-

-

February 15, 2021 at 12:19 pm

M_reda

Subscriber

nI'm simulating a 6/4 SRM I create the model by RMxprt and export it to maxwell, but I notice that there is a big difference between the result of torque from the 2D model (green) and the 3D model (one-forth of the model) and half of the 3D model (blue). so is it a problem of accuracy or there is something wrong?nMy second question is how to export the full 3D model from RMxprt because when I use (Fractions 1) it gave me just the half model not the full.nn

nI'm simulating a 6/4 SRM I create the model by RMxprt and export it to maxwell, but I notice that there is a big difference between the result of torque from the 2D model (green) and the 3D model (one-forth of the model) and half of the 3D model (blue). so is it a problem of accuracy or there is something wrong?nMy second question is how to export the full 3D model from RMxprt because when I use (Fractions 1) it gave me just the half model not the full.nn

-

February 16, 2021 at 2:30 am

NKC

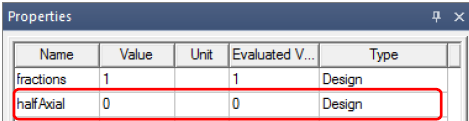

Forum ModeratornHi @M_redanThe assumption when using 2D cross-section to represent a 3D model is that the fields are evenly distributed along the axial direction. This assumption is reasonable when the stack length of the machine is long enough such that the end effect of 3D model can be neglected. However, if your machine has a short stack length the assumption does not match the actual model well so you will get that amount of difference. You will see the difference drops as the stack length increases.n The difference between 3D and 2D model are mainly the end winding effect and the fringe effect in stator/rotor cores. If you have a short stack length it is likely that the difference can not be ignored. The difference is the result of the base assumption of 2D rather than the result of your settings.nSo I would suggest just use 2D simulation for rough calculation and use 3D for fine-tuningnFor your second Question: Select 3D model design, and in the properties window make half Axial value to zero, to get a full machine model in 3D.n nRegardsnNavyan

nRegardsnNavyan

-

February 17, 2021 at 1:31 pm

M_reda

SubscriberThanks Mr nchode your answer really helped me a lot.n n

-

Viewing 2 reply threads

- The topic ‘different results from 2D and 3D simulation’ is closed to new replies.

Innovation Space

Trending discussions

Top Contributors

-

5169

-

1836

-

1387

-

1249

-

1021

Top Rated Tags

© 2026 Copyright ANSYS, Inc. All rights reserved.

Ansys does not support the usage of unauthorized Ansys software. Please visit www.ansys.com to obtain an official distribution.