as Boundary

G) Reference Values

Area: 5e-06 m²

Density: 1000 kg/m³

Characteristic Length: 0.0121 m

Pressure: 0 Pa

Temperature: 288.16 K

Velocity: 0.0001 m/s

Viscosity: 0.001 kg/(m·s)

Specific Heat Ratio: 1.4

Y+ for Heat Transfer Coefficient: 300

H) Solution Methods

Scheme: SIMPLE

I) Solution Controls

Pressure: 0.3

Density: 1

Body Forces: 1

Momentum: 0.7

J) Residuals

Absolute Criteria: 1e-05

Iterations: 1000

-

August 2, 2025 at 3:23 pm

peteroznewman

SubscriberI wouldn’t use the word porous to describe this model as that word has a specific meaning that doesn’t apply to your description. Titanium is not porous for water, the flow is around the titanium body, not through it. The hole down the middle is still outside the titanium body. What you have is simply a block of titanium with large holes in it.

To fix the problem of only one body transferring, open the geometry in SpaceClaim and look at the Structure window on the left. Under FFF-2 you will see the Solid with holes was automatically set to Suppress for Physics when the fluid Enclosure was created. Right click on Solid and select Activate for Physics.

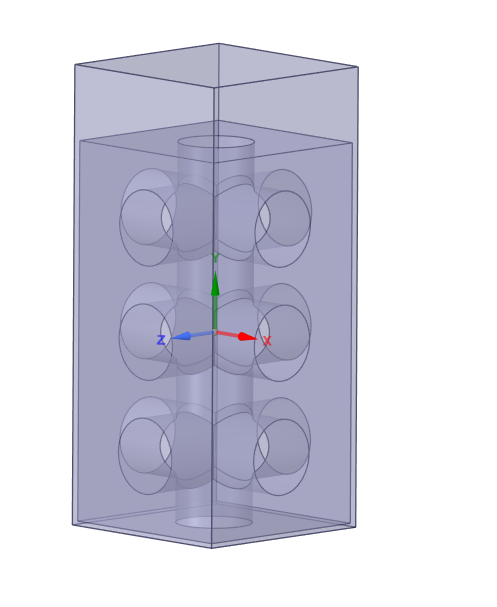

One choice you can make before you leave SpaceClaim is whether you want additional Interfaces created in Fluent on the 22 faces where water touches titanium. I don’t think you need that, but maybe someone with more experience will chime in with a reason why you do. One reason is to use a fine mesh on the fluid and a coarse mesh on the solid. The interface allows non-matching cell faces to transfer the heat. If you use the Share button, the cell faces match at the surface for heat transfer to take place.

If you want mesh interfaces, close SpaceClaim and when you open the Mesh app, you will find an automatically generated Contact Region that Fluent will be able to use as Interfaces.

I generally want to avoid any extra items in Fluent. In SpaceClaim, go to the Workbench tab and click the Share button and close SpaceClaim. When you open this is Mesh, there will be no Contact region and no extra boundary condtions will show up in Fluent.

Now open the Mesh cell, which will reread the geometry and you will have two bodies. One can be set to Solid and the Enclosure can be set to Fluid.

-

August 2, 2025 at 6:03 pm

nitkum221

SubscriberThis is not the actual porous model; I have created a general model because I don't want to share the original file. Secondly, we need to assign material properties such as titanium or aluminum to this model in order to perform fluid flow and heat transfer analysis.

Thirdly, as you mentioned, if we need to import both the enclosure file (which contains the model) and the solid model (from which the enclosure was created) into Fluent, how can we analyze fluid flow and heat transfer in the same body? Could you please perform the analysis or share a reference image/ analysis file for better understanding?

-

-

- You must be logged in to reply to this topic.

-

3582

-

1193

-

1086

-

1063

-

952

© 2025 Copyright ANSYS, Inc. All rights reserved.