-

-

April 11, 2023 at 9:58 am

Navsing

SubscriberHi,

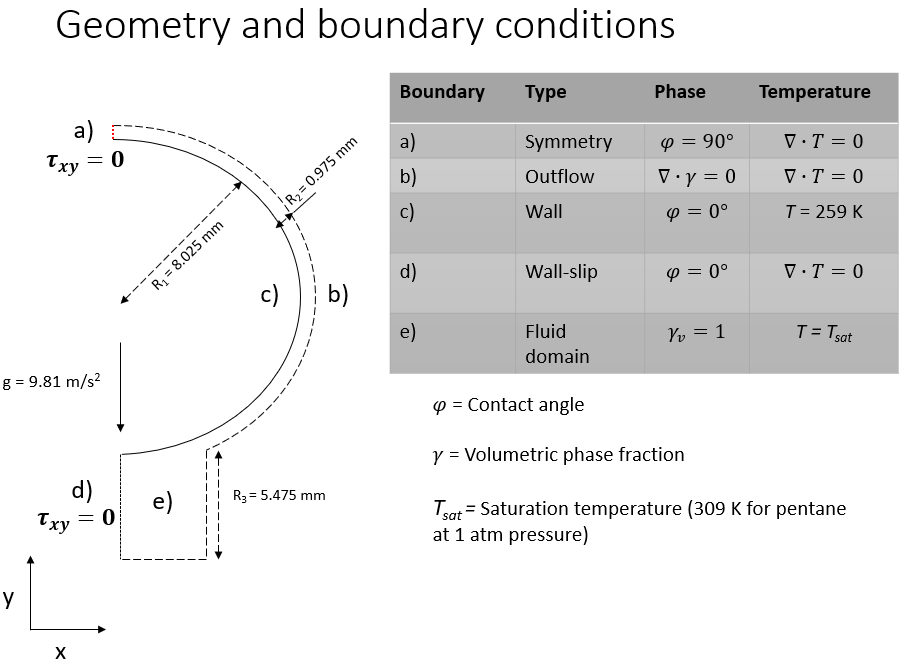

I'm simulating filmwise condensation over a tube in 2D with initally using pentane as the condensate. I'm trying to calibrate my model with another paper (S.R. Thomas Kleiner, Harald Klein, CFD model and simulation of pure substance condensation on horizontal tubes using the volume of fluid method, Int. J. Heat Mass Transfer 138 (2019) 420-431.) which is validated against Nusselt's solution.

During t = 0.05 s, the simulation looks approximatly the same as the papers' result. However, at t = 1.00 s where they say it should provide a steady state solution, my results start to diverge from theirs as the film thickness becomes much larger at the bottom of the tube within the necking region and the jet. Whereas, in their results, the film thickness starts to reduce.

Because of this, I'm obtaining much lower heat transfer coeffcients that what they show. As such, it gives me a larger error in comparison to the Nusselt solution. Does anyone have any ideas as to why this is happening? If it is to do with buoyancy forces, I have set the operating density to be equal to the lightest phase which is the vapour in my case and still made no difference.

Here is the geometry and the mesh of my setup if needed to know.

-

April 11, 2023 at 2:05 pm

Rob

Forum ModeratorWhy is d) set as a wall? Otherwise it looks OK. How is the convergence, and did the paper include the solid pipe region or consider the outer surface as a thin wall? I've seen this model during the wall film testing so the model is fine, but flow and film generation are influenced by many other effects linked to condensation and flow.

-

April 11, 2023 at 4:14 pm

Navsing

SubscriberIts the same boundary condition as they have in the paper. Its so that I can set the contact angle at the wall to 0°, as setting it as symmetry implies the contact angle at the wall is 90°. As a result, it will create dropwise flow and cause the results to deviate away from the Nusselts' model as the theorectical model assumes no surface tension effects.

The convergence is fine. The continuity is always less than one. I've set a globel courant number to be equal to 0.4 to ensure no divergence. The paper does include a solid region for their further investigations. However, just for the validation section, they consider the outer surface as a thin wall. So its' the same as what I show in my model.

As for the mass transfer rate, I've used their proposed mass transfer rate for condensation. Here is the equation:

I've incorperated this equation as a UDF for the DEFINE_MASS_TRANSFER macro and everything seems fine. I get a steady rate of condensation with no divergence issues.

Also here is what I have for the multiphase model options:

Additionally, I've set the viscous model to be laminar. All fluid properties are constant at saturation conditions. I just dont know where my problem lies as everything so far looks good. Its just that the film thickness is bigger than it should be in comparison to the papers' result.

-

April 11, 2023 at 4:27 pm

Rob

Forum ModeratorHow, exactly, was their wall defined? If b) is an outflow (as opposed to pressure outlet) where is the film material coming from?

-

April 11, 2023 at 4:38 pm

Navsing

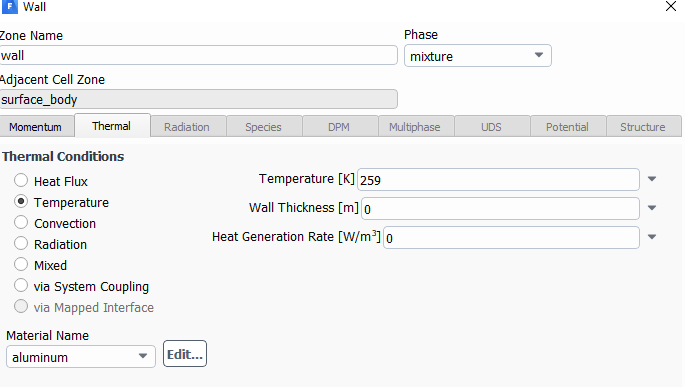

SubscriberThey use a wall with a no-slip boundary having complete wetting (contact angle = 0°) and a constant wall temperature to compare with the Nusselt film theory. I have set the exact same conditions shown here:

By the way, the contact angle set here is 180° as I've set the condensate as the primary phase and the vapour as the secondary phase. And sorry b) is pressure-outlet with a backflow temperature equal to the saturation temperature. I'm not using outflow anymore.

-

January 30, 2024 at 1:18 pm

ibrahimallam087

SubscriberHallo Navsing,

Can you please tell me whether you validate the results in the paper or not and if you do can you show me the setup for the problem and the udf that you made

Thank you

-

- The topic ‘Condensation validation issue’ is closed to new replies.

-

4618

-

1530

-

1386

-

1210

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.