-

-

June 6, 2023 at 11:10 am

Guilherme Nunes

SubscriberHello everybody,

Sorry to bother everyone again, but I've been really struggling with convergence problems during a non-linear static structural analysis of a tubular bonded joint. I've posted already in this forum, but didn't get a reply so I'll post the link to that post, which has my setup in more detail:

/forum/forums/topic/convergence-problem-during-static-strutural-analysis-of-tubular-bonded-joint/

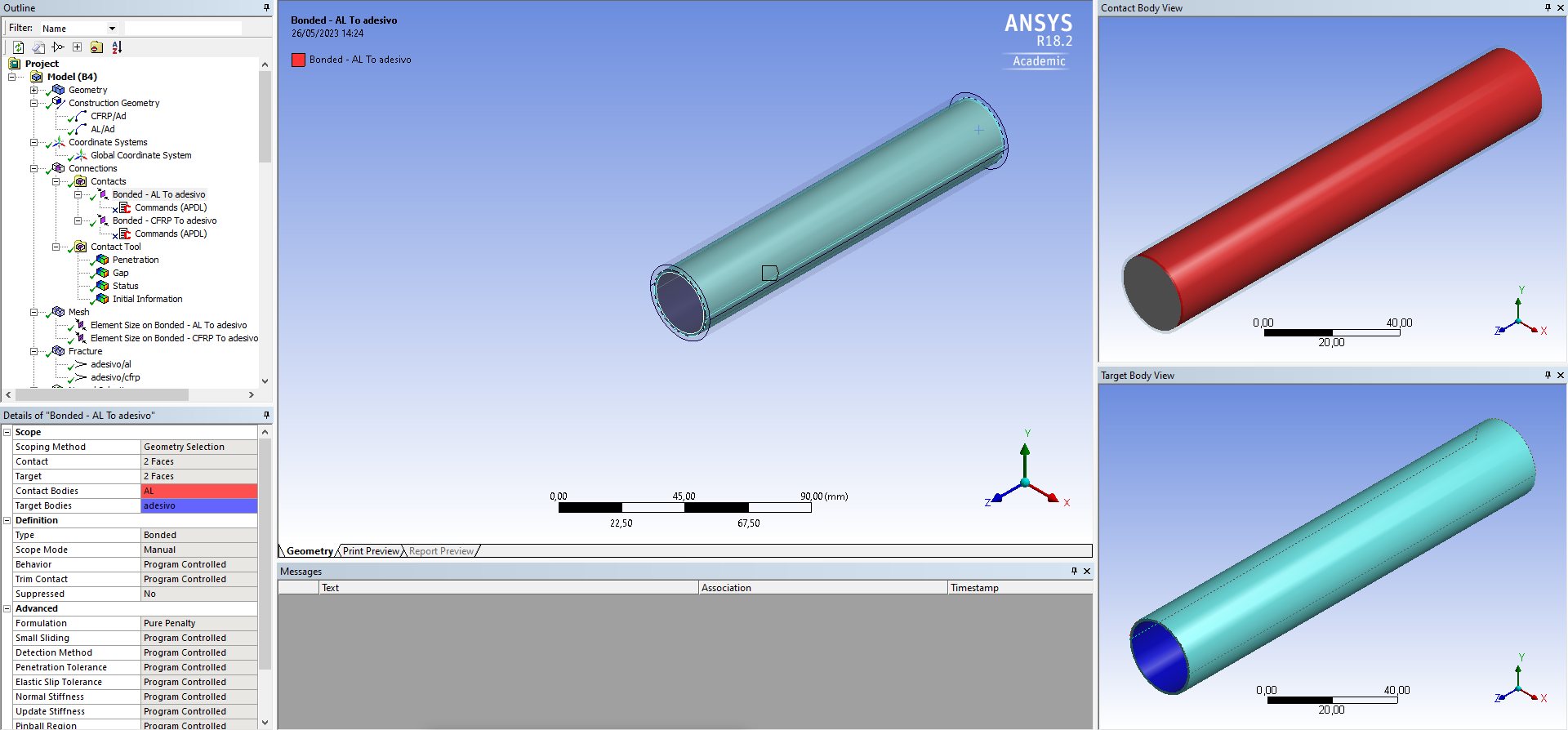

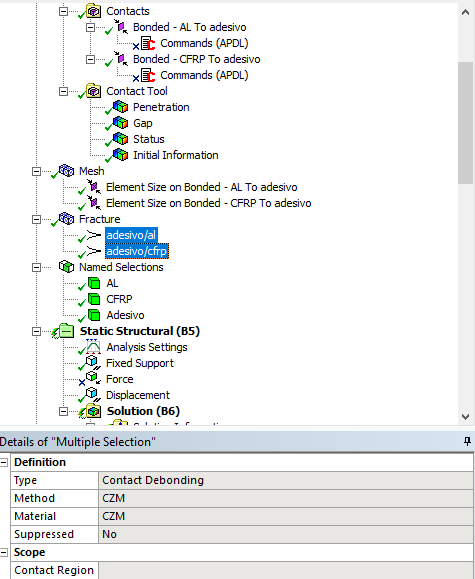

But to give a quick explanation, I'm trying to analyse a tubular bond between CFRP and Aluminium. I am modelling the adhesive layer as well, since I'm trying to compare some results with a collegue that is doing the same analysis in the lab. One of the extremeties is fixed (fixed support on the CFRP face), while one is loaded (Aluminium face on the other side).

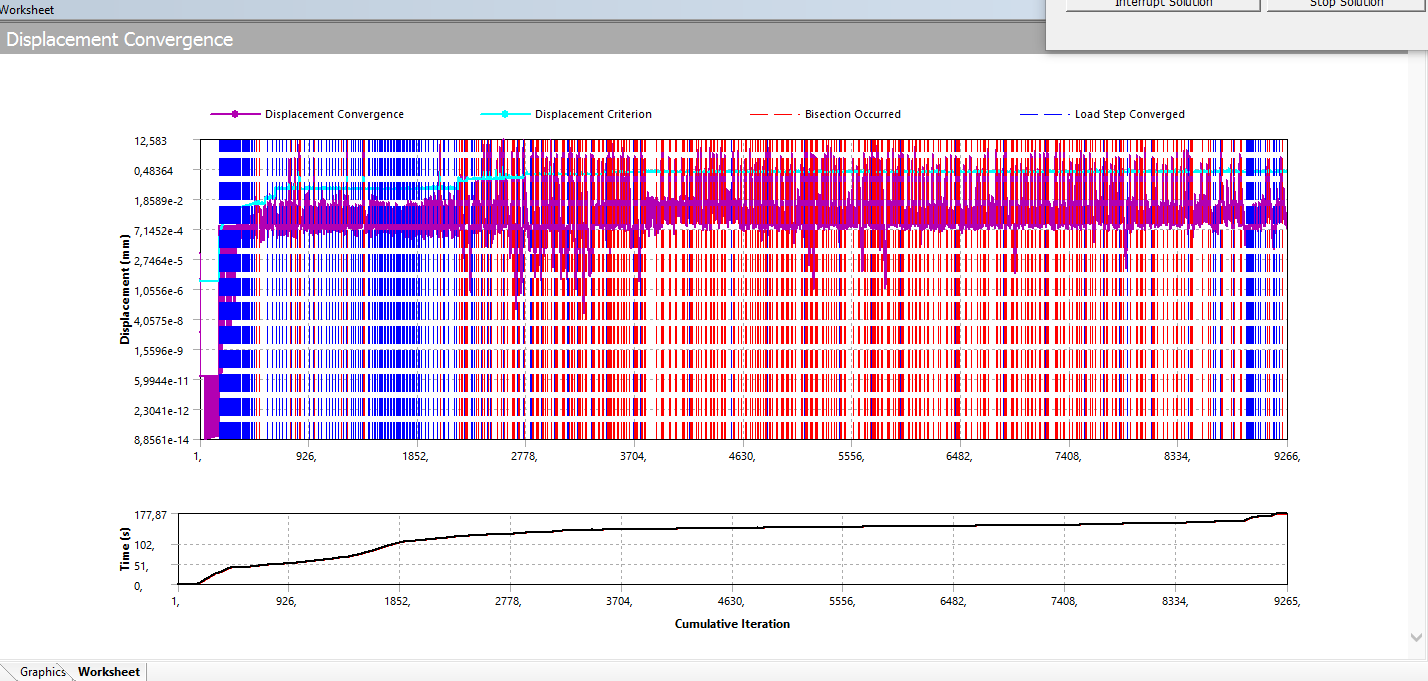

I've tried changing to displacement instead of aplying force as it is easier to converge, and it did do the trick for a smaller amount of displacement (0.55 mm and now 1.1 mm), however as I ramped those values up the problems reapeared. The displacement is ramped in 200 steps from 0 to (ideally i would be) 1.2 mm (ideally i would be until it the bond breaks) to see the maximum strenght of the bond, with 100 min substeps and 1000 max substeps.

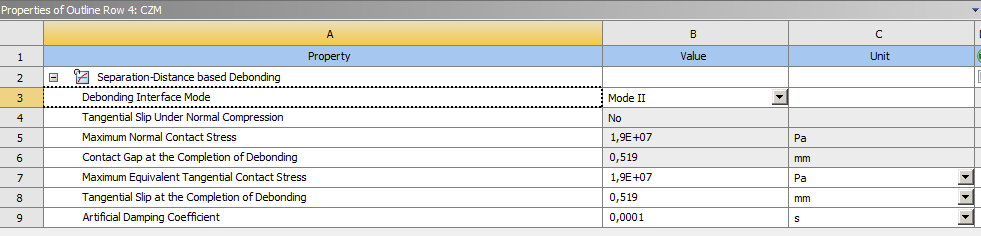

I'm using bonded contact on both faces, so CFRP to Adhesive and Aluminium to Adhesive, with pure penalty formulation. I've changed the stiffness factor but it didn't help for some reason. Both contact surfaces have a fracture input for contact debonding with a CZM that I inputed as well based on previous experiments. I've made a command to try and insert my stiffness value for the contact itself, but it caused more problems than not.

The mesh of the contacts is of 2 mm, the rest is basically set to default values. The paths are set so that I can see the stress on the bonded lenght (I'm also trying to get a bond-slip graph, but haven't found a way to do it properly).

This simulation has been going for a week now, and i don't know what to do.

I would really appreciate your help.

Kind regards.

-

June 9, 2023 at 1:39 pm

Guilherme Nunes

SubscriberI've managed to have a better convergence now with an even lower FKN, however it still failed to converge in the end. At 1.2 mm the bond should break, and the simulation gave an error message of an internal solution magnitude exceeded in a node belonging to the adhesive body.

I don't know, but maybe the convergence problems are related to this fact?

Again, I would really appreciate any help

Thank you

-

June 14, 2023 at 10:10 am

Guilherme Nunes

SubscriberSo, I've changed the contact formulation from pure penalty to augmented lagrange, mantaining the same normal contact stiffness at 0.1 and an induced displacement of 1.15. The convergence went smoothly until about 92% completion, then out of the sudden it failed.

Again, if anybody could help, I would really appreciate it.

Thank you

-

June 14, 2023 at 6:48 pm

John Doyle

Ansys EmployeeIf at 1.2mm the bond should break, perhaps CZM is actually working and your DOF exceeded error is the result.

-

June 15, 2023 at 12:32 pm

Guilherme Nunes

SubscriberHello John! Thank you so much for answering!

I didn't express myself correctly, was kind of anxious while writing it: I wanted to say that 0.519 mm slip the bond should break, I wanted to see if it happened at a displacement of 1.2 mm, because it's at that value that convergence problems start to appear.

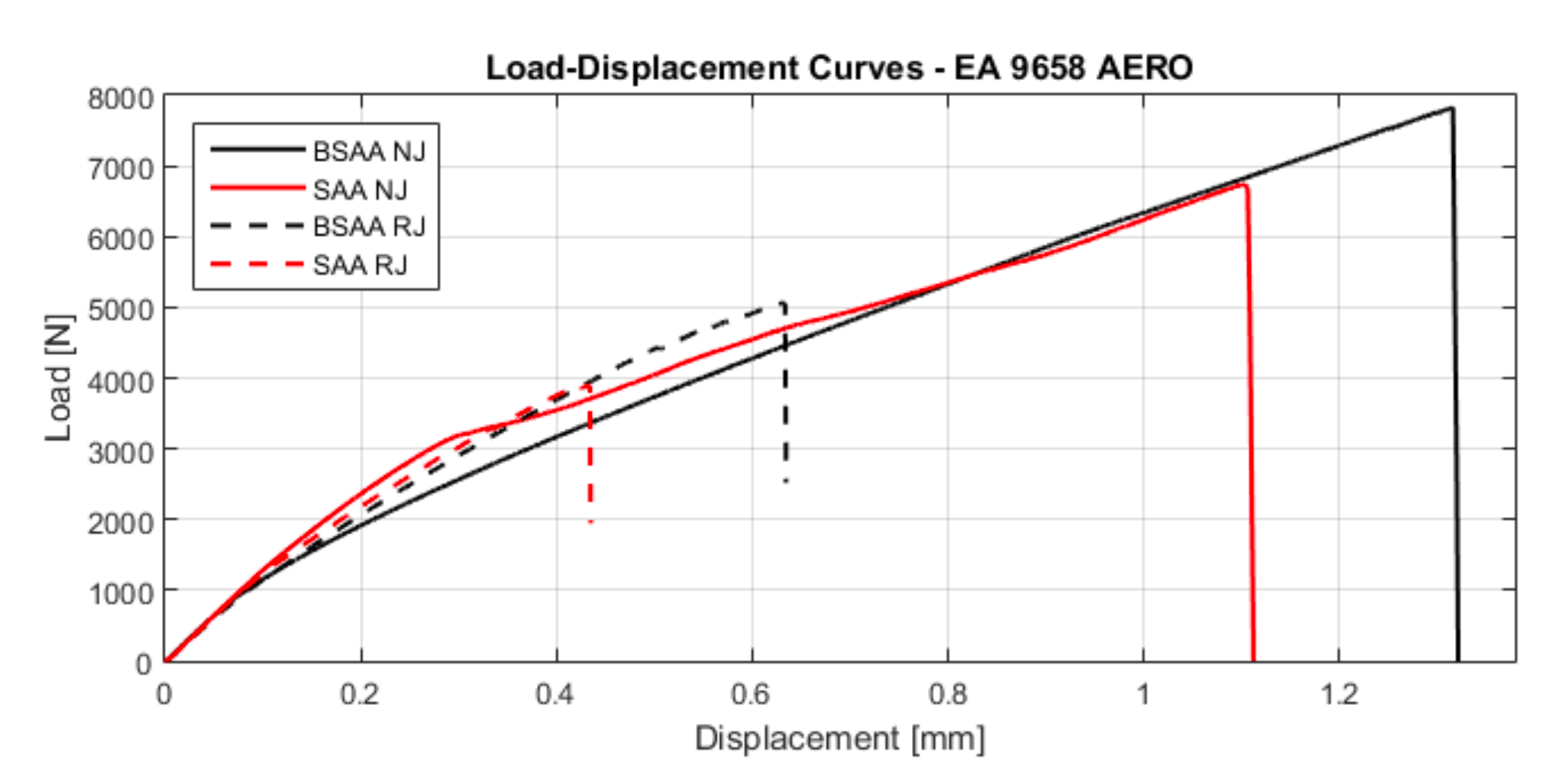

But to better understand the situation, if it constantly fails to converge at that displacement value, it means that the bond breaks, correct? Therefore the force-displacement graph that appears shows the maximum load value before the failure occurs, just like this example of a F/D-curve bellow, but without the vertical line representing the conclusion of debonding

Is there a way to calculate the slip in the bond? I have two construction geometry paths, one at the top of the adhesive and one at the bottom, to try and measure it however I don't know if that is the correct way to do it.

Again, thank you so much for answering. Kind regards.

-

-

- The topic ‘Convergence Problem of Tubular Bonded Joint Analysis’ is closed to new replies.

-

4633

-

1540

-

1386

-

1225

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.