-

-

January 7, 2021 at 1:36 pm

saadia

SubscriberI am doing electromagnetic-structural coupling simulation. The electromagnetic part in Maxwell 3D is done without any problem. But for structural analysis in Ansys workbench getting convergence error. Can I have a suggestion to fix this error in Ansys 18.2?

Please find the attached outfile of solution information.

Thank you,

Mosarraf

-

January 7, 2021 at 1:57 pm

Rob

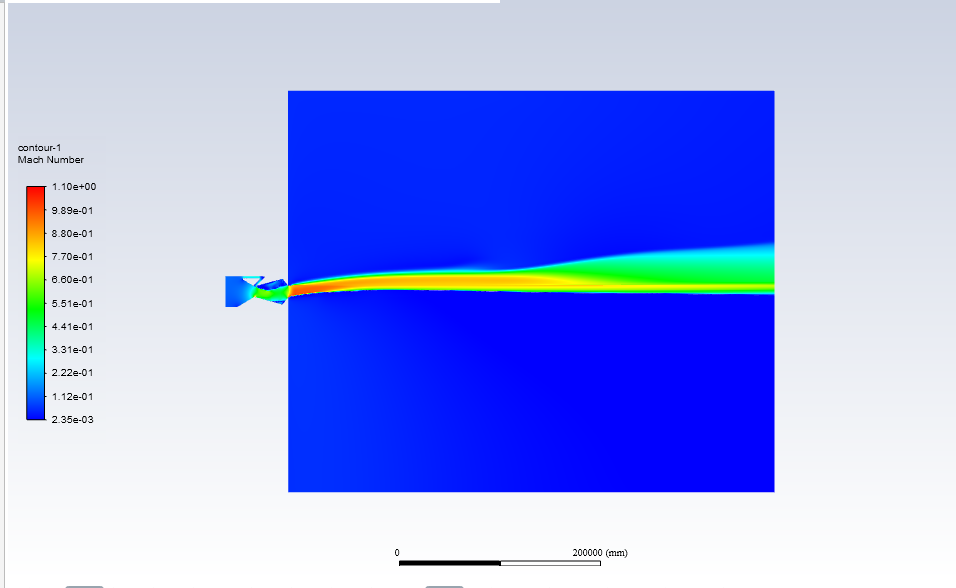

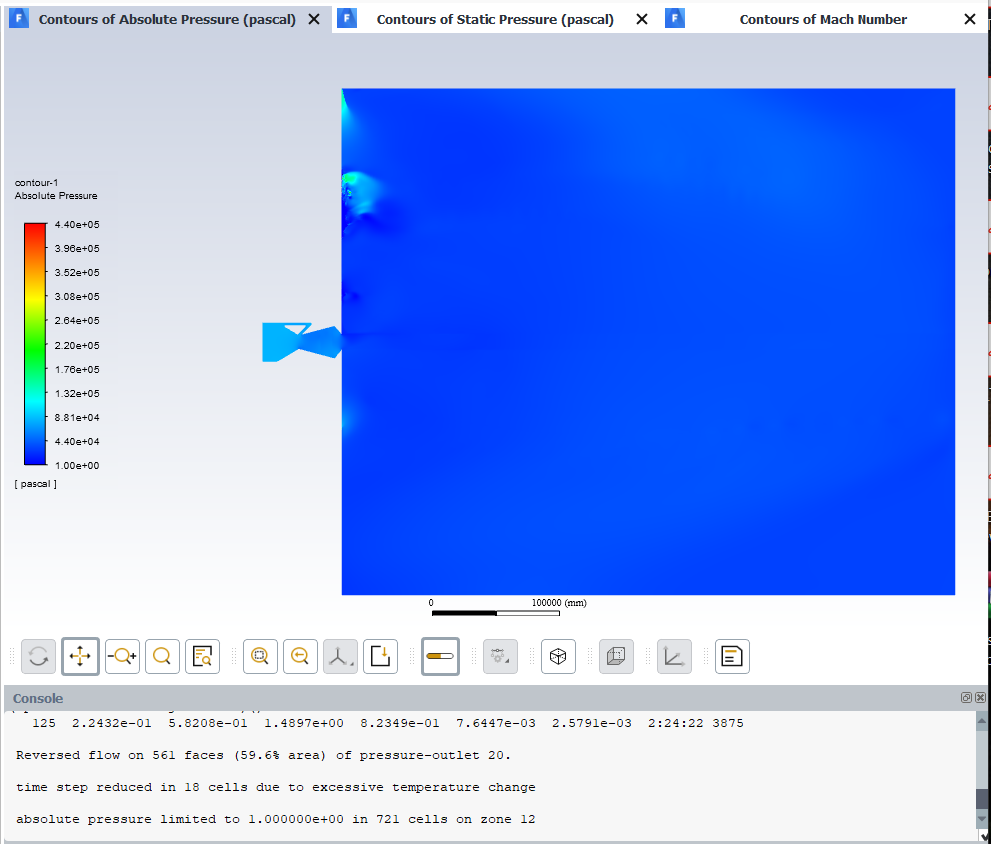

Forum ModeratorPlease can you post images the results? As an aside, far field conditions tend to be used for unconfined flows along way from everything else: ie for aeroplanes. You will be better off with mass flow inlet (if compressible) or velocity inlet (if density is fixed). n -

January 7, 2021 at 2:52 pm

-

January 7, 2021 at 4:48 pm

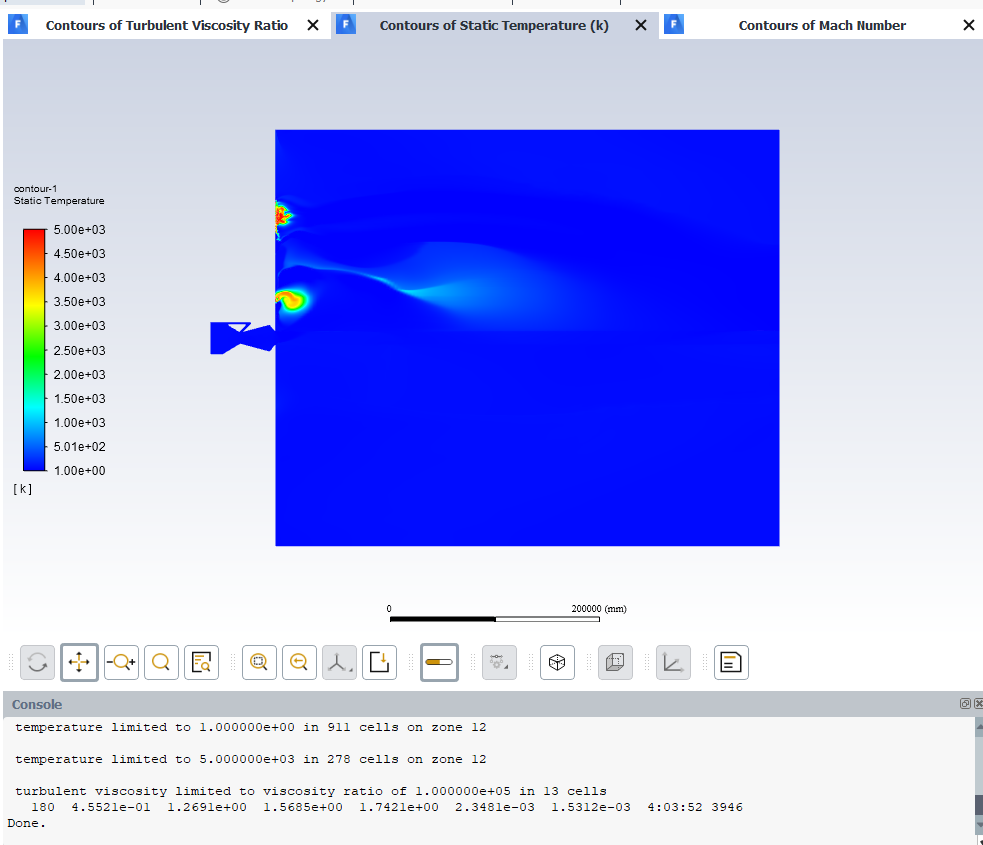

Rob

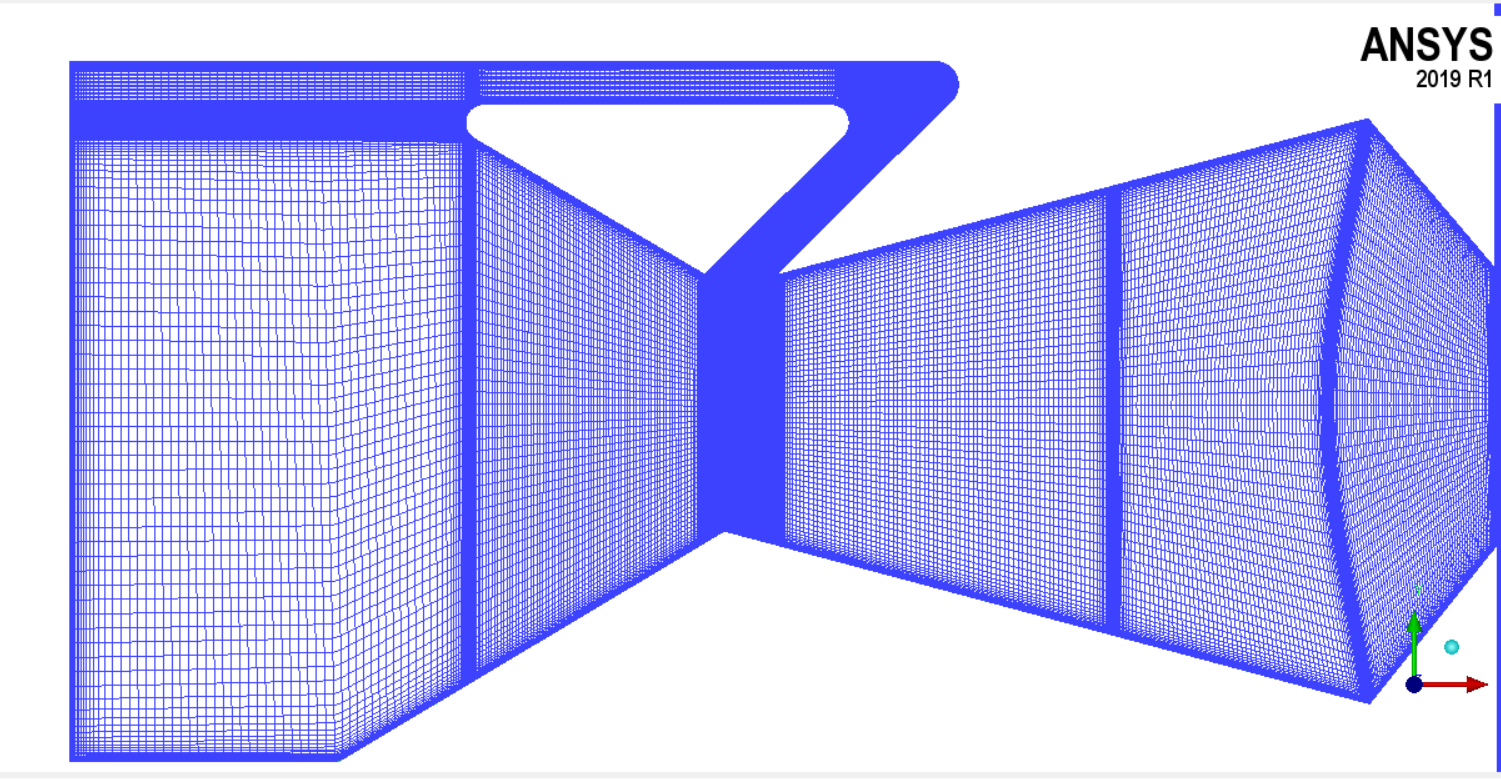

Forum ModeratorOther than a mesh artefact caused by using a mapped/swept mesh downstream of the nozzle that looks to be a very nice result. The boundary combination isn't ideal, but isn't responsible for your convergence problems. Switch to transient and see how the exhaust plume moves. Nice use of the coanda effect and a fluidic switch too. n -

January 7, 2021 at 5:25 pm

saadia

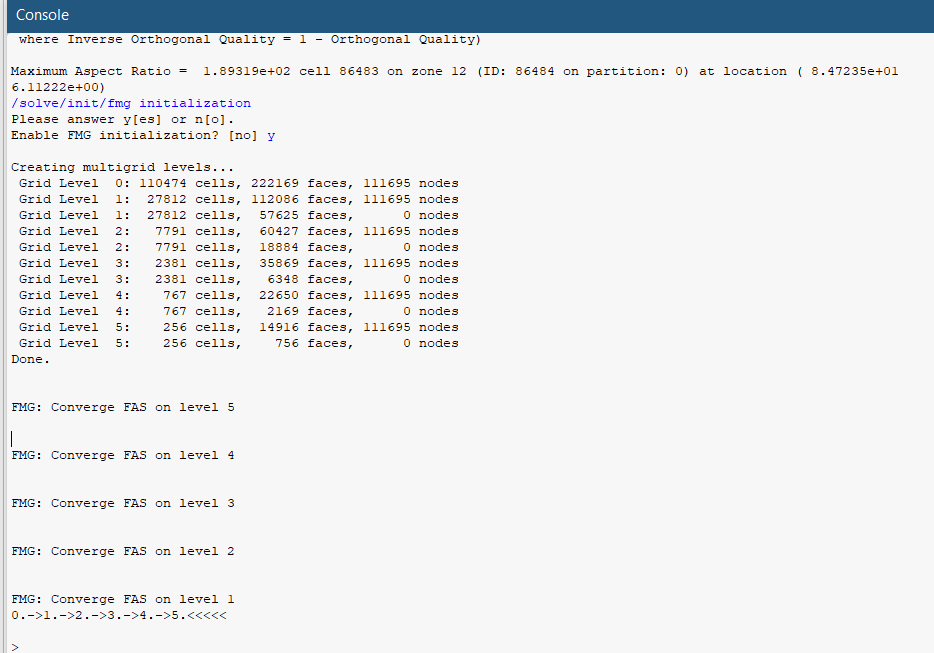

SubscriberUnfortunately, these results don't last till convergence criteria. The paper I need to validate uses steady-state for this model. Due to computational power, I'm using a slightly coarse mesh. Somebody suggested me to play around with courant number and other parameters but that doesn't help me either. The sudden increase in residuals vanishes everything. I don't know how fmg-initialization works, but I was suggested to see if it works. I'll switch to transient as well. n

n

n

-

January 7, 2021 at 5:30 pm

Rob

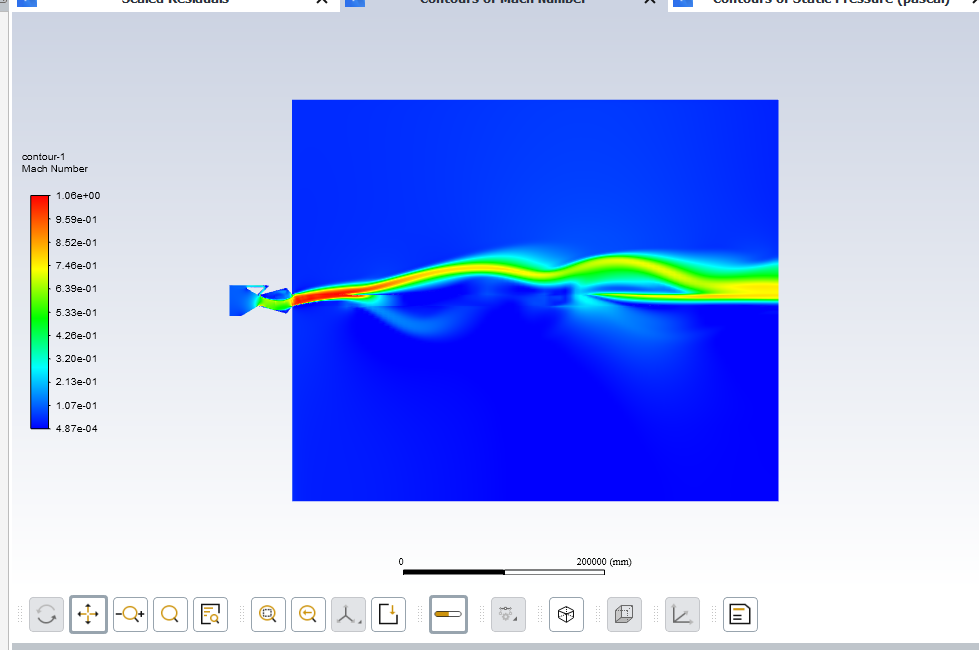

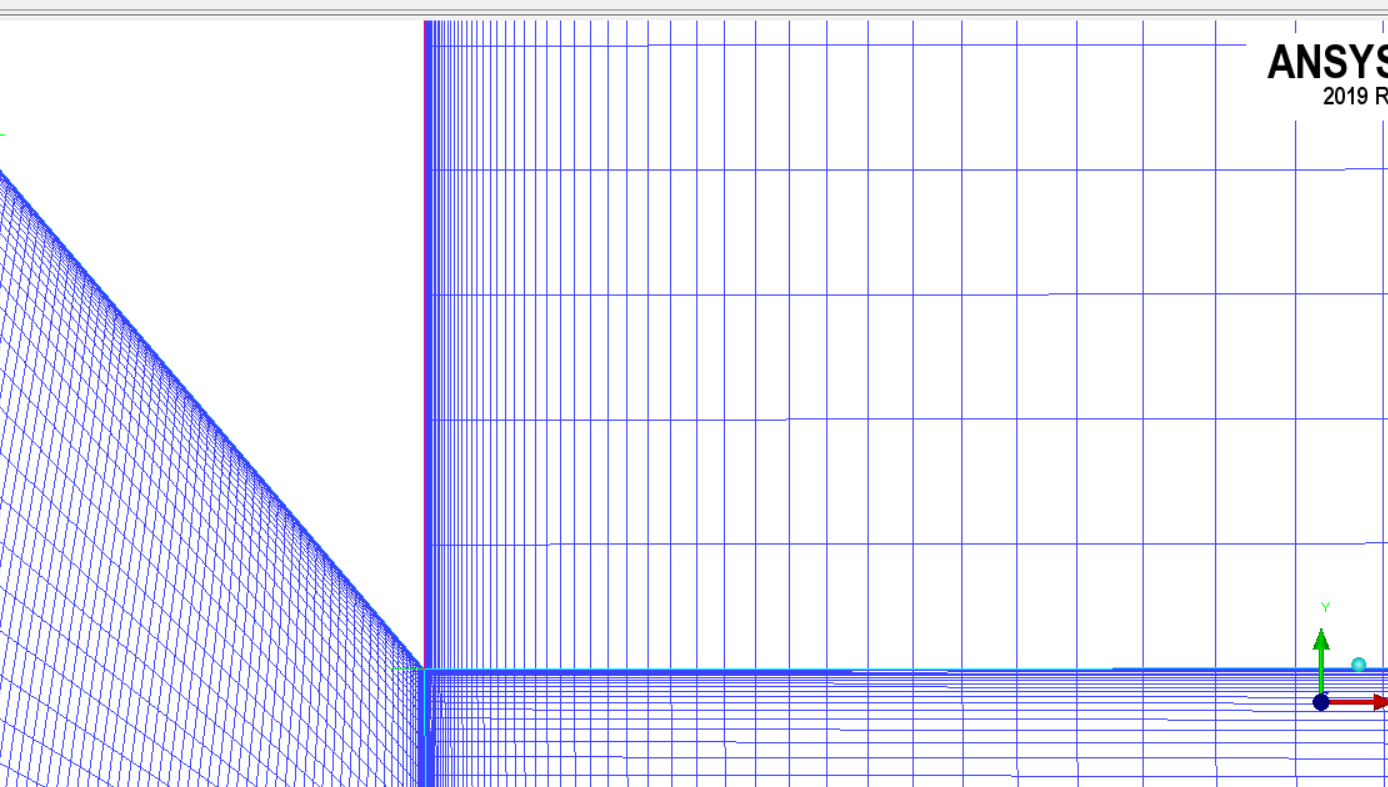

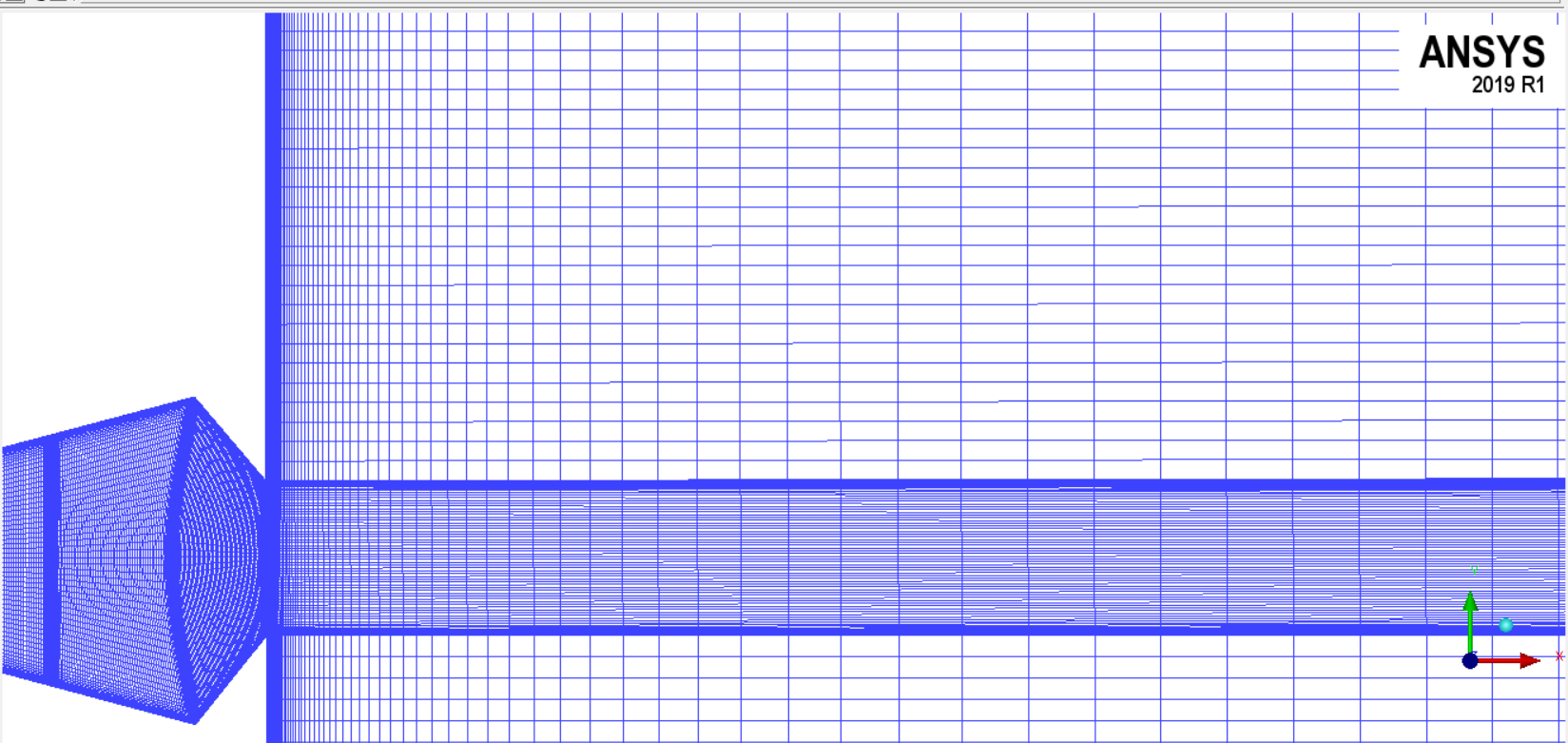

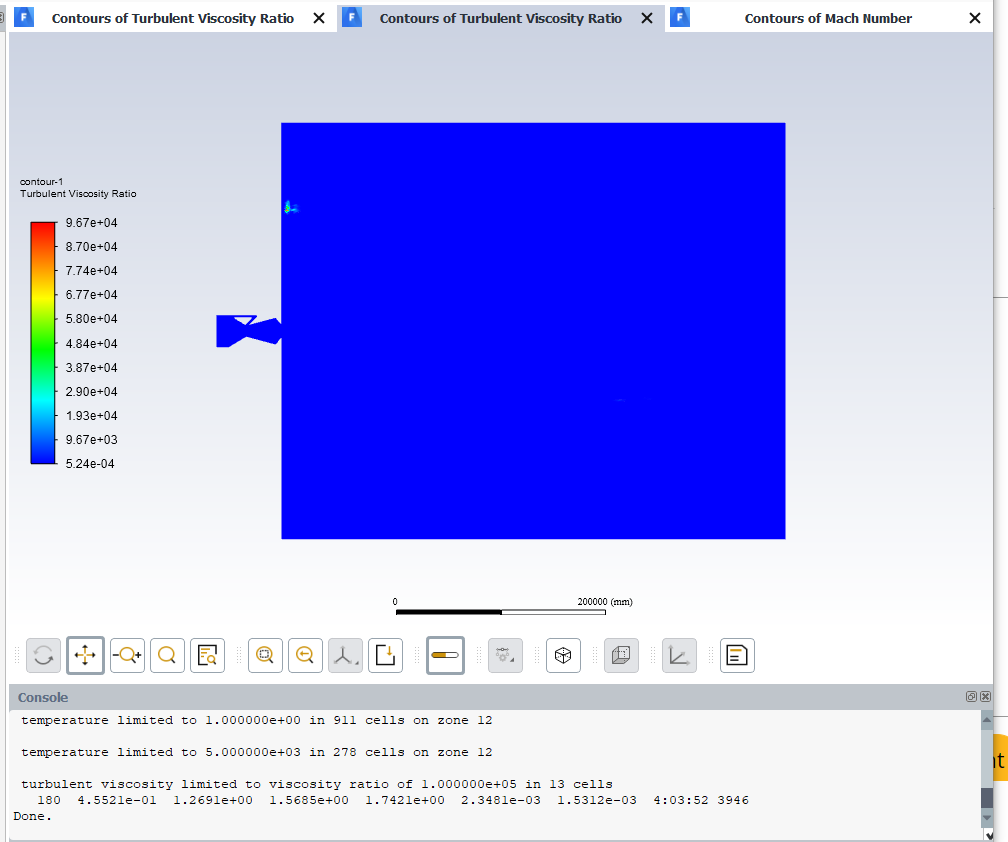

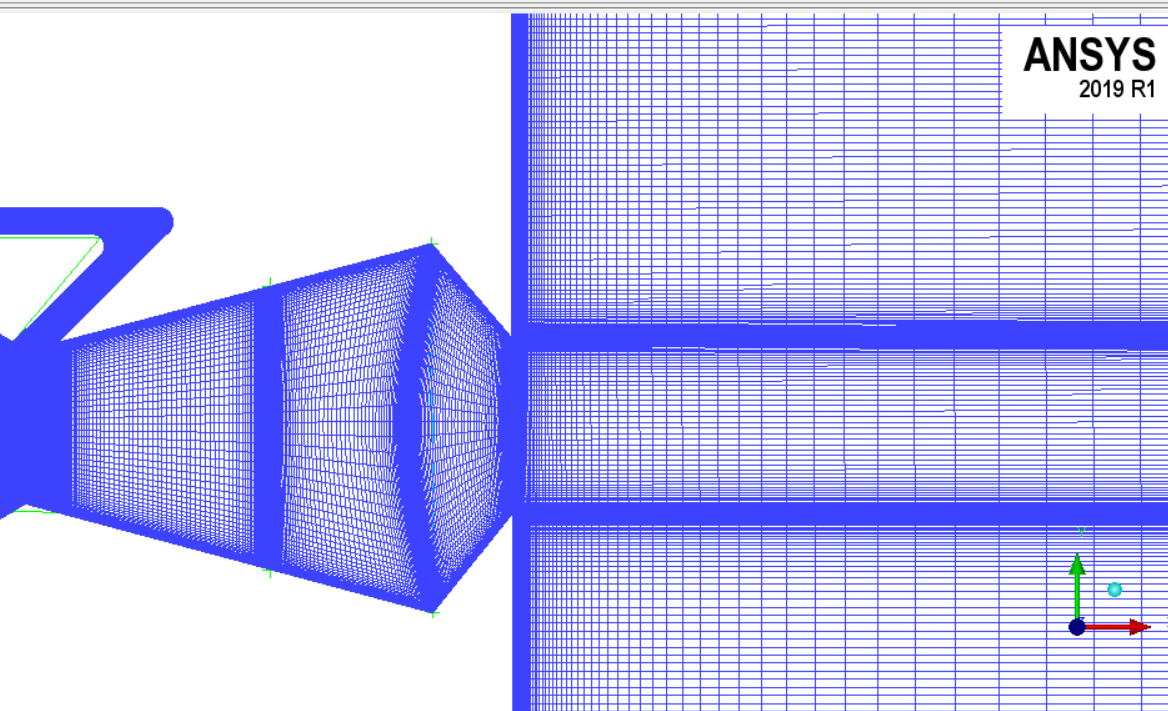

Forum ModeratorFMG gives a reasonable first guess for the solution but as the flow was nearly behaving it'll not do much. Can you post some images of the mesh as removing the sudden jump in cell size downstream of the nozzle will do more to help: the effect is very obvious in the second Mach Number plot. n -

January 7, 2021 at 5:48 pm

-

January 7, 2021 at 10:54 pm

Karthik Remella

AdministratorHello,nBecause your flow is closer to M = 1, there is a good chance that your mesh might affect the overall simulation convergence. nOne thing I can think of - At the nozzle exit, your mesh begins to coarsen the y-direction. The y-direction jump in your mesh in the +ve y direction is too abrupt. Can you perhaps smooth this out?nKarthiknn -

January 8, 2021 at 9:45 am

Rob

Forum ModeratorGiven the way the Coanda flow and attachment flows behave and possible shocks that mesh is going to cause problems. The aim in a good mesh is to have good cell quality but also resolve the flow and avoid large jumps in cell size. If this is 2d use a quad pave mesh to allow good resolution in the nozzle and then roughly where the jet will be. You can coarsen that in two directions. You can also adapt the mesh if you need additional resolution later on. nMapped meshes (like you've shown) are how we'd have done this in the later 90s, but with far fewer cells. Your phone is more powerful than my PhD workstation. n -

January 8, 2021 at 12:00 pm

saadia

Subscriber

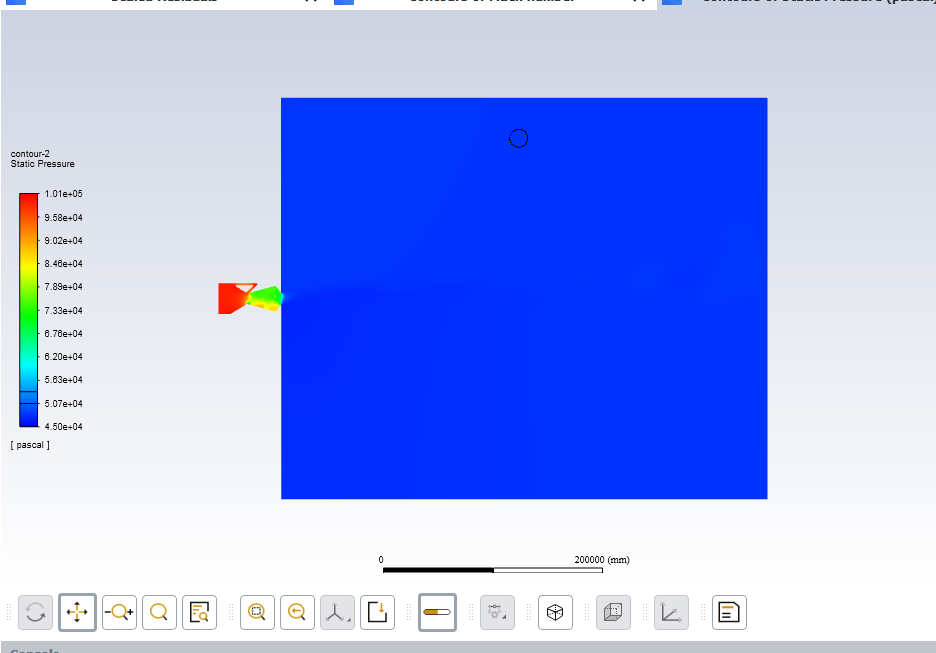

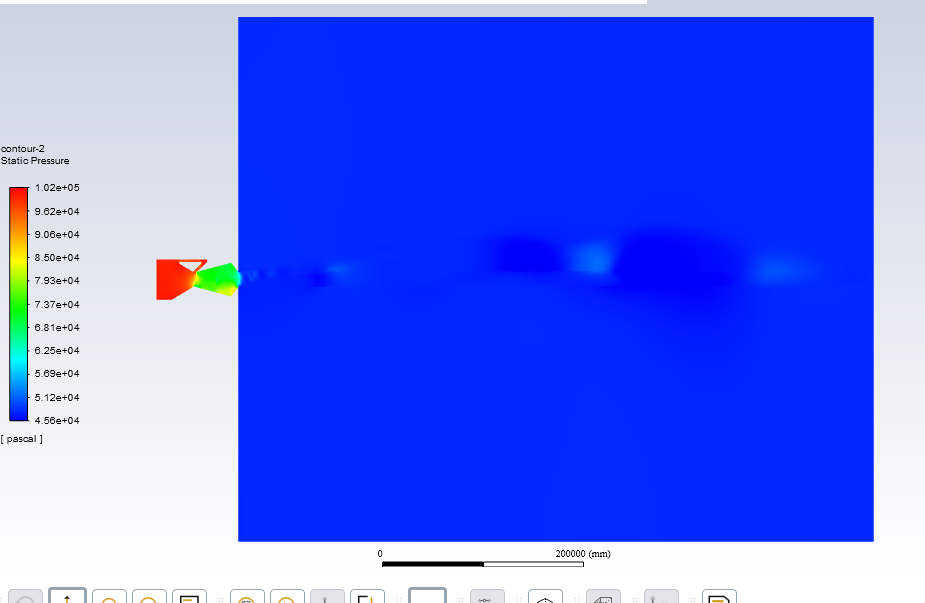

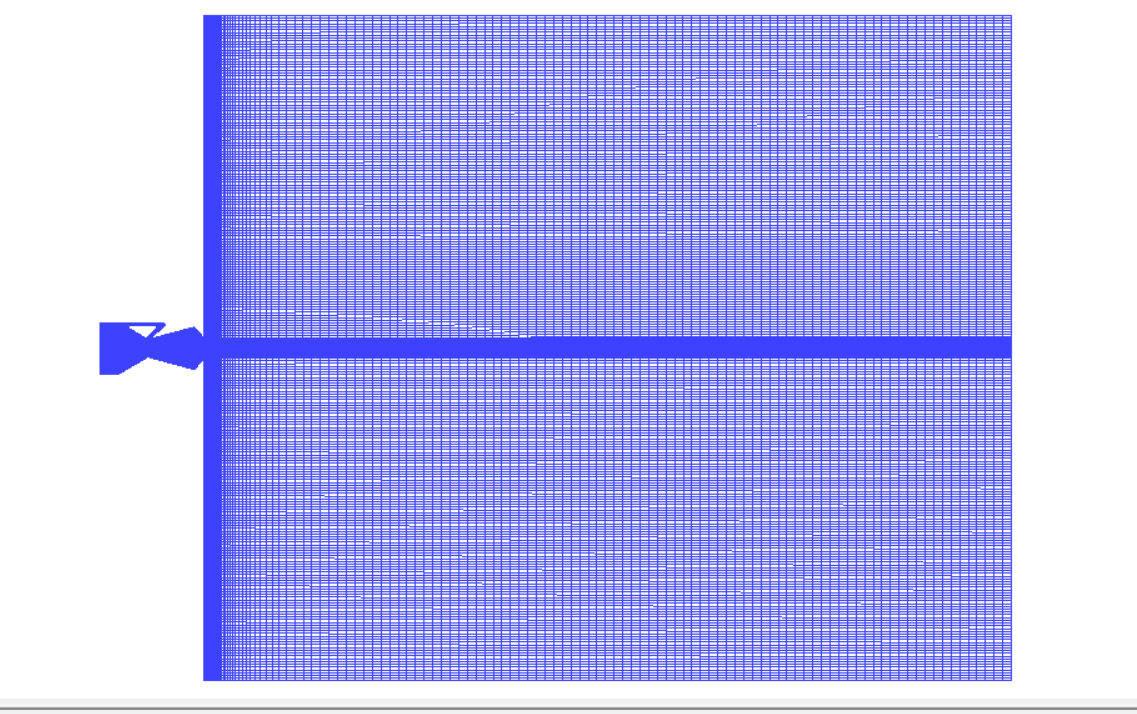

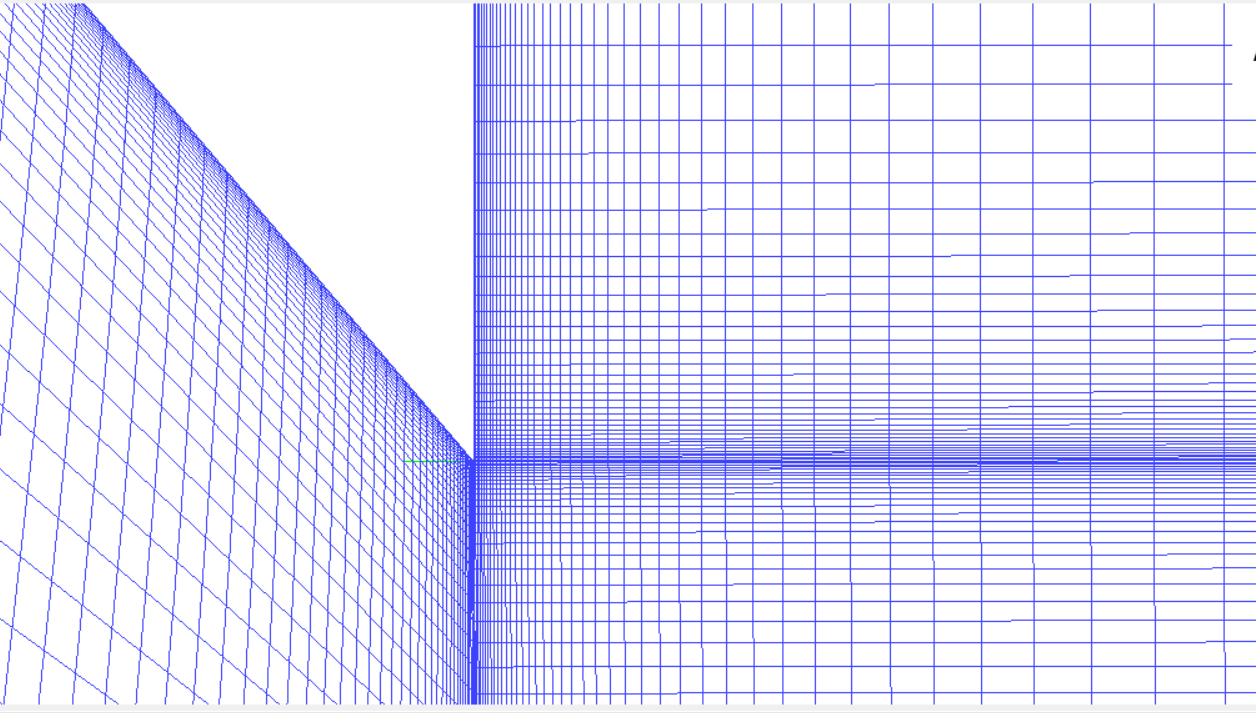

Did I smooth it out correctly? because with this mesh I get the following problems in fluent simulationsn Reversed flow on 549 faces (57.5% area) of pressure-outlet 20.nabsolute pressure limited to 1.000000e+00 in 256 cells on zone 12ntemperature limited to 1.000000e+00 in 785 cells on zone 12 nCan you check my mesh if I upload the mesh file. I'll be highly grateful. I'll check out the quad pave mesh.n

Did I smooth it out correctly? because with this mesh I get the following problems in fluent simulationsn Reversed flow on 549 faces (57.5% area) of pressure-outlet 20.nabsolute pressure limited to 1.000000e+00 in 256 cells on zone 12ntemperature limited to 1.000000e+00 in 785 cells on zone 12 nCan you check my mesh if I upload the mesh file. I'll be highly grateful. I'll check out the quad pave mesh.n

-

January 8, 2021 at 1:20 pm

Karthik Remella

AdministratorHello,nAs Ansys employees, we will not be able to download any attachments from the learning forum.nWhat is the maximum skewness in your mesh? nAlso, can you highlight the boundary where you are getting this reversed flow? nAre you using a pressure-based or density-based solver? If you have not tried, please do attempt using the density-based solver for this problem. In your solution methods, try using Convergence for Stretched Meshes (CASM) and Higher Order Term Relaxation (HOTR).nKarthikn -

January 8, 2021 at 1:23 pm

Rob

Forum ModeratorYou'll not smooth that very easily as it's a block map mesh: all the blocks are cartesian mesh. Hence the suggestion of looking at pave. nReverse flow isn't much of a problem and is caused by the (mostly) low velocity in the far field, just make sure the backflow temperature etc are sensible. nThe limits are more of an issue, and will lead to mass & energy losses in the domain and probably trigger the solver failure. They're caused by a combination of the flow field (high velocity) and mesh quality (high aspect ratio and jump in cell size). nThe community can check your mesh, I'm not allowed to open or download anything from here - /forum/discussion/23093/why-ansys-employees-dont-download-attachments for more details. n -

January 8, 2021 at 3:00 pm

-

January 8, 2021 at 3:25 pm

Rob

Forum ModeratorYes, that's the inlet flow trying to cross the overly refined mesh on that edge. nICEM CFD is an older tool and only really used by turbo machinery people now: I last used it's predecessor in the mid 90s! In Workbench use Ansys Meshing and you'll find it's much more user friendly and should give a pave pretty much automatically. nTo add, the Density based solver is overkill here as you're barely supersonic. Pressure based is good for Mach 2-3 and much easier to converge. Density based is for higher Mach numbers, travelling/interacting shocks and very tightly coupled chemistry: as I handle multiphase for the most part I don't think I've used it since about 2002. The aero team use it more often but are modelling the outside of aeroplanes. n

-

Viewing 13 reply threads

- The topic ‘convergence problem’ is closed to new replies.

Innovation Space

Trending discussions

- Varying Bond model parameters to mimic soil particle cohesion/stiction

- JACOBI Convergence Issue in ANSYS AQWA

- affinity not set

- Resuming SAG Mill Simulation with New Particle Batch in Rocky

- Continuing SAG Mill Simulation with New Particle Batch in Rocky

- Is it able to solve turbomachinery using density-based solver in Fluent?

- Two-way FSI simulation

- Ensight Force_per_unit area_EV

- Question about generating Porous Jumps

- The result in FLUENT differs from CFD Post

Top Contributors

-

4562

-

1494

-

1386

-

1209

-

1021

Top Rated Tags

© 2025 Copyright ANSYS, Inc. All rights reserved.

Ansys does not support the usage of unauthorized Ansys software. Please visit www.ansys.com to obtain an official distribution.