-

-

September 9, 2024 at 8:30 am

sfsalharthi1

SubscriberHello everyone,

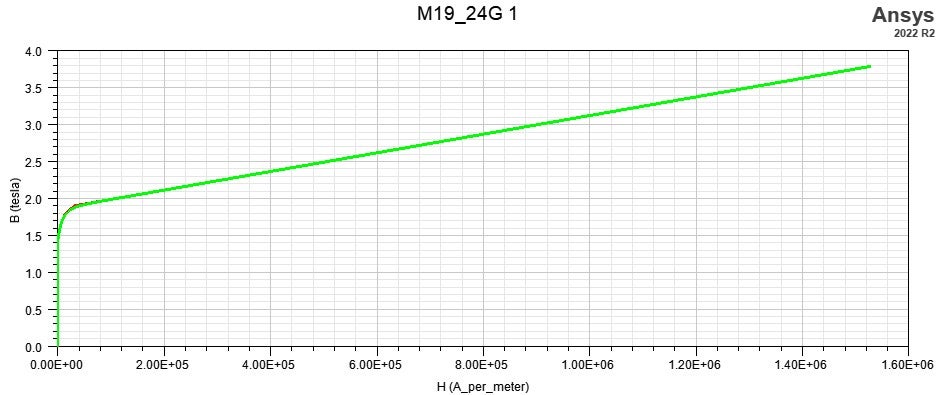

I'm currently simulating an electric motor and generating a Torque vs. Time graph (Transient Simulation). The issue arises with the stator material: when I assign M19-24G, it produces torque close to the expected value. However, when I switch to a material like Cogent Power M330, which has a higher saturation flux density and permeability than M19, the torque drops by about 15%. Interestingly, when I select a superior material (containing cobalt) with significantly higher saturation flux density and permeability, the torque returns to the expected value.

I've experimented with various mesh sizes, boundaries, and regions, but the results consistently show the same pattern. Even when I keep everything identical in the design and only change the B-H curve (which I have verified and tested with multiple grades), the issue persists. I'm honestly quite confused at this point, and I would really appreciate any suggestions you may have.

Thank you!

-

September 9, 2024 at 11:46 am

ErKo

Ansys EmployeeHi

I would suggest to post this in the Electronics forum (e.g., used for Maxwell related Que.), as this forum is for CAD, Spaceclaim and Discovery and not EMAG analysis.

Thank you

Erik

-

- The topic ‘Different Materials Different Torques’ is closed to new replies.

-

4783

-

1566

-

1386

-

1242

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.