-

-

November 13, 2021 at 9:04 pm

nds88

SubscriberHello,

I need to model a series of connecting parts that have clamps at their interfaces (an interlocking curvature). These parts will have some load and the joint connection maintains their precise alignment. I will need to compare my model to some test data and I need a relatively accurate model for that. I am familiar with the contact formulations, I have done some test cases, and I have read some documentation.

I want to use Normal Lagrange contacts at the interface of the clamped components, but the convergence issues and solve time are probably going to be an issue because this model will be a bit large.

I was wondering if anyone could advise on the following:

1) What penetration is considered negligible? If I use Pure Penalty and enforce a Penetration Tolerance Value of 1e-4, is that sufficiently small? How would you expect this to compare to Normal Lagrange?

2) I have read that the quadratic tetrahedral elements (10 node, I think?) are ideal for capturing a curvature, but is there any particular mesh that is recommended for contact accuracy (assuming the area is refined enough)?

3) Does mesh inflation effect contact results?

4) How does the Contact Match (mesh edit tool) affect the analysis? Is that recommended?

5) Are there any good indicators that the resulting contact pressure plot is reliable?

Thank you for any input.

November 13, 2021 at 9:51 pmpeteroznewman

Subscriber1) A negligible amount of penetration is problem specific. If the diameter of the pipe is 3 meters, then 0.3 mm may be considered negligible. On the other hand, for a pipe with a diameter of 3 mm, 0.3 mm would be a huge amount of penetration. In the domain of optics, for a 1 meter mirror, a 0.1 mm penetration would be huge. An acceptable penetration may be on the order of 1e-6 mm.

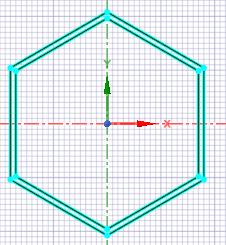

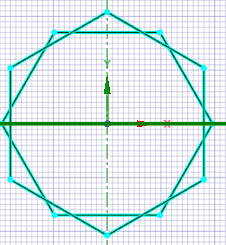

2) Quadratic elements can capture curvature, but are not the only consideration. The first consideration is to have the nodes on each side of the interface line up. That will allow a linear mesh to behave well with the contact elements. Using a grossly exaggerated example so you can see the effect, these two circles were meshed with 6 linear elements around. The first mesh has a clearance when the mesh is lined up but has an interference when the mesh doesn't line up. Quadratic elements can help this, but linear elements tend to have fewer problems with convergence in contact models.

3) Inflation can help to get accurate stress near the surface.

3) Inflation can help to get accurate stress near the surface.

4) Contact Match is great when it works, but sometimes it is simpler to just use sizing controls (number of divisions) on edges and splitting the body to make sure two circles start and end at the same point.

5) If the contours are smooth, that is a good indication of a quality mesh.

November 15, 2021 at 12:54 amnds88

SubscriberThanks Peter In your example for number 2, the misalignment of the nodes would result in a penetration and a higher stress at that area?

Part of the reason I am considering the differences in mesh generation is because the Contact Match is only available for tetrahedral elements. In some test cases, I can see that Contact Match produces a more uniform contact pressure plot, as opposed to a bit more of a jagged plot. Is that it's only real value? Is convergence time affected by contact match that you know of?

November 15, 2021 at 3:19 ampeteroznewman

SubscriberYes, the physical geometry has a clearance between two concentric circles, but due to meshing differences between the two circles, an artificial interference is created along with an artificial stress.

Contact mesh is nice to have, but you can get an aligned hex mesh if the geometry is sliced down to sweepable bodies. Convergence is going to depend on resolving the interference, and will be easier if there is no artificial interference, which will also give smoother pressure plots.

-

January 18, 2023 at 5:31 am

vkm120991

SubscriberHi @peteroznewman,

Since penetration value directly affects the contact pressure and the penetration value is an outcome of normal stiffness value factor:

When should we deviate from the "program controlled" stiffness option? [My current understanding is to always prefer program controlled for most problems unless we see chattering/trouble in convergence]. Most of the theoretical Hertz contact problems when simulated in FEA gave good accuracty with hand calculations with 'program controlled' stiffness but I see alot of literature on the internet suggesting the default 'stiffness factor' of 1 is rarely used and people always override within the range of 0.1 to 1.

Viewing 3 reply threads- The topic ‘Contact Analysis Best Practices’ is closed to new replies.

Innovation SpaceTrending discussionsTop Contributors-

4678

-

1565

-

1386

-

1241

-

1021

Top Rated Tags© 2025 Copyright ANSYS, Inc. All rights reserved.

Ansys does not support the usage of unauthorized Ansys software. Please visit www.ansys.com to obtain an official distribution.

-

Ansys Assistant

Welcome to Ansys Assistant!

An AI-based virtual assistant for active Ansys Academic Customers. Please login using your university issued email address.

Hey there, you are quite inquisitive! You have hit your hourly question limit. Please retry after '10' minutes. For questions, please reach out to ansyslearn@ansys.com.

RETRY