-

-

January 11, 2020 at 7:16 am

Ameet

SubscriberI'm using static structural to simulate a problem which consists of a part. The part has two rubber-like cups attached to it at some distance in the body itself. This body (and the cups) need to move inside a pipe axially with the two cups contacting the inner surface of the pipe. Now, the pipe has a certain wall-thickness and the cups are CAD modeled to the outer diameter which (in reality) will help create a sealing for pressure to build up and push the part-body forward inside the pipe.

Basically, there is penetration between the cup and the wall thickness of the pipe. First, how do I resolve this and establish a contact that will enable me to solve this problem?

Second, I have these cups modeled to a hyper-elastic behavior by inserting a command which basically over-writes material and considers rubber-like behavior but I have no idea if I'm doing this right. The part in real is SS, with cups that are of Polyurethane.

I'm fairly new here and suggestions/explanations are most welcome.

Please help me out. -

January 14, 2020 at 3:44 am

peteroznewman

SubscriberAmeet,

Create a Static Structural analysis.

Define Frictional Contact between the ID of the pipe and external faces on the polyurethane cup.

Under Analysis Settings, turn on Large Deflection. Turn on Auto Time Stepping and set the Initial Substeps to 100 and the Minimum Substeps to 100.

Insert a Contact Tool under the Connections folder and Evaluate Initial Contact Status. You should see the contact is Closed, with the expected penetration.

Depending on the geometry, you might get lucky and during the solve, the penetration will resolve itself automatically. That would be great.

If you are not that lucky, implement a three-step solution and insert a Contact Step Control and a negative radial displacement load on the cup edge. To make a radial load, you need to create a Cylindrical Coordinate System. During Step 1, the contact is set to Dead (Deactivated), while the negative radial displacement is ramped from zero. This pushes the cup inside the pipe. During Step 2, the contact is set to Alive (Activated). During Step 3, the radial displacement is deactivated. An alternative is to replace the radial displacement with a pressure load to compress the cup and step 3 can ramp the pressure down to zero.

Please insert an image of the cross-section of the assembly in your reply. If the loads and the geometry are perfectly axisymmetric, you can reorient the axis to be along the Y-axis, and take a radial slice in the XY plane and just keep the geometry on the +X axis. Then instead of solids, you will have surfaces on the radial slice. You can build your whole model this way and get a solution with much less time and effort.

-

January 21, 2020 at 4:59 am

Ameet

SubscriberHello Peter.

Firstly, no I wasn't lucky with the solve using the first method you suggested.

Secondly, can you please guide me through the second method using contact step control. I tried but I could not make the problem converge the way it would in reality.

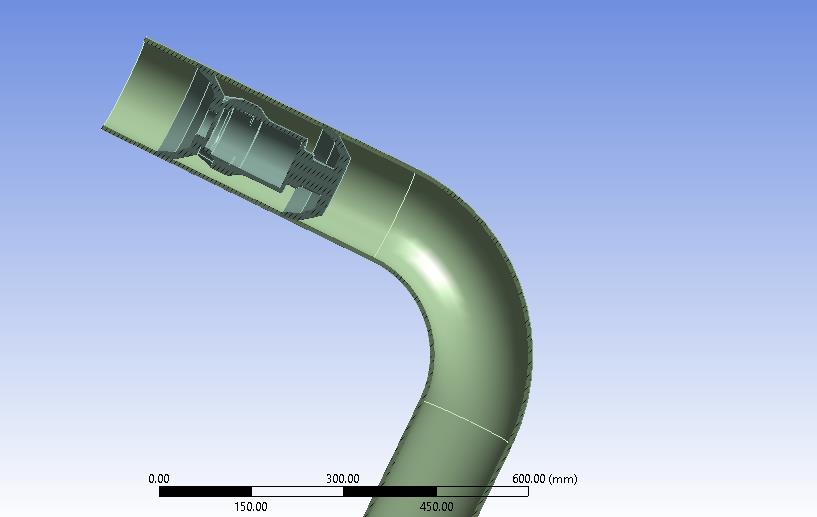

I am attaching a cross-section view for your reference.

-

January 21, 2020 at 10:53 am

peteroznewman

SubscriberPlease reply with the version of ANSYS you are using and after you post the reply, use the Attach button to upload an Archive .wbpz file so I can look at your model. The file size must be < 120 MB. Delete the mesh if it is larger than that.

Do you need this device to be pushed around the bend in the pipe?

Another method is to flare the pipe out to a larger diameter and have the device begin with the first cup just tangent to the flared out section, and use an axial displacement to put the device into the pipe.

-

- The topic ‘Contact problem in a part-body’ is closed to new replies.

-

4833

-

1587

-

1386

-

1242

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.