-

-

January 17, 2025 at 8:39 pm

Zwernjayden

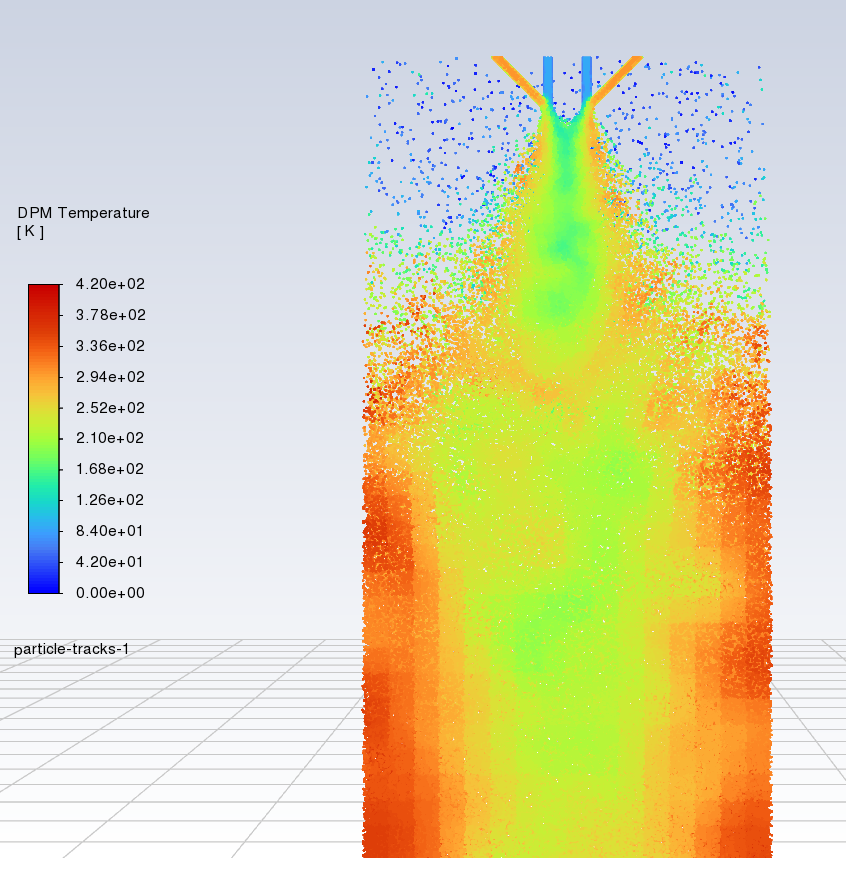

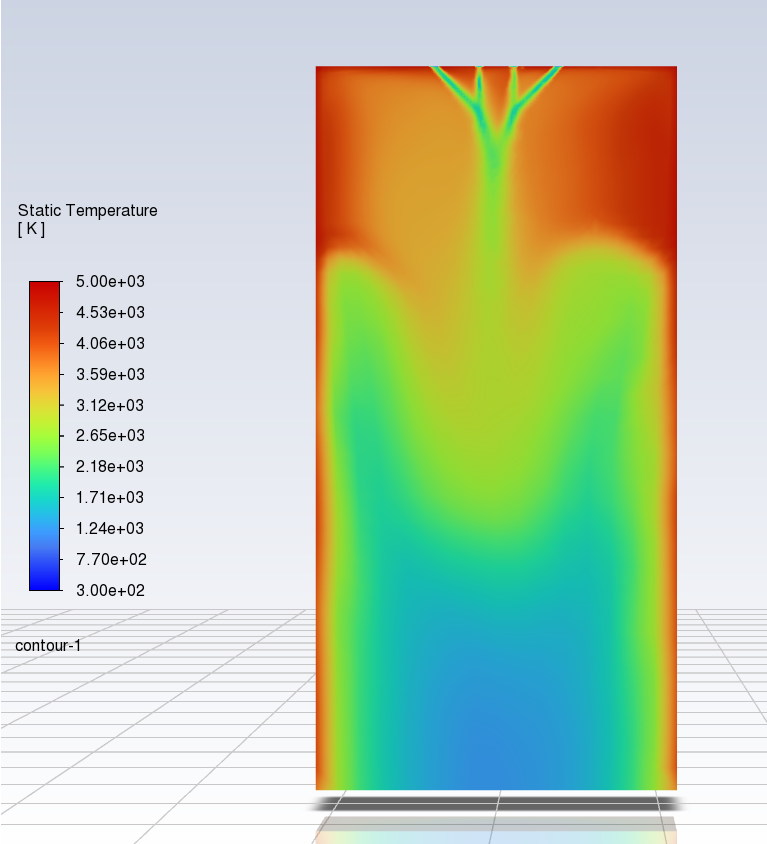

SubscriberI am working on a breakout model for one impinging injector into a combustion chamber using DPM. I am using EDM to model combustion. That being said, the multicomponent droplets are not heating up very fast so evaporation/combustion isn't occuring. It should be evaporating quickly after the impingment occurs instead of filling the whole domain. I have tried fixing the wall temp at 5000 to assist in convective heat transfer, but it doesnt seem to help. I have also tried patching in a high temp mid-simulation but it rapidly cools down before evaporation occurs

Steady state

energy on

kw-sst turbulence model

species transport

- eddy dissipation

- ethyl alcohol air mixture

- relax to chemical equilibirum

Discrete phase

- Interaction with continous phase

- unstead particle tracking

- update DPM sources every flow iteration

- DPM iteration interval = 1

- particle time step 1e-5

- max number of steps = 500

- Pressure dependent boiling

- temp dependent latent heat

- two-way turbulence coupling

- stochastic collision

- breakup

- volume displacement

- tried coupled heat-mass solution on but it seemed to do nothing

Multicomponent surface injections

- diameter = 0.0018542 m (equal to diameter of orifice as I want it to act as a continous liquid jet)

- flow rate 0.025 kg/s for each injection

- two injections are 0.25 h2o(l), 0.75 c2h5oh(l), T=300k

- two injections are 1.0 o2(l), T=90k

Vaporization set to convection/diffusion-controlled as evaporation should occur very quickly

BC

- Pressure outlet (0 psi)

- wall set to 5000k (hope was this would result in evaporation but ideally it would be adiabatic)

- Operating Conditions set to 313.7 psi as this case will be used for high pressure combustion chamber

Standard initialization at 3000k, patched in whole region to 3000k in hopes evaporation to occur. All residuals converged except continuity

-

January 20, 2025 at 2:33 pm

Rob

Forum ModeratorCheck your mesh as I shouldn't be able to see squares in the DPM temperature.

Have you got enough energy in the system to evaporate the droplets? Combustion can only happen if the liquid fuel is a gas, so, if you don't have anything to react it's going to quench very quickly. So, review what species are in the can, and whether the droplets evaporate into those species. Once that's all OK, review the combustion models: my knowledge of combustion chemistry is OK, my knowledge of combustion modelling is somewhat lesser.

-

January 21, 2025 at 9:40 pm

Zwernjayden

SubscriberI will refine my mesh, I just made it course initially to problem solve. In the real system, the engine is ignited with a small estes solid rocket motor which works very consistantly, and is able to evaporate the liquid propellants in the initial transient. In the model, I attempted to simulate the initial evaporation by patching in a high temp. The issue is it seems that DPM isnt able to sustain continous evaporation and combustion unless there is a secondary inlet of a gas phase for fuel or oxidizer. The evaporated mass is on the order of 1e-5 kg/s when the injected mass is 0.1 kg/s or so. In terms of increasing the initial energy of the system. Could I try setting a high heatflux into the chamber until the solution stabalizes, then set it back to adiabatic and wait for it to converge?

-

-

January 22, 2025 at 9:42 am

Rob

Forum ModeratorThat may work, think on the fire triangle: you need heat (easy with bc's), fuel (need to evaporate the liquid) and oxident. If you evaporate too much fuel in the wrong place it'll still not burn well. You can FIX temperatures (cell zone option) in a smaller region to mimic the igniter until it's properly lit. Patch usually works, but you may want to check the DPM fraction (look at what DPM Concentration means and work back from that) to see if you can actually light the flame.

-

January 22, 2025 at 11:56 pm

Zwernjayden

SubscriberI tried fixing the tempurature in the entire region to as high as 5000k and the evaporation rate is still extremely low. The particles are just not evaporating as fast as in real life

-

-

January 23, 2025 at 9:12 am

Rob

Forum ModeratorBe wary of fixing the whole domain as it means Fluent can't adjust the temperature anywhere.

Check droplet composition, and then formation enthalpy: are you evaporating the correct material(s)?

-

January 24, 2025 at 12:18 am

Zwernjayden

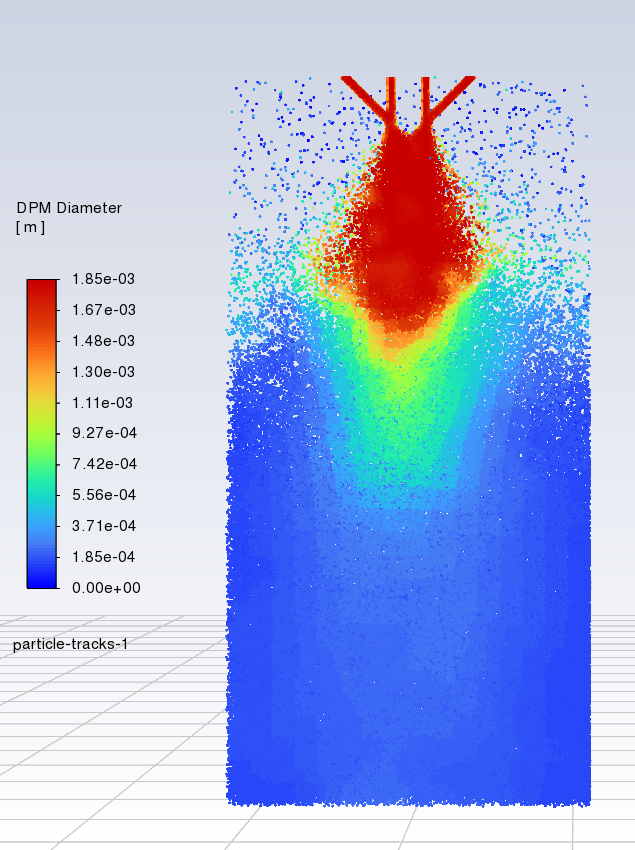

SubscriberYep I am sure about the materials. I think the issue is that droplet collisions don't cause the droplets to breakup. They only breakup due to interactions with the continous phase. That means the droplets are not as small as in real life. Is there a way to fix this?

-

-

January 24, 2025 at 9:48 am

Rob

Forum ModeratorThe break up and collision models should take all forces into account. How many DPM materials have you got? Read how the collison models work.

-

January 24, 2025 at 10:05 pm

Zwernjayden

SubscriberThat unfortunately isn't true as you can see from the DPM diameter image I added. In real life, the atomization occurs due to the collision of the liquid jets which clearly isnt happening. I have tried multiple test cases, and the breakup of droplets are only occuring due to interactions with the continous phase. The DPM material is one multicomponent template of c2h5oh(l), h2o(l), and o2(l). For the fuel injections o2 is set to zero, and for oxidizer injection the ethanol and water is set to zero. I have also tried using a droplet model for o2 instead of multicomponent but I get the same result.

-

-

January 27, 2025 at 12:02 pm

Rob

Forum ModeratorIf you focus the range to show what's going on around the nozzle are you also getting large droplets relative to the injected diameter?

-

January 28, 2025 at 10:19 pm

Zwernjayden

SubscriberYa I set the droplet size to the size of the injector orifice to act as a continous stream.

-

-

January 29, 2025 at 9:40 am

Rob

Forum ModeratorSo no collisions in the nozzle resulting in larger droplets?

-

January 31, 2025 at 2:41 am

Zwernjayden

SubscriberLike I mentioned, colliding droplets doesn't result in smaller droplets. This doesn't seem to be something fluent can model

-

-

January 31, 2025 at 11:20 am

Rob

Forum ModeratorAre there collisions resulting in LARGER droplets?

-

February 1, 2025 at 12:08 am

Zwernjayden

SubscriberOh sorry I misread your message. No, I have coalescence off, so the droplets do not increase in size. The only thing that occurs is momentum transfer, until they progress far enough into the continous phase to breakup

-

-

February 3, 2025 at 1:31 pm

Rob

Forum ModeratorNo worries. Turn on collision too, that way you can see if there is any break up at all.

-

February 3, 2025 at 8:42 pm

Zwernjayden

SubscriberCollision and breakup I have on, its coalescence I have off. I know collisions are occuring becuase I can physically see the particles changing directions when they collide. Multiple people have told me that ANSYS can't model the breakup of particles due to collisions though.

-

-

February 4, 2025 at 10:14 am

Rob

Forum ModeratorAh, you're right. I'd misread the comment on high Weber collisions.

-

- You must be logged in to reply to this topic.

-

4924

-

1618

-

1386

-

1242

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.