-

-

October 31, 2024 at 6:57 pm

jianing2016

Subscriber -

October 31, 2024 at 11:29 pm

peteroznewman

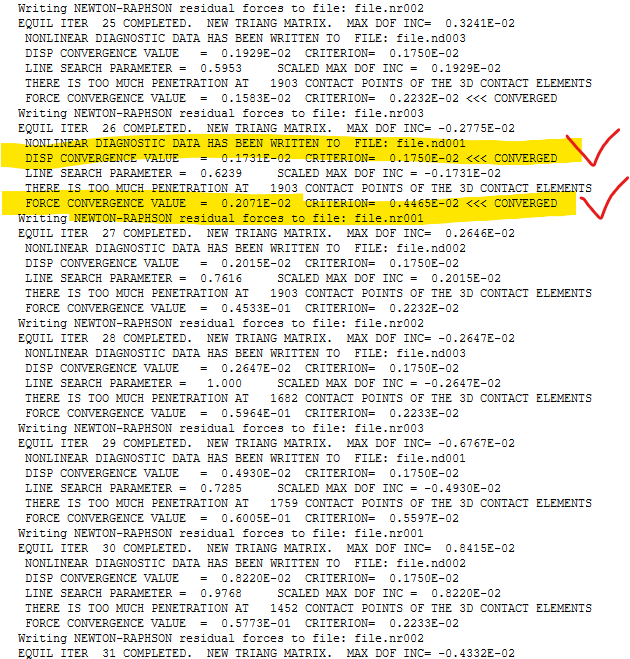

SubscriberThe contact has not converged. Read all the messages that say "There is too much penetration at..."

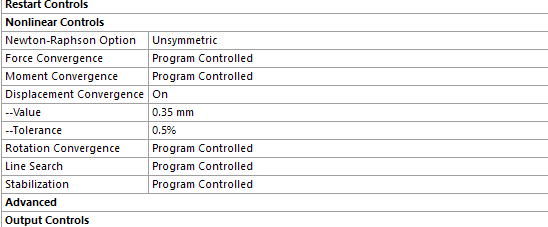

Edit the Contact Details and change the Normal Stiffness from Program Controlled to Factor and type in 0.1 or 0.01 instead of the default Factor 1.0.

That will "soften" the contact surface making it easier to converge. Solve and see how it goes.

-

November 1, 2024 at 2:26 am

jianing2016

SubscriberThank you peter! Yes did change the normal stiffness to 0.05 too. Do I need to change a smaller number?

-

-

November 1, 2024 at 2:24 am

jianing2016

SubscriberThank you peter! Yes did change the normal stiffness to 0.05 too. Do I need to change a smaller number?

-

November 1, 2024 at 11:30 am

peteroznewman

SubscriberUse the largest number less than 1.0 that allows the solution to converge in a reasonable number of iterations. After the model is solved, insert a Contact Tool into the Solution branch, plot the penetration of the contact and decide if the penetration is acceptable.

Some models will have an excessive penetration and the corrective action is to increase the Normal Stiffness to a number larger than 1.0 such as 10.0. This will cause the solver to take more iterations, but that is required. An example would be a shrink fit of a tube over a rod. If there is excessive penetration, the stress from the shrink fit will be underpredicted, which is known because an accurate analytical hand calculation can be used to check the results of the simulation.

There are other settings under the Contact Details that may be helpful such as Update Stiffness. There, you can force a new stiffness to be calculated on Every Iteration, which will take some more time to solve, but may reduce the number of iterations and give a more accurate solution.

A setting under Analysis Setting that may be important is to turn Large Deflection to On. That again will cause the solution to take more time, but will give a more accurate soltion if it was needed.

-

November 4, 2024 at 6:42 pm

peteroznewman

SubscriberHere is a good link explaining this message in detail.

https://featips.com/2021/04/06/too-much-penetration-at-contact-points-ansys-message/

-

- You must be logged in to reply to this topic.

-

5049

-

1764

-

1387

-

1248

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.