-

-

August 17, 2023 at 10:18 am

Oskar Norman

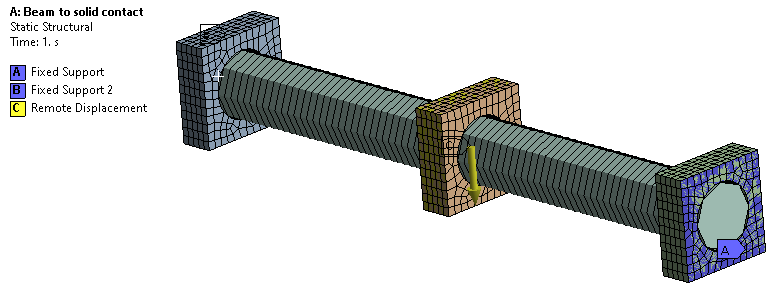

SubscriberI have an FE model with an axle with dia 20 mm inserted in three slots. The outer slots are fixed and the mid slot is pulled down 0.1 mm. Between the axle and slots I have defined a frictional contact with frictional coefficient 0.2. The simulation works well when the axle and slots are meshed with solid elements, but when I mesh the axle with beam elements and the slots with solid elements the contact doesn't work.

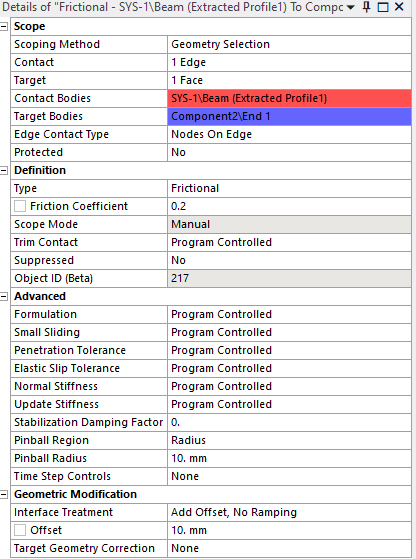

I set the pinball radius and offset (for contact detection) equal to the radius of the axle (10 mm) as seen below:

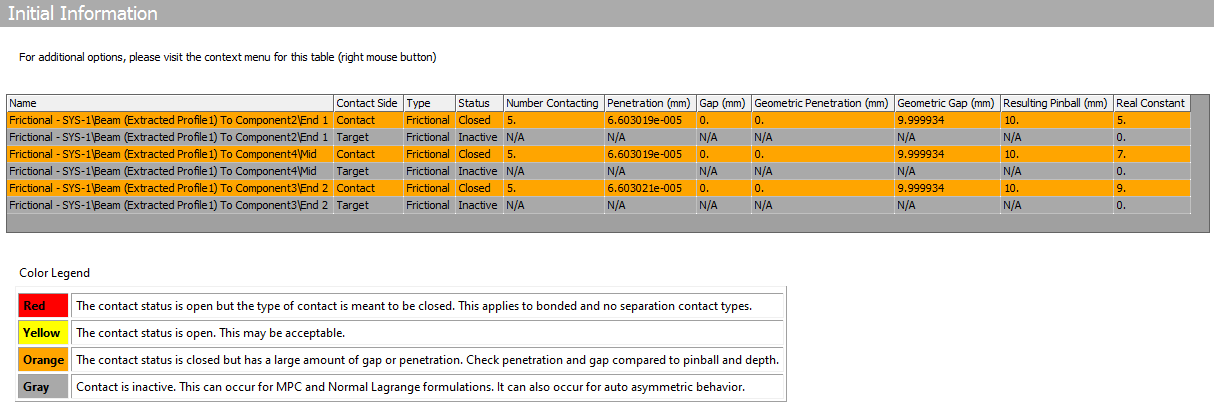

The contact tool shows these results:

But when I try to solve the model it won't converge and it seems that the contact is not detected properly.

Workbench archive is attached.

Any ideas on how to fix the problem? -

August 17, 2023 at 6:46 pm

Sampat Kumar

Ansys EmployeeHi

When using beam elements for the axle instead of solid elements, you’ll face limitations in your contact definition. Beam elements can only have bonded connections with assemblies, while solid elements can use both bonded and frictional contacts. This is why you can’t achieve the desired frictional contact when using beam elements for the axle and solid elements for the slots.

To tackle this problem, you may need to represent the axle using solid elements in order to define the frictional contact between the axle and slots, since frictional connections won’t be sufficient in this case.

follow the following courses for more in details.

Connecting Bolts with the Rest of an Assembly | Ansys Courses

/courses/index.php/courses/connecting-bolts-with-the-rest-of-an-assembly/

Regards,

Sampat -

August 17, 2023 at 7:25 pm

-

- The topic ‘Beam to solid frictional contact problem’ is closed to new replies.

-

4703

-

1565

-

1386

-

1242

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.