-

-

April 29, 2018 at 4:55 pm

deepmech.maurya

SubscriberHello friends

suffering from convergence of forces problem.

1) Rigid body motion is not there as body is under compressive load.

2) Loading cycle: 40 load step with 50N at each step is applied but in standard paper the same body has 2000N (loading step not discuss)

3) Material instability: thats the question how to check it?

4) Element formulation error : this error is always there ?

Every time element get distorted error is there.

check element shape.

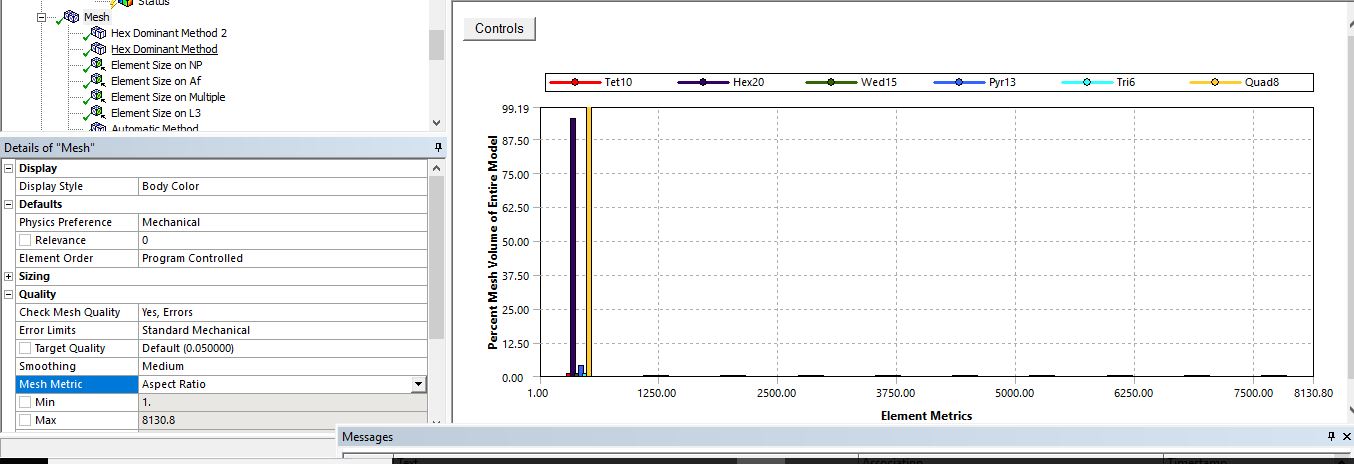

My question is this : In mesh metric after checking that: skewness is below .5 it is good.

But some element(1%) are having skewness 0.9 then what to do?

after that element quality is checked

Now explain me what to do other than decrease the element size?

how to generate mesh for skewness 1, element quality having value near 1.

i Am using newton raphson residual to find out the place where its value is high and using sphere of influence.

thanks

Regards

Deepak maurya

-

April 29, 2018 at 10:00 pm

peteroznewman

SubscriberHello Deepak,

I sent you email about using Adjust to Touch to close frictional contacts that had a small gap.

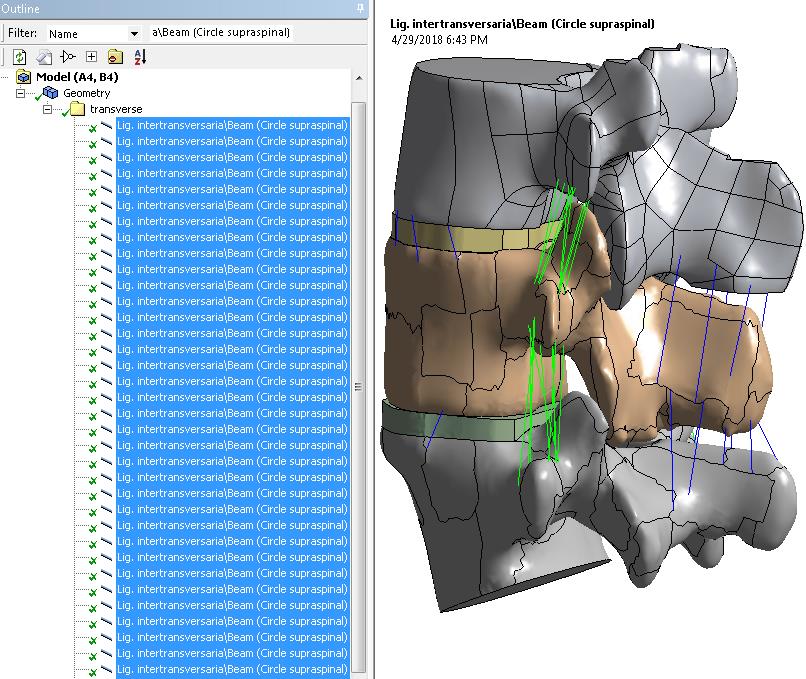

You say you are "using newton raphson residual to find out the place where its value is high" but I don't see any NR residual plots under the Solution Information folder in the screen image above, and NR residual plots were set to zero in the new beginnings model you sent me. I set NR residual plots to a value of 6 and made the adjust to touch change mentioned above. The plot below shows why the solver cannot find equilibrium. It is on this ligament:

It tells you the name of the component that has the Maximum NR residual force. This is usually very helpful, but only if you don't reuse the same name multiple times.

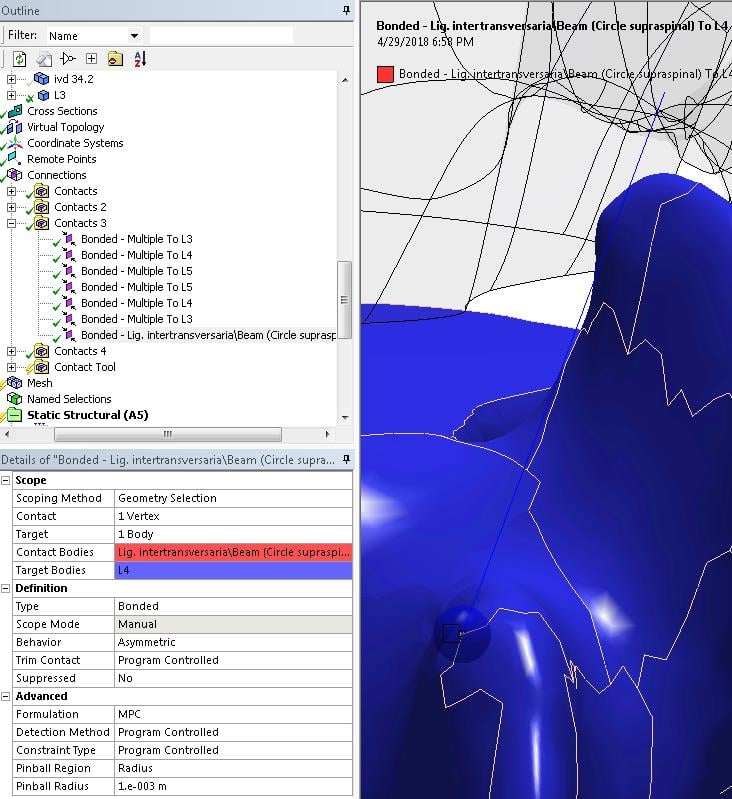

I duplicated that contact and took one vertex off the group contact so the duplicate can have just one vertex to the body. I changed the Bonded contact for that ligament to give it a known pinball radius and use MPC contact.

Here is the unconverged displacement, it looks like using this elements is not going to work for your model.

The next experiment I will do on your model is to convert all frictional contacts to bonded contacts. This is always my strategy, first solve as bonded contact, then convert to frictional.

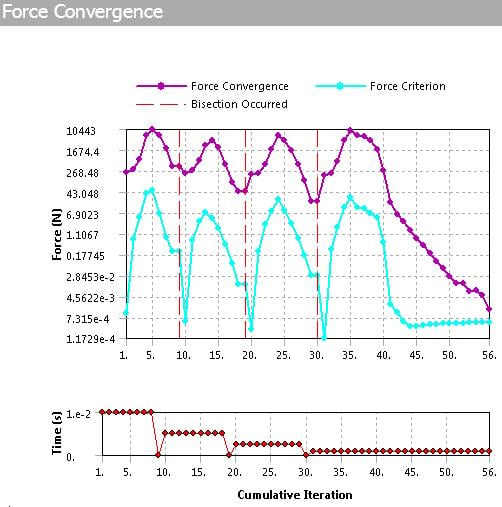

So the next thing is to reduce the initial substep size by a factor of 2^3 = 8 and use the APDL command neqit,50 to get the solver to keep going!

Now with bonded contact, weak springs turned on and step 1 set to -2 N, this model finally started to converge!

Note that it took 163 substeps for step 1 to converge, then only 115 substeps to do the next 20 steps. That all took about 4 hours on 8 cores but is only half way to the final load.

To simplify things, why not use one ligament spring element between the spurs on the bones instead of a bunch of beams?

Good luck,

Peter

-

April 30, 2018 at 3:01 pm

peteroznewman

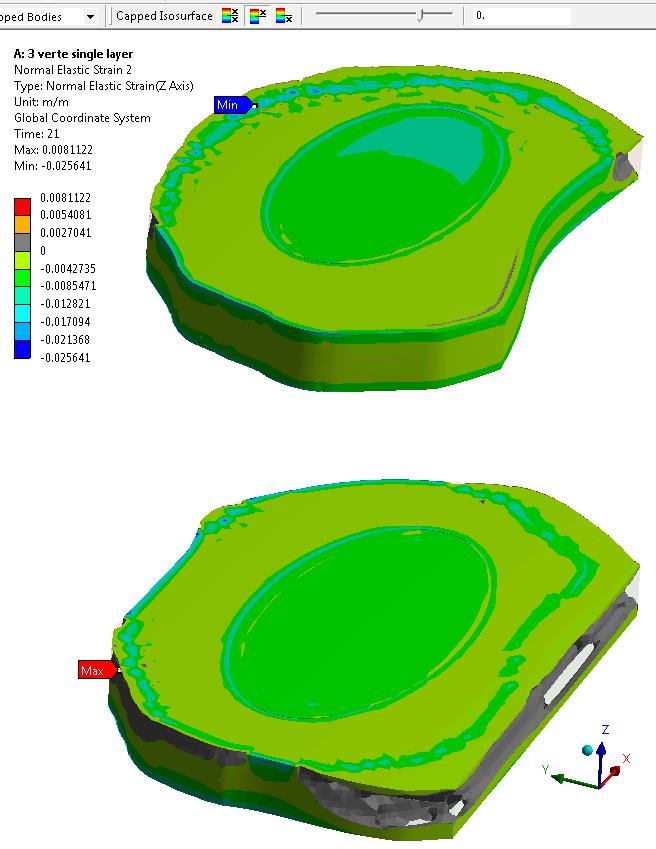

SubscriberI used Capped Isosurfaces in the plot below. With these settings, elements with positive normal z strain become invisible.

In hindsight, I don't think the NR residual plot was helpful in solving the convergence problem. I don't think the beams had anything to do with it. I think it was just the massive amount of contact that had to be resolved that needed a very small initial load to get started and lots of iterations to find equilibrium.

-

May 1, 2018 at 3:35 pm

deepmech.maurya

SubscriberHello sir

we have license of 4 core Ansys module when we use intel xenon processor 20 core with 16 GB memory, is 20 core useful here?

thank you

regards

Deepak

-

- The topic ‘convergence problem of non linear contact and geometric analyses?’ is closed to new replies.

-

5074

-

1798

-

1387

-

1248

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.