-

-

May 20, 2018 at 1:44 am

peteroznewman

SubscriberDeepak Maurya has been working on a simulation of spinal bones and the disks separating them. Bone is a couple of orders of magnitude stiffer than disk material, so one model represents the bones as rigid bodies while the disks are flexible bodies.

Some protrusions from the bones slide on each other, so he has used frictional contact between them. Some diseases of the spine fuse those bones together. To simulate that, the frictional contact is changed to bonded contact.

Deepak asks why there would be any deformation in the disk if the rigid bones are connected with bonded contact. Rather than work on his very large model, I have a very small model.

It has two rigid bodies with a flexible block between them. The block between them is bonded to each rigid end body. One rigid block is fixed and the other has a force applied. There is also a frictional contact between the rigid bodies.

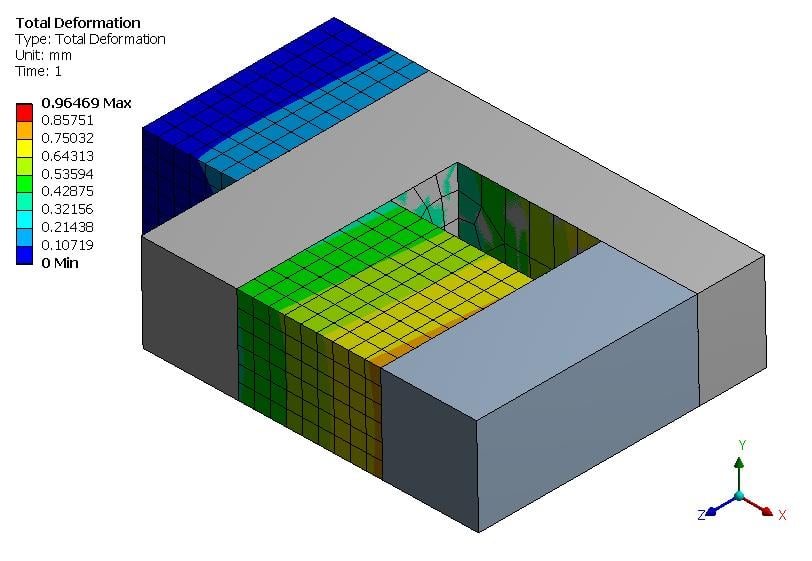

If the frictional contact is changed to bonded contact, this is the result.

The flexible body has practically zero deformation. Is this what you are seeing?

If not and the deformation with bonded contact is similar in magnitude to the frictional contact case above, then that is likely due to some conflict in the model, an over-constraint that makes it impossible for the solver to satisfy all the constraints at the same time and so some constraints are ignored in order for the solver to continue. When this happens, there are always WARNINGS in the output file such as this:

*WARNING*: Some rigid target elements (e.g.810) in real constant set 5

overlap with other MPC/Lagrange based elements (e.g.1123) in real

constant set 10 which can cause overconstraint.

The problem with a complex model is that there are likely to be many warnings, but most of them do not represent a true conflict. For example you can have separate contacts on adjacent faces of a block that gets bonded into a corner. The nodes on the edge of the block belong to two contacts at the same time, so a warning may be issued, but there is not an actual overconstraint.

The ANSYS 19.0 archive for the model above is attached below.

-

May 20, 2018 at 5:33 am

deepmech.maurya

Subscriberhello sir,

can i conclude that for software no body is perfectly rigid as in bonded contact there is deformation even very very less.

In this analyses, after considering rigid body there should not be relative motion even in micron in actual.

Thankyou for that warning concept this warning i observed sometimes.

thankyou

regards

Deepak

-

May 20, 2018 at 11:34 am

peteroznewman

SubscriberHello Deepak,

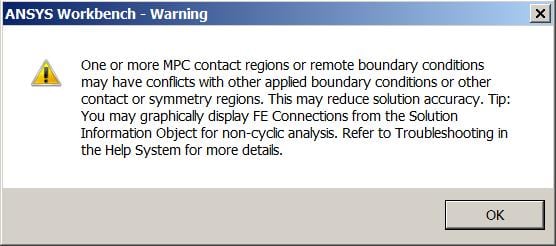

This very simple model includes four warnings, including this scary looking one:

And in this case, there is no actual conflict.

The formulation of Bonded Contact requires some very small movement to generate an opposing force. But the ratio between the motion of the flexible block for frictional:bonded contact is 20000:1 which is adequate for most analyses.

If you need a perfectly rigid connection, then use a fixed joint. Below is the image where I suppressed the Bonded Contact and created a Fixed Joint. This is what you want, but it is more work than simply changing a pull-down menu from Frictional to Bonded.

Now bond a second flexible block to the rigid "L" part and move the fixed face from the rigid "L" piece to the base of the new flexible block and plot the deformation.

You can't tell from this plot of deformation if the first flexible block is being squeezed because it has a rigid body motion through space enabled by the second flexible block. To find out if there is any squeezing, plot strain instead of deformation.

Now it is clear that the fixed joint between the rigid parts is not allowing any deformation into the first flexible block.

I hope this clarified some concepts that apply to your complex spine compression and bending models.

Kind regards,

Peter

Attached is an ANSYS 19.0 archive.

-

May 20, 2018 at 12:18 pm

deepmech.maurya

SubscriberThank you sir very nice

Its cleared

-

October 23, 2018 at 7:26 am

Raaj

SubscriberDear Peter

I performed a modal analysis of the above-discussed problem. In the total deformation, there is relative motion between the flexible and rigid body (one on which force is applied) though I have assigned bonded contact between them. Could you please explain why it is so?

Thanks in advance,

Raaj

-

October 23, 2018 at 12:03 pm

-

September 18, 2019 at 3:59 pm

Autonewbie

SubscriberDear Peter,

I have a question about defining the contact between both rigid bodies. The models below have been simplified. I wanted to make the bottom part as rigid body to reduce the simulation time but when it is changed to rigid body, bonded contact will not be applicable as the screw (the round screw head) is also modeled as rigid body. Do you have any advice? Thank you so much!

-

September 18, 2019 at 7:23 pm

peteroznewman

SubscriberReplace Bonded Contact with a Fixed Joint. Pick the small surface first to locate the coordinate system that locates the joint.

-

September 19, 2019 at 2:08 am

Autonewbie

SubscriberThank you Peter! Does it matter which part is selected for reference or mobile for fixed joint?

-

- The topic ‘Bonded Contact between Rigid Bodies’ is closed to new replies.

-

5014

-

1693

-

1387

-

1248

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.