TAGGED: #mechanical-#workbench, time-dependancy, transient

-

-

February 10, 2023 at 4:32 am

NAVID SALAM

SubscriberDear Peteroznewman and Ansys employees,

I would perform the following steps as suggested by Peteroznewman to simulate a double drop test on a mold:

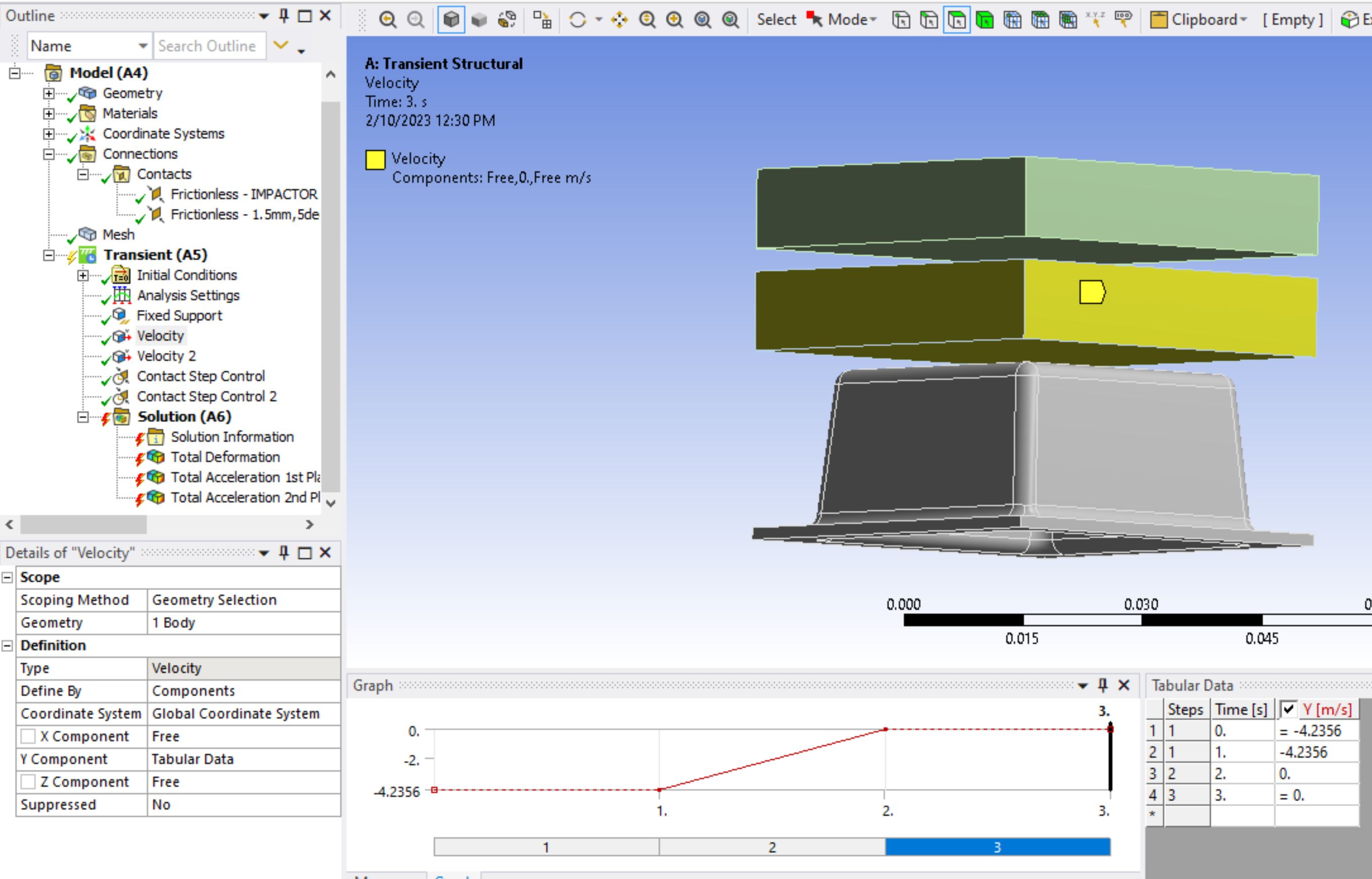

Have two drop plates in the simulation, use Transient Structural and have two contact sets: Contact #1 for Drop Plate #1 contacting the Pulp and Contact #2 for Drop Plate #2 contacting the Pulp. Configure the Drop Plates so they are almost touching the Pulp and use an initial velocity to avoid spending time computing the free fall.

Use a series of steps and control which drop plate contact is active.

These are not the literal steps since it can take two steps to establish an initial velocity for example.

Step 1. Drop Plate #1 has an initial velocity, Drop Plate #2 is supported and solve transient for 100 ms.

Step 2. Time Integration Off, support Drop Plate #1, turn off Contact #1.

Step 3. Drop Plate #2 has an initial velocity and solve transient for another 100 ms.

At the end you will have made two impacts on the same Molded Pulp Package.However, I am facing difficulties in setting up the contact step controls. For example, I am not sure what certain things meant in the aforementioned instructions. Firstly, I am not sure if the steps indicated above are refering to time stepping controls or time stepping in analysis settings. Also by solving 100ms transient, is this value placed in the time stepping controls?

Secondly, when drop plate #2 is supported does it mean that it is suppressed in the time stepping controls during the analysis?

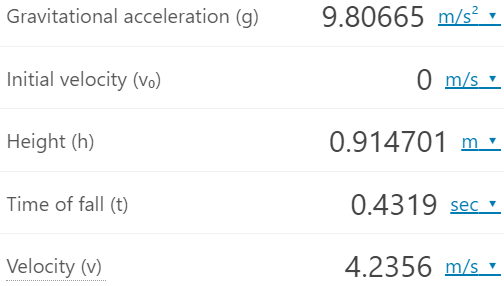

Lastly, I am trying to simulate an initial velocity of 4.23m/s for both plates at different times. Is there a way to make this a step input instead of a ramp input? https://drive.google.com/file/d/1FIjMly0doU8tGfQ5-9Y-v1yzJDAhM4aK/view?usp=sharing

-

February 10, 2023 at 7:29 pm

peteroznewman

SubscriberWhat version of Ansys are you using? Make sure to state the Year and the R version.

I was able to open your file in Ansys Student 2022 R2. But if you are using an older version and I do a lot of work in 2022 R2, you won't be able to open the file I send you.

-

February 11, 2023 at 1:55 pm

NAVID SALAM

SubscriberThank you for the reply Peteroznewman, I am currently using Ansys 2019 R2 software. However, I can download the latest version of 2023 R2 to open the file. May I know where I could find and open the file?

I have tried the double drop with new time step controls but am still struggling to get the results to converge.

https://drive.google.com/file/d/15cuybrnNjNV9HbsKEuFazJg08lZSoqEE/view?usp=sharing

-

February 11, 2023 at 4:01 pm

peteroznewman

SubscriberWhat is the drop height for your simulation (or impact velocity)?

Do you have a simulation for just the first block impacting the MPP?

-

February 11, 2023 at 9:47 pm

NAVID SALAM

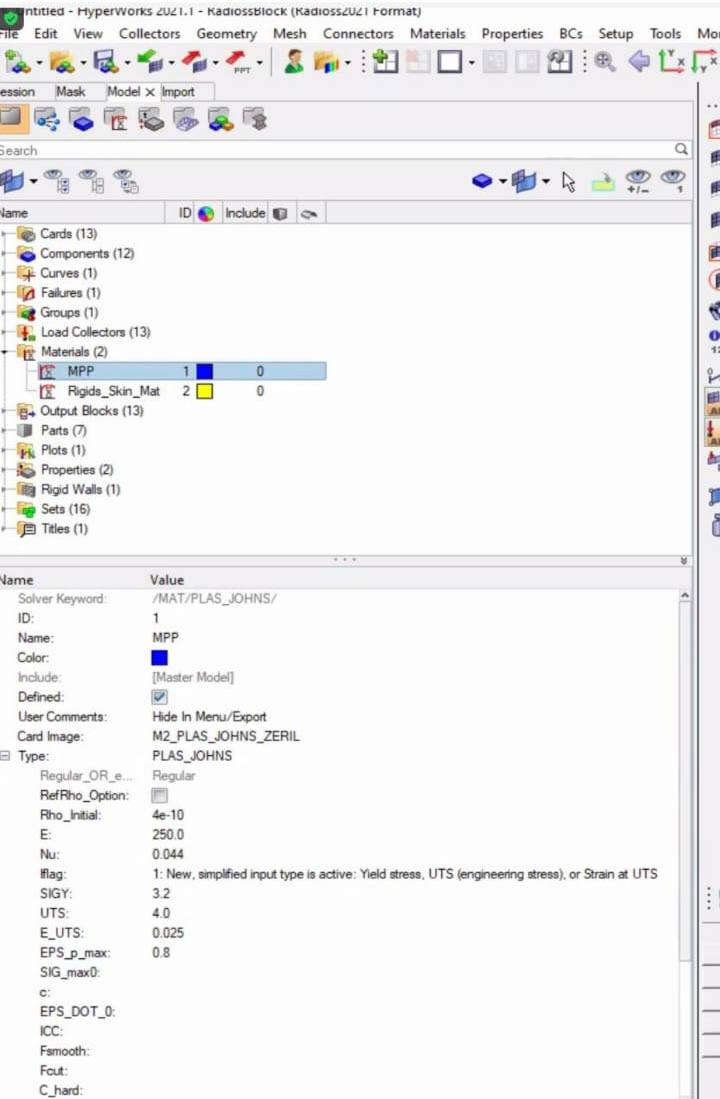

SubscriberI have attached the file for the single drop test on the molded pulp below. It uses an explicit dynamics solver with a constant velocity of the drop plate at 4.23562 m/s and therefore drop height of the plates do not matter and can be almost touching the MPP as you mentioned. Material properties have also been included. I believe we need to use the transient structural solver for the double drop simulation but am still struggling to find convergence.

https://drive.google.com/file/d/1eBFMoX5ivK3O-gqwAo_BupNyqxF69GVm/view?usp=sharing

-

February 12, 2023 at 3:12 am

peteroznewman

SubscriberHere is a Single Drop Example model using Transient Structural in Ansys 2022 R2.

-

February 12, 2023 at 7:06 am

NAVID SALAM

SubscriberHi Peteroznewman,

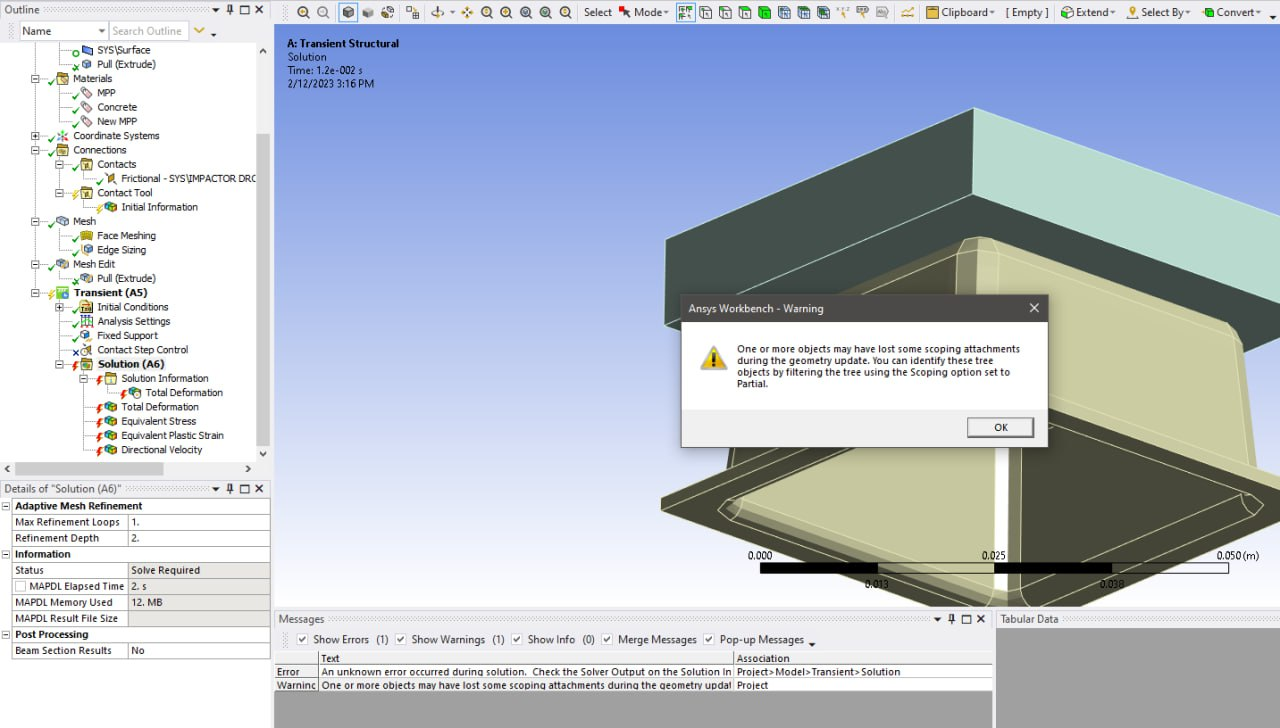

Thank you for the file. I have studied the file and have understood the addtional tabs added to the project. I have just one error on the meshing as attached below.

Besides this, do you have any suggestion on the time stepping controls to facilitate the controlled suppression and contact of the plates with the MPP? A simulation file on this would be much appreciated.

-

February 12, 2023 at 12:09 pm

peteroznewman

SubscriberIf you installed Ansys Student 2022 R2 and you open the archive file I provided, if you hit the Solve button, it will start solving.

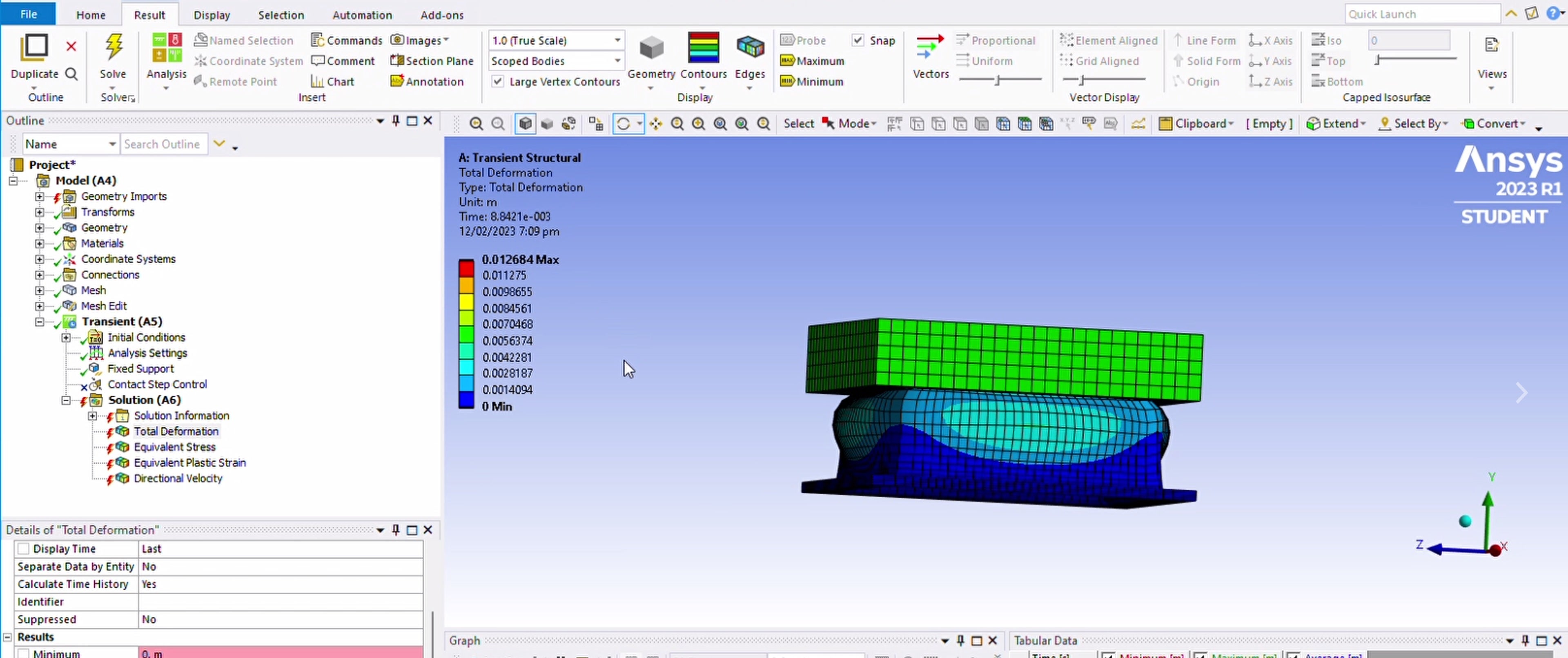

For the MPP material, you need to provide a failure criterion such as the total strain when failure occurs, often called Elongation, or the Ultimate Tensile Strength. When this first block compresses the MPP, the Total Strain reaches 0.935 in the simulation, which is probably way past the point when failure occurs. However, because failed elements that should have been removed were not, the simulation stops with an error that the element is turning inside out. Remeshing the part with smaller elements might make the model run longer. It took about 75 minutes to solve to this point. It will take longer with more elements.

Note that this model is slightly off from the solid you had. I took the outer surface of the solid, but then instead of using the Mesh Pull inward, I pulled the mesh outward, so the MPP is 1.5 mm larger than it should have been. You can redo it by copying the inner face and pull it outward. I think pulling inward is likely to create bad elements.

-

February 12, 2023 at 2:23 pm

NAVID SALAM

SubscriberAlright I have managed to get the simulation to start solving in Transient Structural. Do you have an idea how I can now input time step controls to facilitate a second drop test/second impact? An impact that will fulfill the following steps:

Step 1. Drop Plate #1 has an initial velocity, Drop Plate #2 is supported and solve transient for 100 ms.

Step 2. Time Integration Off, support Drop Plate #1, turn off Contact #1.

Step 3. Drop Plate #2 has an initial velocity and solve transient for another 100 ms. -

February 12, 2023 at 5:48 pm

peteroznewman

SubscriberYes, I have an idea how this might be done as I outlined in my first reply.

Step 1 was attempted in the model I provided. During the solution, the deformation was so high that one of the elements turned inside out and the solution stopped before the first block's downward velocity slowed to zero. Look at the Directional Velocity of the block, it starts at -4.24 and the solution errors out while the block is still going down at -1.33 m/s. This all happened in 4.8 ms.

In an earlier run, the first block slowed all the way to zero then the stored elastic strain energy began lifting the block up and developed some upward velocity. However, in that run, I did not include the sides of the MPP, only the top face and blend radius faces around that to make contact with the block and so during the solution, the sides penetrated through the block, so I added those faces in the model I provided.

Here is the drop height calculated from the impact velocity you provided. Does this look correct?

If you drop the first block from a lower height, the impact velocity will be lower and the solution will be more likely to bounce the first block up and off the MPP before the elements turn inside out. Are you interested in providing a lower impact velocity?

Ideally, the block will bounce up and off the MPP and at that time, the contact with the first block can be turned off. That is because the MPP will be close to being in equilibrium, which it must reach after the contact with block 1 is turned off and contact with block 2 is turned on.

You need to provide information on the failure criterion of MPP as I requested in my previous post so that the step 1 can get to that state.

Where did you get the values of Yield Strength = 3.2 MPa and Tangent Modulus = 25 MPa for the MPP? Ideally, you have a coupon of MPP that was tested in a Tensile Testing Machine to obtain the Stress-Strain curve all the way to failure. You could use that curve to develop a failure criterion in the material model.

-

March 2, 2023 at 9:51 am

NAVID SALAM

SubscriberHey Petro,

I have done some digging and found out that the UTS is 4MPA. I have attached other material properties below here. The drop height calculated is correct. Is it necessary to provide a lower impact velocity as that specific height is the main concern in my study?

With this failure criterion, is it possible to know the workflow of how I would be able to conduct a smooth double drop with 2 plates dropping on the MPP?

-

March 2, 2023 at 7:02 pm

peteroznewman

SubscriberMy first attempt resulted in an element turning inside out before the block reached zero velocity. I just remeshed with half the element size and am running that to see if the simulation makes it further than the first attempt.

Have you successfully run a single drop and had the first block bounce off the MPP?

-

March 6, 2023 at 10:37 am

-

March 6, 2023 at 11:50 am

peteroznewman

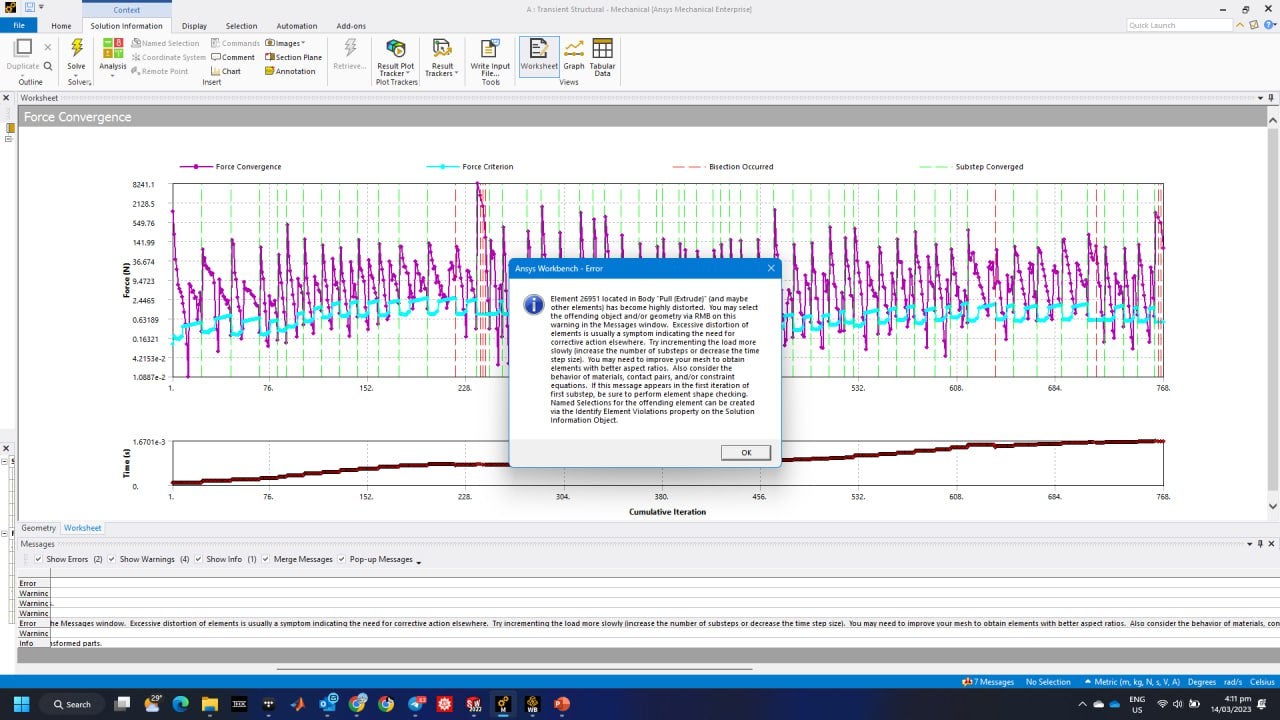

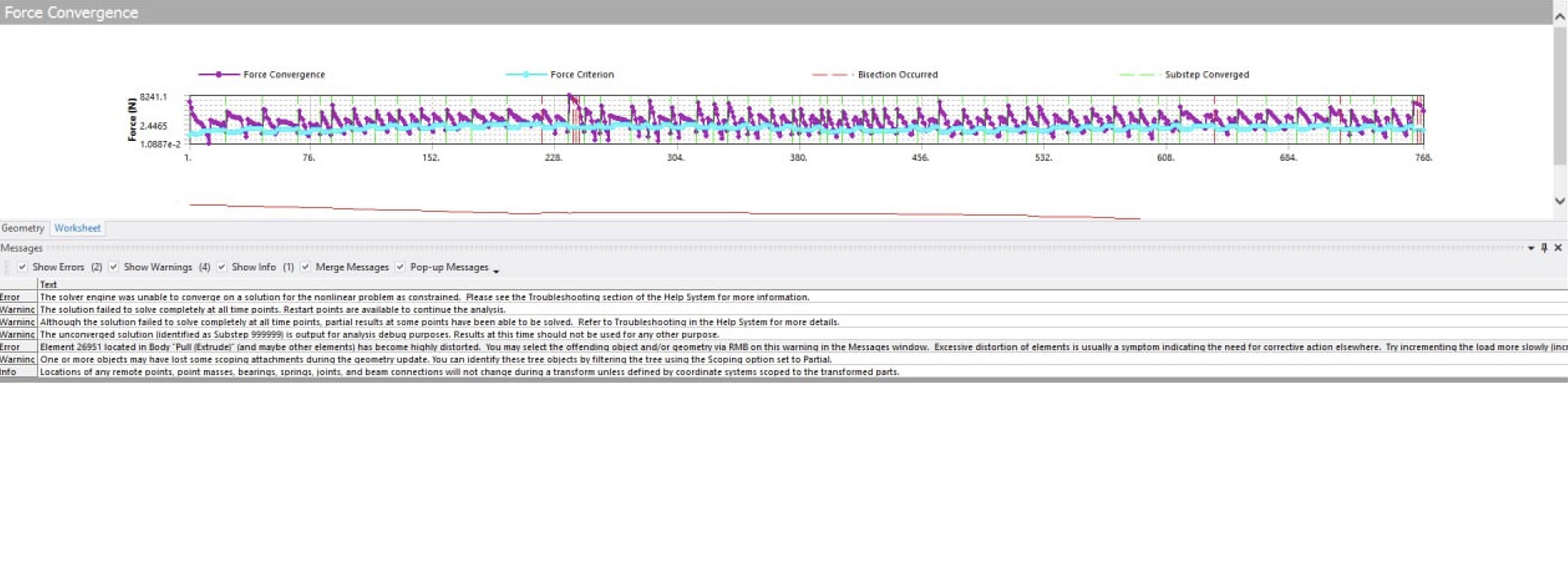

SubscriberYou aren't showing the error that stopped the simulation. You have to look at the details of the error and change the model to see if that takes the solution further.

-

March 27, 2023 at 3:41 am

NAVID SALAM

Subscriber -

March 27, 2023 at 3:42 am

-

March 27, 2023 at 9:14 pm

peteroznewman

SubscriberThe error is a highly distorted element and were unsuccessful incrementing the load more slowly and you don't want to reduce the load to the point where the simulation completes without reaching the point where the highly distorted element happens.

The next step is to remove the element from the simulation before it becomes so highly distorted that it stops the simulation. Use APDL code that will search for elements that are getting highly distorted and use the EKILL command to remove them from the simulation before they stop the solver. An example of that is shown in this discussion. I can't help you with that.

Rather than using EKILL, when I have a problem like this, I turn to Explicit Dynamics which has a built-in, automated feature called Erosion that acts like EKILL, removing elements that have failed. This requires no code. The problem is there is no easy way to make multiple impacts on the same structure in Explicit Dynamics.

-

March 27, 2023 at 9:35 pm

NAVID SALAM

SubscriberThank you for your reply, in the event I were to be able to impose the EKILL command, do you know the method and time stepping parameters to ensure that the second plate drops on the MPP after the first impact in Transient such that 2 drops happen in 1 run of testing?

-

March 27, 2023 at 9:45 pm

NAVID SALAM

SubscriberAlso it seems that the APDL link is no longer available so I can't find it in the discussion you linked.

-

- The topic ‘Double drop test for Molded Pulp Packaging’ is closed to new replies.

-

5274

-

1885

-

1403

-

1257

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.