TAGGED: apdl, parametric, parametric-analysis, parametric-optimization, pyansys, thread

-

-

March 22, 2023 at 1:05 pm

Jake

SubscriberHello,

I have a parametric thread model, and I'm trying to get the parametrized pitch dimension from the model geometry on each run and pass it to APDL. Is there anyway to achive this?

Thanks.

-

March 27, 2023 at 3:56 pm

wrbulat

Ansys EmployeeHi Jake,

Was your parameterized geometry created in a CAD application outside of MAPDL? What do you intend to do with the thread pitch dimension once you have it in MAPDL? Do you want MAPDL to change the geometry if you change the value of the thread pitch in MAPDL, or do you instead intend to use the pitch doimension in some other way - say, in some kind of expression for post processing purposes?

--Bill

-

March 28, 2023 at 1:58 pm

Chandra Sekaran

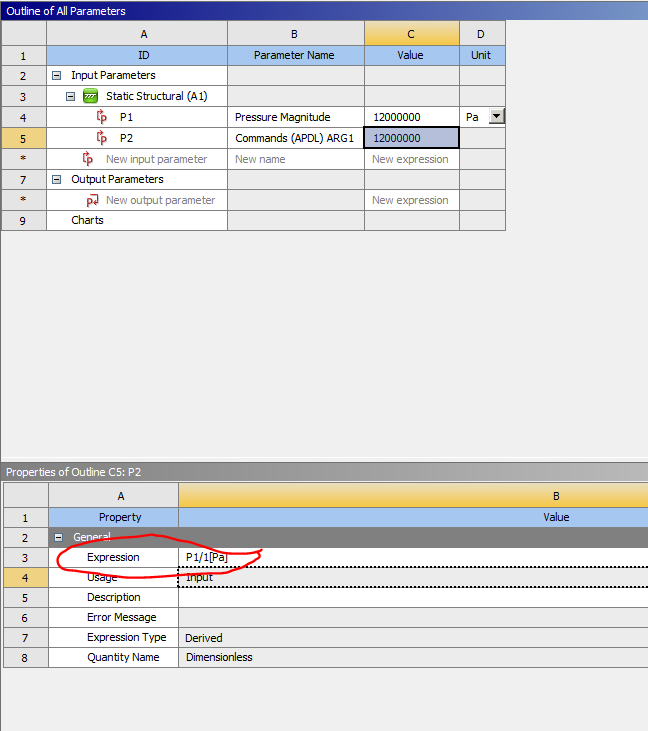

Ansys EmployeeYou can take an already defined parameter in Workbench and assign it to a APDL parameter in the 'commands' object as shown below. Here I marked a pressure load in WB/Mechanical as a parameter (P1). Then I created a command object and made ARG1 a parameter (P2 in picture). Then you can set P2's expression as "P1/1 [Pa]" as shown in red circle in picture below. This is required to make it dimensionless MAPDL quantity. This will make arg1 equal the pressure value. Then in the commands you can use arg1.

-

March 28, 2023 at 1:58 pm

Chandra Sekaran

Ansys EmployeeYou should be able to use this method for geometric parameters or any parameter that shows up in parameter set.

-

March 28, 2023 at 6:54 pm

Jake

SubscriberHi Bill,

The geometry is created in Autodesk Inventor, I am loading the geometry into workbench and simplifying/modifying with Spaceclaim then setting up my analysis in mechanical. I am using Spaceclaim to take the 3D Inventor geometry and turn it into a 2D axisymmetric cross section and to access the geometrical parameters from Inventor.

I intend to use the pitch to calculate thread dimensions so I can dynamically create named selections for each thread contact and retrieve the reaction force data for each thread contact as the pitch/geometry changes. The pitch will be changed via a parameter in a DesignXplorer and passed back to inventor for the model to be updated automatically.

I was originally trying to accomplish this via ADPL but it appears as if ADPL cannot access contacts. I believe I will need to use the python scripting feature in mechanical.

Thanks.

-

March 30, 2023 at 8:13 pm

wrbulat

Ansys EmployeeHi Jake,

Thanks for the additional details.

This (APDL code below) may (or may not) be helpful. If the number of threads is paramemetrized ("n_threads") and your 2D axisymmetric model contact is asymmetric, then this code might work on your model. It's objective is to create a unique named component for each group of the nodes used by the contact elements on each thread face. This assumes there are gaps in the contact elements as you go up the threaded fastener (e.g., there aren't any contact elements on the non-contacting face of each thread). If, in your project, you save nodal force results (under Analysis Settings Details), then you should be able to select each nodal component and use FSUM, then *GET,name,FSUM,,ITEM,FY to get net thread contact force for each thread individually.

n_threads=5

C*** ASSIGN UNIQUE COMPONENT NAMES TO NODES USED BY CONTACT ELEMENTS ON EACH THREAD FACEesel,s,ename,,172 ! SELECT CONTACT ELEMENTSnslecm,contact_e,elem ! NAME CONTACT ELEMENTScm,contact_n,node ! NAME NODES USED BY CONTACT ELEMENTScm,contact_n_i,node ! UNPROCESSED CONTACT NODES IN PASS i IN DO LOOP*do,i,1,n_threads ! LOOP OVER # OF THREADScmse,s,contact_n_i ! SELECT UNPROCESSED CONTACT NODES*get,ymin,node,,mnloc,y ! ymin = MIN Y LOCATION OF SELECTED NODESnsel,r,loc,y,ymin ! RESELECT THE NODE AT y=yminn_start_i=ndnext(0) ! n_start_i = THIS NODE'S NODE NUMBERd_eselnum=1 ! INITIALIZE CHANGE IN NUMBER OF SELECTED ELEMENTS*dowhile,d_eselnum ! DO WHILE CHANGE IN # OF SELECTED CONTACT ELEMENTS IS NONZEROesln ! SELECT ALL ELEMENTS USED BY SELECTED NODEScmsel,r,contact_e ! RESELECT CONTACT ELEMENTS*get,n_esel_1,elem,,count ! n_esel_1 = # OF SELECTED ELEMENTSnsle ! SELECT ALL NODES USED BY SELECTED ELEMENTSesln ! SELECT ALL ELEMENTS USED BY SELECTED NODEScmsel,r,contact_e ! RESELECT CONTACT ELEMENTS*get,n_esel_2,elem,,count ! n_esel_2 = # OF SELECTED ELEMENTSd_eselnum=n_esel_2-n_esel_1 ! d_eselnum = CHANGE IN # OF SELECTED ELEMENTS*enddocm,contact_n_%i%,node ! NAME CONTACT NODES ON THREAD insel,inve ! REDEFINE contact_n_i TO NOT INCLUDE NODES ON THREAD icmse,r,contact_n_icm,contact_n_i,node*enddo ! END DO LOOPesel,all ! THE FOLLOWING POST PROCESSING (UNDER SOLUTION BRANCH) IS UNTESTEDesel,u,ename,,172*do,i,1,n_threadscmsel,s,contact_n_%i%fsum*get,net_FY,fsum,,item,fymy_net_FY_%i%=net_FY*enddo

-

- The topic ‘Getting Geometric Parameters in APDL’ is closed to new replies.

-

4678

-

1565

-

1386

-

1241

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.