-

-

March 17, 2020 at 5:10 am

HCR_student

SubscriberHello everyone, I am facing a problem with the convergence graph.

Before, I ran 300 iterations for my solution and I was unable to reach convergence. This is the graph I have achieved.

After that, I ran 850 iterations and reached convergence. The graph is as shown below.

I observed that there is a big spike at around 400~500 iterations. I am not so sure about convergence as I am still a beginner at ANSYS Fluent. I am not sure if there is a problem with this graph and if my convergence is correct or wrong.

Please help!

-

March 17, 2020 at 2:20 pm

Rob

Forum ModeratorLook at your flow field. Residuals are a function of the numerical error in the model, but aren't the only convergence check: do the tutorials and you'll be shown monitor points too. Chances are the flow has a number of stable solutions, and it took a while for the bulk flow to establish and then settle down.

To add, I'd be wary of those results and run on for another few hundred iterations. Turn off convergence checking on the Residuals panel.

-

March 19, 2020 at 7:32 am

HCR_student

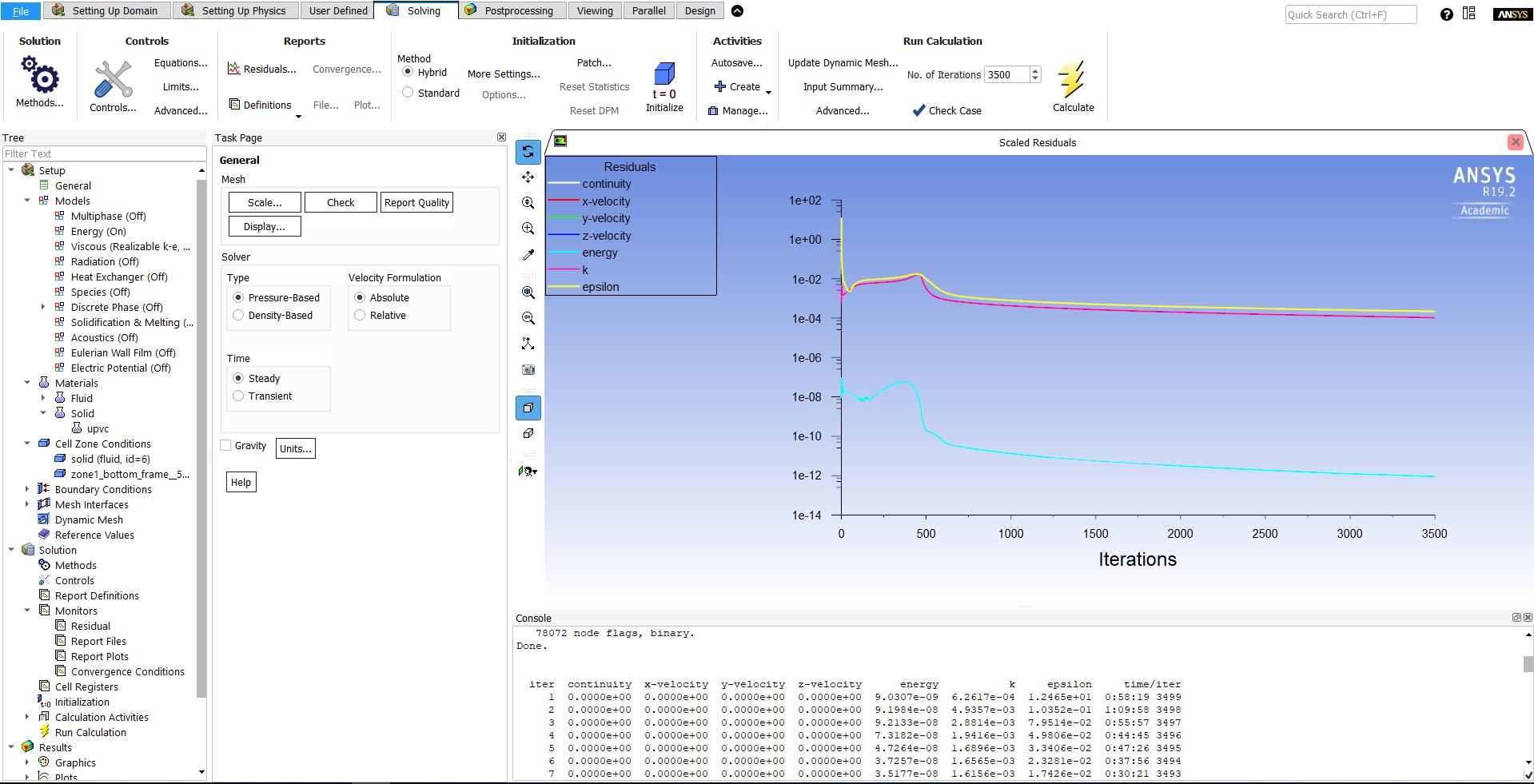

SubscriberThank you for your reply! I ran 3500 iterations to check and this is the result that I have:

I have checked my results and there is no difference from the previous simulation shown in the first post with 850 iterations.

(temperature graph for 3500 iterations)

VERSUS

(temperature graph for 850 iterations(or less due to convergence))

Since this is the case, would it be correct for me to state that it reached convergence correctly and that I am able to use 850 iterations for all my simulations?

-

March 19, 2020 at 7:55 am

Keyur Kanade

Ansys Employeeplease check mesh density. you may need to refine the mesh. also check orthogonal quality of the mesh.

please search quality and refinement on this community. you would find many posts.

Regards,

Keyur

If this helps, please mark this post as 'Is Solution' to help others.

Guidelines on the Student Community

How to access ANSYS help links

-

March 19, 2020 at 12:36 pm

HCR_student

SubscriberThis is the best mesh I can achieve with the Student License. Did the lack of mesh quality result in that huge spike?

-

March 20, 2020 at 6:08 am

Keyur Kanade

Ansys Employeeyes.

please check min orthogonal quality. it should be above 0.1.

https://www.youtube.com/watch?v=AzvPxjNyr3w

Regards,

Keyur

If this helps, please mark this post as 'Is Solution' to help others.

Guidelines on the Student Community

How to access ANSYS help links

-

March 22, 2020 at 8:58 am

HCR_student

SubscriberIt is above 0.1. However I am not able to further reduce the element size due to my student license.

-

March 23, 2020 at 4:54 am

Keyur Kanade

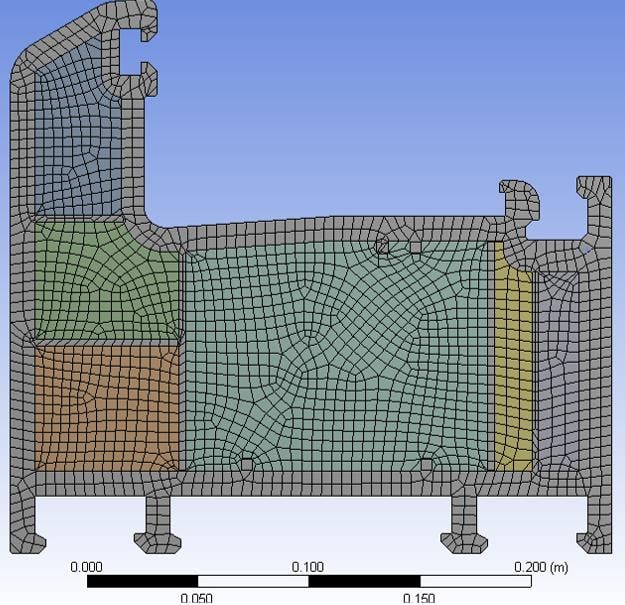

Ansys Employeecan you please post image of your mesh cross section.

please try to change your inputs so that you can solve it on student license.

reduce your problem size by using symmetry if possible.

Regards,

Keyur

If this helps, please mark this post as 'Is Solution' to help others.

Guidelines on the Student Community

How to access ANSYS help links

-

March 23, 2020 at 7:28 am

-

March 23, 2020 at 1:28 pm

Rob

Forum ModeratorThe jumps in cell size aren't going to help, and resolution isn't enough assuming you have fluid regions. What are you trying to model, as I'd expect some temperature variation over a fluid zone. Also, if you used "hex dominant" method, don't it's only for Mechanical and should never be used for CFD.

-

March 23, 2020 at 1:37 pm

HCR_student

SubscriberThank you for your response! That is what I am trying to model. It is a solid window cross section with fluid addition for the air. For the mesh settings, I used Multizone method while leaving the default 'mapped mesh type' to hexa. For this case, do I change it to prism?

-

March 24, 2020 at 3:36 am

Keyur Kanade

Ansys Employeeuse tri elements. make sure you have atleast 3 elements across any gap. use edge or face sizing.

Regards,

Keyur

If this helps, please mark this post as 'Is Solution' to help others.

Guidelines on the Student Community

How to access ANSYS help links

-

March 25, 2020 at 7:45 am

HCR_student

SubscriberThank you for your reply!!

I am able to get this mesh after changing the mapped mesh type to prism under multizone method. The Orthogonal Quality value is 0.11. However, my mesh quality metrics were better with the previous hexa shape.

How do I make sure that I am getting at least 3 elements across any gaps?

I am running this simulation with FEA and CFD. For the FEA, does it matter more for my quality metrics to be optimal or tri element (PRISM setting)?

Please help!

-

March 26, 2020 at 4:19 am

Keyur Kanade

Ansys Employeeto get more no. of elements across gap, please use edge sizing.

please check more on edge sizing in help doc. you can also find many threads on this community.

Regards,

Keyur

If this helps, please mark this post as 'Is Solution' to help others.

Guidelines on the Student Community

How to access ANSYS help links

-

March 26, 2020 at 11:39 am

HCR_student

SubscriberAlright thank you. However may I know if there is a difference between using Hex-dominant method and using multizone method (hexa)?

Since I am not able to use the Hex-dominant method for CFD, will multizone method (prism) or tetrahedrons be better?

When comparing the mesh quality metrics between the multizone method (prism) or tetrahedrons, the quality of multizone method (prism) is better. However I understand that prism is considered a 'wedge', so in this case, I am unsure of what to use for the mesh setting for CFD.

I am solving this in the 3D Computational Grid.

-

March 26, 2020 at 5:00 pm

Rob

Forum ModeratorHex dominant method gives a very good layer of cells next to the surface and fills the rest up with rubbish quality. Multizone with hex uses a pave/map mesh as required and will usually give a very good mesh.

Hex & tet are both good in their own way. I'll leave you to read up on the various reasons. In your case if the domain is extruded then sweep to give prisms is fine. However, the cells quality in the corners of some of the zones is awful: why have you chamfered those corners?

What are you actually trying to solve? Once you get a mesh?

-

March 27, 2020 at 4:23 am

Keyur Kanade

Ansys EmployeePlease see help documentation to get more information about meshing methods.

Regards,

Keyur

If this helps, please mark this post as 'Is Solution' to help others.

Guidelines on the Student Community

How to access ANSYS help links

-

March 27, 2020 at 12:17 pm

HCR_student

SubscriberHi, I have created a section view of a window frame by referencing to a picture model and there were chamfered edges hence I chamfered those corners.

I am doing a CFD and FEA thermal model of this window frame. In the model above, the window frame has air "solids" to study the effect of the inclusion of air in thermal transfer.

Just to clarify some more, for CFD, you have mentioned that hex dominant should never be used for CFD and so I used Multizone method and selected the prism setting instead.

For FEA, even though the analysis is the same as CFD and it is going through a "fluid" (air "solids"), is it wrong to use multizone method with hexa setting? The reason I am choosing hexa setting is because it gives a better mesh compared to the prism setting.

Thank you so much for your help!

-

March 30, 2020 at 7:09 am

Keyur Kanade

Ansys Employeei suggest you use tri mesh with prisms.

please go through meshing methods

https://www.youtube.com/watch?v=nEOC8rDnnRo

Regards,

Keyur

If this helps, please mark this post as 'Is Solution' to help others.

Guidelines on the Student Community

How to access ANSYS help links

-

- The topic ‘Convergence Solution’ is closed to new replies.

-

5094

-

1830

-

1387

-

1248

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.

-c-horizontal-5mm.jpg?width=690&upscale=false)