-

-

July 1, 2020 at 7:55 am

htozam

Subscriber

Dear all,

I have used so many concrete material models like TB,concr,matid to TB,concr,matid,DP etc and from the old legacy element to new technology unfortunately non of these responds as needed. the closest response is from the last model i.e. TB,concr,matid with MISO points.

Can someone please advise me if I am making the right approach of testing all these materails models and elements?

The material models are enlised below. Some of them I have taken from ansys help sys examples and some from Mr. Mirghani posts in the student commnunity:

ET,MATID,CPT215 Coupled nodes with Rebars in all directions

E=20000, v=0.2 Fuc=31.6 Fbc=36.34 Fut=3 Rt=1 D=4e4 Scv=-35 R=2 Yt0=0 Yc0=2e-5 Bt=3000 Bc=2000 c=1600 m=2.5

MP,ex,1,E

MP,NUXY,1,v

TB,MPLA,1,,,DPC

TBDATA,1,Fuc,Fbc,Fut,Rt,D,SCV

TBDATA,7,R,Yt0,Yc0,Bt,Bc

TB,MPLA,1,,,NLOCAL

TBDATA,1,c,m

ET,MATID,185 ! Define elements as SOLID185

MP,EX,MATID,29100 ! Define Elasticity Modulus

MP,NUXY,MATID,0.2 ! Define Poisson's ratio

TB,MPLANE,MATID,,6 ! Define the microplane model parameters

tbdata,1,0.75,0.75,0.208,6.109e-05,0.512,98 !k0,k1,k2,α_mic, β_mic, beta_mic

TBTEMP,22

ET,MATID,185

Drucker Prager Concrete Model with Dilitancy Parameters

! ELASTIC CONSTANTS

MP,EX,MATID,20.0E9

MP,NUXY,MATID,0.2

! Base Drucker-Prager concrete

Rc=30.0E6 ! uniaxial compressive strength

Rt=3.0E6 ! uniaxial tensile strength

Rb=36.0E6 ! biaxial compressive strength

delta_t=0.25 ! dilatancy factor tension

delta_c=1.0 ! dilatancy factor compression

! Linear hardening/softening

kappa_cm=0.0025-Rc/20.0E9

kappa_cr=0.0025

omega_ci=0.33

omega_cr=0.1

kappa_tr=0.0005

omega_tr=0.2

TB,CONCR,matid,,,DP

TBDATA,matid,Rc,Rt,Rb

TB,CONCR,matid,,,DILA

TBDATA,matid,delta_t,delta_c

TB,CONCR,matid,,,HSD6

TBDATA,matid,kappa_cm,kappa_cr,omega_ci,omega_cr,kappa_tr,omega_tr

continued.....

-

July 1, 2020 at 7:55 am

htozam

Subscriber

rest of the post is here as it wouldnt fit in one post:

ET,MATID,185 ! Define elements as SOLID185

MP,EX,MATID,29100 ! Define Elasticity Modulus

MP,NUXY,MATID,0.2 ! Define Poisson's ratio

TB,MPLANE,MATID,,6 ! Define the microplane model parameters

tbdata,1,0.75,0.75,0.208,6.109e-05,0.512,98 !k0,k1,k2,α_mic, β_mic, beta_mic

TBTEMP,22

ET,MATID,SOLID65

R,MATID,0,0,0,0,0,0

RMORE,0,0,0,0,0

MP,EX,MATID,30999.9726

MP,PRXY,MATID,0.2

MPTEMP,MATID,0

TB,CONCR,MATID,1,9

TBTEMP,22

TBDATA,,0.1,0.9,1.5,33

TB,MISO,MATID,1,100,0

TBTEMP,22

TBPT,,0,0

TBPT,,0.000002,0.0619999452874679

TBPT,,0.000004,0.123999562300902

TBPT,,0.000006,0.185998522772063

.................

..........

-

July 1, 2020 at 8:39 pm

Wenlong

Ansys EmployeeHi,

I haven't got a chance to look into your commands, but just FYI, here is an example of using microplane material to model concrete damage: https://ansyshelp.ansys.com/account/secured?returnurl=/Views/Secured/corp/v193/ans_tec/tecreinfconcmatprop.html

Regards,

Wenlong

================ Note ====================

If you have trouble opening the links I attached, please see the first useful link below

Useful Links

- How to access Ansys Online Help Document

- How to show full resolution image

- How to use Google to search within Ansys Student Community

-

July 2, 2020 at 5:11 am

htozam

SubscriberDear Wenlong,

Thank you very much for considering to answer this post which is important for me. I checked the link for the material properties of the microplane model for concrete you have shared. The links took me to another page than i have been before; however, the model is still the same as I have borrowed before from the help documents. It is first model in the list of the models I posted; I posted the command in a row rather in the column just to make sure it fits the requirement of posting length limits. Appreciate you considerations.

Regards,

-

July 2, 2020 at 1:40 pm

Wenlong

Ansys EmployeeHi htozam,

Thanks for your reply. Can you please tell us more about what experiment curves are you trying to fit? Thanks!

Regards,

Wenlong

-

July 3, 2020 at 7:37 am

htozam

SubscriberHi Wenlong,

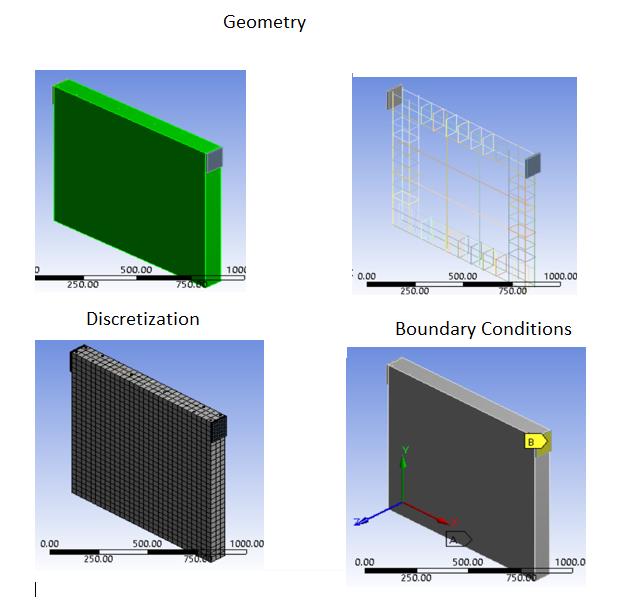

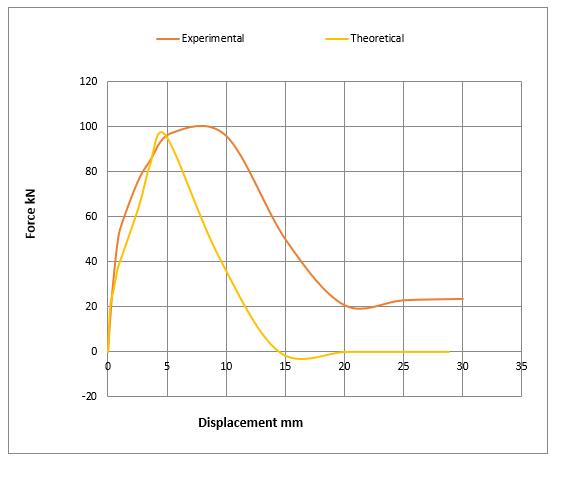

Thank you for reply, I wholeheartedly appreciate your considerations as I am terrribly stuck with such kind of curve response, please find a copy of the curve attached (it include both FEA and Experimental responses). Also included is a wbmz of the model if needed.

Kind regards,

https://drive.google.com/drive/folders/11HUIbDUaYg7QPdYUKx9fY_mkENPiS1xR?usp=sharing

-

July 3, 2020 at 4:26 pm

Wenlong

Ansys EmployeeHi htozam,

Sorry that I should mention earlier: Ansys employees are allowed to download or access the link you shared due to company policy. Can you please insert an image of your experiment data plot (and your FEA plot)? Can you briefly describe what type of experiment is it that you are trying to replicate in simulation (beam bending test? column crushing test? etc)? Maybe add a screenshot of your model to show the experimental setup?

Thanks!

Regards,

Wenlong

-

July 3, 2020 at 4:47 pm

Wenlong

Ansys EmployeeI have two more questions: you have shown several material models: Microplane model, Druker-Prager with linear softening, multilinear hardening, etc. Did you 1) incorporate them all into the model? 2) Or just list them to show the models you have tried? If the answer is the 2), can you please clarify which materials combinations did you use in a simulation?

The second question is: did you have rebar reinforcement in the concrete? If yes, how did you model them?

Thanks,

Regards,

Wenlong

-

July 3, 2020 at 4:48 pm

-

July 3, 2020 at 5:06 pm

htozam

Subscriber -

July 3, 2020 at 6:02 pm

htozam

SubscriberDear Wenlong,

I am not sure why I couldnt see your second post earlier my apologies. With regards to the two questions, 1) I tried the material models one by one. 2) the reinforcements were always explicity defined, following is the defination:

ET,matid,LINK180 ! define link element

SECTYPE,matid,LINK ! assign link

Area=78.536

SECDATA,Area

MPDATA,EX,matid,,5e4

MPDATA,PRXY,matid,,0.23

TB,BISO,matid,1,2,

TBDATA,,1000,0

Please advise if there is any more information needed. Thank you for your considerations.

Kind regards,

-

July 3, 2020 at 6:06 pm

Wenlong

Ansys EmployeeHi htozam,

Thanks for sharing the information. Looks like you already have some good preliminary FEA predictions. (Is the theoretical plot the FEA result?). It seems your model predicts a very good peak force. It is just the softening part doesn't match very well, which means your model dissipates less energy than the experiment.

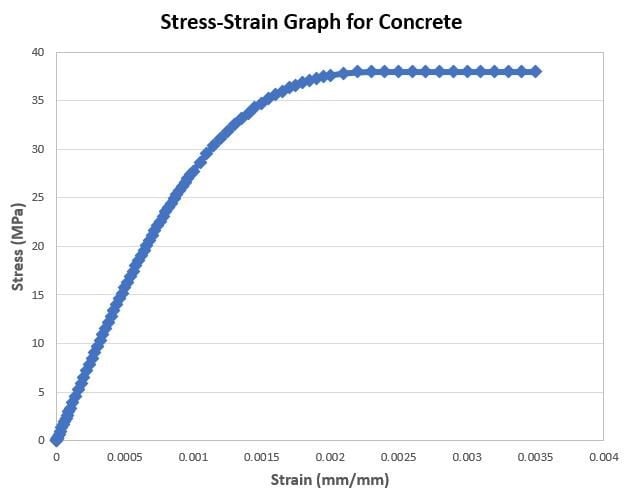

You mentioned the closest result to the experiment is by using "TB,concr,matid with MISO points". You have probably calibrated the material model input with your experiment data, right? How did you define softening using this model?

Apart from this wall shear test, have you conducted any smaller-scale test on the concrete (to obtain material parameters)? Do you have output information (like force-displacement plot) from these tests? I mention this because to calibrate and verify your concrete material model, it is better to start with some smaller test. It allows you to eliminate the influence of the effect of rebars and other complex condition so that you can make sure the concrete model is right. For example, for some plasticity experiment data, after I extracted the material properties, I would run a dog-bone simulation and compare it with the experiment, and only after making sure the material model is defined correctly, I would move on to apply that plastic material to some large-scale complex model.

If you don't have other small scale tests, I would play with the softening law's parameter to see if it will give me a better match.

One quick question: So you are applying cyclic loading to the concrete wall, then why is the force vs. displacement plot monolithic?

Regards,

Wenlong

-

July 3, 2020 at 6:19 pm

Wenlong

Ansys EmployeeHi htozam,

Sorry, I just see your previous post too. I guess the page wasn't refreshed while I was typing.

I see, so you are using link elements for the rebars. I wonder how did you tie the rebars to the concrete? Did you use REINF elements or did you use bonded contact, I asked because bonded contact is not ideal in this case to combine these two materials since the rebars are inside the concrete. If you want to see more info about this topic about REINF, please see this post: /forum/forums/topic/error-contact/

Regards,

Wenlong

-

July 3, 2020 at 8:37 pm

htozam

SubscriberHi Wenlong,

Thank you for your considerations. Yes, preliminary predictions are thankfully conforming regarding peak forces. Yes, the theoretical plot is the FEA result. You have pinpointed my concerns before I mention it which is the energy dissipation.

The conforming results are from TB,conc,matid and TB,MISO,matid but it would not allow definition of the softening part meaning the analysis will immediately fail as soon as it is run.

Apart from the main experiment specimen dimension (1x1x0.1m) cubes and cylinders tests were conducted based on which the MISO points were developed. I tried to model uniaxial crush tests we had on the cubes but it will fail immediately without any convergence.

You are absolutely right; the actual response is hysteresis and the load-displacement is actually an averaged of the envelope of the hysteresis response developed for comparison reasons.

Thank you for the second post as well, I used constraint command CEINTF to tie all the reinforcements except vertical bars. Since vertical bars had bond-slip in the experimental specimens I modelled the tie with the nonlinear interface spring element Combin39 in y direction using EINTF command for offset nodes. The vertical bars were also constrained in x and z direction using CEINTF command. Followings are the snippets:

! to tie all other bars except vertical bars

/PREP7

cmsel,s,Conc,elem

cmsel,r,OBars,node

ceintf,0.0001

ALLSEL,ALL

/SOLU

OUTRES,ALL,ALL

! to tie vertical bars in x and z directions

/PREP7

cmsel,s,Conc,elem

cmsel,r,VBars,node

ceintf,0.0001,ux

ceintf,0.0001,uz

!ceintf,0.0001,uy

ALLSEL,ALL

/SOLU

OUTRES,ALL,ALL

! to tie vertical bars in y direction using non linear interface element to model bond-slip

/PREP7

cmsel,s,selection,node

cmsel,a,selection2,node

ET,MATID,39,0,0,2,0,0,0

TYPE,MATID

REAL,MATID

R,MATID,-30,0.0001, -15,0.0001, -5,0.0001 ! Modified Bo Di et al model

rmore, 0,0, 0.0001,1140, 2.6,3824

RMORE, 5,3900, 10,3910, 15,3920

RMORE, 20,3930, 25,3940, 30,3950

!et,matid,40

!keyopt,matid,3,2

!k1=1000 !400 !600 !500 !700 !900! 1000 !1479

!k2=90! 400 !1000

!c=0.5 !50 no effect !5 no effect !0.5 no efect !1!0 no effect

!gap=0

!fslide=200 !1100!1525!2250!4250

!m=0

!r,matid,k1,c,m,gap,fslide,k2 !k1,k2,c,gap,fslide

EINTF,0.01, ,LOW,0 , 19.483,0 ,18.333 , 0

EINTF,0.01, ,LOW,0 , 19.483,0 ,-18.333 , 0

EINTF,0.01, ,LOW,0 , 2.93,0 ,18.333 , 0

EINTF,0.01, ,LOW,0 , 2.93,0 ,-18.333 , 0

EINTF,0.01, ,LOW,0 , 4.31,0 ,16.667 , 0

EINTF,0.01, ,LOW,0 , 2.36,0 ,16.667 , 0

ALLSEL,ALL

/SOLU

OUTRES,ALL,ALL

I tried combin40 as well but to no avail meaning not much correspondence with the experimental results. I tried quite a few bond-slip models from the literature for Combin39 before the model in the snippet could produce the FEA curve.

I used the bonded contact type with MPC formulation for the steel plates which worked very well and resolved the non-convergence issues. I used Mesh200 and Reinf elements but it produced a non-conforming result meaning it will not correspond to the experimental results.

Please find a couple of screen shots for MISO and Hysteresis response attached.

Is there a way the model could produce a more corresponding amount of energy dissipation ?

Thank you for your considerations.

Kind regards

-

July 3, 2020 at 8:42 pm

htozam

SubscriberHi Wenlong,

Thank you for your considerations. Yes, preliminary predictions are thankfully conforming regarding peak forces. Yes, the theoretical plot is the FEA result. You have pinpointed my concerns before I mention it which is the energy dissipation.

The conforming results are from TB,conc,matid and TB,MISO,matid but it would not allow definition of the softening part meaning the analysis will immediately fail as soon as it is run.

Apart from the main experiment specimen dimension (1x1x0.1m) cubes and cylinders tests were conducted based on which the MISO points were developed. I tried to model uniaxial crush tests we had on the cubes but it will fail immediately without any convergence.

You are absolutely right; the actual response is hysteresis and the load-displacement is actually an averaged of the envelope of the hysteresis response developed for comparison reasons.

Thank you for the second post as well, I used constraint command CEINTF to tie all the reinforcements except vertical bars. Since vertical bars had bond-slip in the experimental specimens I modelled the tie with the nonlinear interface spring element Combin39 in y direction using EINTF command for offset nodes. The vertical bars were also constrained in x and z direction using CEINTF command. Followings are the snippets:

! to tie all other bars except vertical bars

/PREP7

cmsel,s,Conc,elem

cmsel,r,OBars,node

ceintf,0.0001

ALLSEL,ALL

/SOLU

OUTRES,ALL,ALL

! to tie vertical bars in x and z directions

/PREP7

cmsel,s,Conc,elem

cmsel,r,VBars,node

ceintf,0.0001,ux

ceintf,0.0001,uz

!ceintf,0.0001,uy

ALLSEL,ALL

/SOLU

OUTRES,ALL,ALL

! to tie vertical bars in y direction using non linear interface element to model bond-slip

/PREP7

cmsel,s,selection,node

cmsel,a,selection2,node

ET,MATID,39,0,0,2,0,0,0

TYPE,MATID

REAL,MATID

R,MATID,-30,0.0001, -15,0.0001, -5,0.0001 ! Modified Bo Di et al model

rmore, 0,0, 0.0001,1140, 2.6,3824

RMORE, 5,3900, 10,3910, 15,3920

RMORE, 20,3930, 25,3940, 30,3950

!et,matid,40

!keyopt,matid,3,2

!k1=1000 !400 !600 !500 !700 !900! 1000 !1479

!k2=90! 400 !1000

!c=0.5 !50 no effect !5 no effect !0.5 no efect !1!0 no effect

!gap=0

!fslide=200 !1100!1525!2250!4250

!m=0

!r,matid,k1,c,m,gap,fslide,k2 !k1,k2,c,gap,fslide

EINTF,0.01, ,LOW,0 , 19.483,0 ,18.333 , 0

EINTF,0.01, ,LOW,0 , 19.483,0 ,-18.333 , 0

EINTF,0.01, ,LOW,0 , 2.93,0 ,18.333 , 0

EINTF,0.01, ,LOW,0 , 2.93,0 ,-18.333 , 0

EINTF,0.01, ,LOW,0 , 4.31,0 ,16.667 , 0

EINTF,0.01, ,LOW,0 , 2.36,0 ,16.667 , 0

ALLSEL,ALL

/SOLU

OUTRES,ALL,ALL

I tried combin40 as well but to no avail meaning not much correspondence with the experimental results. I tried quite a few bond-slip models from the literature for Combin39 before the model in the snippet could produce the FEA curve.

I used the bonded contact type with MPC formulation for the steel plates which worked very well and resolved the non-convergence issues. I used Mesh200 and Reinf elements but it produced a non-conforming result meaning it will not correspond to the experimental results.

Please find a couple of screen shots for MISO and Hysteresis response attached.

Is there a way the model could produce a more corresponding amount of energy dissipation ?

Thank you for your considerations.

Kind regards

-

July 3, 2020 at 8:50 pm

-

July 4, 2020 at 11:39 pm

Wenlong

Ansys EmployeeHi Htozam,

Thanks for the detailed reply. I am curious about one thing: if you don't have any softening defined in the concrete model, then how to get the softening behavior in the overall behavior? Is it from the slipping between steel and concrete?

I did a quick test on a concrete cube compression using material model and analysis settings from this example: https://ansyshelp.ansys.com/account/secured?returnurl=/Views/Secured/corp/v193/ans_tec/tecdynardo.html. I've also used 0.1 nonlinear stablization energy ratio. Luckily I am able to get a converged softening behavior:

So in "tb,concr,matid,,,HSD5", there is a Gfc and Gft parameter that control the compression and tensile fracture energy. I think these are the values you are looking for. I tried two Gfc values, 1 N/mm and 3N/mm, respectively, and here is the difference in force-time plot. (Note that my displacement is linear with time, so the plot is equivalent to force-disp plot)

Below are the command snippet I used for material:

! elastic properties

Ec=30000 ! Young's modulus [N/mm2]

EX,1,Ec

NUXY,1,0.2 ! Poisson's ratio [-]

! density

dens,1,2.5e-6 ! density [kg/mm3]

! strength parameters - concrete

Rc=20 ! uni-axial compressive strength [N/mm2]

Rb=1.2*Rc ! bi-axial compressive strength [N/mm2]

Rt=2.2 ! uni-axial tensile strength [N/mm2]

delt=0.25 ! dilatancy factor in tension [-]

delc=1.00 ! dilatancy factor in compression [-]

tb,concr,matid,,,DP

TBDATA, matid, Rc, Rt, Rb

tb,concr,matid,,,DILA

TBDATA, 1, delt, delc

! hardening/softening - uni-axial stress-strain curve

! compression

Oci=0.33 ! relative stress level at start of hardening

Ocu=0.85 ! relative stress level at ku (mlaw=1)

Ocr=0.2 ! residual relative stress level

kcm=0.002-Rc/Ec ! plastic strain at uni-axial compressive strength

kcu=0.0035-Ocu*Rc/Ec ! plastic strain defining start of exponential softening law

Gfc=3 ! area specific fracture energy [Nmm/mm2] (mlaw=1)

! tension

Otr=0.1 ! residual relativ stress level in tension

Gft=0.100 ! area specific fracture energy [Nmm/mm2] (mlaw=1)

tb,concr,matid,,,HSD5

TBDATA, 1, kcm, Oci,Ocr, Gfc, Gft, Otr

TB,CONCR,matid,,,MSOL

TBDATA,1,2 ! elastic material tangent

And commands for solution control:

ERESX,NO ! copy integrationpoint data to node (no extrapolation)

NROPT,INIT ! Use initial stiffness matrix

NEQIT,100

PRED,off,,off

DELTIM,0.05,0.0001,0.1 ! define time steps (load increments)

OUTRES,ALL,ALL ! save data for all increments

ALLS

Hope this is helpful.

Regards,

Wenlong

-

July 5, 2020 at 5:49 pm

htozam

SubscriberHi Wenlong,

Thank you indeed for your consideration especially taking your valuable time testing the model.

I think some the softening like behaviour could be due to the bond-slippage and some contribution from ductility of the reinforcements.

I tried the model with different combinations of analysis settings and it would finally converge only until about 10.3 mm displacement amplitude without the bond-slip model and up to 3.6 mm displacement amplitude with the bond-slip model.

Above partial convergence happened at 50 substeps for each step without NEQIT and DELTIM controls (leaving NEQIT as default i.e. "program controlled" and trying load steps increase from 10 to 100) I tried a 100 substeps too but it did not improve the convergence. One thing is very interesting that the peak of the performace is very high with or without the bond-slip. Please kindly share your valuable views on the results.

Please find a few screen shots from the analysis attached.

I tried quite a few number of models borrowing from the help systems and the work of the others however non of these models are behaving like experimental curves except the classic model but without the softening and with a significantly reduced energy dissipation which is begining to worry me if this model could be improved at all.

I really wholeheartedly appreciate your time and considrations.

Kind regards,

-

July 6, 2020 at 2:09 pm

Wenlong

Ansys EmployeeHi,

Sorry, I don't have any further comments about the high reaction force predicted using the DP model. Maybe keep adjusting the parameters?

Regarding the convergence, I have one more comment you can try: SEMIIMPLICIT command, it can let your solver switch to explicit solver to get through the Hard-to-convergence points. https://ansyshelp.ansys.com/account/secured?returnurl=/Views/Secured/corp/v201/en/ans_cmd/Hlp_C_SEMI.html?q=semiimplicit. Here is a nice introduction about it:http://www.padtinc.com/blog/ansys-mechanical-semi-implicit/

In the worst scenario, if have time and don't want to pursue the current approach, you can still try a complete explicit analysis. It doesn't have convergence issue so you don't need to worry about the softening behavior-caused convergence. There are two solvers you can choose within Workbench: explicit dynamics and Workbench LS-DYNA. Both support concrete materials. LS-DYNA has more options about contact and allows you to do the bond-slips. However, since they are different solvers, they do require some learning curve especially LS-DYNA.

Regards,

Wenlong

-

July 7, 2020 at 4:41 am

htozam

SubscriberHi Wenlong

Thank you very much for taking me through the technicalities, I can understand the limits and policies and that there could be parts that you may no be able to comment upon. Please ignore any of the question that may not be pertinent. It has been a great and fruitfull discussion so far I learned from it and may other too.

I adjusted several of the parameters for the DP model using the initial load steps only but the peak of the performace is still too high I know you may not be able to comment on these. However, I tried a couple of more models and the maximum performace of one model would adjust with adjusting the parameters, it was quite a lengthy process but it worked for one model, as you advised. Two models are as followings:

One - using TB,mplane calculating the parameters from the elaboration of Flavia Gelatti deciphering the parameters and then adjusting them as you advised. This model’s hysteresis response peaks at lower displacements followed by gradual decrease in the loop maximums. The load displacement graph shows a residual strength which may be left as result of softened stregth. This model adjusted its performace with adjusting parameters however maximum of the loops will increase first followed by a decrease in contrast with experiments and the tb,concr,,,1,9 model which the hysteresis gradually increase but unfortunately it quickly drops in the FEA model do to non existence of the softening effects.

Second - using the Coupled Damage-Plasticity Microplane Model Input from the Example 4.23, chapter 4, material reference of 2019 R3 in Ansys help systems which uses tb,mpla,,,,dpc and tb,mpla,,,,,nlocal. This model would partially converge only at the moment.

I belive the tb,mplane used in the first model is the same as non-regularized elastic damage microplane model, an example of which is given in example 4.21, chapter 4, material reference of 2019 R3 Ansys help systems?

I also tried regularized elastic damage microplane model an example of which is given in example 4.22 of same reference as above but it would also partially converge as well.

A few question, hope they are pertinent:

What version of Ansys support SEMIIPLICIT?

Does Explicit Dynamic use LS Dyna Solver or Autodyn as default solver?

If autodyn is used as default is it sufficient if not how a solver is selected after preprocessing?

I think explicit dynamics do not support command snippets, is dp, dpc, mplan etc available in its material liberary?

If it they available on which solver are they available?

Thank you very much once again for your time and considerations.

Kind regards,

Tb,concr,,,,1,9

-

July 7, 2020 at 4:49 am

htozam

SubscriberHi Wenlong

Thank you very much for taking me through the technicalities, I can understand the limits and policies and that there could be parts that you may no be able to comment upon. Please ignore any of the question that may not be pertinent. It has been a great and fruitfull discussion so far I learned from it and may other too.

I adjusted several of the parameters for the DP model using the initial load steps only but the peak of the performace is still too high I know you may not be able to comment on these. However, I tried a couple of more models and the maximum performace of one model would adjust with adjusting the parameters, it was quite a lengthy process but it worked for one model, as you advised. Two models are as followings:

One - using TB,mplane calculating the parameters from the elaboration of Flavia Gelatti in the student community deciphering the parameters and then adjusting them as you advised. This model’s hysteresis response peaks at lower displacements followed by gradual decrease in the loop maximums. The load displacement graph shows a residual strength which may be left as result of softened stregth. This model adjusted its performace with adjusting parameters however maximum of the loops will increase first followed by a decrease in contrast with experiments and the tb,concr,,,1,9 model which the hysteresis gradually increase but unfortunately it quickly drops in the FEA model due to non existence of the softening effects in the model.

Second - using the Coupled Damage-Plasticity Microplane Model Input from the Example 4.23, chapter 4, material reference of 2019 R3 in Ansys help systems which uses tb,mpla,,,,dpc and tb,mpla,,,,,nlocal. This model would partially converge only at the moment.

I belive the tb,mplane used in the first model is the same as non-regularized elastic damage microplane model, an example of which is given in example 4.21, chapter 4, material reference of 2019 R3 Ansys help systems?

I also tried regularized elastic damage microplane model an example of which is given in example 4.22 of same reference as above but it would also partially converge as well.

A few question, hope they are pertinent:

What version of Ansys support SEMIIPLICIT?

Does Explicit Dynamic use LS Dyna Solver or Autodyn as default solver?

If autodyn is used as default is it sufficient if not how a solver is selected after preprocessing?

I think explicit dynamics do not support command snippets, is dp, dpc, mplan etc available in its material liberary?

If it they available on which solver are they available?

Thank you very much once again for your time and considerations.

Kind regards,

Tb,concr,,,,1,9

-

July 7, 2020 at 3:14 pm

Wenlong

Ansys EmployeeHi,

I think SEMIIMPLICIT starts from version 2019R1. It can help achieve convergence in some very different problems such as this one. I forgot to mention (but you probably already know it), did you change the element to linear order? It typically is easier to converge than higher-order elements.

The default solver in Explicit Dynamics is AutoDyn. You are right that some material models (such as the Microplane model) no longer exist in the Explicit Dynamics library. However, it has its own concrete models such as RHT concrete strength and the John-Holmquist strength model (https://ansyshelp.ansys.com/account/secured?returnurl=/Views/Secured/corp/v201/en/exd_ag/ds_ex_mat_britgran.html).

LS-DYNA has a wider collection of material and contact models. For concrete itself, it has 8 different material models. To use LS-DYNA, you will need to enable it in Extensions -> LSDYNA. Then it will appear in Workbench. Note that LS-DYNA does not come with a student license. In LS-DYNA, you are able to insert command snippets as you did in Static Structural, but it uses a different language.

If possible, may I add you on Researchgate? I am very interested in your research. Thanks!

Regards,

Wenlong

-

July 8, 2020 at 6:03 am

htozam

SubscriberHi Wenlong,

Thank you very much for your help and support, it was a great amount of information and technical support, hope i can find a proper concrete model which corresponds with the experimental result of the cyclic load tests as will as converges, I will find you in the research gate. Thanks.

Kind regards,

-

September 29, 2020 at 2:45 pm

vaibhavtaranekar

Subscriberdid you find any success in analysing your structure for cyclic loading? I am planning to conduct cyclic loading tests on column and plot their hysterisis curves, can you guide me in regards to any other information which you may have found till now?n

-

- The topic ‘Concrete Material Model’ is closed to new replies.

-

4778

-

1565

-

1386

-

1242

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.