-

-

February 21, 2023 at 3:58 pm

Amir

SubscriberHello All,

I have been trying to simulate the condensation of hot humid air while passing through a pipe at a relatively lower temperature. We are mainly interested in the condensation that would happen on the inner surface of the pipe as humid air passes through it, not bulk condensation. So far we have used VoF and Mixture models, but we faced some difficulties on modeling humid air (as a fluid consisted of air and water vapor). Using VoF model, we were able to observe liquid water at the end of simulation, but the initial fluid in that case was just pure water vapor, not a mixture of air and water vapor. recently I started learning about Eulerian Wall Film which seems to be more comprehensive than other models. There is a tutorial by Ansys on using Wall Film model for the simulation of the Defogging phenomena in car's windows. My question is that would it be a reasonable approach to consider condensation [hypothetically] as reverse defogging or fogging in this case and then use Wall Film model to simulate the condensation we are looking for? and if there is anyone with some experience or knowledge on this model who can give us some advice or comments

Thank you.

-

February 21, 2023 at 4:56 pm

Rob

Forum ModeratorYes, set up the model in much the same way, and then watch the film form. You may want to review the EWF<>VOF too if the film is expected to become thick relative to the domain.

-

March 8, 2023 at 3:48 pm

Amir

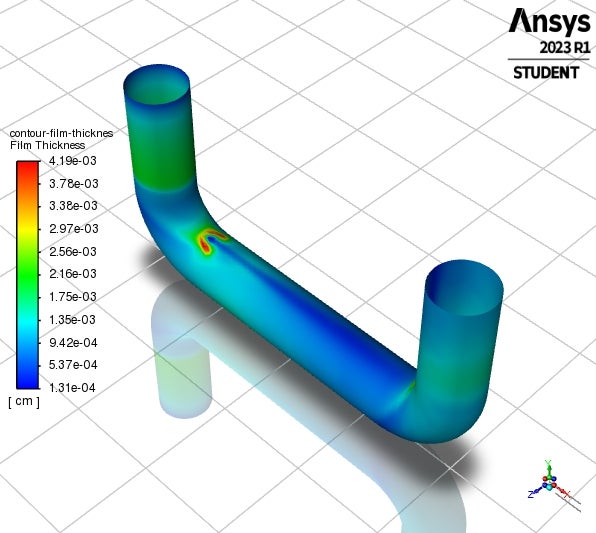

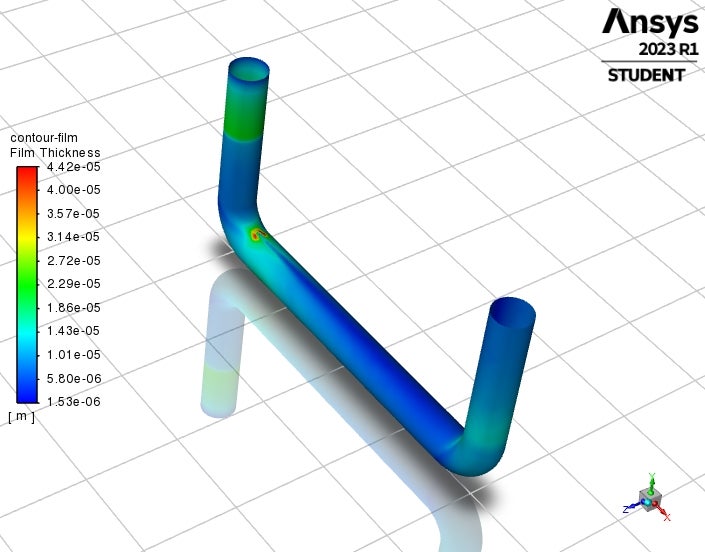

SubscriberThank you very much Rob. When setting boundary condition on walls, I was not sure which option under the "Film Condition Type" should be used. There are two options: "Boundary Condition" and "Initial Condition". I ran two similar simulations with only difference being the film condition type and the results for film thickness were almost identical.

problem description:

INLET: humid air enters the domain with the velocity of 5m/s, at 27C, and the Species Mass Fraction of H2O being 0.01771.

Walls: thermal condition set as "Temperature" at 15C(to facilitate condensation and film formation) with EWF activated.

For the first case, the film condition type was: Boundary Condition with Film mass flux and mumentum fluxes being zero and Incoming Film Temperature being 27C same as humid air going through the domain.

For the second case, it was set as "Initial condition" with film height as zero and film temperature as 27C.

At the end, contours of "film thickness" looked almost identical for both cases!

My question is that is this expected? what are the differences between two options under Film Condition Type?

-

March 8, 2023 at 4:11 pm

Rob

Forum ModeratorThat setup looks reasonable.

The two options aren't well explained. Initial condition is just that, the amount of film present when you initialise the film. The boundary condition is how much film is added/removed and if any momentum is added to the film on that boundary, that's continuous throughout the simulation. Because you're just condensing vapour to form a film and the wall temperature is set in the Thermal tab you should get (near enough) the same result with either option.

The difference is for when you start with a film. So, initial condition might be 2mm of film that you then add to or evaporate, nothing else is added to the film from that boundary (film boundary conditions are zero). Or, if a film is continuously added by some other mechanism (eg spraying an area or rain onto a roof) but starts from a zero thickness film.

-

- The topic ‘Condensation of humid air using Eulerian Wall Film and Species Transport’ is closed to new replies.

-

4939

-

1639

-

1386

-

1242

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.