-

-

May 19, 2022 at 4:33 pm

baharaksajjadi

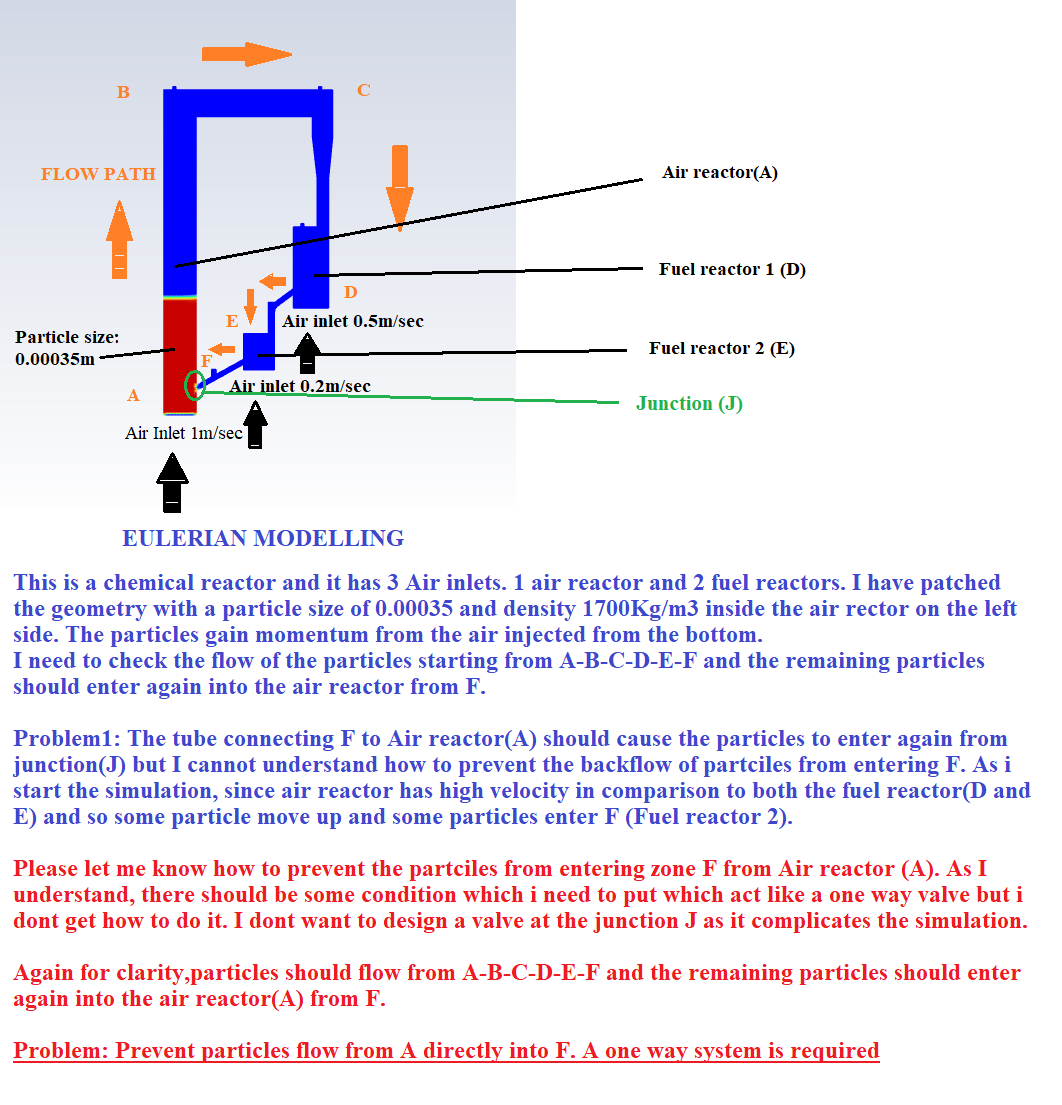

SubscriberThis is a chemical reactor and it has 3 Air inlets. 1 air reactor and 2 fuel reactors. I have patched the geometry with a particle size of 0.00035 and density 1700Kg/m3 inside the air rector on the left side. The particles gain momentum from the air injected from the bottom.

I need to check the flow of the particles starting from A-B-C-D-E-F and the remaining particles should enter again into the air reactor from F.

Problem1: The tube connecting F to Air reactor(A) should cause the particles to enter again from junction(J) but I cannot understand how to prevent the backflow of particles from entering F. As i start the simulation, since air reactor has high velocity in comparison to both the fuel reactor(D and E) and so some particle move up and some particles enter F (Fuel reactor 2).

Please let me know how to prevent the particles from entering zone F from Air reactor (A). As I understand, there should be some condition which i need to put which act like a one way valve but i don't get how to do it. I don't want to design a valve at the junction J as it complicates the simulation.

Again for clarity, particles should flow from A-B-C-D-E-F and the remaining particles should enter again into the air reactor(A) from F.

Problem: Prevent particles flow from A directly into F. A one way system is required

May 19, 2022 at 7:24 pmDrAmine

Ansys EmployeeAre u modeling particles in Eulerian Framework? Shall the particles do not enter F in reality? IF YES do u know why?

May 19, 2022 at 7:25 pmDrAmine

Ansys EmployeeVia momentum source terms one can try avoiding that but will it be realistic?

May 19, 2022 at 7:27 pmbaharaksajjadi

SubscriberYes, It is in Eulerian framework. And the particles should not enter the F in reality. It is because, in reality there will be a one way valve attached at the junction between F and A. So, a one way valve will not let the particles enter back to F from A. The flow of the particles should only be a closes loop from A to F and back to A.

May 19, 2022 at 7:31 pmbaharaksajjadi

Subscriber@DrAmine"Vis momentum source terms one can try avoiding that but eill it be realistic?"

Can you please be clear? I don't understand what you want to convey.

May 19, 2022 at 7:37 pmDrAmine

Ansys EmployeeSorry.. if you have a valve then one should think about how to introduce its effect on the flow allowing particles to flow in one direction snd not in the other one. For me it will require more thoughts andcdome coding. One can simplify it by splitting the contact into inlet and outlet and just using averages to transfer information from outlet of F to another inlet to A.

That is one very simple but not completely correct idea.

May 19, 2022 at 7:42 pmbaharaksajjadi

SubscriberOne can simplify it by splitting the contact into inlet and outlet and just using averages to transfer information from outlet of F to another inlet to A."

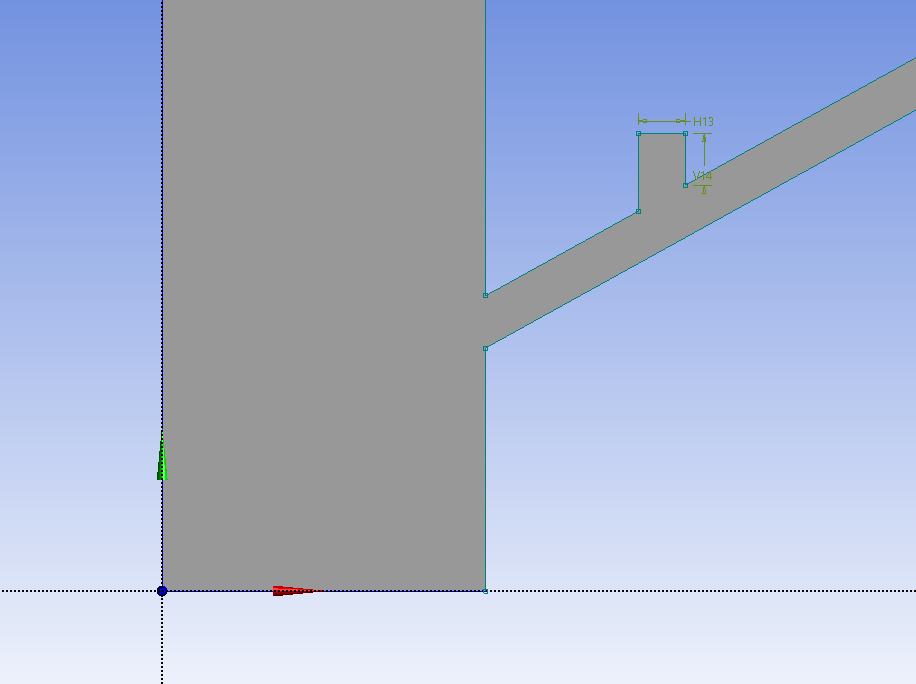

I thought of doing it, but i don't understand how do i make an inlet and outlet section. During geometry creation in design modular, i use surface from sketches to do so. If i split a line in center at the junction, the surface is not created.

Could you describe me how do i make an inlet and outlet and split the contact?

thanks'

May 19, 2022 at 7:46 pmbaharaksajjadi

SubscriberMay 20, 2022 at 2:48 pmRob

Forum ModeratorViewing 8 reply threads- The topic ‘Chemical reactor and fluid flow (Eulerian Modelling) – Flow through the system’ is closed to new replies.

Ansys Innovation SpaceTrending discussionsTop Contributors-

3727

-

1328

-

1163

-

1090

-

1014

Top Rated Tags© 2025 Copyright ANSYS, Inc. All rights reserved.

Ansys does not support the usage of unauthorized Ansys software. Please visit www.ansys.com to obtain an official distribution.

-

Ansys Assistant

Welcome to Ansys Assistant!

An AI-based virtual assistant for active Ansys Academic Customers. Please login using your university issued email address.

Hey there, you are quite inquisitive! You have hit your hourly question limit. Please retry after '10' minutes. For questions, please reach out to ansyslearn@ansys.com.

RETRY