-

-

September 26, 2023 at 7:39 am

yang suli

SubscriberThe heat transfer of the Venturi reactor jacket is carried out with an inlet diameter of 15mm, an outlet diameter of 22.5mm, and a jacket thickness of 12mm. The length of the straight pipe section at the rear end of the reactor is 1000mm. The boundary conditions are set as follows: both inlets of the reactor have a velocity inlet of 1m/s, and the outlet has a pressure outlet of 0.1MPa. The jacket uses 300 ° C thermal oil for heat transfer, with an inlet velocity of 2m/s and an outlet pressure of 0.1MPa. The heat transfer cloud diagram and the temperature curve along the axis direction are shown below.

The simulation adopts fluid solid coupling heat transfer, and the outer wall of the reactor is set as air convective heat transfer. Is the simulation result reasonable?

I would like to ask if the heat transfer effect is reasonable. The simulation shows that the fluid temperature rises slowly, making it difficult to meet the actual reaction requirements.

-

September 26, 2023 at 12:38 pm

Rob

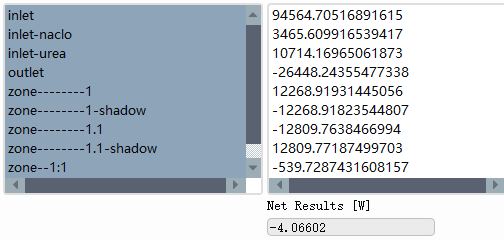

Forum ModeratorHow well resolved is the mesh (near wall and bulk flow) and what have you got set as the boundary between the two fluid zones? How does the heat flux balance look?

-

October 12, 2023 at 7:50 am

yang suli

SubscriberThe coupling heat transfer between fluid and solid is set up, and a shared topology is set up inside the SC. The simulation results show that the heat flux appears to be balanced.

Grid partitioning is performed in fluent messaging, but the quality of partitioning is poor. After using automatic node movement to improve the grid quality, the overall orthogonal quality is greater than 0.5.

-

-

October 12, 2023 at 1:07 pm

Rob

Forum ModeratorOverall balance looks OK, now, if you look at heat transfer from one zone to the next (via the wall & wall: shadow pairs) how warm/cold should the material be?

-

- The topic ‘Heat transfer problem of reactor jacket’ is closed to new replies.

-

4673

-

1565

-

1386

-

1231

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.