TAGGED: fatigue-analysis, fatigue-life

-

-

May 17, 2024 at 2:57 pm

Sneha E S

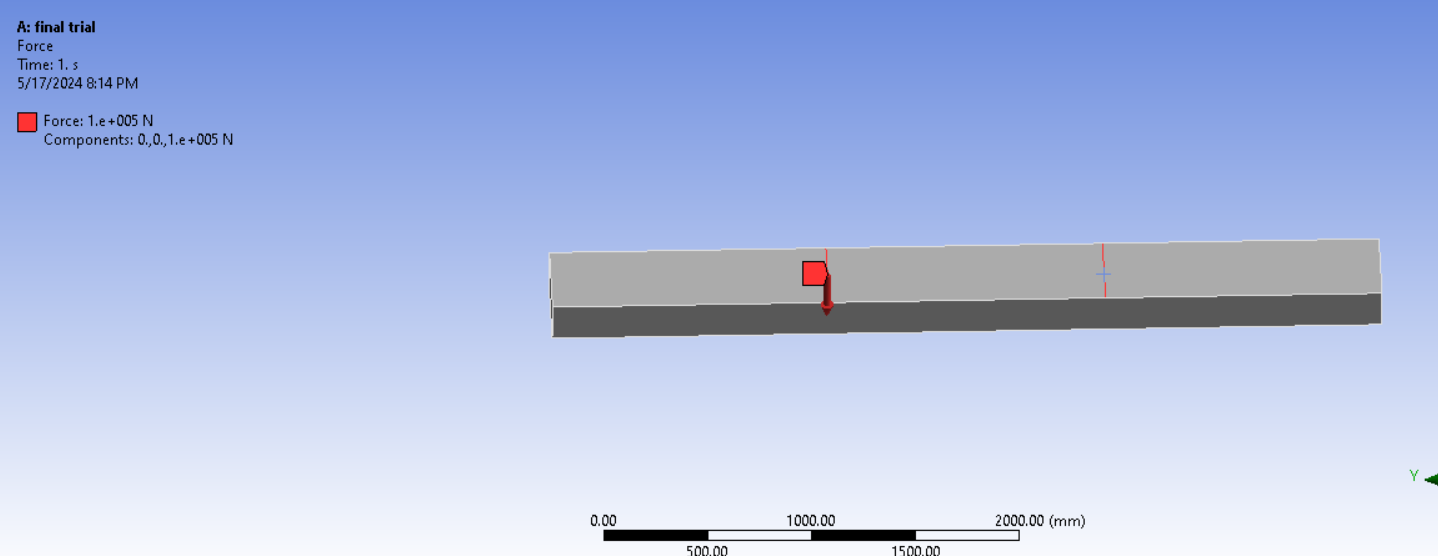

SubscriberI am analyzing an RCC beam for fatigue analysis, and I applied a cyclic load of 100kN on two points. These are the steps I followed. Is my result correct?

1. I applied a load of 100kN on two points and solved it for total deformation, and noted the maximum deflection obtained.

2. With this value I created a table of time and displacement. The time or steps given was 100 sec and displacement was 2.8842 mm.

At t=0 seconds, the displacement is 00 mm.

At t=1 second, the displacement is 1.4421 mm.

At t=2 seconds, the displacement reaches its peak at 2.8842 mm.

At t=3 seconds, the displacement returns to 1.44211 mm.

At t=4 seconds, the displacement returns to 0 mm.

At t=5 seconds, the displacement goes to −1.4421 mm.

At t=6 seconds, the displacement reaches its negative peak at −2.8842 mm.

At t=7 seconds, the displacement returns to −1.4421 mm.

At t=8 seconds, the displacement returns to 0 mm.

This cycle repeats consistently without any abrupt jumps, ensuring a smooth sinusoidal variation over the entire time period. The point where I applied load is,

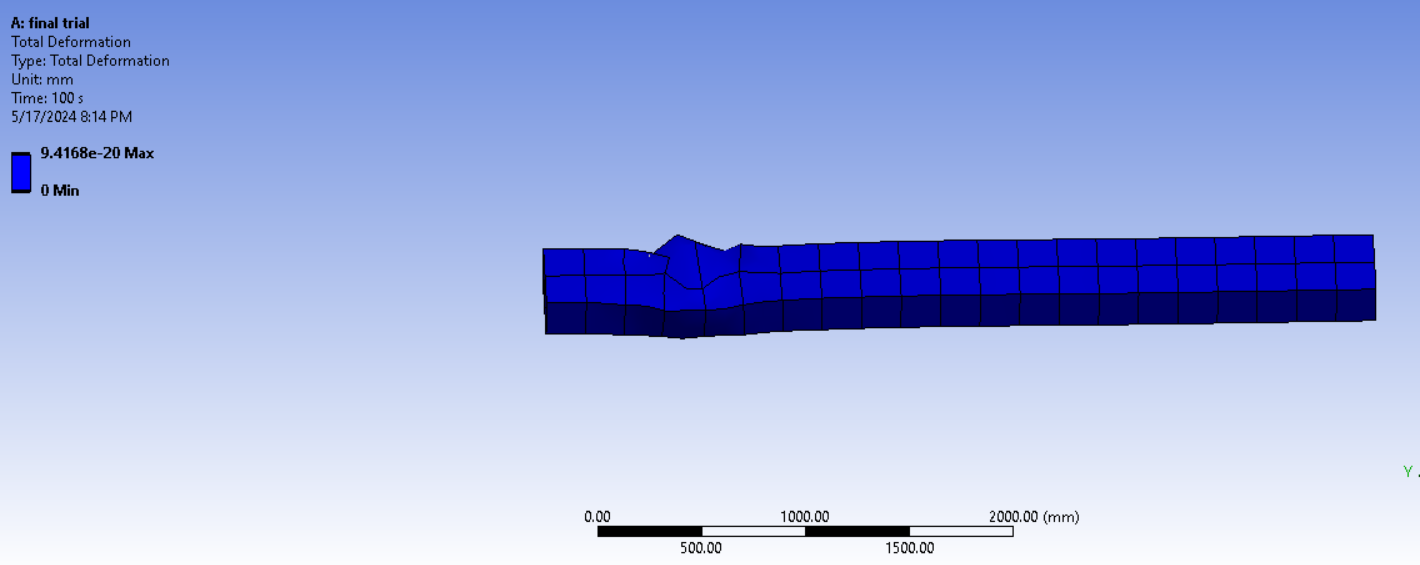

But the plot I got for cyclic loading is,

-

May 19, 2024 at 10:00 am

peteroznewman

SubscriberDon't apply line contact to solid elements. Stress is force/area. A line has zero area, therefore the stress is infinity.

Create a two cylinder bodies to make frictional contact with the RCC beam. Use a small element size under the point of contact. This will allow many element faces on the RCC to make contact with the cylinder and create a finite area so the force applied by the cylinder will create a finite stress.

-

May 19, 2024 at 3:49 pm

Sneha E S

SubscriberThank you,

I added a material over the point where I had to apply load with dimension 100mm x 100mm(a rectangular projection as it was more convenient), but now while solving an error popped, "An error occurred inside the FATIGUE module: Invalid or missing stress life curve." So should I add SN curve for that material as well, if so what should be the value for alternating stress and cycles. The material properties provided were, Young's modulus = 10000 psi and poisson's ratio = 0.49999 also it is an isotropically elastic material.

-

-

May 20, 2024 at 1:00 am

peteroznewman

SubscriberSN curves come from experiments on test coupons of the material of interest. If you are not provided with the SN curve or cannot find one in the literature, then you can obtain material samples and perform fatigue testing on those samples. Fatigue is most common on ductile metals, however you say the material has a Poisson's ratio of 0.49999 which sounds like it is an elastomer such as rubber. Rubbers have a more complex response to fatigue than ductile metals. Perhaps you can do some research on that.

-

May 20, 2024 at 4:49 am

Sneha E S

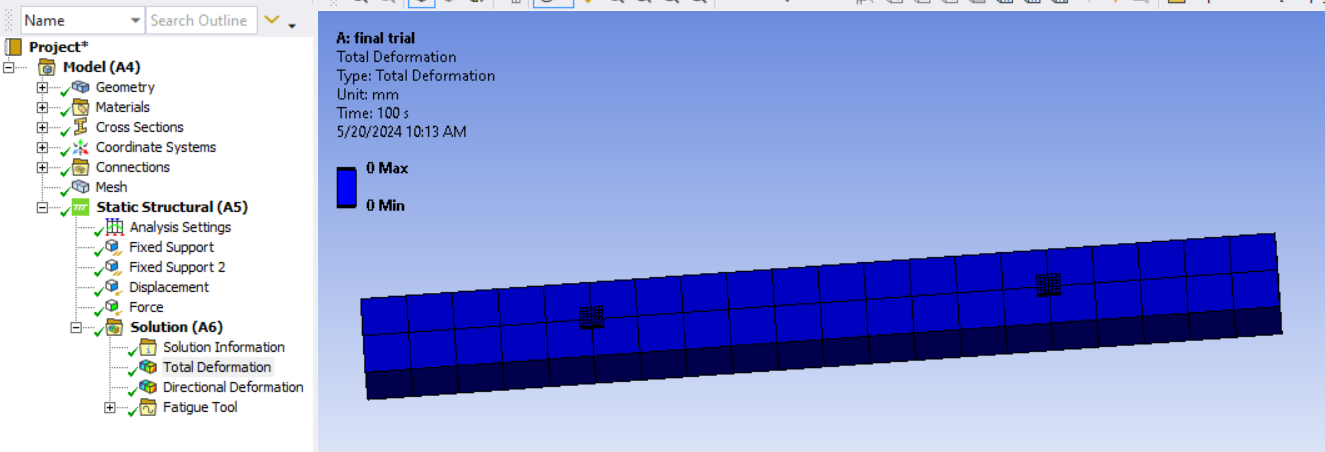

SubscriberWhen i apply cyclic loading, ie displacment with a tabular data which has time and displacement in mm, the model shows zero deflection. When i apply force alone it shows defelection, but when displacement for cyclic

loading is also applied it shows zero deflection.Here i have applied both force and displacement on the two rectangular sections, butat the same time when load is applied all over the face and displacement just over the small section it is the only case when deflection is shown.

-

-

- The topic ‘Why is deflection for fatigue life not at point of loading?’ is closed to new replies.

-

4838

-

1587

-

1386

-

1242

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.