TAGGED: ansys-material-designer, aspect-ratio, rve

-

-

September 20, 2021 at 6:38 pm

sadiqamin475550

SubscriberHow can I change the size of RVEs because I have an aspect ratio of 5000 ( 25mm divided by 5 micrometers ). Because the space claim does not support the resulting geometry.

Can I use the 20 or 10 etc aspect ratio... B

October 13, 2021 at 6:54 pmSean Harvey

Ansys EmployeeHello @shinwari Can you share what your composite looks like? Like provide a sketch with dimensions? Thanks.

Regards Sean

October 20, 2021 at 5:48 pmOctober 29, 2021 at 9:21 pmSean Harvey

Ansys Employee

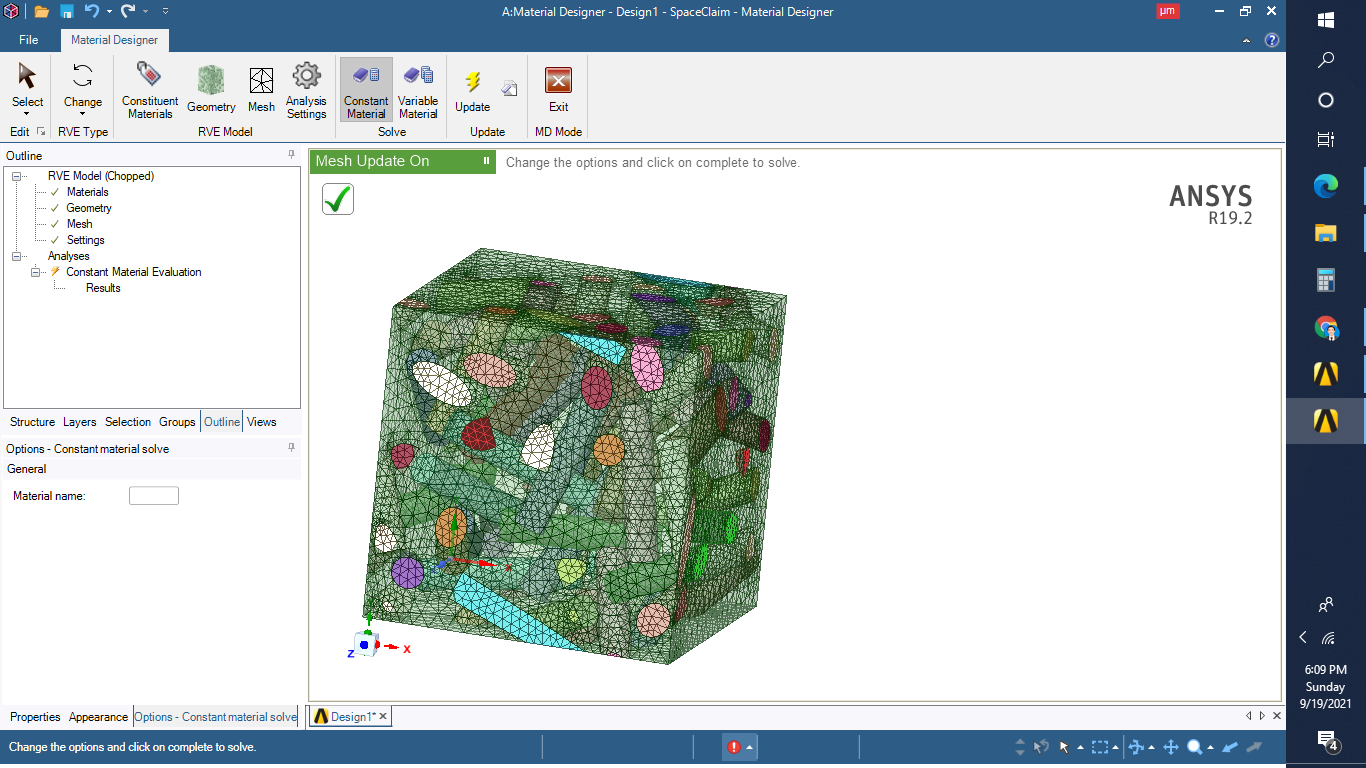

I ran a study for short fiber (have not address the high aspect ratio yet) and made repeat count a parameter and I do see variability. I think this is expected because they are similar RVE form a volume fraction point of view, but one is more densely packed. They are not the same RVE. I saw modulus vary by 10% or so when go from 2 to 3 to 4, etc. How much % difference are you seeing?

Regards Sean

October 30, 2021 at 12:20 pmsadiqamin475550

SubscriberThank you so much What workbench version are you using?

My problem: I am using a chopped strand mat of E glass fiber and polyester matrix. these two materials can be selected from engineering data. I have a fibre lenght of 25mm and dia of 10micrometer so aspect ratio becomes 2500 but this aspect ratio is not supported by material designer so which aspect ratio should I use?

Secondly, what mesh size or repeat count should I choose in order to get an accurate and not changing result?

Thirdly when I change a seed ( random number generator ) each time, the results change drastically each time. So Please suggest me a better solution.

My complete info is

fibre= E glass , E=73Gpa

matrix=polyester, E=3GPa

Fibre volume fraction=0.6

I want to calculate the elastic properites only.

October 30, 2021 at 12:25 pmsadiqamin475550

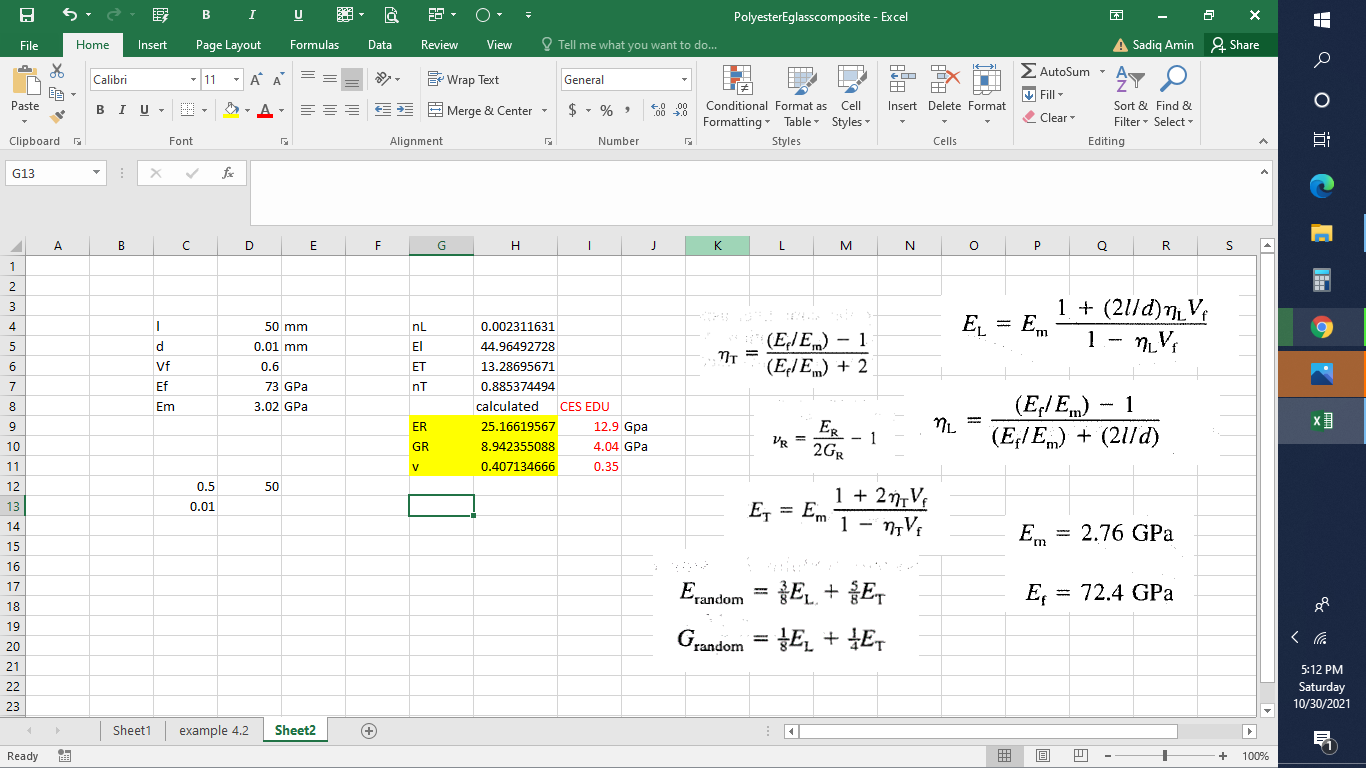

SubscriberAnother issue I am facing is wether I can consider a multi-layered chopped strand mat-resin composite as isotropic in 3d? because fibres in chopped strand mat are distributed only in a plane.

So I have also calculated values of this composite considering it as isotropic as per Agarwal composite book.

I have attached a screentshot.

November 2, 2021 at 5:57 pmSean Harvey

Ansys Employee

I am using 2021r2. So I consulted a colleague and he basically said that the Short Fiber RVE is not really meant for such long fiber composites, you'd have a very hard time trying to generate an RVE with such an aspect ratio. We may be running up against the limitations since Material Designer is creating solid elements for the fiber.

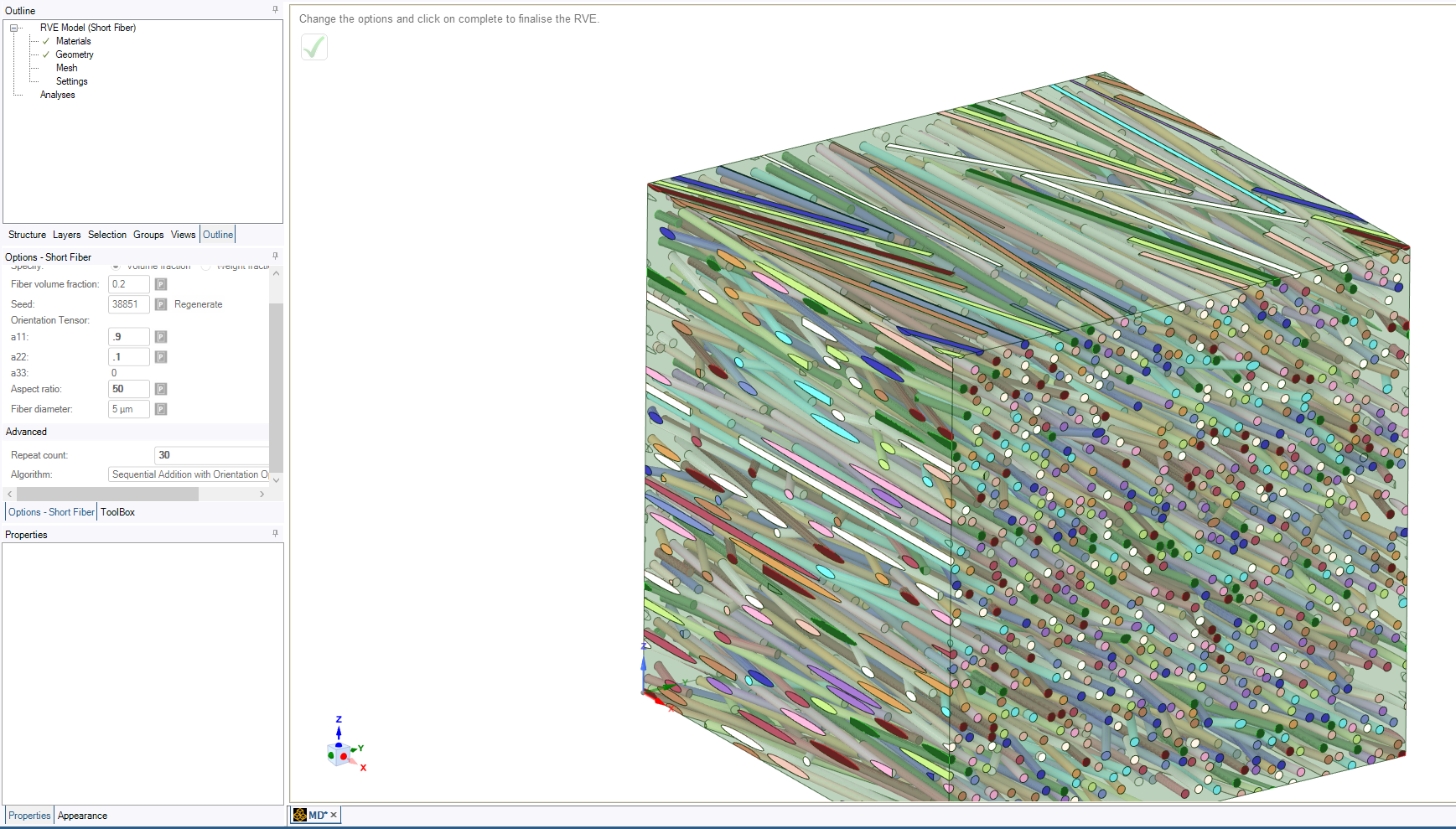

To answer your question, to achieve only random in plane, then you can change the orientation vector such that a33 is zero, and there is equal weight in a11 and a22 which must sum to 1.0 You can see you get an inplane layered effect when I have the repeat count increased as shown. See the image below.

There is another technology you could try and that is to use reinforcements in an APDL setup, not Material Designer. This is covered in chapter 14 of the structural analysis guide of the Mechanical APDL Help. The link to that section if you have customer portal login is

Chapter 14: Reinforcing (ansys.com)

You can also find under student version help, and then you can search for it there.

Using reinforcements, we don't have a conformal mesh, but rather the fibers can be modeled as line elements and their displacements are interpolated to an underlying solid "matrix" Here aspect ratio is not an issue since the line element (beam element) is not modeled as a solid. The challenge here is you will need to learn APDL if you don't know it, but then you could script something that randomly generates long slender fibers. It would take a fair amount of scripting.

Let me know if this helps. Thank you

Regards Sean

November 6, 2021 at 10:50 amsadiqamin475550

SubscriberCan you please tell me why random seed number generates different results each time we change it. What is the limit or number of samples or the repeat count in order for it to give us an accurate and constant result.

lets assume I have an aspect ratio of 20 and using chopped fibre. what repeat count should I choose or how many seed number should be regenerated to give us a constant result. because each time we change seed, fibres are oriented in a different direction which give us a different result.

Thanks

November 19, 2021 at 6:27 pmSean Harvey

Ansys Employee

Sorry on the delay. I believe we should expect to see variability because the fiber direction can basically take any orientation. But I do not know how much statistical scatter you are seeing or expect, but it won't be zero. If your manufacturing may produce orientations more aligned (but still variable) then you can specify orientation vector of something like shown below. Feel free to change the .9,.1 to other values. This orientation is almost unidirectional. This may give you more constant results. Let us know if that helps.

Regards Sean

Viewing 8 reply threads- The topic ‘Changing RVEs size in Material Designer’ is closed to new replies.

Innovation SpaceTrending discussionsTop Contributors-

5574

-

1885

-

1403

-

1298

-

1021

Top Rated Tags© 2026 Copyright ANSYS, Inc. All rights reserved.

Ansys does not support the usage of unauthorized Ansys software. Please visit www.ansys.com to obtain an official distribution.

-