TAGGED: ansys-fluent, error, fluent

-

-

June 5, 2020 at 10:12 am

robmen

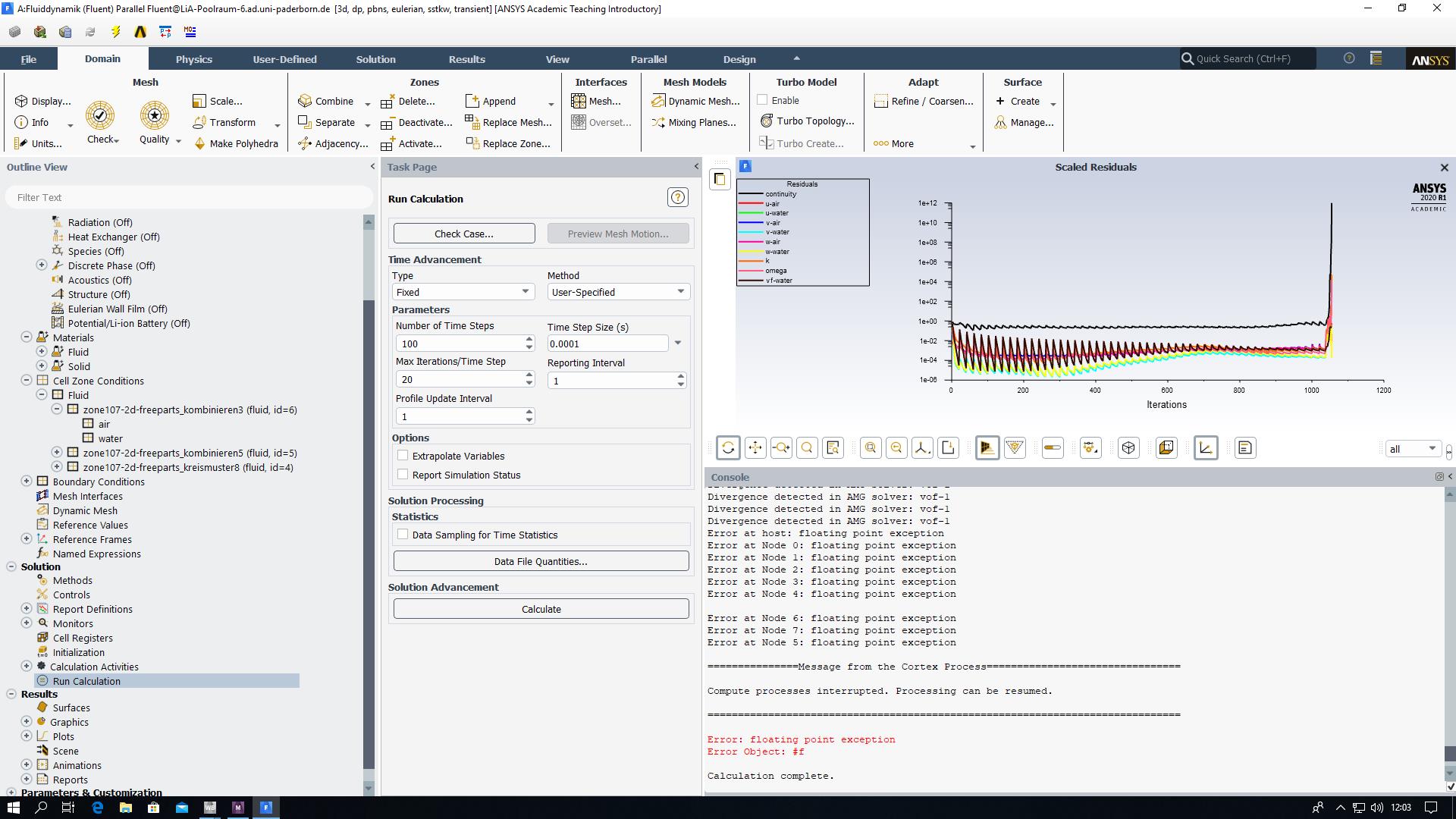

SubscriberI always get this error in my simulation. I am simulating a transient flow through cooling nozzles of a milling tool. Because of the flow i use an eulerian 2-phase model filled with air and incoming water through the inlet.

How can i fix this? Should i reduce my time step size even more?

izing vof-1 using GMRES to enhance linear solver robustness.

Divergence detected in AMG solver: vof-1

turbulent viscosity limited to viscosity ratio of 1.000000e+05 in 109740 cells

Divergence detected in AMG solver: vof-1

Divergence detected in AMG solver: vof-1

Divergence detected in AMG solver: vof-1

Divergence detected in AMG solver: vof-1

Divergence detected in AMG solver: vof-1

Divergence detected in AMG solver: vof-1

Divergence detected in AMG solver: vof-1

Error at host: floating point exception

Error at Node 0: floating point exception

Error at Node 1: floating point exception

Error at Node 2: floating point exception

Error at Node 3: floating point exception

Error at Node 4: floating point exception

Error at Node 6: floating point exception

Error at Node 7: floating point exception

Error at Node 5: floating point exception

===============Message from the Cortex Process================================

Compute processes interrupted. Processing can be resumed.

==============================================================================

Error: floating point exception

Error Object: #f

Calculation complete.

-

June 5, 2020 at 3:50 pm

Rob

Forum ModeratorAssuming it ran any iterations have a look at the flow just before the model fails. Then review the mesh quality, are the cells good, and are there enough of them. Also check boundary conditions, are they physically sensible?

-

June 5, 2020 at 5:51 pm

robmen

Subscriber

I attached the picture properly now. It failed at about 1050 iterations. My timestep size is 0.0001 so i also considered my mesh as bad, but i checked the metrics and my averages of skewness, element quality and orthogonal quality are fine.

What do you mean by checking the boundary conditions in terms af physically sensible? I did use frame motion for rotating the whole geometry.

-

June 8, 2020 at 1:17 pm

Rob

Forum ModeratorIf the average is OK how're the worst cells coming out?

Looking at the residuals you aren't converging any time steps: decrease the time step and try again.

Re the settings being sensible: it's a sanity check. Ie is the mass flow right, is the inlet velocity as expected or is it a silly number.

-

June 12, 2020 at 12:21 pm

robmen

SubscriberThanks for the help!

I dont know the exact min and max anymore, but the min orthogonal quality was above 0.2 and the max skewness was about 0.8 with just a few cells with that mentioned amount.

I could fix the problem through using an older CAD file that didnt had any issues.

-

- The topic ‘Floating Point Exception’ is closed to new replies.

-

5119

-

1831

-

1387

-

1248

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.