-

-

October 26, 2025 at 7:34 am

martin.munck

SubscriberHi

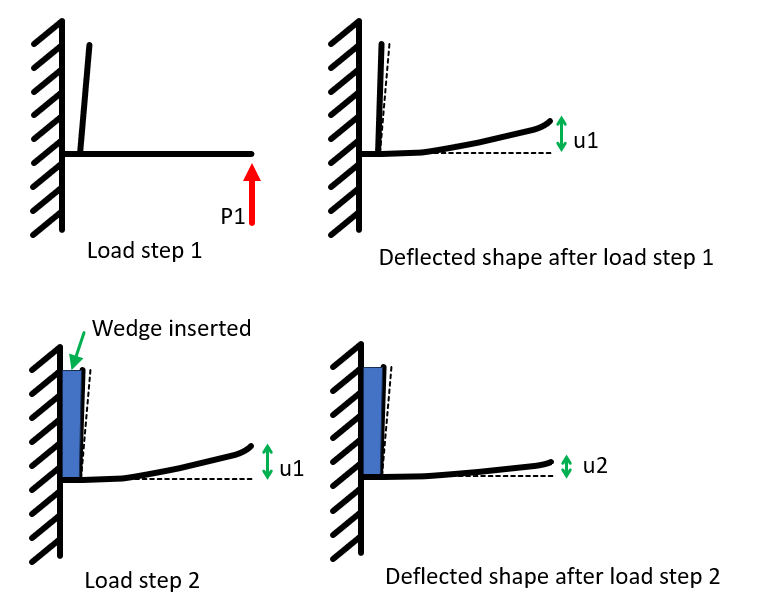

I am analysing a system where I need a structure to deflect under its selfweight with a given support condition (pretty basic so far). There is a 100 mm gap between two parts of the structure which will be descresead to lets say 90 mm during that load step. After that I need to put in a wedge made in a hard plastic in this gap and then add additional load in the following load step. The wedge will deform but will of course restrict the deformation to a certain extend compared to the first load step.

The way I have tried to model it is to use a fictive material in the first load step with negligable stiffness (air basically) and then change the material properties to the right material in the next load step (with a small APDL command). Something like:

cmsel,s,Vertical_wedges ! Select named selection

mpchg,mat_POM,all ! Change material ID

ALLSELThis seems to be working fine, but my issue is, that it seems like simply adding the new material changes the deflections in the model - maybe because the model "remembers" the strain in the first fictive material to begin with...

Any ideas how to solve this? Maybe the strain in the fictive material can be reset? Or is there a smarter way to deal with this problem?

Thanks

-

October 26, 2025 at 5:00 pm

Dennis Chen

SubscriberI think you can simply turn on and off contact between the hard wedge and the other parts during step 1 and turn it back on in step 2.

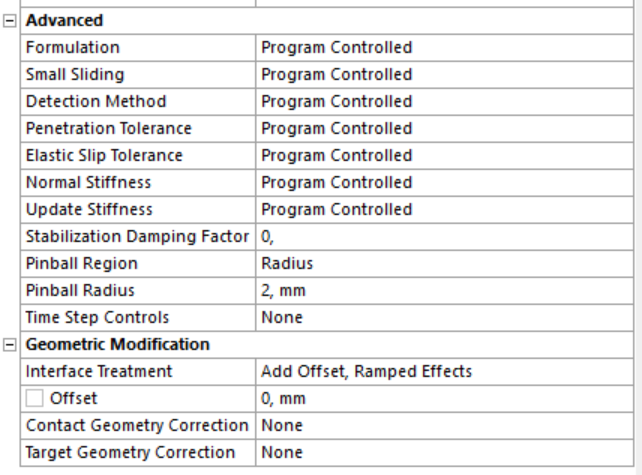

When you turn the contact back on, make sure to use a frictional contact and then use ramped effect to ramp the intereference resolution. Make sure the pinball radius is large enough to cover the interference at the end of step 1.

at the end of step 2, you should have the wedge there fully in closed contact with the other parts and having the right pressure placed on the wedge.

-

October 27, 2025 at 7:44 am

martin.munck

SubscriberThanks for your reply. I have tried above using the following:

- Used a frictional contact with the rammed effect on and a pinball radius of 2 mm (see attached picture)

- Used the "contact step control" to have it "dead" in the first load step and "alive" in the next

The result was the same. I get a certain deflection in load step 1 as expected but once the contact step control is activated (not even applying any new load) the deflection decrease again. So I basically have:

- LS 1: Apply some load

- LS 2: Insert wedge

And the deflection changes between LS1 and LS2 which should not be the case (u2 < u1 in sketch below)

Any suggestions to what I might do wrong?

(I have attached a sketch to illustrate the model further)

-

- You must be logged in to reply to this topic.

- LPBF Simulation of dissimilar materials in ANSYS mechanical (Thermal Transient)

- Convergence error in modal analysis

- APDL, memory, solid

- Meaning of the error

- How to model a bimodular material in Mechanical

- Simulate a fan on the end of shaft

- Real Life Example of a non-symmetric eigenvalue problem

- Nonlinear load cases combinations

- How can the results of Pressures and Motions for all elements be obtained?

- Contact stiffness too big

-

4167

-

1487

-

1338

-

1172

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.