-

-

September 15, 2025 at 12:34 pm

giacomo.falascino

SubscriberHello everyone.

I'm here for ask help on my thesis project.

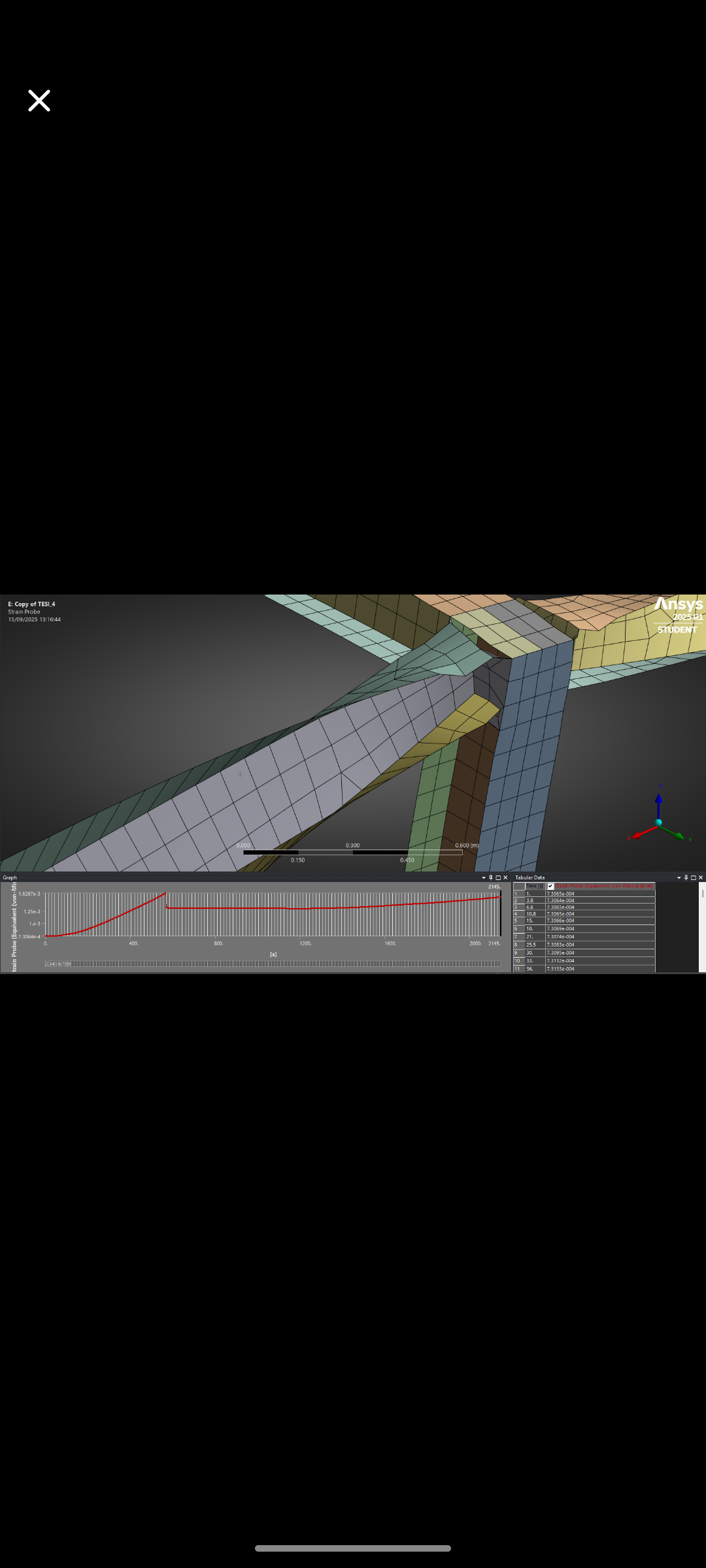

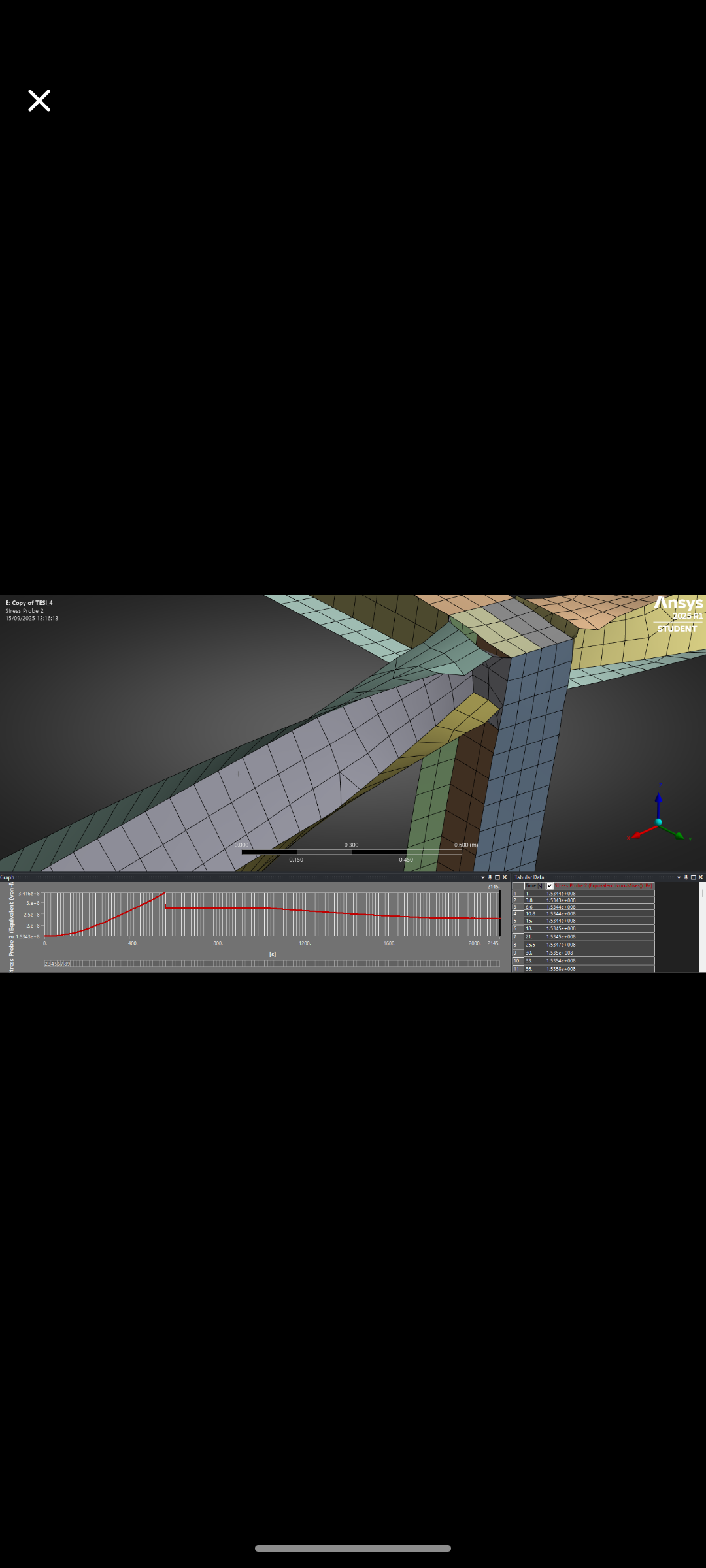

I model a steel structure with shell element and i import body temperature from a transient thermal analysis.

I insert a multilinear isotropic hardening for define the plasticity of the steel depending on temperature with a plateu value at 275 MPa and i insert the Young's Modulus depending on temperature.

When i start the non linear static analysis i notice a problem.

The Equivalent Stress (Von Mieses) exceed the maximum value for plasticity strenght (2.75e08 Pa).

Someone can help me for understand where i'm going wrong?

I also insert two screen for understand the problem.

-

September 16, 2025 at 1:43 am

Shashidhar Reddy

Ansys EmployeeHi,

Is your plasticity data contains only one point i.e (Yield stress, 0 plastic strain)? Perfect plasticity?

If yes, model may experience convergence issues as the stiffness of the element goes to zero once it cross yield stress.

Further, vonMises stress may exceed the yield stresss probably in the following case.

1. If an element is highly distorted due to the aforesaid issue.

2. May be stress singularity issue due to geometric discontinuity. See if you are getting such abnormality at the edges.

2. If you have a rough mesh, one element may have high gradient. In this case, one node of it may be less than yield and other may not. This requires refinement.

3. You might need to refine time step.

I would suggest you to identify the location on the model where it is experincing stress beyond yield. You will get to know some insights where it is due to aforesaid problems.

You can also see solverout file to understand whether solver is taking plastic increment at each iteration (for a confirmation whether solver is implementing plasticity).

Regards

Shashidhar, PhD

-

September 16, 2025 at 7:55 am

giacomo.falascino

SubscriberHi Shashidhar, thanks for the response.

In multilinear i insert three point each temperature line, the first point is 0 strain plasticity and yield stress, second and third are a plateu. The model is a perfect plastic material like indicated in the eurocodes 93 1-2 for steel under fire.

The excesses are in the point where the beam is collegate to the plate in the column, in the point where the plate is distorte like you can see in the screen.

Also the plasticity is only in the plate, the other elements like beams and columns don’t exceed the yield and don’t have any plasticity strain.

The solution can’t converge for moment criterion.

-

-

September 16, 2025 at 10:23 pm

giacomo.falascino

SubscriberUpdate:

Reading various websites and watching videos on ANSYS, I think I’ve figured out that this is a singularity.

Now the problem is: how can I avoid creating a sharp corner, given that I’m working with shell elements?

-

- You must be logged in to reply to this topic.

- The legend values are not changing.

- LPBF Simulation of dissimilar materials in ANSYS mechanical (Thermal Transient)

- Convergence error in modal analysis

- APDL, memory, solid

- How to model a bimodular material in Mechanical

- Meaning of the error

- Simulate a fan on the end of shaft

- Nonlinear load cases combinations

- Real Life Example of a non-symmetric eigenvalue problem

- How can the results of Pressures and Motions for all elements be obtained?

-

3882

-

1414

-

1241

-

1118

-

1015

© 2025 Copyright ANSYS, Inc. All rights reserved.