-

-

April 21, 2023 at 12:58 pm

Xabier Tamayo

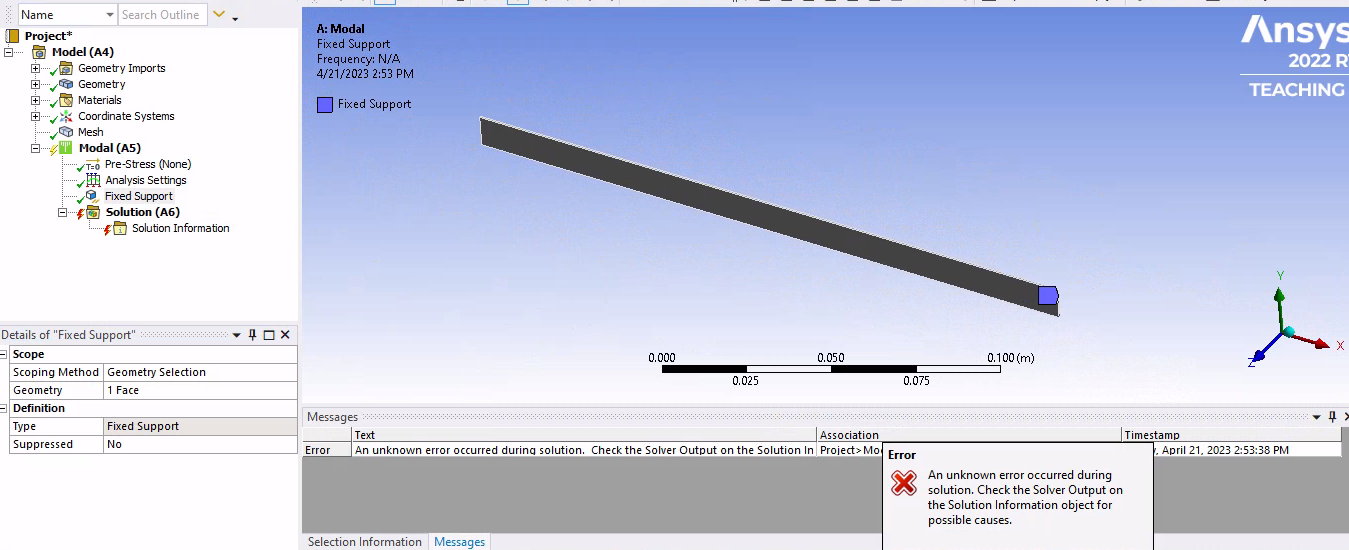

SubscriberHi everyone, Im trying a really simple modal simulation, but it always gives me an error message. I have tried to find out what the error is using the output solver, but I still don't know what it is. I attach some screenshots and the solver output.

And the output solver says the next:

Ansys Mechanical Enterprise Academic Teaching

*------------------------------------------------------------------*

| |

| W E L C O M E T O T H E A N S Y S (R) P R O G R A M |

| |

*------------------------------------------------------------------*

***************************************************************

* ANSYS 2022 R1 LEGAL NOTICES *

***************************************************************

* *

* Copyright 1971-2022 ANSYS, Inc. All rights reserved. *

* Unauthorized use, distribution or duplication is *

* prohibited. *

* *

* Ansys is a registered trademark of ANSYS, Inc. or its *

* subsidiaries in the United States or other countries. *

* See the ANSYS, Inc. online documentation or the ANSYS, Inc. *

* documentation CD or online help for the complete Legal *

* Notice. *

* *

***************************************************************

* *

* THIS ANSYS SOFTWARE PRODUCT AND PROGRAM DOCUMENTATION *

* INCLUDE TRADE SECRETS AND CONFIDENTIAL AND PROPRIETARY *

* PRODUCTS OF ANSYS, INC., ITS SUBSIDIARIES, OR LICENSORS. *

* The software products and documentation are furnished by *

* ANSYS, Inc. or its subsidiaries under a software license *

* agreement that contains provisions concerning *

* non-disclosure, copying, length and nature of use, *

* compliance with exporting laws, warranties, disclaimers, *

* limitations of liability, and remedies, and other *

* provisions. The software products and documentation may be *

* used, disclosed, transferred, or copied only in accordance *

* with the terms and conditions of that software license *

* agreement. *

* *

* ANSYS, Inc. is a UL registered *

* ISO 9001:2015 company. *

* *

***************************************************************

* *

* This product is subject to U.S. laws governing export and *

* re-export. *

* *

* For U.S. Government users, except as specifically granted *

* by the ANSYS, Inc. software license agreement, the use, *

* duplication, or disclosure by the United States Government *

* is subject to restrictions stated in the ANSYS, Inc. *

* software license agreement and FAR 12.212 (for non-DOD *

* licenses). *

* *

***************************************************************

2022 R1

Point Releases and Patches installed:

ANSYS, Inc. License Manager 2022 R1

Ansys, Inc. Products 2022 R1

SpaceClaim 2022 R1

CFX (includes CFD-Post) 2022 R1

Chemkin 2022 R1

EnSight 2022 R1

FENSAP-ICE 2022 R1

Fluent (includes CFD-Post) 2022 R1

Polyflow (includes CFD-Post) 2022 R1

Forte (includes EnSight) 2022 R1

TurboGrid 2022 R1

Icepak (includes CFD-Post) 2022 R1

ACIS Geometry Interface 2022 R1

AutoCAD Geometry Interface 2022 R1

Catia, Version 4 Geometry Interface 2022 R1

Catia, Version 5 Geometry Interface 2022 R1

Catia, Version 6 Geometry Interface 2022 R1

Creo Elements/Direct Modeling Geometry Interface 2022 R1

Creo Parametric Geometry Interface 2022 R1

Inventor Geometry Interface 2022 R1

JTOpen Geometry Interface 2022 R1

NX Geometry Interface 2022 R1

Parasolid Geometry Interface 2022 R1

Solid Edge Geometry Interface 2022 R1

SOLIDWORKS Geometry Interface 2022 R1

Ansys Sherlock 2022 R1

Autodyn 2022 R1

LS-DYNA 2022 R1

Aqwa 2022 R1

Additive 2022 R1

Mechanical Products 2022 R1

***** ANSYS COMMAND LINE ARGUMENTS *****

BATCH MODE REQUESTED (-b) = NOLIST

INPUT FILE COPY MODE (-c) = COPY

DISTRIBUTED MEMORY PARALLEL REQUESTED

2 PARALLEL PROCESSES REQUESTED WITH SINGLE THREAD PER PROCESS

TOTAL OF 2 CORES REQUESTED

INPUT FILE NAME = \\dcloud.local\public\018\018_xabier.tamayo\Desktop\Ansys pruebas\_ProjectScratch\Scr1F42\dummy.dat

OUTPUT FILE NAME = \\dcloud.local\public\018\018_xabier.tamayo\Desktop\Ansys pruebas\_ProjectScratch\Scr1F42\solve.out

START-UP FILE MODE = NOREAD

STOP FILE MODE = NOREAD

RELEASE= 2022 R1 BUILD= 22.1 UP20211129 VERSION=WINDOWS x64

CURRENT JOBNAME=file0 14:53:35 APR 21, 2023 CP= 0.109

PARAMETER _DS_PROGRESS = 999.0000000

/INPUT FILE= ds.dat LINE= 0

*** NOTE *** CP = 0.219 TIME= 14:53:35

The /CONFIG,NOELDB command is not valid in a Distributed ANSYS

solution. Command is ignored.

*GET _WALLSTRT FROM ACTI ITEM=TIME WALL VALUE= 14.8930556

TITLE=

Modal_piezasolid--Modal (A5)

ACT Extensions:

LSDYNA, 2021.1

5f463412-bd3e-484b-87e7-cbc0a665e474, wbex

SET PARAMETER DIMENSIONS ON _WB_PROJECTSCRATCH_DIR

TYPE=STRI DIMENSIONS= 248 1 1

PARAMETER _WB_PROJECTSCRATCH_DIR(1) = \\dcloud.local\public\018\018_xabier.tamayo\Desktop\Ansys pruebas\_ProjectScratch\Scr1F42\

SET PARAMETER DIMENSIONS ON _WB_SOLVERFILES_DIR

TYPE=STRI DIMENSIONS= 248 1 1

PARAMETER _WB_SOLVERFILES_DIR(1) = \\dcloud.local\public\018\018_xabier.tamayo\Desktop\Ansys pruebas\Modal_piezasolid_files\dp0\SYS\MECH\

SET PARAMETER DIMENSIONS ON _WB_USERFILES_DIR

TYPE=STRI DIMENSIONS= 248 1 1

PARAMETER _WB_USERFILES_DIR(1) = \\dcloud.local\public\018\018_xabier.tamayo\Desktop\Ansys pruebas\Modal_piezasolid_files\user_files\

--- Data in consistent MKS units. See Solving Units in the help system for more

MKS UNITS SPECIFIED FOR INTERNAL

LENGTH (l) = METER (M)

MASS (M) = KILOGRAM (KG)

TIME (t) = SECOND (SEC)

TEMPERATURE (T) = CELSIUS (C)

TOFFSET = 273.0

CHARGE (Q) = COULOMB

FORCE (f) = NEWTON (N) (KG-M/SEC2)

HEAT = JOULE (N-M)

PRESSURE = PASCAL (NEWTON/M**2)

ENERGY (W) = JOULE (N-M)

POWER (P) = WATT (N-M/SEC)

CURRENT (i) = AMPERE (COULOMBS/SEC)

CAPACITANCE (C) = FARAD

INDUCTANCE (L) = HENRY

MAGNETIC FLUX = WEBER

RESISTANCE (R) = OHM

ELECTRIC POTENTIAL = VOLT

INPUT UNITS ARE ALSO SET TO MKS

*** ANSYS - ENGINEERING ANALYSIS SYSTEM RELEASE 2022 R1 22.1 ***

DISTRIBUTED Ansys Mechanical Enterprise Academic Teaching

00000000 VERSION=WINDOWS x64 14:53:35 APR 21, 2023 CP= 0.219

Modal_piezasolid--Modal (A5)

***** ANSYS ANALYSIS DEFINITION (PREP7) *****

*********** Nodes for the whole assembly ***********

*********** Elements for Body 1 "Part 1" ***********

*********** Send User Defined Coordinate System(s) ***********

*********** Set Reference Temperature ***********

*********** Send Materials ***********

*********** Fixed Supports ***********

***** ROUTINE COMPLETED ***** CP = 0.234

--- Number of total nodes = 1370

--- Number of contact elements = 0

--- Number of spring elements = 0

--- Number of bearing elements = 0

--- Number of solid elements = 156

--- Number of condensed parts = 0

--- Number of total elements = 156

*GET _WALLBSOL FROM ACTI ITEM=TIME WALL VALUE= 14.8930556

***** ANSYS SOLUTION ROUTINE *****

PERFORM A MODAL ANALYSIS

THIS WILL BE A NEW ANALYSIS

PARAMETER _THICKRATIO = 0.000000000

USE SYM. BLOCK LANCZOS MODE EXTRACTION METHOD

EXTRACT 7 MODES

NORMALIZE THE MODE SHAPES TO THE MASS MATRIX

ERASE THE CURRENT DATABASE OUTPUT CONTROL TABLE.

WRITE ALL ITEMS TO THE DATABASE WITH A FREQUENCY OF NONE

FOR ALL APPLICABLE ENTITIES

WRITE NSOL ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE ETMP ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

EXPAND ALL EXTRACTED MODES

DO NOT CALCULATE ELEMENT RESULTS

DO NOT COMBINE ELEMENT SAVE DATA FILES (.esav) AFTER DISTRIBUTED PARALLEL SOLUTION

DO NOT COMBINE ELEMENT MATRIX FILES (.emat) AFTER DISTRIBUTED PARALLEL SOLUTION

DO NOT COMBINE ASSEMBLED MATRIX FILES (.full) AFTER DISTRIBUTED PARALLEL SOLUTION

*GET ANSINTER_ FROM ACTI ITEM=INT VALUE= 0.00000000

*IF ANSINTER_ ( = 0.00000 ) NE

0 ( = 0.00000 ) THEN

*ENDIF

*** NOTE *** CP = 0.266 TIME= 14:53:35

The automatic domain decomposition logic has selected the MESH domain

decomposition method with 2 processes per solution.

***** ANSYS SOLVE COMMAND *****

*** WARNING *** CP = 0.266 TIME= 14:53:35

Element shape checking is currently inactive. Issue SHPP,ON or

SHPP,WARN to reactivate, if desired.

*** NOTE *** CP = 0.281 TIME= 14:53:35

The model data was checked and warning messages were found.

Please review output or errors file (

\\dcloud.local\public\018\018_xabier.tamayo\Desktop\Ansys

pruebas\_ProjectScratch\Scr1F42\file0.err ) for these warning

messages.

*** SELECTION OF ELEMENT TECHNOLOGIES FOR APPLICABLE ELEMENTS ***

--- GIVE SUGGESTIONS AND RESET THE KEY OPTIONS ---

ELEMENT TYPE 1 IS SOLID186. KEYOPT(2)=0 IS SUGGESTED AND HAS BEEN RESET.

KEYOPT(1-12)= 0 0 0 0 0 0 0 0 0 0 0 0

*** ANSYS - ENGINEERING ANALYSIS SYSTEM RELEASE 2022 R1 22.1 ***

DISTRIBUTED Ansys Mechanical Enterprise Academic Teaching

00000000 VERSION=WINDOWS x64 14:53:35 APR 21, 2023 CP= 0.281

Modal_piezasolid--Modal (A5)

S O L U T I O N O P T I O N S

PROBLEM DIMENSIONALITY. . . . . . . . . . . . .3-D

DEGREES OF FREEDOM. . . . . . UX UY UZ

ANALYSIS TYPE . . . . . . . . . . . . . . . . .MODAL

EXTRACTION METHOD. . . . . . . . . . . . . .BLOCK LANCZOS

OFFSET TEMPERATURE FROM ABSOLUTE ZERO . . . . . 273.15

NUMBER OF MODES TO EXTRACT. . . . . . . . . . . 7

GLOBALLY ASSEMBLED MATRIX . . . . . . . . . . .SYMMETRIC

NUMBER OF MODES TO EXPAND . . . . . . . . . . .ALL

ELEMENT RESULTS CALCULATION . . . . . . . . . .OFF

*** NOTE *** CP = 0.281 TIME= 14:53:35

The conditions for direct assembly have been met. No .emat or .erot

files will be produced.

D I S T R I B U T E D D O M A I N D E C O M P O S E R

...Number of elements: 156

...Number of nodes: 1370

...Decompose to 2 CPU domains

...Element load balance ratio = 1.000

L O A D S T E P O P T I O N S

LOAD STEP NUMBER. . . . . . . . . . . . . . . . 1

THERMAL STRAINS INCLUDED IN THE LOAD VECTOR . . YES

PRINT OUTPUT CONTROLS . . . . . . . . . . . . .NO PRINTOUT

DATABASE OUTPUT CONTROLS

ITEM FREQUENCY COMPONENT

ALL NONE

NSOL ALL

ETMP ALL

*********** PRECISE MASS SUMMARY ***********

TOTAL RIGID BODY MASS MATRIX ABOUT ORIGIN

Translational mass | Coupled translational/rotational mass

0.91539E-02 0.0000 0.0000 | 0.0000 0.27736E-05 -0.45312E-04

0.0000 0.91539E-02 0.0000 | -0.27736E-05 0.0000 0.91539E-03

0.0000 0.0000 0.91539E-02 | 0.45312E-04 -0.91539E-03 0.0000

------------------------------------------ | ------------------------------------------

| Rotational mass (inertia)

| 0.30018E-06 -0.45312E-05 -0.27736E-06

| -0.45312E-05 0.12205E-03 -0.13729E-07

| -0.27736E-06 -0.13729E-07 0.12235E-03

TOTAL MASS = 0.91539E-02

The mass principal axes coincide with the global Cartesian axes

CENTER OF MASS (X,Y,Z)= 0.10000 0.49500E-02 0.30300E-03

TOTAL INERTIA ABOUT CENTER OF MASS

0.75044E-07 0.35662E-20 0.29390E-21

0.35662E-20 0.30513E-04 0.81169E-23

0.29390E-21 0.81169E-23 0.30588E-04

The inertia principal axes coincide with the global Cartesian axes

*** MASS SUMMARY BY ELEMENT TYPE ***

TYPE MASS

1 0.915388E-02

Range of element maximum matrix coefficients in global coordinates

Maximum = 2.90253469E+09 at element 103.

Minimum = 2.90253454E+09 at element 100.

*** ELEMENT MATRIX FORMULATION TIMES

TYPE NUMBER ENAME TOTAL CP AVE CP

1 156 SOLID186 0.000 0.000000

Time at end of element matrix formulation CP = 0.484375.

BLOCK LANCZOS CALCULATION OF UP TO 7 EIGENVECTORS.

NUMBER OF EQUATIONS = 4056

MAXIMUM WAVEFRONT = 153

MAXIMUM MODES STORED = 7

MINIMUM EIGENVALUE = 0.00000E+00

MAXIMUM EIGENVALUE = 0.10000E+31

Process memory allocated for solver = 6.656 MB

Process memory required for in-core solution = 6.346 MB

Process memory required for out-of-core solution = 3.976 MB

Total memory allocated for solver = 13.364 MB

Total memory required for in-core solution = 12.741 MB

Total memory required for out-of-core solution = 7.949 MB

*** NOTE *** CP = 0.703 TIME= 14:53:35

The Distributed Sparse Matrix Solver used by the Block Lanczos

eigensolver is currently running in the in-core memory mode. This

memory mode uses the most amount of memory in order to avoid using the

hard drive as much as possible, which most often results in the

fastest solution time. This mode is recommended if enough physical

memory is present to accommodate all of the solver data.

*** ANSYS - ENGINEERING ANALYSIS SYSTEM RELEASE 2022 R1 22.1 ***

DISTRIBUTED Ansys Mechanical Enterprise Academic Teaching

00000000 VERSION=WINDOWS x64 14:53:35 APR 21, 2023 CP= 0.781

Modal_piezasolid--Modal (A5)

*** FREQUENCIES FROM BLOCK LANCZOS ITERATION ***

MODE FREQUENCY (HERTZ)

1 11.71618911070

2 73.41753812852

3 190.2039651007

4 205.5969093043

5 403.0167525196

6 450.9853165402

7 666.5432548624

*** ANSYS - ENGINEERING ANALYSIS SYSTEM RELEASE 2022 R1 22.1 ***

DISTRIBUTED Ansys Mechanical Enterprise Academic Teaching

00000000 VERSION=WINDOWS x64 14:53:36 APR 21, 2023 CP= 0.797

Modal_piezasolid--Modal (A5)

***** PARTICIPATION FACTOR CALCULATION ***** X DIRECTION

CUMULATIVE RATIO EFF.MASS

MODE FREQUENCY PERIOD PARTIC.FACTOR RATIO EFFECTIVE MASS MASS FRACTION TO TOTAL MASS

1 11.7162 0.85352E-01 0.0000 0.000000 0.00000 0.00000 0.00000

2 73.4175 0.13621E-01 0.0000 0.000000 0.00000 0.00000 0.00000

3 190.204 0.52575E-02 0.0000 0.000000 0.00000 0.00000 0.00000

4 205.597 0.48639E-02 0.0000 0.000000 0.00000 0.00000 0.00000

5 403.017 0.24813E-02 0.0000 0.000000 0.00000 0.00000 0.00000

6 450.985 0.22174E-02 0.0000 0.000000 0.00000 0.00000 0.00000

7 666.543 0.15003E-02 0.0000 0.000000 0.00000 0.00000 0.00000

***** PARTICIPATION FACTOR CALCULATION ***** Y DIRECTION

CUMULATIVE RATIO EFF.MASS

MODE FREQUENCY PERIOD PARTIC.FACTOR RATIO EFFECTIVE MASS MASS FRACTION TO TOTAL MASS

1 11.7162 0.85352E-01 0.0000 0.000000 0.00000 0.00000 0.00000

2 73.4175 0.13621E-01 0.0000 0.000000 0.00000 0.00000 0.00000

3 190.204 0.52575E-02 0.74898E-01 1.000000 0.560975E-02 1.00000 0.612828

4 205.597 0.48639E-02 0.0000 0.000000 0.00000 1.00000 0.00000

5 403.017 0.24813E-02 0.0000 0.000000 0.00000 1.00000 0.00000

6 450.985 0.22174E-02 0.0000 0.000000 0.00000 1.00000 0.00000

7 666.543 0.15003E-02 0.0000 0.000000 0.00000 1.00000 0.00000

-----------------------------------------------------------------------------------------------------------------

sum 0.560975E-02 0.612828

-----------------------------------------------------------------------------------------------------------------

***** PARTICIPATION FACTOR CALCULATION ***** Z DIRECTION

CUMULATIVE RATIO EFF.MASS

MODE FREQUENCY PERIOD PARTIC.FACTOR RATIO EFFECTIVE MASS MASS FRACTION TO TOTAL MASS

1 11.7162 0.85352E-01 0.74819E-01 1.000000 0.559793E-02 0.666584 0.611536

2 73.4175 0.13621E-01 -0.41479E-01 0.554393 0.172053E-02 0.871460 0.187956

3 190.204 0.52575E-02 0.0000 0.000000 0.00000 0.871460 0.00000

4 205.597 0.48639E-02 0.24338E-01 0.325287 0.592328E-03 0.941992 0.647078E-01

5 403.017 0.24813E-02 -0.17416E-01 0.232769 0.303305E-03 0.978109 0.331340E-01

6 450.985 0.22174E-02 0.0000 0.000000 0.00000 0.978109 0.00000

7 666.543 0.15003E-02 0.13559E-01 0.181220 0.183840E-03 1.00000 0.200833E-01

-----------------------------------------------------------------------------------------------------------------

sum 0.839793E-02 0.917417

-----------------------------------------------------------------------------------------------------------------

***** PARTICIPATION FACTOR CALCULATION *****ROTX DIRECTION

CUMULATIVE RATIO EFF.MASS

MODE FREQUENCY PERIOD PARTIC.FACTOR RATIO EFFECTIVE MASS MASS FRACTION TO TOTAL MASS

1 11.7162 0.85352E-01 0.37036E-03 1.000000 0.137163E-06 0.514958 0.456940

2 73.4175 0.13621E-01 -0.20532E-03 0.554393 0.421573E-07 0.673231 0.140441

3 190.204 0.52575E-02 -0.22694E-04 0.061277 0.515026E-09 0.675164 0.171573E-02

4 205.597 0.48639E-02 0.12047E-03 0.325287 0.145135E-07 0.729653 0.483497E-01

5 403.017 0.24813E-02 -0.86207E-04 0.232769 0.743173E-08 0.757554 0.247577E-01

6 450.985 0.22174E-02 0.24510E-03 0.661790 0.600728E-07 0.983088 0.200124

7 666.543 0.15003E-02 0.67116E-04 0.181220 0.450455E-08 1.00000 0.150063E-01

-----------------------------------------------------------------------------------------------------------------

sum 0.266358E-06 0.887334

-----------------------------------------------------------------------------------------------------------------

***** PARTICIPATION FACTOR CALCULATION *****ROTY DIRECTION

CUMULATIVE RATIO EFF.MASS

MODE FREQUENCY PERIOD PARTIC.FACTOR RATIO EFFECTIVE MASS MASS FRACTION TO TOTAL MASS

1 11.7162 0.85352E-01 -0.40827E-02 0.623871 0.166685E-04 0.177793 0.136568

2 73.4175 0.13621E-01 0.65441E-02 1.000000 0.428259E-04 0.634591 0.350880

3 190.204 0.52575E-02 0.0000 0.000000 0.00000 0.634591 0.00000

4 205.597 0.48639E-02 -0.42373E-02 0.647492 0.179546E-04 0.826102 0.147105

5 403.017 0.24813E-02 0.31592E-02 0.482753 0.998059E-05 0.932559 0.817726E-01

6 450.985 0.22174E-02 0.0000 0.000000 0.00000 0.932559 0.00000

7 666.543 0.15003E-02 -0.25145E-02 0.384239 0.632278E-05 1.00000 0.518036E-01

-----------------------------------------------------------------------------------------------------------------

sum 0.937523E-04 0.768129

-----------------------------------------------------------------------------------------------------------------

***** PARTICIPATION FACTOR CALCULATION *****ROTZ DIRECTION

CUMULATIVE RATIO EFF.MASS

MODE FREQUENCY PERIOD PARTIC.FACTOR RATIO EFFECTIVE MASS MASS FRACTION TO TOTAL MASS

1 11.7162 0.85352E-01 0.0000 0.000000 0.00000 0.00000 0.00000

2 73.4175 0.13621E-01 0.0000 0.000000 0.00000 0.00000 0.00000

3 190.204 0.52575E-02 0.40917E-02 1.000000 0.167416E-04 1.00000 0.136833

4 205.597 0.48639E-02 0.0000 0.000000 0.00000 1.00000 0.00000

5 403.017 0.24813E-02 0.0000 0.000000 0.00000 1.00000 0.00000

6 450.985 0.22174E-02 0.0000 0.000000 0.00000 1.00000 0.00000

7 666.543 0.15003E-02 0.0000 0.000000 0.00000 1.00000 0.00000

-----------------------------------------------------------------------------------------------------------------

sum 0.167416E-04 0.136833

-----------------------------------------------------------------------------------------------------------------

*** NOTE *** CP = 0.797 TIME= 14:53:36

The modes requested are mass normalized (Nrmkey on MODOPT). However,

the modal masses and kinetic energies below are calculated with unit

normalized modes.

***** MODAL MASSES, KINETIC ENERGIES, AND TRANSLATIONAL EFFECTIVE MASSES SUMMARY *****

EFFECTIVE MASS

MODE FREQUENCY MODAL MASS KENE | X-DIR RATIO% Y-DIR RATIO% Z-DIR RATIO%

1 11.72 0.2283E-02 6.185 | 0.000 0.00 0.000 0.00 0.5598E-02 61.15

2 73.42 0.2283E-02 242.9 | 0.000 0.00 0.000 0.00 0.1721E-02 18.80

3 190.2 0.2293E-02 1637. | 0.000 0.00 0.5610E-02 61.28 0.000 0.00

4 205.6 0.2282E-02 1904. | 0.000 0.00 0.000 0.00 0.5923E-03 6.47

5 403.0 0.2281E-02 7314. | 0.000 0.00 0.000 0.00 0.3033E-03 3.31

6 451.0 0.1511E-02 6065. | 0.000 0.00 0.000 0.00 0.000 0.00

7 666.5 0.2279E-02 0.1999E+05 | 0.000 0.00 0.000 0.00 0.1838E-03 2.01

--------------------------------------------------------------------------------------------------------------

sum | 0.000 0.00 0.5610E-02 61.28 0.8398E-02 91.74

--------------------------------------------------------------------------------------------------------------

*** ANSYS BINARY FILE STATISTICS

BUFFER SIZE USED= 16384

1.688 MB WRITTEN ON ASSEMBLED MATRIX FILE: file0.full

0.125 MB WRITTEN ON MODAL MATRIX FILE: file0.mode

0.500 MB WRITTEN ON RESULTS FILE: file0.rst

*************** Write FE CONNECTORS *********

WRITE OUT CONSTRAINT EQUATIONS TO FILE= file.ce

*GET _NMODALSOLPROC FROM ACTI ITEM=NUMC VALUE= 2.00000000

FINISH SOLUTION PROCESSING

***** ROUTINE COMPLETED ***** CP = 0.906

PRINTOUT RESUMED BY /GOP

*GET _WALLASOL FROM ACTI ITEM=TIME WALL VALUE= 14.8933333

*** ANSYS - ENGINEERING ANALYSIS SYSTEM RELEASE 2022 R1 22.1 ***

DISTRIBUTED Ansys Mechanical Enterprise Academic Teaching

00000000 VERSION=WINDOWS x64 14:53:36 APR 21, 2023 CP= 0.906

Modal_piezasolid--Modal (A5)

***** ANSYS RESULTS INTERPRETATION (POST1) *****

*** NOTE *** CP = 0.969 TIME= 14:53:36

Reading results into the database (SET command) will update the current

displacement and force boundary conditions in the database with the

values from the results file for that load set. Note that any

subsequent solutions will use these values unless action is taken to

either SAVE the current values or not overwrite them (/EXIT,NOSAVE).

PRINTOUT RESUMED BY /GOP

Set Encoding of XML File to:ISO-8859-1

Set Output of XML File to:

PARM, , , , , , , , , , , ,

, , , , , , ,

DATABASE WRITTEN ON FILE parm.xml

EXIT THE ANSYS POST1 DATABASE PROCESSOR

***** ROUTINE COMPLETED ***** CP = 1.141

PRINTOUT RESUMED BY /GOP

*GET _WALLDONE FROM ACTI ITEM=TIME WALL VALUE= 14.8933333

PARAMETER _PREPTIME = 0.000000000

PARAMETER _SOLVTIME = 1.000000000

PARAMETER _POSTTIME = 0.000000000

PARAMETER _TOTALTIM = 1.000000000

*GET _DLBRATIO FROM ACTI ITEM=SOLU DLBR VALUE= 1.00000000

*GET _COMBTIME FROM ACTI ITEM=SOLU COMB VALUE= 0.186647900

*GET _SSMODE FROM ACTI ITEM=SOLU SSMM VALUE= 2.00000000

*GET _NDOFS FROM ACTI ITEM=SOLU NDOF VALUE= 4056.00000

/FCLEAN COMMAND REMOVING ALL LOCAL FILES

--- Total number of nodes = 1370

--- Total number of elements = 156

--- Element load balance ratio = 1

--- Time to combine distributed files = 0.1866479

--- Sparse memory mode = 2

--- Number of DOF = 4056

EXIT ANSYS WITHOUT SAVING DATABASE

NUMBER OF WARNING MESSAGES ENCOUNTERED= 1

NUMBER OF ERROR MESSAGES ENCOUNTERED= 0

+--------- D I S T R I B U T E D A N S Y S S T A T I S T I C S ------------+

Release: 2022 R1 Build: 22.1 Update: UP20211129 Platform: WINDOWS x64

Date Run: 04/21/2023 Time: 14:53 Process ID: 10464

Operating System: Windows 10 (Build: 19042)

Processor Model: Intel(R) Xeon(R) Gold 6240R CPU @ 2.40GHz

Compiler: Intel(R) Fortran Compiler Version 19.0.5 (Build: 20190815)

Intel(R) C/C++ Compiler Version 19.0.5 (Build: 20190815)

Intel(R) Math Kernel Library Version 2020.0.0 Product Build 20191125

BLAS Library supplied by Intel(R) MKL

Number of machines requested : 1

Total number of cores available : 4

Number of physical cores available : 4

Number of processes requested : 2

Number of threads per process requested : 1

Total number of cores requested : 2 (Distributed Memory Parallel)

MPI Type: INTELMPI

MPI Version: Intel(R) MPI Library 2019 Update 10 for Windows* OS

GPU Acceleration: Not Requested

Job Name: file0

Input File: dummy.dat

Core Machine Name Working Directory

-----------------------------------------------------

0 AB018IND038 \\dcloud.local\public\018\018_xabier.tamayo\Desktop\Ansys pruebas\_ProjectScratch\Scr1F42

1 AB018IND038 \\dcloud.local\public\018\018_xabier.tamayo\Desktop\Ansys pruebas\_ProjectScratch\Scr1F42

Latency time from master to core 1 = 8.192 microseconds

Communication speed from master to core 1 = 5838.61 MB/sec

Total CPU time for main thread : 1.3 seconds

Total CPU time summed for all threads : 1.5 seconds

Elapsed time spent obtaining a license : 0.3 seconds

Elapsed time spent pre-processing model (/PREP7) : 0.0 seconds

Elapsed time spent solution - preprocessing : 0.0 seconds

Elapsed time spent computing solution : 0.4 seconds

Elapsed time spent solution - postprocessing : 0.2 seconds

Elapsed time spent post-processing model (/POST1) : 0.3 seconds

Eigensolver used : Block Lanczos

Equation solver computational rate : 4.8 Gflops

Sum of memory used on all processes : 92.0 MB

Sum of memory allocated on all processes : 3136.0 MB

Physical memory available : 16 GB

Total amount of I/O written to disk : 0.0 GB

Total amount of I/O read from disk : 0.0 GB

+------ E N D D I S T R I B U T E D A N S Y S S T A T I S T I C S -------+

*---------------------------------------------------------------------------*

| |

| DISTRIBUTED ANSYS RUN COMPLETED |

| |

|---------------------------------------------------------------------------|

| |

| Ansys 2022 R1 Build 22.1 UP20211129 WINDOWS x64 |

| |

|---------------------------------------------------------------------------|

| |

| Database Requested(-db) 1024 MB Scratch Memory Requested 1024 MB |

| Maximum Database Used 1 MB Maximum Scratch Memory Used 45 MB |

| |

|---------------------------------------------------------------------------|

| |

| CP Time (sec) = 1.516 Time = 14:53:37 |

| Elapsed Time (sec) = 4.000 Date = 04/21/2023 |

| |

*---------------------------------------------------------------------------* -

April 21, 2023 at 1:25 pm

ErKo

Ansys EmployeeHi

So it is solving as you can see (frequencies are there and no errors), so there is something when opening results. Likely the result file does not exist or is not written (.rst file).

Can you clear solution and data and untick the distributed solve box when solving, and solve again.

If that does not work, try not to use any cloud related services/folders, just solve it locally on your lapotop/desktop.

Thank you

Erik

-

April 21, 2023 at 5:59 pm

Xabier Tamayo

SubscriberI opened it again from another remote and this time it worked. Thank you very much.

-

- The topic ‘Error: An unknown error occurred during solution’ is closed to new replies.

-

5014

-

1682

-

1387

-

1248

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.