TAGGED: ansys-thermal, convection, convection-coefficient

-

-

June 24, 2023 at 6:53 am

Hakim Dina Anjum

SubscriberIn theory, we know that Qconvection = hA (Ts-Ta).

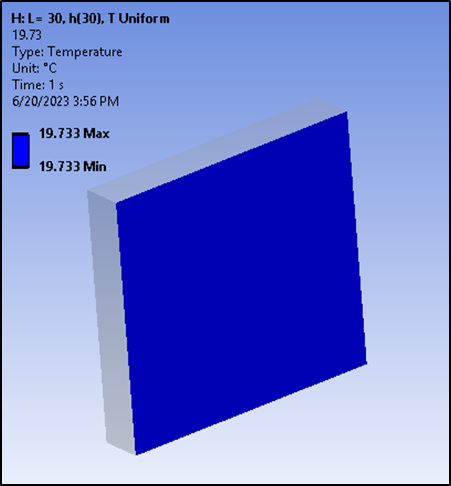

More surface area means more convection. What is the effect of this area in simulation? If I reduce my model size for computational efficiency by taking half of a whole body, how will the reduced area affect the thermal results?I have a solid rectangular part with a length of L, width W and thickness T. To reduce computational time, I have cut the part in half and modeled a rectangle with length L/2, width W and thickness T. The input boundary conditions are temperature at surface, convection and radiation surface B. I need to find the temperature on surface B. Will halving the model affect the output temperature on surface B?

Note: For convection, I had to input h. I have calculated h for the actual length L, and not L/2 as h depends on characteristic length.

Image are of two rectangles with different length. All boundary conditions (Temperature, convection, radiation) are same. If Qconvection depends on Area, shouldn't the output temperature be different? What am I missing. And if not, then can I assume that I can reduce the model size for computational efficiency?

-

June 27, 2023 at 2:58 pm

mjmiddle

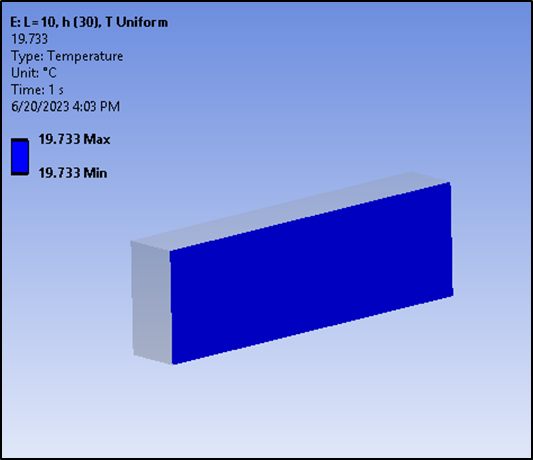

Ansys EmployeeWhat you describe here is an intention to use a symmetry model. You can insert a symmetry region in the Outline and select a symmetry face(s). Also select the normal axis.

Note that a symmetry condition for heat transfer analysis enforces flux parallel at that face. So you can accomplish the same thing by enforcing a “prefectly insulated” boundary condition at that face. This is the same as enforcing a heat flow of zero at that face.

The reason you get the same answer in your full model and half-model without setting up a symmetry or flux parallel condition is that you probably applied the temperature on the opposite face of the convection, so heat flows straight across, which creates flux parallel conditions at the perimeter faces. Also note that any faces without a load or BC appied and no contact, are considered perfectly insulated faces by default, which is flux parallel.

The heat transfer coefficient (h) in a convection is not macro-geometry dependant. There is no characteristic length for this. That is why there is an area (A) in the convection equation to account for the geometry. You’ll also notice that the h units includes length^2 in the denominator showing that h is a per-area factor, meaning it has factored out model total area. It will depend on micro-geometry such as surface roughness seen under microscope, and the solid and fluid materials involved. This would normally describe natural convection but even forced flow convection can be accounted-for by adjusting h.

An intuitive review of your model would explain that even though the convection area is cut in half in the symmetry model (half the convective heat transfer loss to ambient), with temperature the same on the other side, you still get the same results because you have half the material to heat.

-

July 6, 2023 at 5:09 am

Hakim Dina Anjum

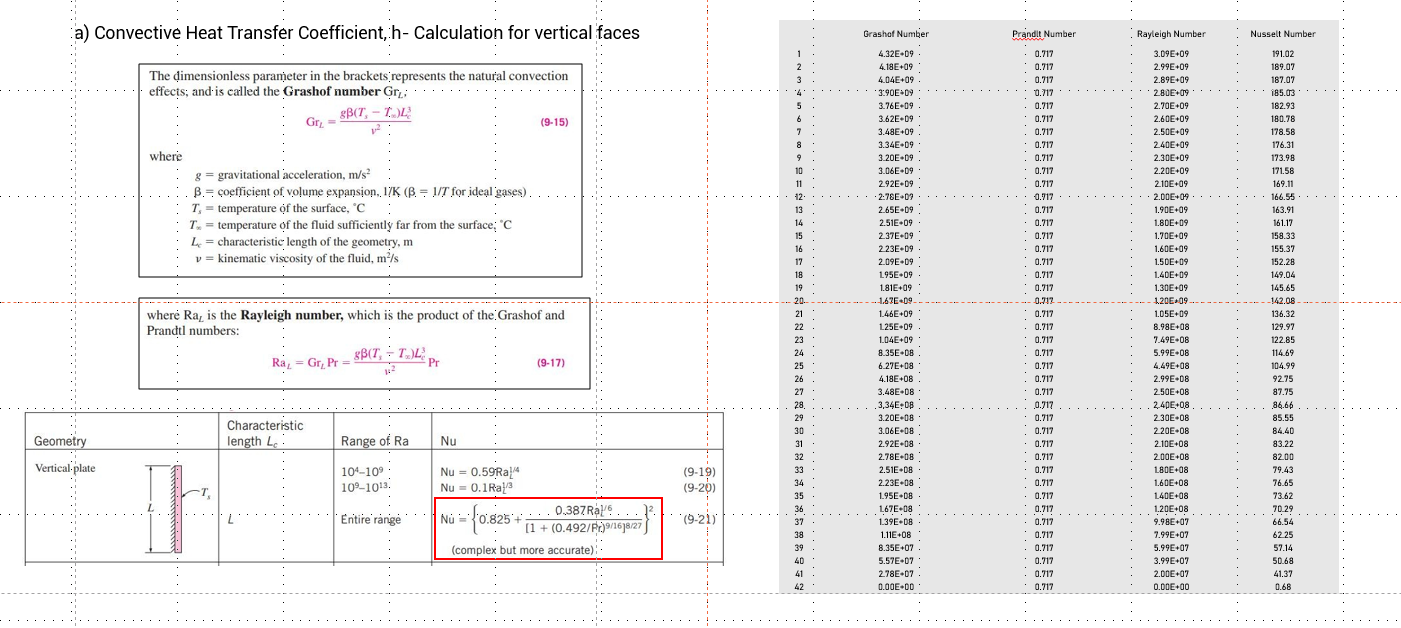

SubscriberExcuse my confusion, but isn't h in convection a macro-geometry dependent component? There is characteristic length in the equation of Grashof Number that we use to calculate Nusselt Number, which again is used to calculate the convective heat transfer coefficient. Again, characteristic length is dependent on the shape and orientation of the geometry, so doesn't it make h a macro geometry dependent component?

I understand how the area in the convection equation accounts for the geometry, but apart that, the h value in the convection equation also relies on the geometry of the part. And this dependancy of h on L (characteristic length) is not linear either. This is where the complexity arises if I want to change the geometry, as in, should I consider the change in geometry, thus change in characteristic length in the value of h? My understanding tells me not to. Please share your thoughts on it.

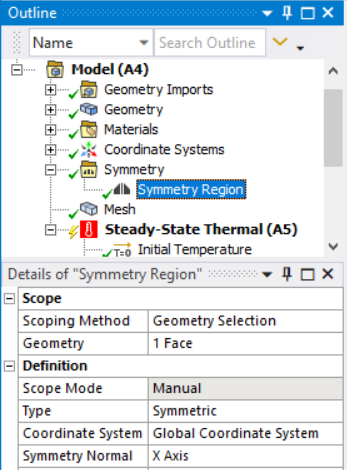

I have added pictures of the actual model. -

July 6, 2023 at 8:20 am

mjmiddle

Ansys EmployeeI mentioned forced flow in my previous message affecting h because I was thinking of transition from laminar to turbulent flow, and this would be where the characteristic length, determined from the Reynolds numbers applies for your geometry, so yes that would be a macro geometry parameter. But I was not considering viscous friction even in natural convection that the Grashof number characterizes. But even this is really a forced flow from the bouyant force. And there are other fluid characterizations that is going to affect h over the surface. I'm sorry, but I have been focusing on the Mechanical field for over 20 years, and have forgotten a lot of this basic fluid analysis stuff, because I haven't had to worry about this for a while.

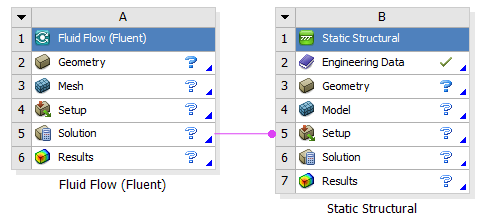

But the convection BC specified in Mechanical is a simple load/BC. The h you specify is a constant over the surface, so you can use the average over the entire surface. If you need to get real accurate for heat transfer to the fluid, you can run a fluid solver such as Fluent or CFX, and transfer those results to a structrual analysis by linking the Solution cell of the Fluent/CFX system to the Setup cell of the structural system.

Or you can export an XYZ data file from these fluid systems and use an "External Data" system to read into your structural system.

Or you can export an XYZ data file from these fluid systems and use an "External Data" system to read into your structural system.This will allow you an accurate heat transfer coefficent and fluid bulk temperature at all points (and times) on the surface you choose for your imported convection load/BC.

-

July 6, 2023 at 11:51 am

Hakim Dina Anjum

SubscriberIt is absolutely okay. I appreciate the prompt clarification of the confusion, and all the insights on the flux parallel conditions and the intuitive review in the previous response. I myself am a newbie in the field and am finding the forum pretty supportive.

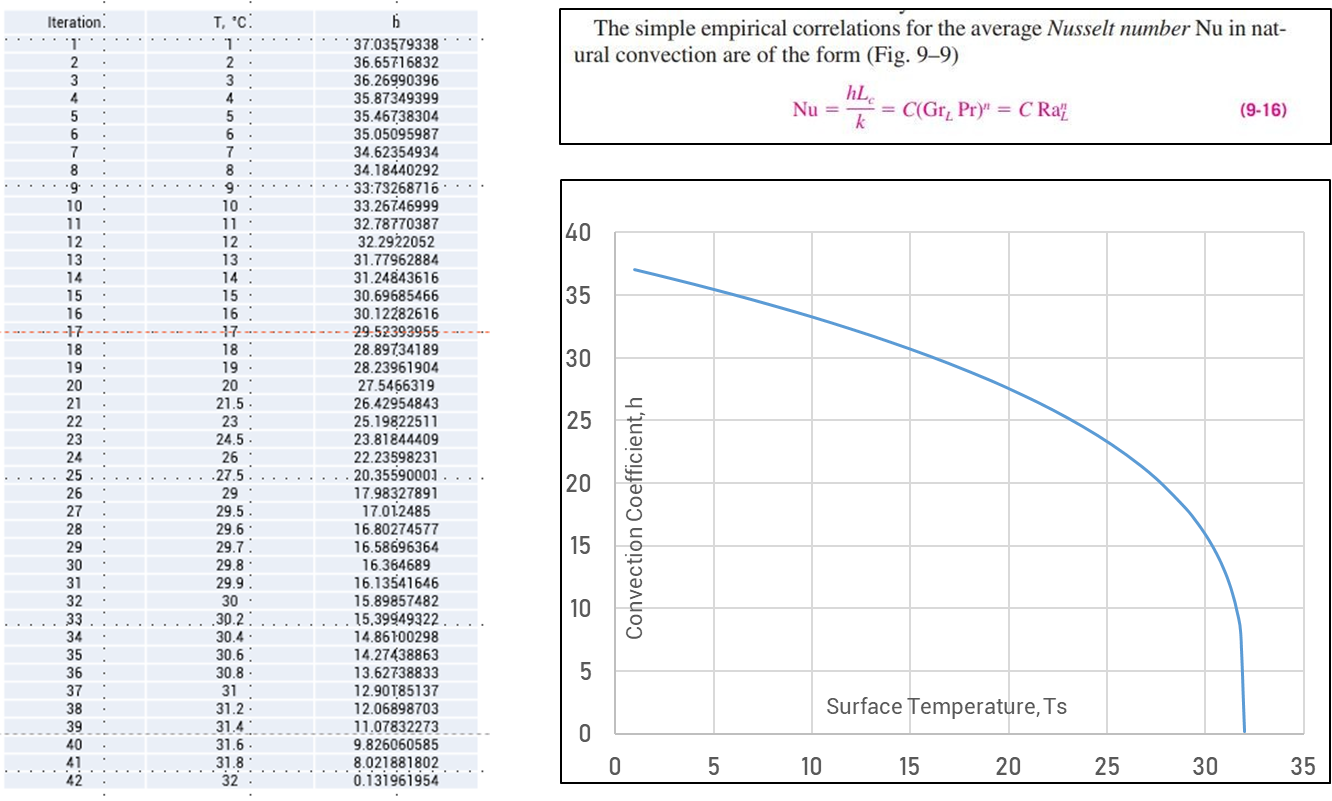

I want to clarify that the convection coefficient (h) was not one constant value over the surface. I did not input one constant value of h over the surface, as I do not know the temperature of that surface (which is the output of this simulation) that is required to calculate h.

Instead, I calculated the values of h for 42 temperature values ranging from -1C (minimum T of the setup, the temperature of the inside face of the refrigerator door) and 32C (maximum T of the setup, the ambient temperature) using the following equations, and input a tabular data of h vs Ts in the field of Convection BC.

So, as the geometry is not of uniform thickness (the actual model I showed in my second reply), the outer surface temperature will vary, and ANSYS will solve the model using different values of h for different nodes, according to their corresponding surface temperature.

Again, the L value used in calculation of h is of the actual refrigerator door, not of the reduced (upper third portion of the refrigerator door) model. My understanding behind it is that I only reduced the geometry for computational efficiency. The surface of that reduced portion would've had the same effect of h if the whole model was taken. So h should account for the whole surface.

This was my overall understanding of the simulation. I would like to understand if there's anything noticably incorrect in my approach.

Having said all that, I did not understand what you meant about using 'the average' value of h, but feel free to skip it if it not related to the updated contex anymore.Lastly, I would prefer Mechanical over Fluent or CFX as a conduction based solver seems sufficient enough in simulating such simpler cases of heat transfer where we do not require to model the fluid flow. The aim of this simulation is to simply find out the temperature on the outer face of a refrigerator door. The geometry might be complex but the overall setup here is pretty simple. As ANSYS Mechanical provides enough flexibilities in the input of h, I definitely want to put those to use before, if not rather than, opting for a computationally more expensive CFD solver.

Once again, I appreciate the insightful discussions and support. Thank you for your enormous patience.

-

July 7, 2023 at 12:06 am

mjmiddle

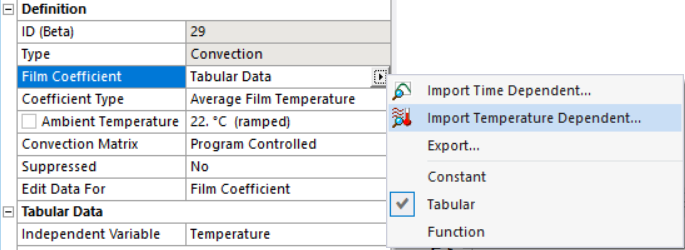

Ansys EmployeeWhen I said average h, I was considering using a constant for h, but sure, there are other options for a variable h rather than just importing a time or spacial varying value from a linked fluid system or "External Data." You can use an equation in x,y,z, or time, or use tabular with Temperature as independent variable, or import time or temperature dependent data.

-

- The topic ‘Effect of Surface Area in Convection in Steady State Thermal Simulation’ is closed to new replies.

-

5069

-

1771

-

1387

-

1248

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.