-

-

September 18, 2023 at 6:43 pm

Laura Osorio Ojeda

SubscriberHello,

I am trying to simulate a Gas-Liquid Centrifugal (swirl) Separator. The inlet is located at the bottom of the equipment and the two outlets (one for gas and one for liquid). I am using water (primary phase) and air (secondary phase). The models I activated are Multiphase (Mixture with surface tension) and Viscous (Reynolds Stress). The simulation is transient and it accounts for gravity). the inlet is a velocity-inlet and water and air are at 2 m/s, graction of air is 0.3. both outlets are pressure-outlets and they are at 0 Pa.

The issue I am having is that there is REVERSE FLOW. Has anyone simulated this type of equipment and got this same issue, how did you solve this? any kind of help or suggestion is welcome. -

September 20, 2023 at 2:19 pm

Federico

Ansys EmployeeHow are you initializing the flow? Perhaps you need to run a steady-case first and use this as your initial condition for your transient run

-

September 20, 2023 at 2:56 pm

Laura Osorio Ojeda

SubscriberHello Federico.

I did that. First, I enlarged my outlets and inlet by 100 inches. I ran a steady-state case with just water. I did not activate the multiphase flow but I did activate the Reynolds Stress model. However, I keep getting a reversed flow. Do you have any suggestions to solve this issue?

-

-

September 20, 2023 at 3:00 pm

Rob

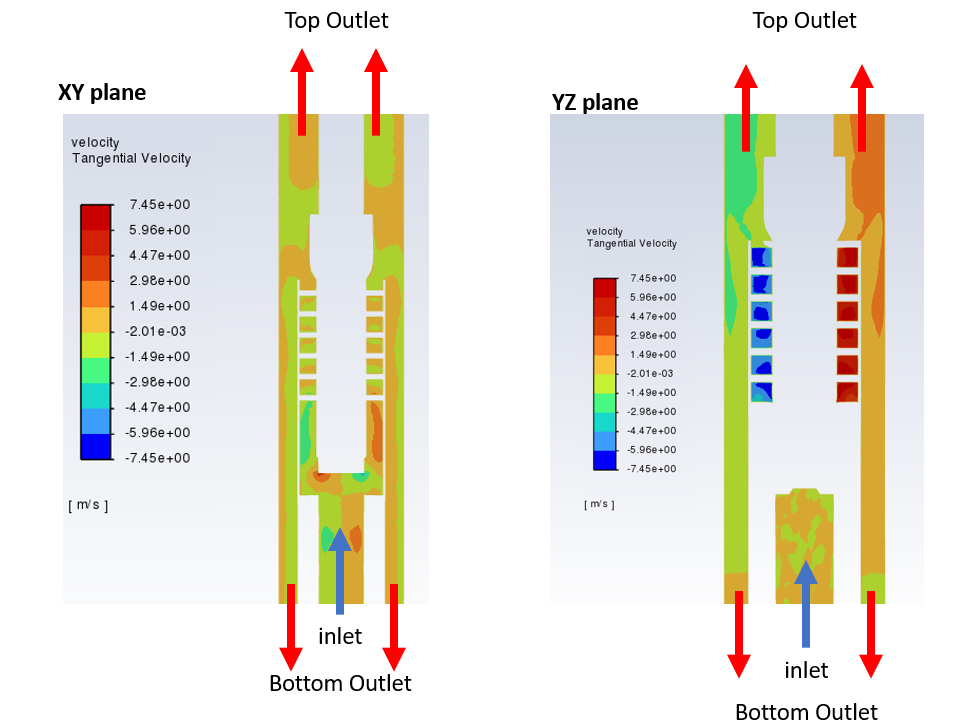

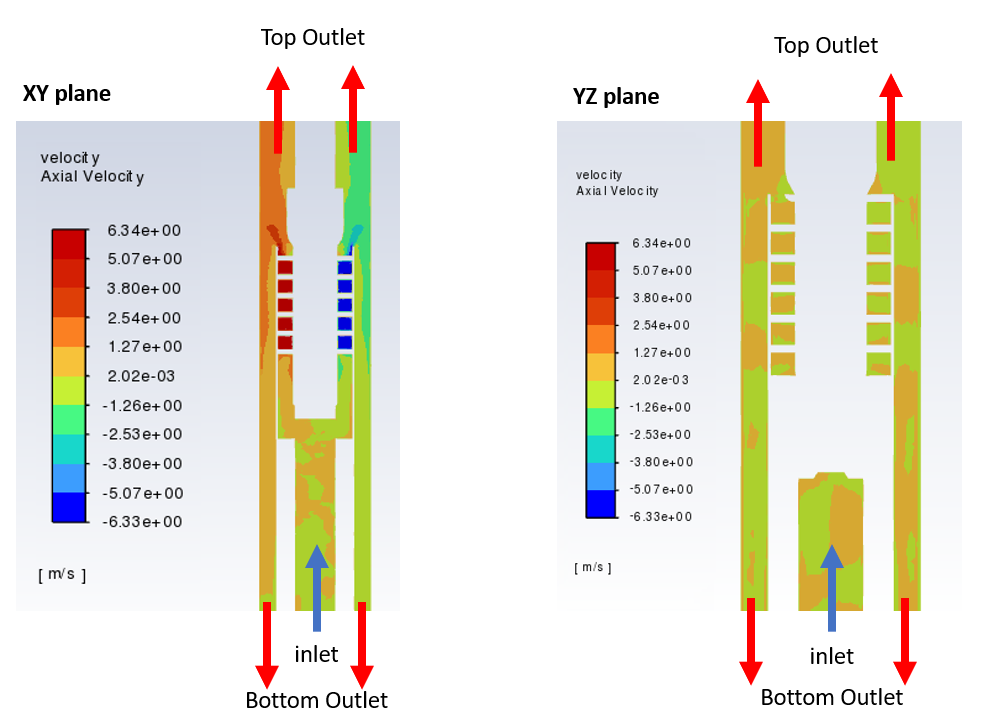

Forum ModeratorI think I know what's going on, but need some images to confirm. Please can you post axial and tangential velocity contours aligned with the axis? You may find overlaying "in plane" vectors to be helpful too.

-

September 20, 2023 at 3:06 pm

Laura Osorio Ojeda

SubscriberSure! Do you want me to post from the case where I did single-flow and steady-state?

-

-

September 20, 2023 at 3:18 pm

Rob

Forum ModeratorPlease. I've run a few of these over the years but am not supposed to use "engineering knowledge": pictures mean I can comment on what I'm seeing.

-

September 20, 2023 at 4:38 pm

Laura Osorio Ojeda

SubscriberAs I mentioned, I just want to address the Reversed Flow situation here. So I am simulation a single flow (water), with the model viscous (Reynolds Stress), velocity inlet 2 m/s, both outlets are pressure outlets at 0 Pa.

Also, I zoom in the geometry but the geometry is long, as I elongated the outlets and inlet by 100 in, as seen in the following screenshot.

-

-

September 21, 2023 at 7:37 am

Rob

Forum ModeratorCheck the cell zone reference settings. The idea of the tangential & axial velocity is for cyclones where we expect a constant tangential velocity with radius.

Not clear on here but you may want to read up on (precessing) vortex cores - Nick Syred did a lot of the earlier work. Also have a look at the radial pressure distribution option on the pressure outlet.

We can stop the backflow numerically, but it's not going to mean you're not modelling reality. It's also why one of the last lines in the Accuracy lecture is roughly "understand what you're modelling". In this case, that's not easy.

-

- The topic ‘Gas-Liquid Centifugal Separator. Please Help.’ is closed to new replies.

-

5264

-

1859

-

1398

-

1256

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.