TAGGED: creep-analysis, mesh, meshing, Quadratic

-

-

April 1, 2024 at 9:42 am

dinhan0394

SubscriberDear all

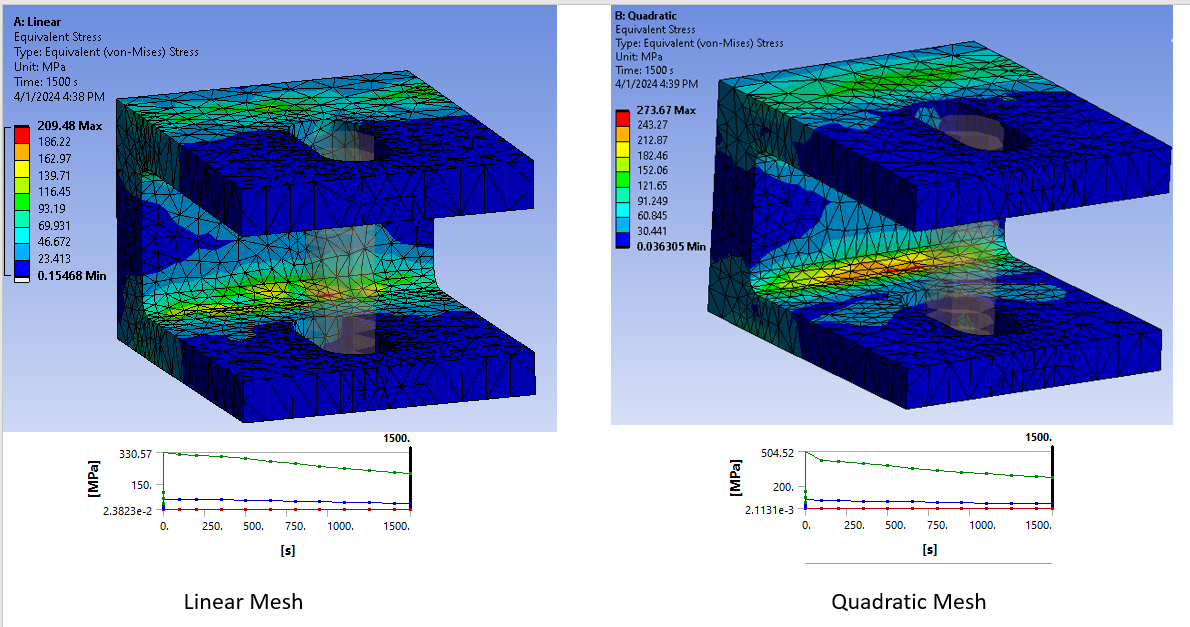

I tried simple creep analysis, but when I changed the default mesh settings to Linear or Quadratic (all other settings keep the same by duplicate project), I got different results

Are there any recommendations regarding the use of mesh in this problem? Or how to determine the exact results?

Thank you,

-

April 1, 2024 at 11:21 am

peteroznewman

SubscriberYou should do a Mesh Convergence Study to determine the "true" value of stress in the model with the quadratic mesh. Add a Mesh Sizing control on the blend radius and make the element size a Parameter. Make a Stress Result at the End Time and make the Maximum Equivalent Stress a Parameter.

Open the Parametric Set box from Workbench. Now you can type smaller and smaller element sizes in row after row. Ideally, make the element size a constant ratio such as 1.5 between rows. If the first row has a size of 1.5 mm, then the sequence of sizes is

- 1.5

- 1.0

- 0.6667

- 0.4444

- 0.2963

Click the Update All Design Points and Ansys will automatically run through all these analyses and place the peak stress in the column with the lightning bolts in it, assuming the solution is not prevented by limits of the Student license or the resources of the computer.

Plot those 5 points and extrapolate to a zero element size. That is the "true" stress for this model.

-

April 1, 2024 at 12:12 pm

Giorgos Papa

Forum ModeratorHello,

When deciding whether to use linear or quadratic mesh for a creep analysis, it's important to consider the specific requirements of your analysis.

According to the Ansys documentation, in nonlinear structural analyses, which would include creep analysis, you will usually obtain better accuracy at less expense if you use a fine mesh of linear elements rather than a comparable coarse mesh of quadratic elements.

URL: https://ansyshelp.ansys.com/Views/Secured/corp/v232/en/ans_mod/Hlp_G_MOD2_4.html.

However, quadratic elements are recommended when Tetrahedral elements are meshing solid bodies or for shell elements on surface bodies with curved edges.

Ultimately, the choice between linear and quadratic elements should be based on the geometry of the model, the type of analysis, and the desired accuracy.

For a creep analysis, if the geometry is not excessively curved and a high level of accuracy is required, a fine mesh of linear elements might be more cost-effective.

If the geometry has significant curvature, quadratic elements might be more suitable to capture the curvature accurately.

On your analysis, where the number of elements on both models is the same, quadratic mesh is expected to yield more accurate results.

Then, performing a mesh sensitivity analysis is recommended to determine a satisfying level of accuracy for your application.

Kind Regards,

Giorgos

-

April 1, 2024 at 3:17 pm

dinhan0394

SubscriberDear all

Thank you for your response.

I know that I need to run the sensitivity analysis to get the accuracy results. But for the first overview, this is nott neccessery due to it will take very long time.

In my mind, the will be different between Linear and Quadratic mesh but I don't the the difference is large like this case (maximum stress in Quadratic mesh ~ 1.5 times of Linear mesh, and in my actual model, the ratio is larger).

-

- The topic ‘Creep analysis – Linear and Quadratic mesh’ is closed to new replies.

-

5194

-

1848

-

1387

-

1249

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.