TAGGED: corrosion, electrochemistry, multi-species

-

-

September 22, 2023 at 5:20 pm

Shamkhal Mammadov

SubscriberHello Forum,

I am working on research connected with CO2 Corrosion in PIpe. I am doing also experiments and trying to match them with the model in Ansys.

I am currently facing a problem related to the definition and calculation of Corrosion rates in Ansys. After completing the simulation I go to the results sections and I can observe the results of the corrosion of the pipes. in any plotting section, I choose the potential section, where I have two corrosion results.

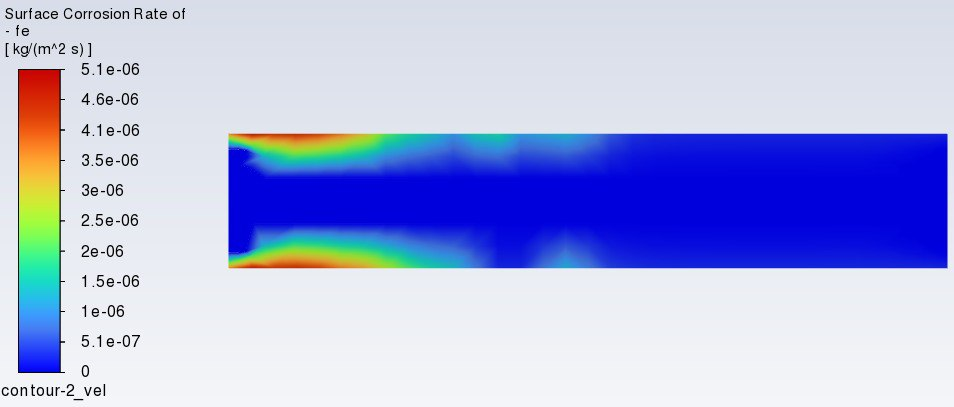

1) Surface corrosion rate in: kg / (m^2 * s);

2) Total Accumulated Corrosion rate, in: (kg / m^2);

I do understand that the second value is integral to the first one throughout the simulation (in my case 1 year).

However, I need to understand how the surface corrosion rate is calculated by the software. I am planning to convert this value to mm/y and compare it to literature data and my experiments.

I have read the 2023 R2 - Ansys Manual and there is no information about this.

-

September 25, 2023 at 3:03 pm

Rob

Forum ModeratorAssuming you don't need to set the wall material in the bc panel to be the material in the reaction I suspect the kg/m2/s is based on the reaction mechanism. That's likely the facet (cell) area and you then need the wall material density that you'd like to corrode. That would be consistent with the erosion models.

-

September 25, 2023 at 3:22 pm

Shamkhal Mammadov

Subscriberthis is CO2 corrosion. Not an Errosion case.

I agree with your assumption, this is a fluid domain. I selected a fluid wall to be a boundary for combined electrochemical reactions.

I have been trying to get help from Ansys, but no one knows.

Will something change if I create a pipe instead of a fluid domain, and setup a corrosion reaction to happen on the pipe's internal wall?

-

September 25, 2023 at 3:41 pm

Rob

Forum ModeratorDon't you need the fluid region to attach the reactions too? The fluid side species mixture may alter the corrosion rate. Note, I've not tried the model yet: I am very familiar with the erosion model and it's initial UDF implementation.

-

September 25, 2023 at 3:53 pm

Shamkhal Mammadov

SubscriberI have no idea. Could you please try to also run a case with me? So we can try to figure this out?

-

September 26, 2023 at 12:37 pm

Rob

Forum ModeratorOK, looks like wall material density has no effect on the corrosion rate. So, kg/m2/s is likely as suspected and you need facet area and wall material density in a function to switch to mm/s.

-

September 28, 2023 at 3:05 pm

Shamkhal Mammadov

SubscriberCan you elaborate on this? you said density does not affect corrosion rate. then you said I need wall material density to make the conversion. How should I calculate the corrosion rate for different pipe materials? Currently, I am calculating it with the Total surface corrosion rate, which is in kg/m^2.

I divided it by density (kg/m^2) / (kg/m^3) which becomes just (m), for the duration of simulation (in my case 1 year). then I multiply it by 1000 to convert it to mm. Is this method correct?

-

September 28, 2023 at 3:15 pm

Rob

Forum ModeratorWhere's the time value in the rate? Otherwise, yes, you will probably need the pipe material density to then covert to mm. This assumes the set up is similar to the erosion models. Once there are tutorials it'll be clearer.

-

September 28, 2023 at 3:37 pm

Shamkhal Mammadov

SubscriberDo you have any idea when the tutorial will be posted? or at least whom I can contact to clarify this? the picture I posted above your comment is the total accumulated rate, it sums up all corrosion for a simulation period, and there is no time in units.

I want to try a constant case of corrosion, where Pressure and volume are static, but my simulation blows up. when I set inlet-velocity to 0, or i set inlet pressure and outlet pressures to be the same. Any suggestions regarding this?

-

September 28, 2023 at 3:44 pm

Rob

Forum ModeratorStaff are limited to what's in documentation, so we're a little stuck until the tutorial is made public. I don't have a time frame for that. Check the theory guide as the maths may well be explained in detail.

If a static model is failing check what the initial condition is and whether that's physically sensible.

-

September 28, 2023 at 6:09 pm

Shamkhal Mammadov

Subscribercan you provide me with some resources for this guide? I have access to the manual for 2023R2 and was using that.

-

September 29, 2023 at 8:28 am

Rob

Forum ModeratorThat is currently all I have to share too.

-

-

-

September 28, 2023 at 2:41 am

Shamkhal Mammadov

SubscriberCould you help me to set it up? Can you elaborate? I am currently working with a fluid domain I create a 2"x10" pipe and turn on the species transport and the corrosion tool for my study

-

September 28, 2023 at 7:51 am

Rob

Forum ModeratorI just followed the instructions in the User's Guide. You'll need the fluid region for the pipe, no need to model a solid for the metal part.

-

- The topic ‘Corrosion in Ansys Corrosion rate’ is closed to new replies.

-

4833

-

1587

-

1386

-

1242

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.