TAGGED: gravity-acceleration

-

-

September 13, 2024 at 10:10 am

s113010505s

SubscriberHi, I am currently working on simulating breast deformation from the prone to supine position, but I’ve encountered issues where my results differ from the paper by Lianghao Han et al. (2014)(A Nonlinear Biomechanical Model Based Registration Method for Aligning Prone and Supine MR Breast Images). I’d like to understand if there’s anything in my setup that needs adjustment.

-

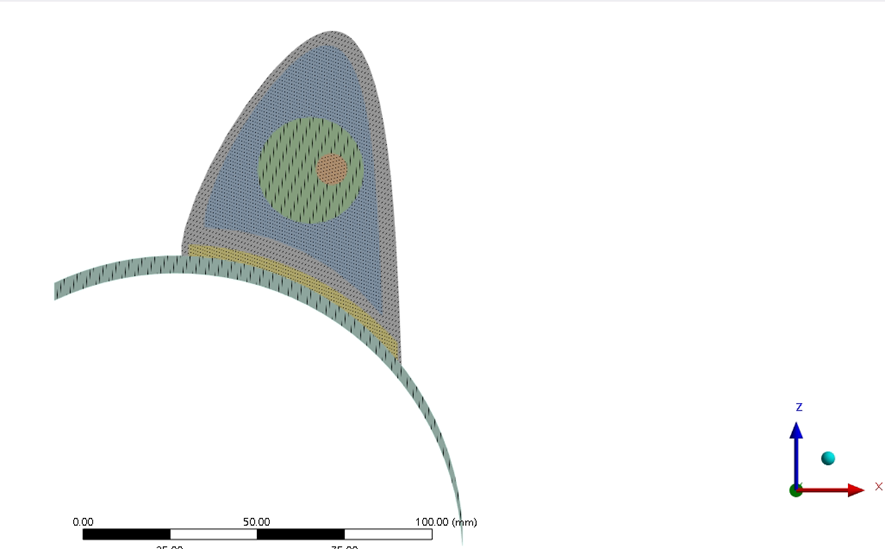

Here’s the setup of my simple model:

Green: Chest wall

Yellow: Pectoral muscle

Gray: Skin

Blue: Fat

Light green (inside): Gland

For materials, I’m using the Mooney-Rivlin model, which was validated in a previous study with no issues in the parameter settings.

-

Contact settings:

Skin/chest wall: Frictionless

Skin/pectoral muscle: No separation

Pectoral muscle/chest wall: Frictionless

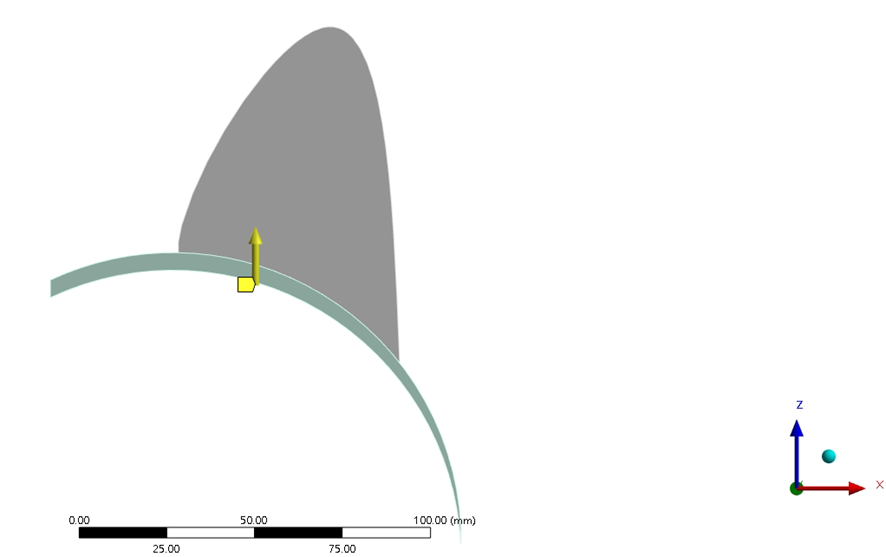

The mesh size is 3 mm. I’ve tried smaller meshes, but the results don’t seem to differ. To simulate gravity’s effect on deformation, I set the acceleration to 20000 mm/s², as the paper suggests that transitioning from prone to supine requires double the gravitational force (prone > unload > supine). I’ve accounted for the direction change, but the results still seem unrealistic, with the breast approaching the sternum.

-

Boundary conditions:

1. Fixed on the chest wall’s six faces

2. Set at the edge of the breast near the sternum

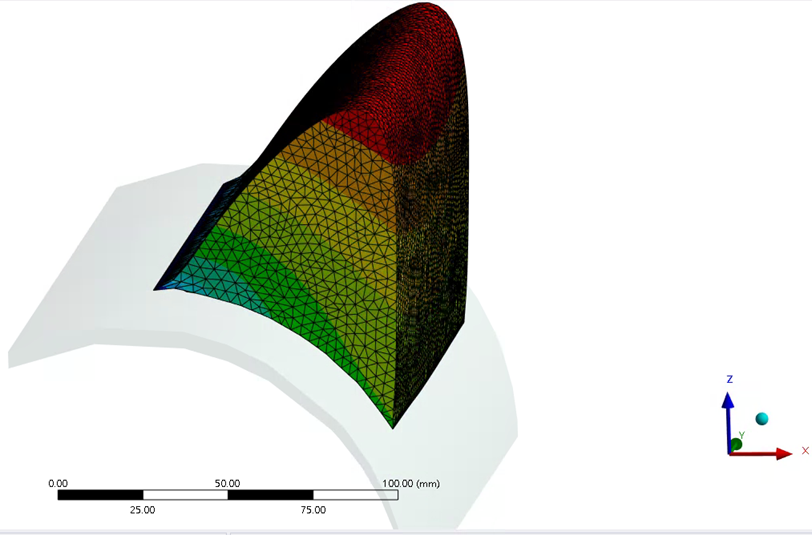

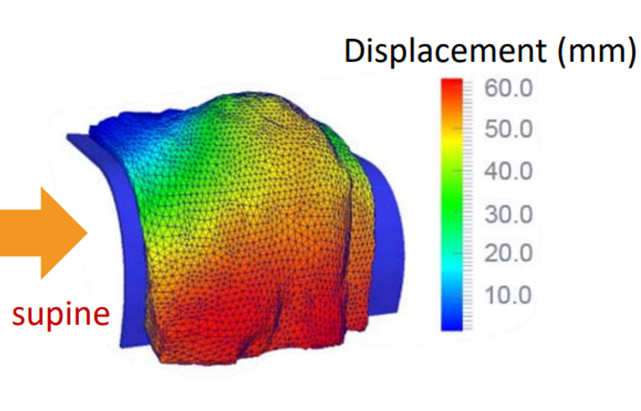

In my simulation, the maximum deformation is only 22 mm (below 1), while the paper shows deformation reaching 60 mm (below 2). Additionally, the location of the maximum deformation in my model occurs at the anterior end, whereas the paper’s results show it near the shoulder. I’m puzzled by these differences and would appreciate any suggestions on how to improve the setup to align more closely with the paper’s results.

-

Thank you for taking the time to read this. Since I’m still new to ANSYS, any feedback is greatly appreciated.

-

September 20, 2024 at 6:24 pm

John Doyle

Ansys EmployeeSince your displacement is 33% of expected, you are overpredicting the stiffness. Assuming your load is correct, it is either the material model, the geometry or the boundary constraints. You mentioned that you are using a Mooney Rivlin model, but you did not say how many terms? Perhaps your material model needs more terms to account for an important inflection point in the stress-strain history at higher strains. Maybe you are overpredicting the stiffness at higher strains.

-

- You must be logged in to reply to this topic.

-

5274

-

1859

-

1403

-

1257

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.