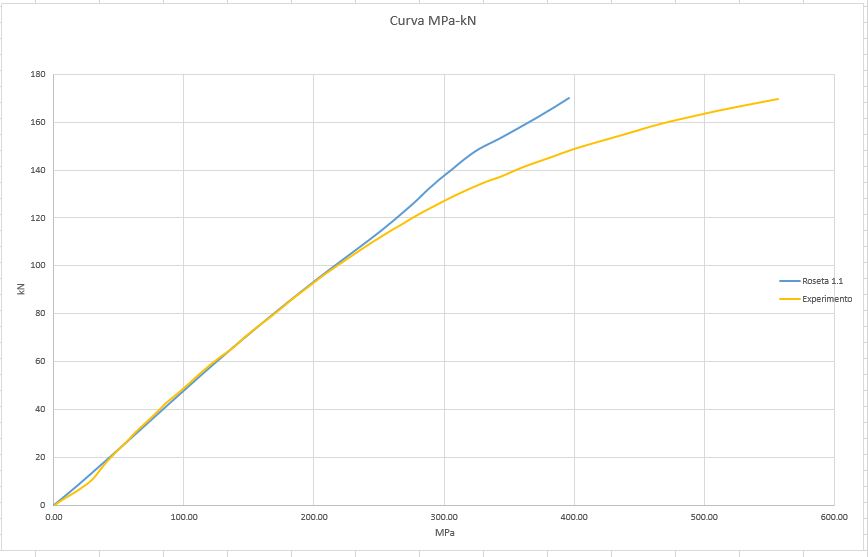

-

-

December 30, 2018 at 2:34 pm

-

December 30, 2018 at 4:23 pm

peteroznewman

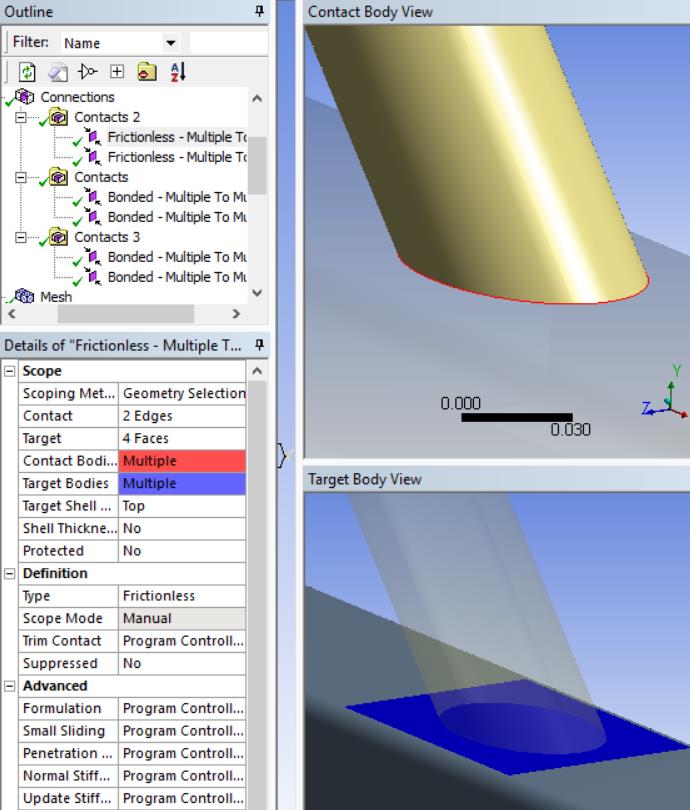

SubscriberI don't understand why you would have Frictionless contact between the edges and the faces.

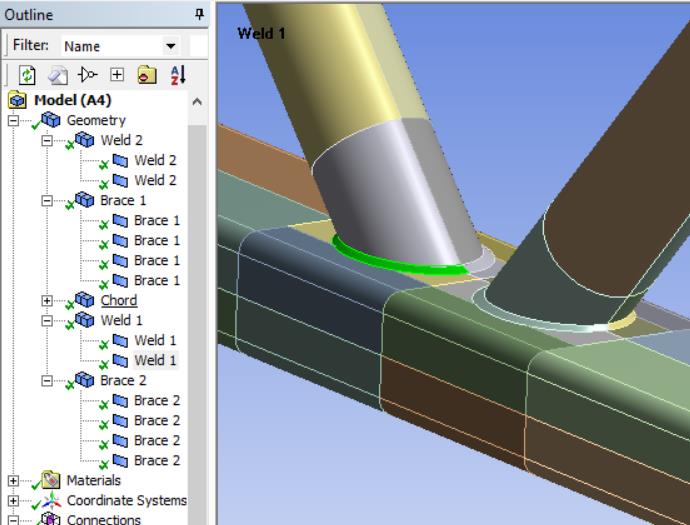

I see that the entire model is made of sheet bodies.

If you convert the welds and all the bodies that touch the weld to solids, you may start to get a better match of the simulation result to the experimental.

Regards,

Peter -

January 3, 2019 at 8:16 pm

mekafime

SubscriberHi Peter,

you want to say that I must in solidworks I have to make a model containing solids and sheets, then export them to ansys and work it like that?

-

January 3, 2019 at 8:26 pm

peteroznewman

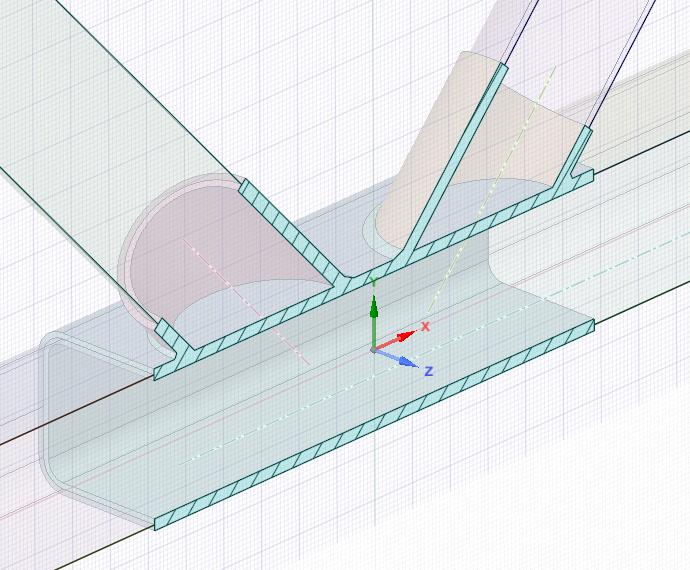

SubscriberThe model you have is entirely composed of sheet bodies that are assigned a thickness. You are using bonded contact to connect edges of surfaces to faces of surfaces.

I am suggesting that you take the center portion of this K joint and use solid modeling to have a solid extrusion that has an actual wall thickness (not a surface with an assigned thickness property). The weld weld bead will be a fillet feature on the edge that is created when the pipe is united (boolean addition) to the tube.

-

January 4, 2019 at 2:49 pm

-

January 4, 2019 at 4:30 pm

jj77

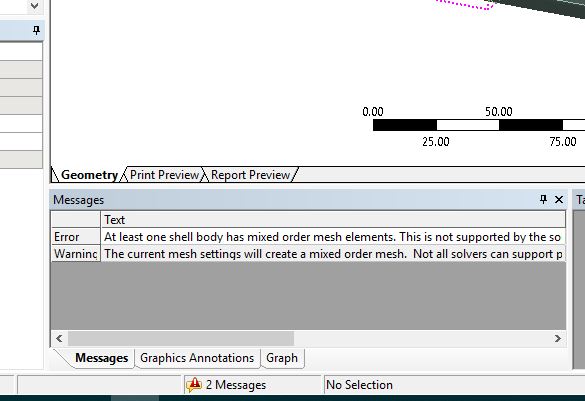

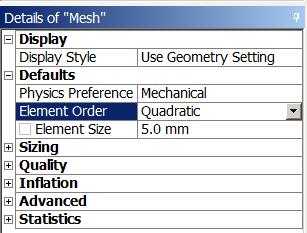

SubscriberThis error says that QUAD8 and QUAD4, or TRI3 and TRI6 elements are used in the same model. That is lower order and higher order shell elements, are mixed together something that is not recommended.

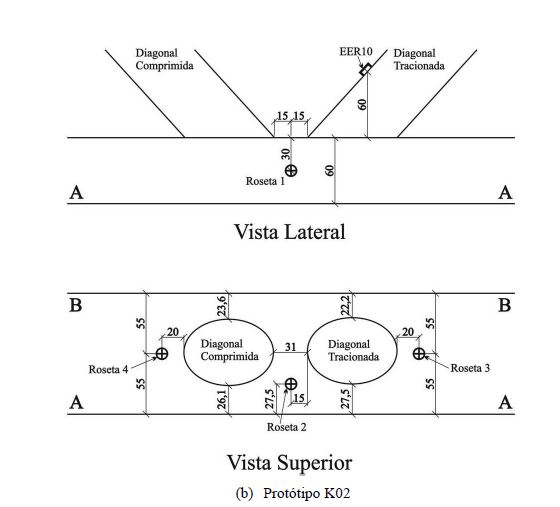

As peteroznewman said, why are there friction less contacts? I assume everything to be welded. If that is the case attached is a half symmetry model that is fully welded as multi-body part so no need for bonded contacts or anything.

Try this and make sure you have the correct material data, shell thickness, and forcing/boundary conditions as the experiments. Also it is important to understand the failure mechanics in your experiments (is it buckling, or global yielding or both), in order to see why there is a difference to FEA.

-

January 4, 2019 at 5:12 pm

peteroznewman

SubscriberHi Mekafime,

JJ77 is right about the error being mixed order elements. You can force the mesher to use only quadratic elements by clicking on Mesh and setting the Element Order to Quadratic

I also agree with JJ77 that a half symmetry model would save you some time.

What I was describing above was the idea that you can have a tet mesh on a solid body at the K-joint, which will allow plastic deformation to occur much more like the real part than the shell model that you have with bonded contact. Then you can have a shell mesh on the extensions from the joint to reduce the node count and have bonded contact between the solid face and the shell edge.

ANSYS 19.2 archive attached. Sorry if I got the ANSYS release you are using wrong. Please mention it each time you attach an archive. I also attached a Parasolid file in the zip file that you can import into DM using File > Import External Geometry File.

Kind regards,

Peter -

January 5, 2019 at 12:23 am

mekafime

SubscriberHi Peter

this solid was created in Spaceclaim? the model sheets are external faces

-

January 5, 2019 at 2:17 am

peteroznewman

SubscriberYes, it was created in SpaceClaim.

What release of ANSYS are you using?

Are you opening the Parasolid?

What geometry editor are you opening it with?

-

January 5, 2019 at 12:59 pm

mekafime

Subscriber1. 19.2

2. Yes

3. DesignModeler

-

January 5, 2019 at 3:58 pm

peteroznewman

SubscriberHere is the same geometry, just in DM now and I linked the geometry cell to the Static Structural model, which I didn't do above.

-

January 12, 2019 at 11:41 am

mekafime

SubscriberHi Peter, What is the tool in SpaceClaim to make the geometry?, the initial solids in sheets were the external faces of the tubes.

-

January 12, 2019 at 12:58 pm

-

January 12, 2019 at 3:21 pm

peteroznewman

SubscriberHello Mekafime,

I used the Pull tool in SpaceClaim to thicken the sheets. I assumed they were midsurface sheets, so I used the "both directions" pull option, but you are telling me they were outside sheets, so you wouldn't use that option.

I agree the drawing shows that symmetry is not possible for this problem.

Regards,

Peter

-

- The topic ‘Curve deviates a lot’ is closed to new replies.

- LPBF Simulation of dissimilar materials in ANSYS mechanical (Thermal Transient)

- Real Life Example of a non-symmetric eigenvalue problem

- How can the results of Pressures and Motions for all elements be obtained?

- BackGround Color

- Contact stiffness too big

- Element Birth and Death

- Python-Script to Export all Children of a Solution Tree

- Which equations and in what form are valid for defining excitations?

-

4597

-

1495

-

1386

-

1209

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.