TAGGED: contact, force-reaction, mechanical

-

-

September 22, 2024 at 5:52 pm

javat33489

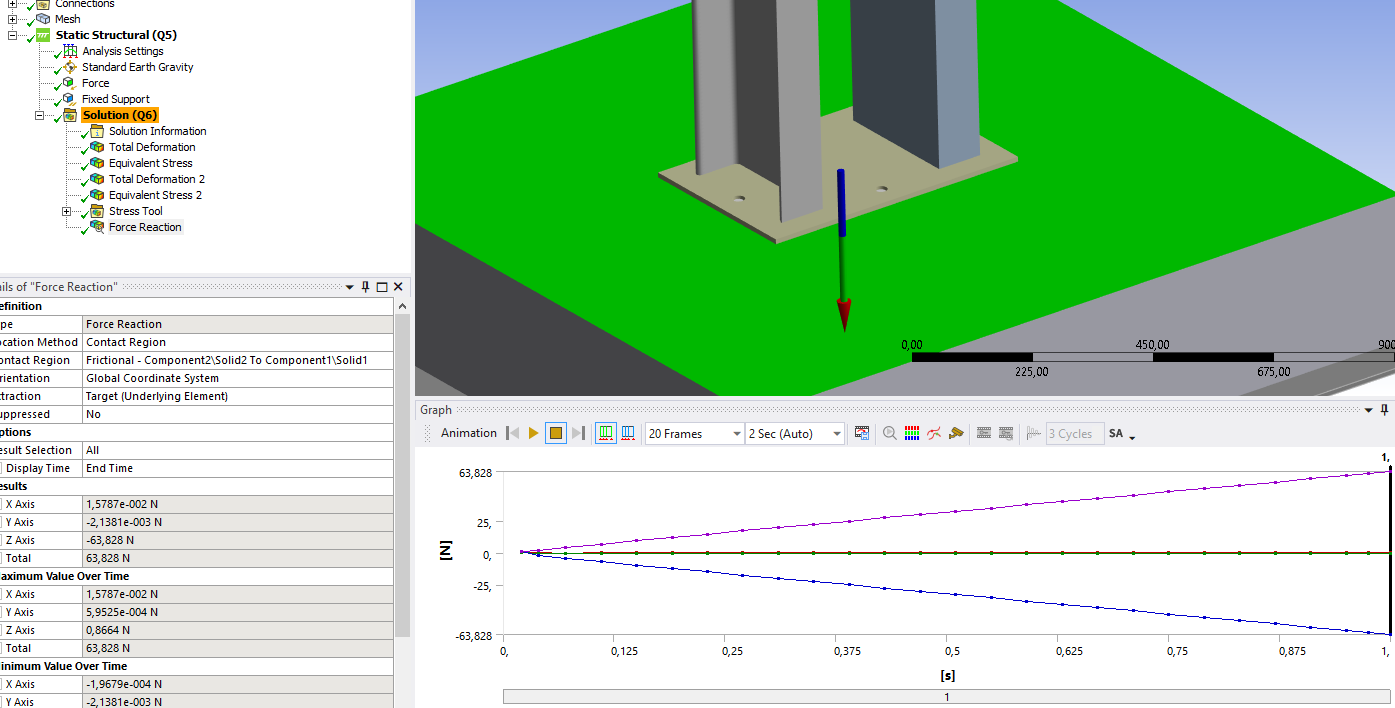

SubscriberHello everyone. I made a calculation where the structure with the plate presses on the concrete slab. I also used 4 holes in the plate and 4 wells in the concrete slab to use the beam mount. Now I need to know the force reaction with what force the plate reacts to the concrete slab. If I use symmetrical contact I see 15K newton, if I use asymmetrical contact I see only 64 newton. Why? How to do it right?

-

September 23, 2024 at 9:42 am

Stella Peloni

Ansys EmployeeHello,

The difference in reaction forces when using symmetric versus asymmetric contact in simulations is due to the way contact and target are defined and how the rules for contact apply. In asymmetric behavior, one side is always contact and the other is always target. The rules for contact apply only to the contact side, meaning that the contact should not penetrate the target. The target is considered a geometric boundary that should not be violated by the contact. Results for the contacts are generated on both surfaces for symmetric while for asymmetric they are only generated on the contact surface.

You can, also, refer to this Forum post, which explains the difference.

Regards,

Stella

-

September 23, 2024 at 10:24 am

mohan.urs

Ansys EmployeeHey,

Adding to Stella's reply

To know more about symmetric and asymmetric behavior you can check out his link from ANSYS help. Do check if you've assigned the correct contact and target surfaces too. It is covered in the same article.

https://ansyshelp.ansys.com/Views/Secured/corp/v242/en/ans_ctec/Hlp_ctec_dessurf.htmlTo ensure you're doing it right, you should check the following:

1. Ensure that the material properties for both the plate and the concrete slab are defined correctly.

2. Verify that the boundary conditions, especially the constraints on the wells and holes, are accurately represented.

3. Review the contact definitions and ensure that the contact behavior is appropriate for the physical scenario you are trying to simulate.

4. Consider the mesh quality and density, as they can significantly affect the accuracy of the contact and stress results.

5. Perform a convergence study to ensure that the results are not sensitive to the size of the mesh elements.Regards,

Mohan Urs

-

September 23, 2024 at 5:59 pm

javat33489

SubscriberSir, I understand that, thank you.

Then why is there such a big difference?

For example, with symmetrical contact, I got 15K N.

When I made an asymmetrical contact, I made two calculations, I made each side with a target surface, but the result was 64 N. Why wasn't one of the sides equal to about 15K N?

-

-

- You must be logged in to reply to this topic.

-

5049

-

1764

-

1387

-

1248

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.