-

-

July 21, 2021 at 8:31 am

Haiquan

SubscriberHello

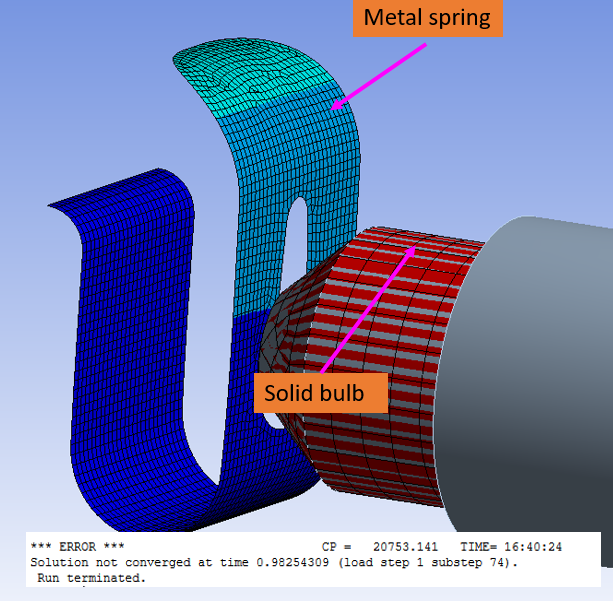

Simulation case is shown below, the solid bulb is inserted into the hole of metal spring from the top. Convergence issue arises when shell edge of the hole comes into contact with solid body. Is there any technique to overcome such convergence difficulty? Thank you in advance!

July 21, 2021 at 8:56 amErKo

Ansys EmployeeHi

I suggest to look for discussion on convergence in this forum and on the internet - there is a lot of material there which might help.

Also we have a course in contact modelling I would suggest to look into that also.

Thank you

Erik

July 21, 2021 at 9:18 amHaiquan

SubscriberThank you so much for your comments!

July 21, 2021 at 10:16 amEmperor

Subscriber

Have you tried the semiimplicit command? Are you doing a static analysis? Did you also activate the large deflections? Did you put in several sub-steps?

July 23, 2021 at 12:52 amHaiquan

SubscriberThank you very much for your suggestions. I am not familiar with the semi-implicit method. This is a static with large deflection on and enough sub steps

July 23, 2021 at 7:05 amEmperor

SubscriberI learned that the semiimplicit method could solve this kind of non convergence, you just have to avoid solid285 elements (according to my calculations) in the analysis. To do this you just have to add an APDL command in the static structral branch and write semiiplicit, this will activate a semiimplicit scheme that is not activated by default. It switches to the semiimplicit method when the implicit solution fails to converge.

You can learn more about this method by looking at the help : https://ansyshelp.ansys.com/account/secured?returnurl=/Views/Secured/corp/v212/en/ans_cmd/Hlp_C_SEMI.html?q=semiimplicit

Also, you can look at this page where these gentlemen have explained it very well.

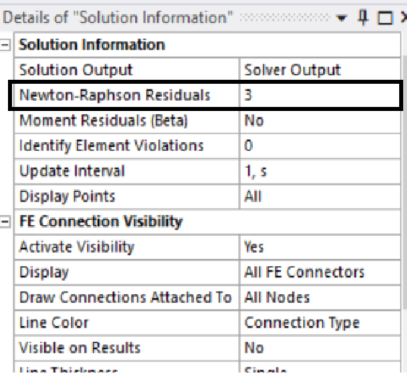

Plot also the Newton-Raphson residuals, put at least 3 elements (see below), this will help to see the elements that caused the convergence to stop

Hoping that it helps you

July 23, 2021 at 9:28 amHaiquan

SubscriberThank you very much for your comments! I will try the semiimplicitmethod

July 23, 2021 at 10:12 amEmperor

SubscriberI advise you to look at this page too (I forgot to put the link in my previous comment) : https://www.padtinc.com/blog/ansys-mechanical-semi-implicit/

It seems that your problem is caused by the contacts (see Newton-Raphson residues to confirm it), so I also thought that you could solve your problem with one of the following methods (I often practiced these methods to solve my contact problems):

First of all I would like to know if you are driving your study in Force or in displacement?Refine the mesh in contact with the bulb.

1- You put the two bodies in contact from the modeling tool you are using (if they are not in contact from the beginning), then in mechanical you just drive your bulb to insert it with an initial time step at 100, minimum substep at 10 and maximum substep 1000.

or :

2- If at the beginning of the analysis the bodies are not in contact, you make a solution in 2 steps. A first step where you move the ampoule to the contact and a second step where you insert the ampoule.

If you display the Newton-Raphson residues, someone will surely be able to tell you what the problem is if the steps I gave you do not work.

Tell us if it works for you

July 26, 2021 at 12:56 amHaiquan

Subscriber@brivael Thank you very much for these suggestions ! I am using displacement for insertion

July 26, 2021 at 2:40 ampeteroznewman

SubscriberIt's good that your model is using Displacement to move the bulb down. has some good suggestions. Here are some other things that you can try.

It looks like the solid bulb is a rigid body. Try using smaller elements on the solid bulb surface.

You don't show the tip of the bulb. Is there a radius on that? There should be.

Finally, try using a different Detection method: Nodal-Normal to Target.

July 26, 2021 at 2:44 amHaiquan

SubscriberThank you so much for your comments! Yes, the spring is much more flexible than the bulb. What you see in the picture is rigid body for solid bulb

July 26, 2021 at 2:51 ampeteroznewman

SubscriberYes, I realized that after I posted so I edited what you first read and put up a different list of suggestions. Please reread the post above.

Viewing 11 reply threads- The topic ‘Convergence difficulty when shell edges come into contact with solid body’ is closed to new replies.

Innovation SpaceTrending discussionsTop Contributors-

5289

-

1885

-

1403

-

1267

-

1021

Top Rated Tags© 2026 Copyright ANSYS, Inc. All rights reserved.

Ansys does not support the usage of unauthorized Ansys software. Please visit www.ansys.com to obtain an official distribution.

-

The Ansys Learning Forum is a public forum. You are prohibited from providing (i) information that is confidential to You, your employer, or any third party, (ii) Personal Data or individually identifiable health information, (iii) any information that is U.S. Government Classified, Controlled Unclassified Information, International Traffic in Arms Regulators (ITAR) or Export Administration Regulators (EAR) controlled or otherwise have been determined by the United States Government or by a foreign government to require protection against unauthorized disclosure for reasons of national security, or (iv) topics or information restricted by the People's Republic of China data protection and privacy laws.