-

-

January 11, 2023 at 8:35 pm

Wegner

SubscriberHello,

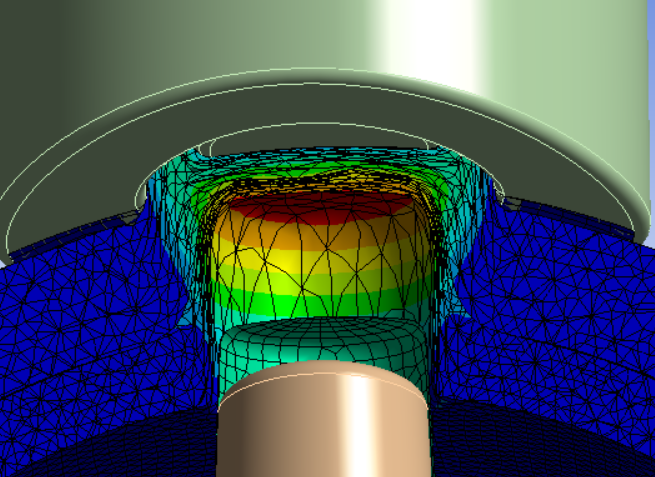

Does anyone could help me with clinching simulation in Ansys.

What I have got is stamping by punch in materials, but it can't make that charakteristic interlock between them.

What I have done till now:

- I design a new material and enter date of multilinear isotropic hardening, as you can see below:

- make calculations in subprogram "structural static"

- you can see what have I done below on screen

I am looking for help of anyone who have any ideas or tips how to solve that problem in Ansys. -

January 12, 2023 at 1:21 am

-

January 12, 2023 at 6:44 am

Wegner

SubscriberI think that conversation is about how to design clinching joint.

I already have a punch and die and I want to make a full simulation as on the first post is showed.

The problem which I have is that I can't make that "interlock" between the parts.

Do you know if it is a problem with mesh sizing or some connection problems?

Or simply I have to use other simulation that "statit structural" like LS-dyna or explit dynamics?

Of course I try to do that with "large deflection" etc.

It is hard to try all options because all calculations take time.

-

January 12, 2023 at 1:37 pm

peteroznewman

SubscriberYes, these calculations are time consuming.

I suggest you try a material model with less hardening so the material can flow more easily and will not be "held back" by the stress in the material. Use a Bilinear Kinematic Hardening model and set the Tangent Modulus to 0.

-

January 14, 2023 at 3:13 pm

-

January 14, 2023 at 3:32 pm

peteroznewman

SubscriberIt's not clear from the plots you showhow far away from "not working" the results are. I want to see an orthogonal view of the cut section and see the rigid surfaces as well as the deformation in the metal sheets. Without seeing that, it's not clear that the change in the material model made no difference.

One idea is to do these calculations in an axisymmetric model. The benefit is that the computation will be an order of magnitude faster, which make testing different material models or other treatments less time consuming.

When you say you are not getting the clinched result you want, is that because the simulation doesn't complete to the end or it does complete to the end but the shape is not what you want. If it is the latter, maybe the problem is the shape of your punch and die.

-

January 14, 2023 at 7:18 pm

Wegner

SubscriberI will show you that view in next post.

It is some idea to do that in axisymmetric model to make it easier and faster. I didn't do that before because it is not axisymmetrical model but I can make one and try it.

I know that everythink is fine with the model of punch and die because I did that experiment in reallity and it works and make that "interlock".

Thanks for all your reply so far

-

- The topic ‘Clinching’ is closed to new replies.

- The legend values are not changing.

- LPBF Simulation of dissimilar materials in ANSYS mechanical (Thermal Transient)

- Convergence error in modal analysis

- APDL, memory, solid

- How to model a bimodular material in Mechanical

- Meaning of the error

- Simulate a fan on the end of shaft

- Nonlinear load cases combinations

- Real Life Example of a non-symmetric eigenvalue problem

- How can the results of Pressures and Motions for all elements be obtained?

-

3862

-

1414

-

1221

-

1118

-

1015

© 2025 Copyright ANSYS, Inc. All rights reserved.