-

-

October 30, 2025 at 2:34 am

kattar

SubscriberI need to define an injection for a research project dealing with non-uniform multiphase flows.

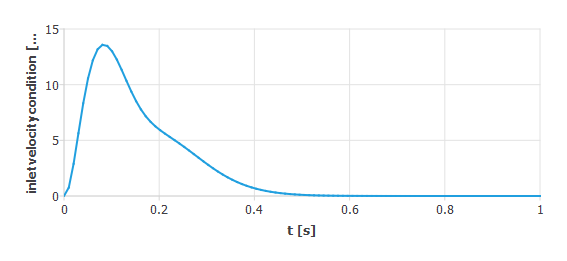

The velocity at the inlet is defined by a piecewise function, and I need to inject particles when the fluid flow is at its max velocity.

Furthermore, I need the particles at the inlet to be travelling at the same speed as the flow at the moment of injectionI need to inject a fixed number of particles that have diameters governed by a distribution table.

Ideally, I would inject all particles at the same timestep, i.e. pvt(peak velocity time)

Is there a way to do this within the gui itself, or do I need to write a udf?

Do I need to specify a mass flowrate (kg/s), or can I specify a #particles/time flowrate

Is it possible to simply release all particles instantaneously at a certain time interval?

Say I didn't want all particles released at one time, and instead wanted them released at constant #particles/time. How would I go about this?

I am including my particle distribution table, and the plot of the function I am using for my velocity inlet condition.

Particle Distribution Table

Dist-chao-table1

drop-diam num-frac

3e-6 4.0

6e-6 55.0

12e-6 20.4

20e-6 6.7

28e-6 2.5

36e-6 2.4

45e-6 2.0

62.5e-6 2.0

87.5e-6 1.4

112.5e-6 1.7

137.5e-6 1.6

175e-6 4.4

225e-6 2.5

375e-6 2.1

750e-6 1.4

Inlet Velocity Plot:

-

October 30, 2025 at 9:07 am

Rob

Forum ModeratorOK, breaking things out a little.

Particle release time - have a look at the injection panel for injection start and stop times. You may need to release over a few time steps but that's down to time step size and how precisely you set the start & stop.

Particle velocity - as you know the flow speed you can set a fixed speed on the particles. Expressions don't fully work within the injections as of 25R2 so you may or may not find you can set the velocity, try it.

Fluent uses parcel theory. We also use parcel and particle interchangeably courtesy of some misunderstandings and programming in the 80s-90s. So, you are not tracking particles you are tracking parcels. We also call droplets and bubbles particles just keep things simple.... So, you're tracking a mass of parcels. This has the advantage of meaning you can track enough parcels to have a statistical output. Ie looking at your mass curve there may only be one of the largest diameter - where do you plan on releasing it from?

So, for the above size range. I would consider creating 5+ injections of fixed size to ensure a good number of parcels per band and set the injection mass to reflect that band. Use DPM reporting (read the User's Guide & look at tutorials) to see how. That means you may have "lots" of larger parcels but only a small mass per parcel.

-

October 30, 2025 at 2:17 pm

kattar

SubscriberRob,

Thank you for replying to my post.

Should I make enough injections so as to allow for each injection to be of constant diameter? (In other words, should I make 15 injections).If not, how do I specify the diamter distribution within the injection? Do I continue to use the tabular diameter distribution option?

Furthermore, how exactly do I specify an exact number of particles for an injection in fluent?

If parcles are used, How do I specify #particles/parcel and number of parcels?

Also, a number of people told me that if I leave the initial velocity of particles as zero, fluent would automatically impose the fluid velocity at that region onto them. Is this true?

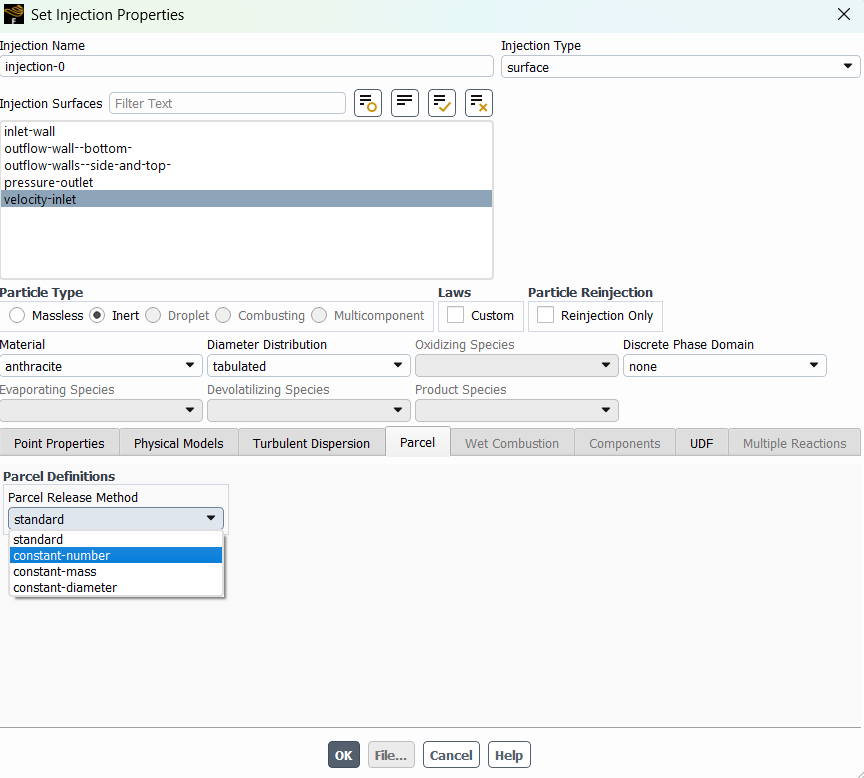

If I set parcel method to constant number, then use randomize starting points to specify number of streams, would this allow me to determine the number of particles injected?

-

October 30, 2025 at 2:24 pm

Rob

Forum ModeratorYou're welcome.

If you want 15 sizes then you may want 15 injections. Tables also work, but depending on mass splits the number of parcels may not be high enough to give a good distribution.

Don't mess with the parcel methods without doing a lot more reading. If you don't have enough mass injected you may not see any parcels and as you're adding mass over a short period there's a good chance it'll not behave as you expect.

As the injection mass is often small relative to the flow particles will accelerate quickly. They enter the domain as set in the panel: so no, they won't enter with the flow velocity if you set 0m/s. It's just difficult to see in the post processing.

Read my comments re parcels again. You are NOT setting a number of particles. Do you really count the particles in your experiment? Or just weigh the impactor trays?

-

October 30, 2025 at 2:32 pm

kattar

SubscriberIn my specific experiment, discrete particles are counted. I am simulating a cough, and the particles are expectorate. Our particle distribution was taken from an experiment that used a laser sheet to measure number and diameter of particles.

So, I would make 15 injections, and release each over one or two timesteps, using the mass flow rate according to the amount of mass in the particular injection, correct?

-

October 30, 2025 at 2:44 pm

Rob

Forum ModeratorAnd how many particles of each size? Do you know precisely where to inject each one?

If you want yes. I'd perhaps review just how much post processing you want to do before using 15 injections. I'd also suggest doing some trials with DPM out files to make sure you're not going to run a model and not get any results.

-

- You must be logged in to reply to this topic.

- air flow in and out of computer case

- Varying Bond model parameters to mimic soil particle cohesion/stiction

- Eroded Mass due to Erosion of Soil Particles by Fluids

- I am doing a corona simulation. But particles are not spreading.

- Centrifugal Fan Analysis for Determination of Characteristic Curve

- Guidance needed for Conjugate Heat Transfer Analysis for a 3s3p Li-ion Battery

- Issue to compile a UDF in ANSYS Fluent

- JACOBI Convergence Issue in ANSYS AQWA

- affinity not set

- Resuming SAG Mill Simulation with New Particle Batch in Rocky

-

4167

-

1487

-

1358

-

1189

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.