TAGGED: ansys-aqwa, ansysaqwa, aqwa, aqwa-errors, aqwa-suite, aqwareader, joints-ansys-aqwa

-

-

October 25, 2024 at 11:59 am

S.S.S.ShankaVasuki

SubscriberHi,

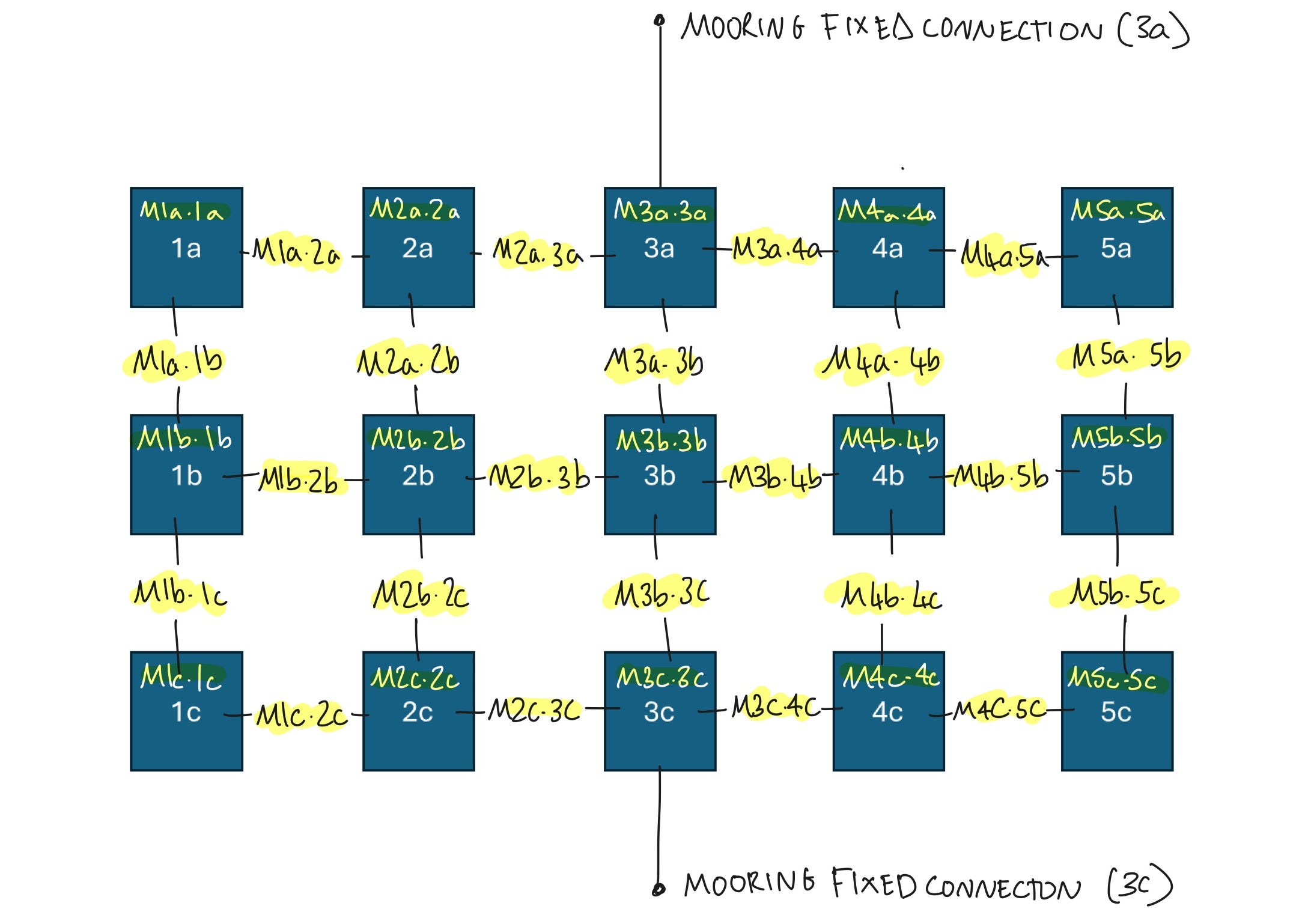

I am working on a floating problem with 15 connected bodies as shown in the figure. The dimensions of the structure is 1.88x1.88x0.14m and the draft is 0.096m. The mesh size was set to 0.08m with 20,000 panels.

Kxx = 0.48m, Kyy = 0.48m, Kxx = 0.62m, CoG = 0.03m

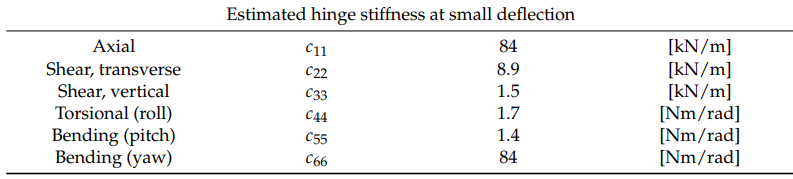

Hydrodynamic diffraction analysis: To run the diffraction analysis, I specified the connection stiffness matrix between each body (a total of 21 matrices) as shown in the figure below. I have not included the mooring stiffness matrix in this calculation and the simulation runs without errors BUT the results dont match the reference results as shown below for the pitch RAO for all the middle blocks. I dont know where I am going wrong here. As even if I include the mooring line stiffness, the RAOs will reduce even further which still does not match the reference values. Also, I have not included any additional damping matrices as well. So can you please let me know where the mistake is?

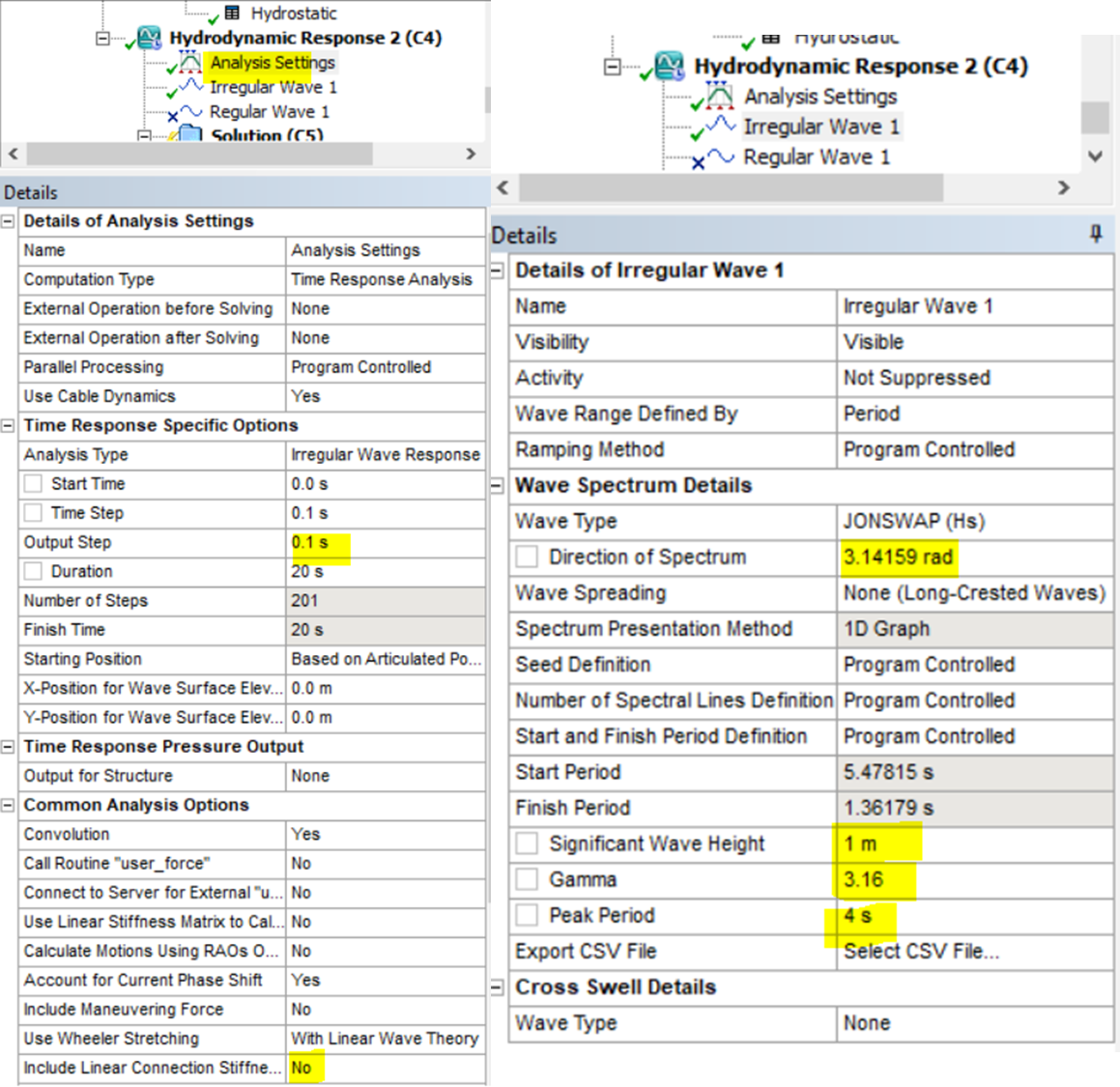

Hydrodynamic Response: For the time domain analysis, I replaced all double hinges (as shown in the first image) with a ball and socket joint as shown in the figure below to avoid the closed loop error along with a soft mooring line with the properties as shown below. I used an irregular wave spectrum with a JONSWAP spectrum with properties as shown in the last image. With all these definitions, the time domain solution tends to diverge about RZ-Yaw (as shown in the last image), I also tried to reduce the time step to 0.001s, but no luck. Hence could you please let me know on how to resolve this issue as I have been asking this question from a month, but have not received any response from the Ansys team.

-

October 30, 2024 at 4:38 pm

-

October 30, 2024 at 5:05 pm

S.S.S.ShankaVasuki

SubscriberThank you for the reply.

I read the thread you attached. But could not quite understand it well, hence could you please explain it and how I can incorporate that in my simulation?

Also, I dont know why I am unable to run the hydrodynamic response analysis. because It says solution diverging as shown in the image above for the given JONSWAP spectrum.I checked the mass and inertial properties and they seem to be okay.

-

October 30, 2024 at 6:33 pm

Shuangxing Du

Ansys EmployeeWill you need to define more connection stiffness 6x6 sub-matrices? For example, from the linkages of the first row of 5 structures, you may need

(1A,1A), (1A,2A), (2A,2A), (2A,3A), (3A,3A), (3A,4A), (4A,4A), (4A,5A), (5A,5A) (9 6X6 sub-matrices for the first row). 27 6x6 sub-matrices for all 3 rows.

For the first column's additional sub-matrices due to the linkages, you should have (1A, 1B), (1B,1C) 6X6 sub-matrices. 10 additional sub-matrices for all the columns.

In total, you may have 37 6x6 sub-matrices.

Will the fixed point to structure mooring lines represent the joint condition well? It may be nice to use the connection stiffness matrices directly. You could use a presolve script to remove NASF option (Not use the additional structure stiffness matrix) from the hydrodynamic response analysis input data file. Alternative, switch on the beta option,

Then in Hydrodyanmci response analsyis, set Include Linear Connection Stiffness Matrices as Yes. It will include the connection stiffness if it is defined.

-

October 30, 2024 at 6:42 pm

Shuangxing Du

Ansys EmployeeNote that the diagonal 6x6 submatrices may be the assebles of sub-matrices from all the linkages. For example the 6x6 submatrix for structure 3B to Structure 3B, the total assembled 6x6 matrix should be the summation of the contributions from the linkages between 3A and 3B, 3B and 3C, 2B and 3B, 3B and 4B.

-

October 30, 2024 at 7:14 pm

S.S.S.ShankaVasuki

SubscriberSo if I understand correctly, I need to have a total 37 connection stiffness matrices for the joints and two fixed "equilibrium" connection stiffness matrices for the mooring lines right? I have made an image which shows all the connection matrices I need to define in my simulation as highlighted in yellow. Could you please let me know if this is correct?

Also I have some questions on your next comment:

- You mentioned - "Note that the diagonal 6x6 submatrices may be the assembles of sub-matrices from all the linkages" ... I could not quite understand this. Because the reference article I am referring to gives the matrices as shown in the figure below. So should I give all the 37 connection stiffness matrix (excluding the mooring lines) as a diagonal matrix with C11,C22,...C66?

2. If I use the beta options and include the connection stiffness matrices for the hydrodynamic response analysis, do I still need to define joints such as hinge joints or ball or socket? And do I have enable a linear cable connection for the mooring lines?

Please help me out with this as I have been trying a lot of things which have not been working.

-

October 31, 2024 at 9:25 am

Shuangxing Du

Ansys Employee(1) Only 37 6x6 submatrices are added. The matrices due to moorling lines need to be added in the diagonal 6x6 matrices of M3a-3a and M3c-3c respectively. Please read the finite element method book for the global stiffness assemble from the element stiffness sub-matrices. Each connection and mooring stiffness matrix could be considered as a stiffness matrix of a structural element, and needs to be assembled into the global stiffness matrix, which is the connection stiffness required by the Hydrodynamic Diffraction and Hydrodynamic Response analyses.

(2) If the connection stiffness matrices have been used, there is no need to define any joint/mooring, otherwise they will be duplicated.

-

October 31, 2024 at 12:03 pm

S.S.S.ShankaVasuki

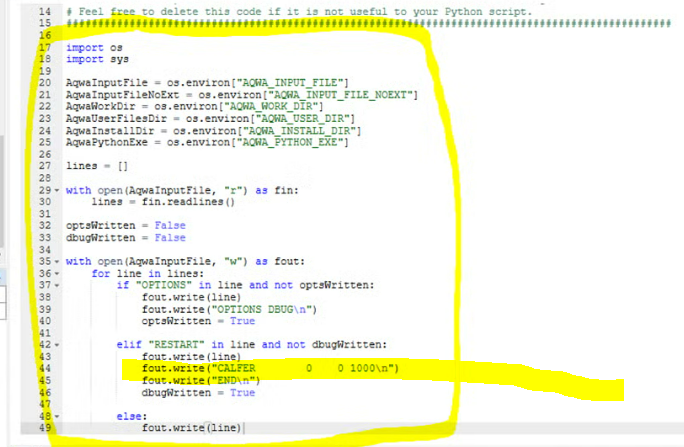

SubscriberI tried including the 37 matrices as you suggested and here are the results:

Hydrodynamic diffraction: The figure below shows the pitch RAO (deg/m) as a function of frequncy (rad/s) for the middle section of the bodies (1b,2b,3b,4b,5b). I tried running the diffraction analysis with the 37 connection matrices and without the connection matrices. The response of the system with 37 connection stiffness matrices is lower than when there are no connection matrices mentioned which is suprising. Because just with the mass and inertial properties of all the 15 bodies, the results are still lower than the reference values. Also when i add the structure motion amplitude, the motion looks weird as shown in the second image below. So I dont know what the error here. Could it be the z-location of CoG? The reference mention the CoG from keel to be 0.1m, hence I calculated the CoG from the waterline to be 0.03m. I hope this is correct?

So could you help me with understanding whats going wrong here?

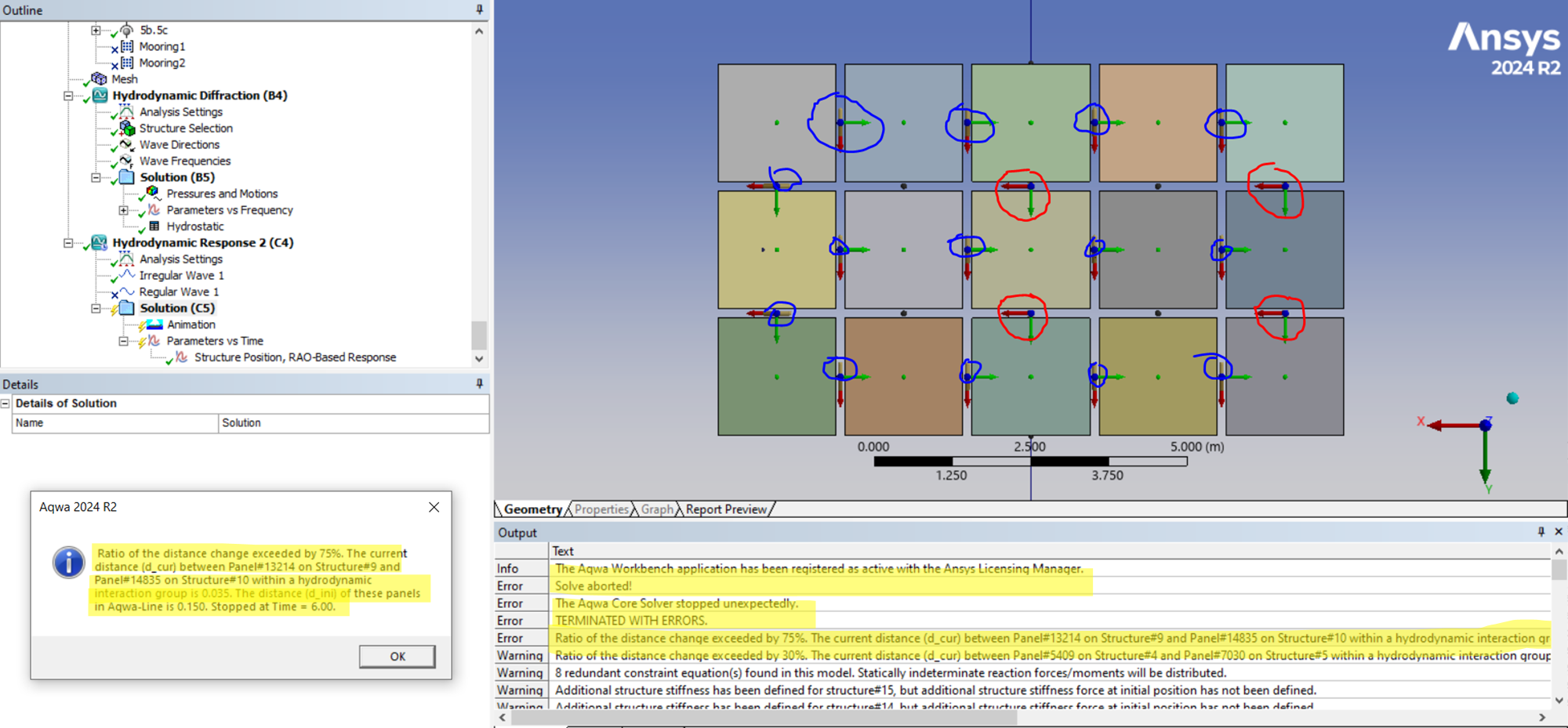

Hydrodynamic Response: Now, for the response analysis, I turned on the beta options and included the connection stiffness matrix in the time domain analysis and I get the same error saying - HYDRODYNAMICALLY INTERACTING STRUCTURES HAVE MOVED TOO FAR FROM ANALYSIS POSITION MOVEMENT EXCEEDS 75% STOPPED AT TIME = 0.50. as shown in the figure below. So I am not sure whats going wrong. Because I have double checked everything and it seems to be okay.

-

November 1, 2024 at 9:14 am

Shuangxing Du

Ansys Employee(1) Please check your reference article on the defintion of the reference degrees of freedoms for the stiffness matrix. Is the stiffness with respect to the motions at the ends of the connection points or with respect to the COGs of connecting structures?

(2) Please check the sign of the coefficients of the off-diagonal 6x6 matrices. I expect the values to be negative.

-

November 1, 2024 at 9:29 am

S.S.S.ShankaVasuki

SubscriberHi,

I checked the above two points you mentioned in the reference article and it seems they are not specified the reference DoF for the stiffness matrix. All they have provided is this matrix. Also this is link to the reference article: https://www.mdpi.com/1996-1073/17/9/2059

But one question that is very weird is when I dont specify any connection stiffness matrix and I run the diffraction analysis just with the mass and inertial properties of the 15 bodies, the RAOs are still lower than the reference values. So does this mean that the mass and inertial properties are wrong??

-

November 1, 2024 at 9:45 am

Shuangxing Du

Ansys EmployeeNo comment. Please check your model.

-

November 1, 2024 at 9:51 am

S.S.S.ShankaVasuki

SubscriberThe comment is post checking my model. If my model was working I dont think I would be asking a question on the forum :)

I'm just trying to understand whats wrong in my model.

-

November 4, 2024 at 4:13 pm

S.S.S.ShankaVasuki

SubscriberI checked my model and tried to implement ebveryhting you suggested but no luck in getting the same results as the reference article. I tried to manually change some values of the connection stiffness matrix to negative and I did get a better match with the reference but I dont think this is the right approach to validate the results. Hence, I am now also trying to run the hydrodynamic response analysis with physical definitions of the connections and mooring lines to see if get a better match with respect to the RAOs.

Connections: In order to replicate the connection sequence between each body as the reference article as shown in the first post, and to also avoid the closed loop error in the aqwa simulation, I replaced double connections with single hinge (circled in blue) and ball&socket (circled in red) connections as shown in the figure below. The stiffness of the each connection is given as twice the value mentioned in the connection stiffness matrix in the reference article along Rx-Rx, Ry-Ry, Rz-Rz as I am technically replacing two connection joints with one. The details of the connections are shown below.

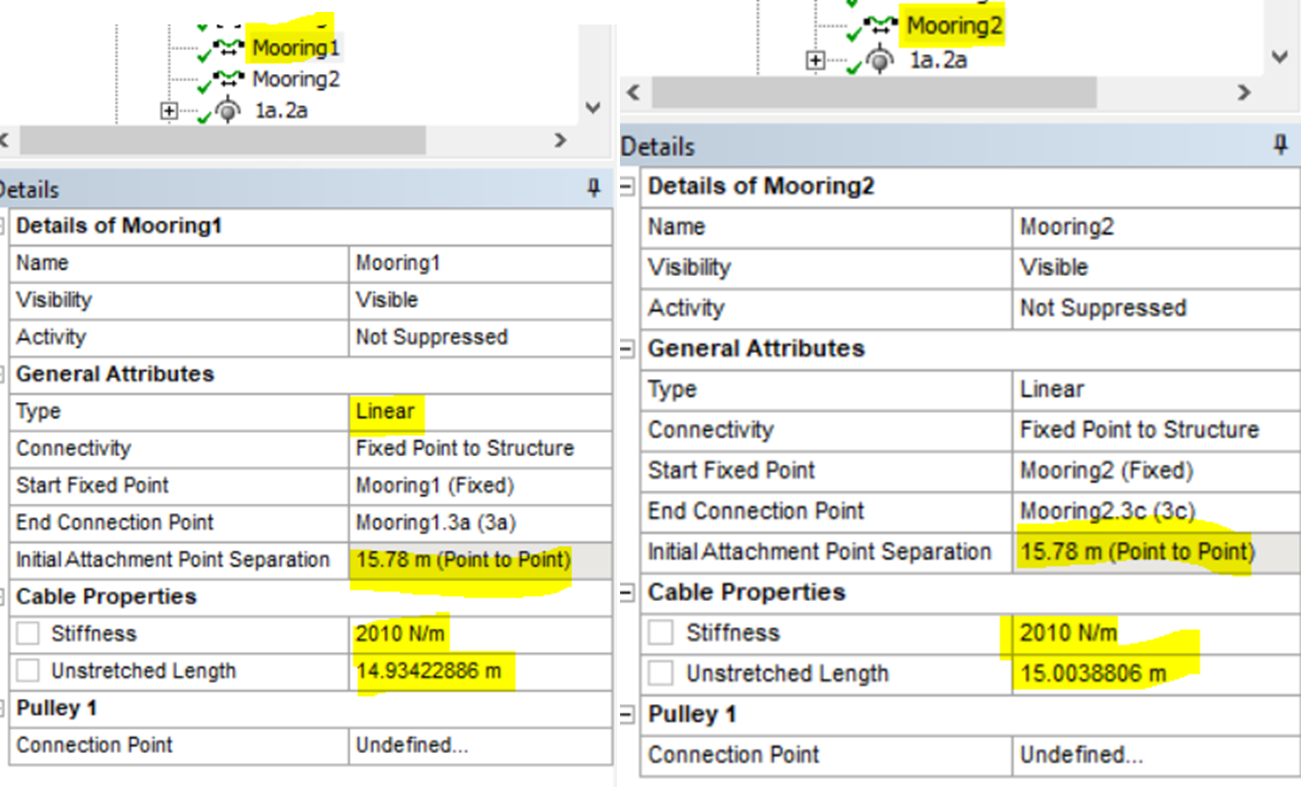

Mooring line cables: I have included two linear mooring line cables as shown in the figure below:

Waves: I have used an irregular wave with the jonswap spectrum with the following paramters:

time domain results: With these parameters as mentioned, I get an error as shown in the figure below. But when I change the Hs from 1m to 0.15m, the simulation run without any errors but when Hs>0.15m, the simulation results in this error. So I am guessing the system is unstable at high wave heights which could be due to mooring line cables or connections between the bodies. So is there any recommendations to run the simulation without this error at Hs = 1m?

-

November 4, 2024 at 5:16 pm

Shuangxing Du

Ansys EmployeeFrom Ansys 2024 R2, the looped redundant constraints are permitted. See 1. Aqwa Solver Modules.

Note that in your model the structure’s size is 1.88m with the draft of 0.096m, but the siginficant wave height is 1m, is it what you want to define?

-

November 4, 2024 at 5:24 pm

S.S.S.ShankaVasuki

SubscriberAh thats nice, I am using the Ansys 2024 R2, so do you suggest that I give all the connections as used in the reference article that is 44 ball&socket connections?

Yes, this the wave spectrum used in the reference article as shown in the figure below

Also, since i am using the full-scale dimensions, I also need to specify the wave conditions at full-scale.

So any suggestions on what is the issue might be? Also I would want to understand what is wrong in the physics of the problem. Could you please help me with that?

-

November 5, 2024 at 10:05 am

Shuangxing Du

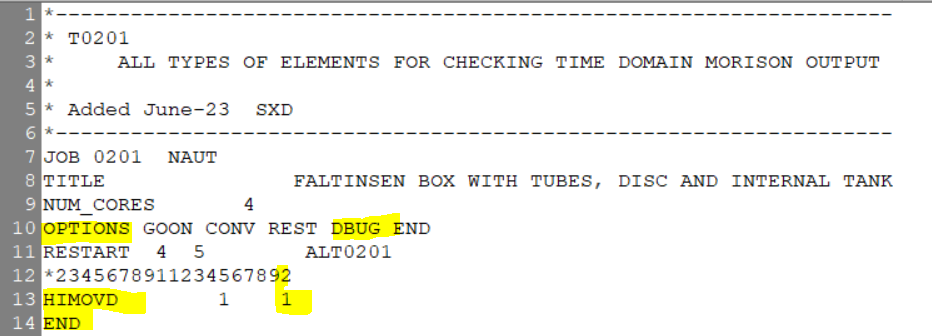

Ansys EmployeeThe hydrodynamic properties of the integration structures are sensitive to their relative locations defined in the Hydrodynamic Diffraction analysis. In the time domain analysis, the relative positions between the program selected pairs of the diffraction panels of adjacent structures are checked and are not permitted to excess certain criterions.

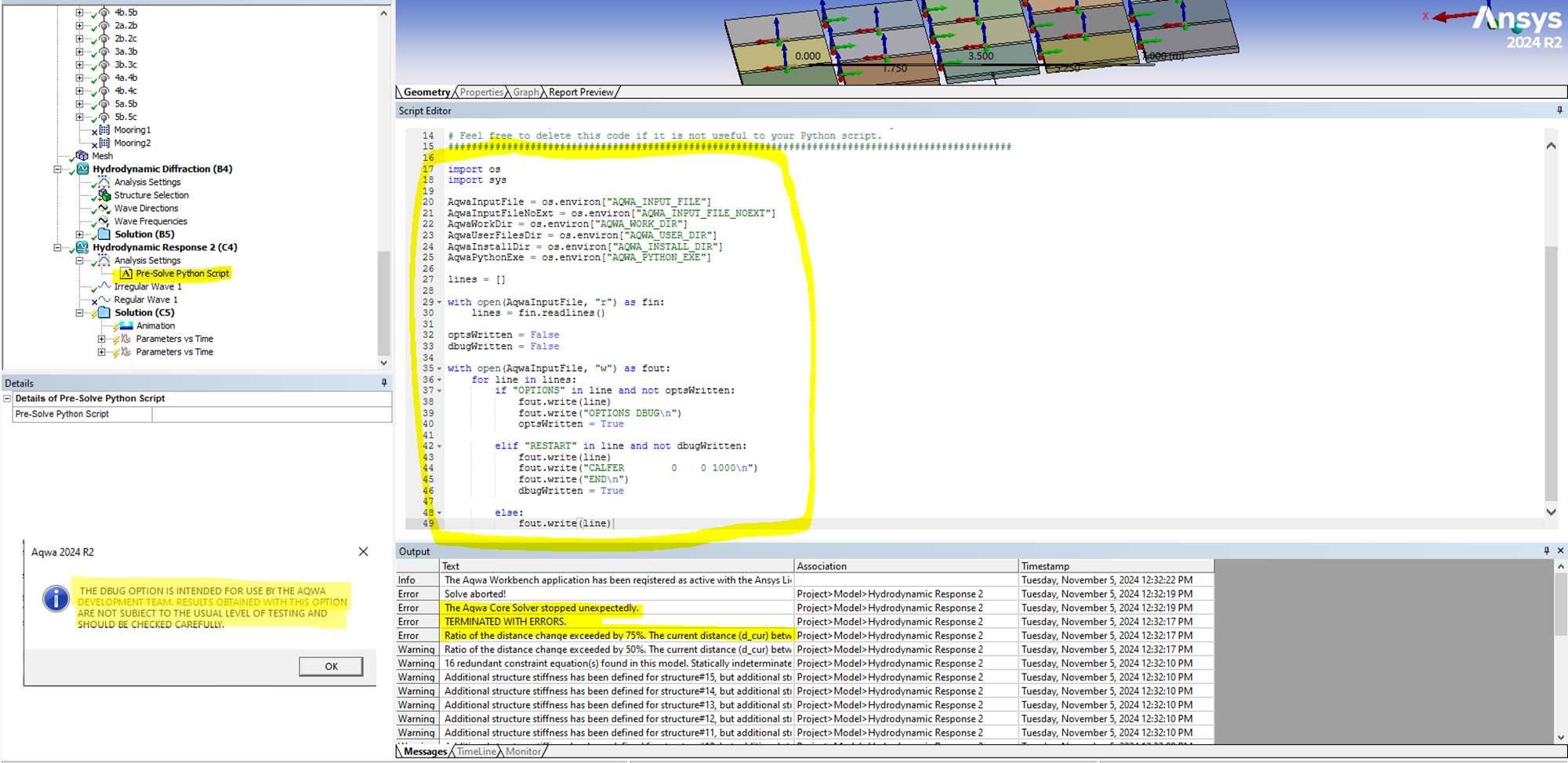

If you cannot avoid this problem, and want the analysis to be carried out, you could define the debugging option in the time domain analysis input data file, such as

If you are running Hydrodynamic Response (time domain analysis) in Workbench, you could use the pre-solve command (5.9.1. Specifying External Pre- or Post-Solve Operations) to run the python script for adding these terms into the input data file of (your project)\dp0\AQW-1\AQW\AQ\Analysis\TimeResponse.dat

-

November 5, 2024 at 11:37 am

S.S.S.ShankaVasuki

SubscriberHi,

I tried including a python script to include the debugging option, but I get a warning and the same error as before while running the response analysis from the workbench. Could you let me know if the code is wrong?

Also, does the simulation run without the current error when I include the debugging option?

-

November 5, 2024 at 11:58 am

-

November 5, 2024 at 12:18 pm

-

November 5, 2024 at 2:07 pm

Shuangxing Du

Ansys EmployeeCan you try to define a smaller wave height first?

-

November 5, 2024 at 2:56 pm

S.S.S.ShankaVasuki

SubscriberYes, I tried running the simulation with Hs = 0.15m and the simulation ran without any errors but when I change Hs = 1m, the error as attached above stops the simulations.

-

November 5, 2024 at 3:40 pm

Shuangxing Du

Ansys EmployeeThe relative motions may be too big when H1/3=1m for the model with draft less than 0.1m.

-

November 5, 2024 at 4:38 pm

S.S.S.ShankaVasuki

SubscriberYes, the relative motions may be too big. What can be the reason for this? is it just due to the mass and inertial properties of the system? or anything else?

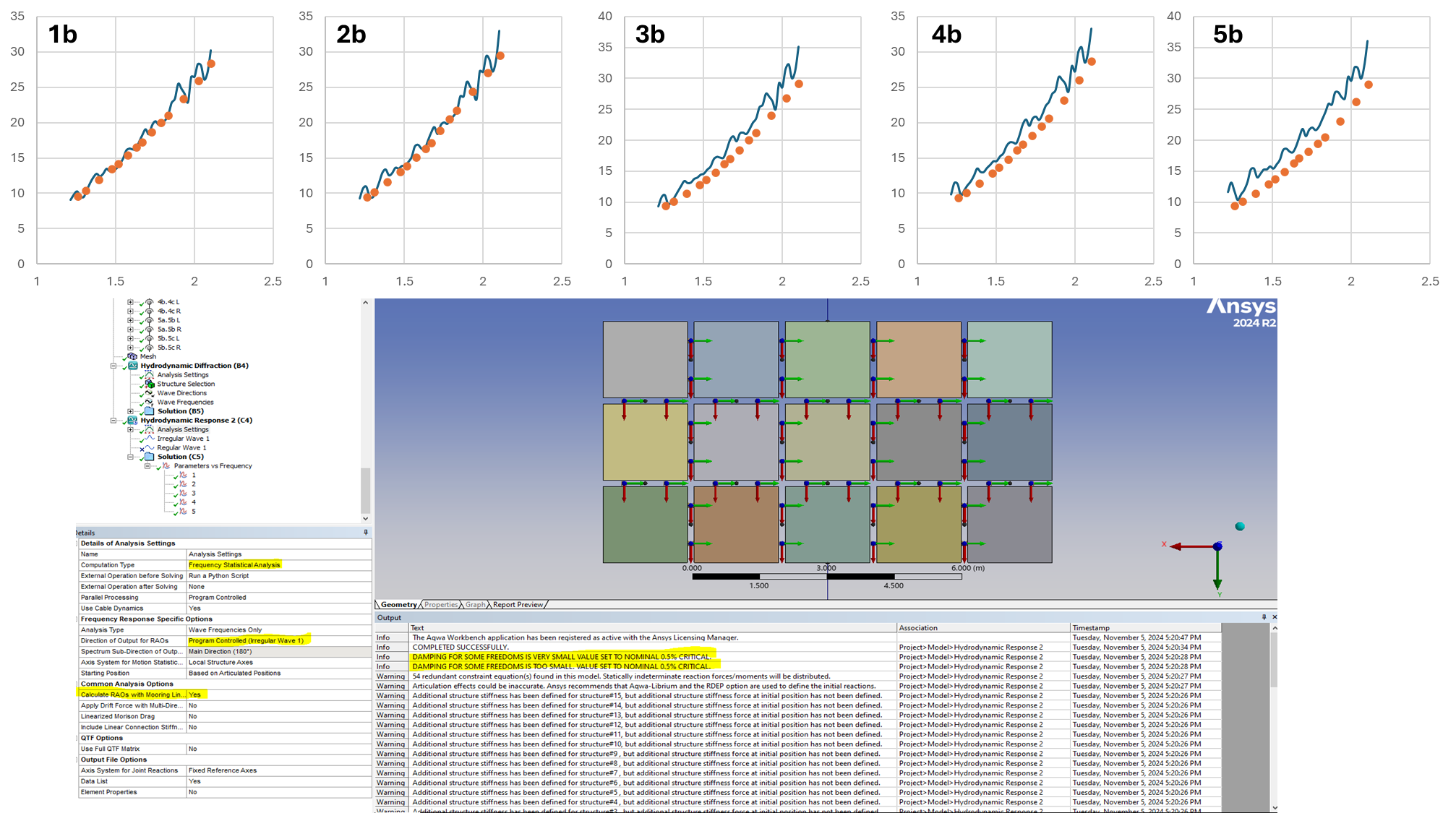

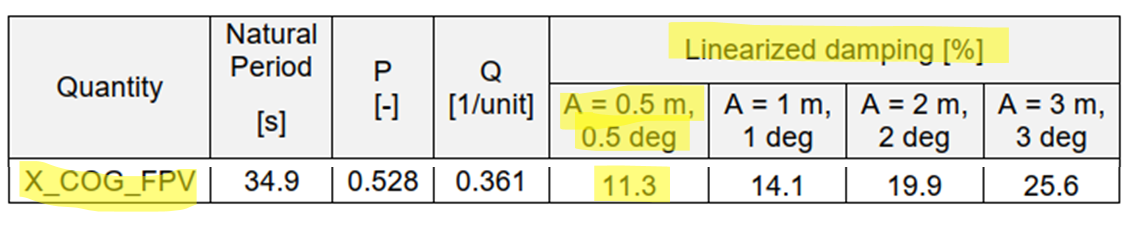

Also I tried to run the Frequency statistical analysis with the jonswap spectrum with Hs = 1m and the I also added all the connections as used in the reference article with all ball&socket connections as shown in the figure below. The Pitch RAOs seems to match better than the RAOs from the diffraction analysis as shown in the plots below.

So, I wanted to know a few things:

- How is the HR analysis giving errors whereas the frequency statistical analysis works without any errors?

- I observed that the Pitch RAOs match well but other RAOs such as Roll and yaw dont match well. Does that mean there is something wrong in the model??

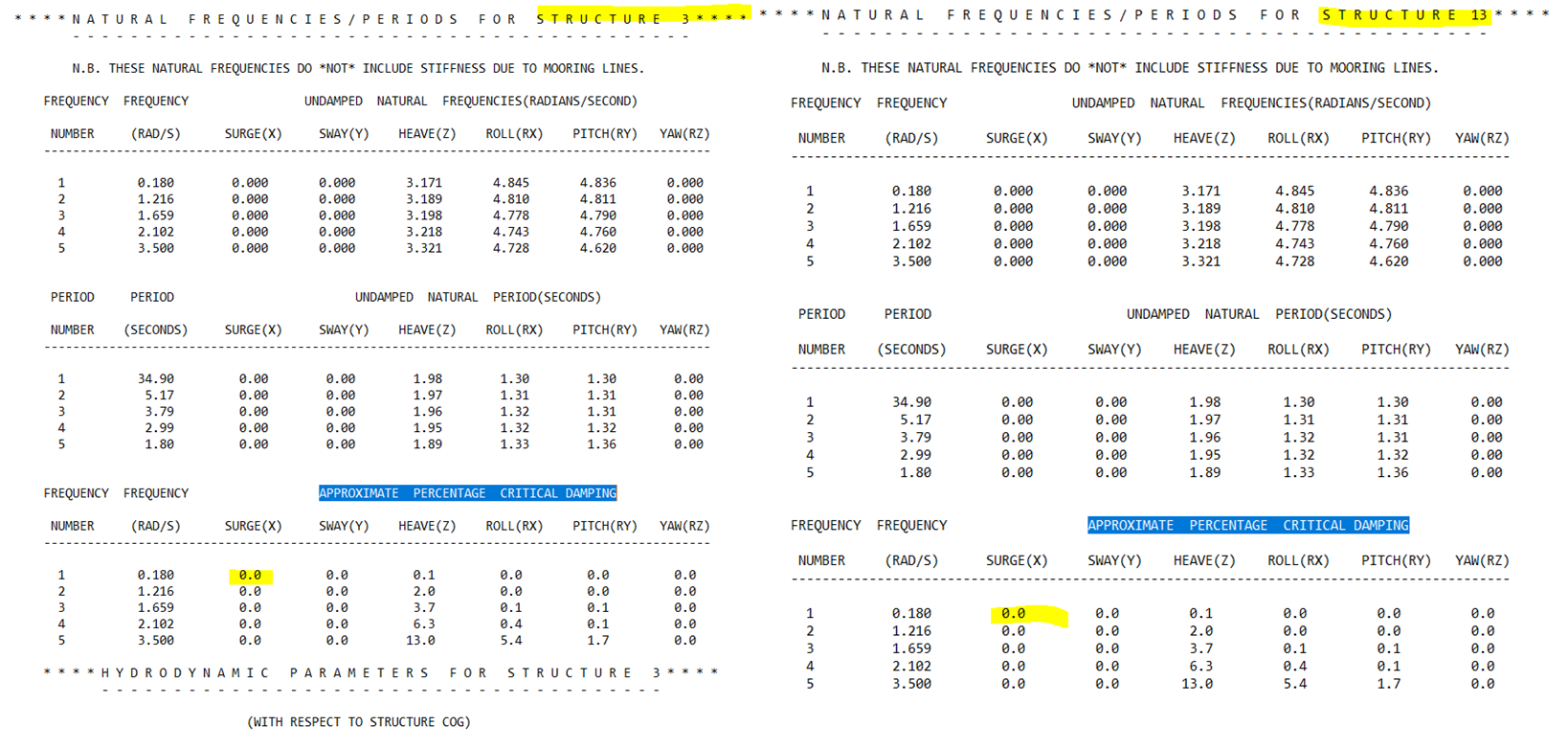

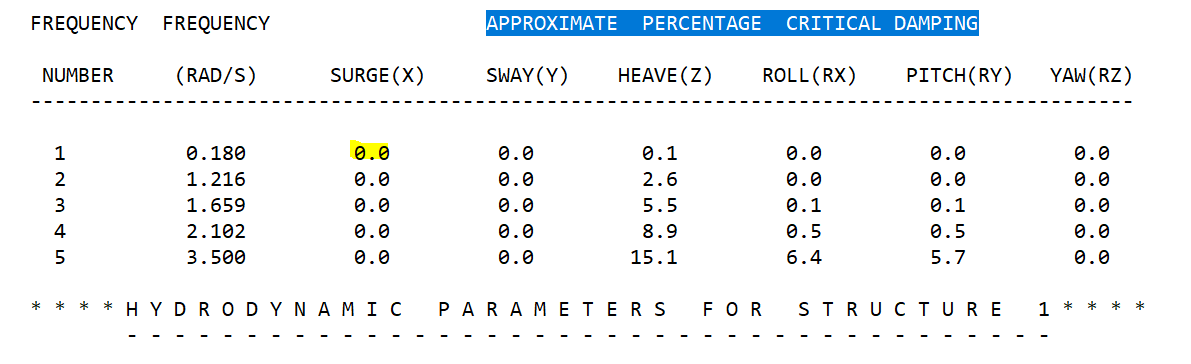

- Also I get the info that " DAMPING FOR SOME FREEDOMS IS VERY SMALL VALUE SET TO NOMINAL 0.5% CRITICAL." . I tried also adding additional damping matrix in the surge direction to a large number, but still in the .LIS file, the percentage of critical damping still says 0%. So this value doesnt change irrespective of any high number I give in the additional damping matrix. Why is it so?

Can you please let me know the answers to the above questions.

Thanks!

-

November 5, 2024 at 5:48 pm

Shuangxing Du

Ansys EmployeeExtreme larger wave height of 1m (comparing to the draft of 0.1m) and short wave length of 26m (comparing to the model size of 15m) will have relative large motions related to the mesh size.

(1) HR time domain analysis is nonlinear analysis, but HR frequency domain statastic analysis is linear which does not check the relative motion criterions.

(2) Wave direction is 180 degrees, Roll and Yaw motions should be very small (or zero) if the system is port-starboard symmetry.

(3) It is a hydrodynamic interaction structure model, the hydrodynamic damping coupling terms may be big.

-

November 5, 2024 at 5:58 pm

S.S.S.ShankaVasuki

SubscriberAh, thank you for these replies. They are very helpful!!

Also, can I rely on the results of the frequency statistical analysis as it is giving me the best match with the reference article compared to diffraction and response analysis. So my question is – can I directly rely on the results from the frequency statistical analysis? Also, does the nonlinearity influence the RAO largely?

Another observation:

- My simulation results match well with the reference article for – Surge, Heave and pitch RAOs. But they are extremly low for Sway, Roll and Yaw RAOs compared to the reference (almost by a factor of 10). So I am wondering if my simulation is correct as the dynamics seems not match with the reference. As you mentioned, when wave direction is 180 deg, these RAO will almost be zero (which is what I get in my simulation). But how does the reference article get a higher RAO in sway, roll and yaw for the same set of conditions? Also, the reference article is an experimental study.

- The reference article mentions that additional damping has to be provided in the surge direction (x) which is approximately 11% of critical damping as shown in the figure, but when I add additional damping to each body with a very high number for x-x element in the matrix and when I check .LIS file, the percentage of critical damping remains 0. So, why is it that is not increasing irrespective of my giving a very high number?

-

November 6, 2024 at 9:43 am

Shuangxing Du

Ansys EmployeeNonlinearity comes from (1) nonlinear wave exciting force, (2) nonlinear hydrostic force, (3) any nonlinear hull drag force if defined, (4) nonlinear mooring force if the nonlinear cable is defined, (5) nonlinear inertia force (13.4. Inertia Forces in Time Domain Analysis) if motions are large.

The numerical model is ideal, for a port-starboard symmetric structure systems in 180 degree wave condition with other current/wind in other direction, the responses for sway/roll/yaw should be very small. But the model test is not ideal, both the model geometry and wave condition cannot be exactly port/starboard symmetric.

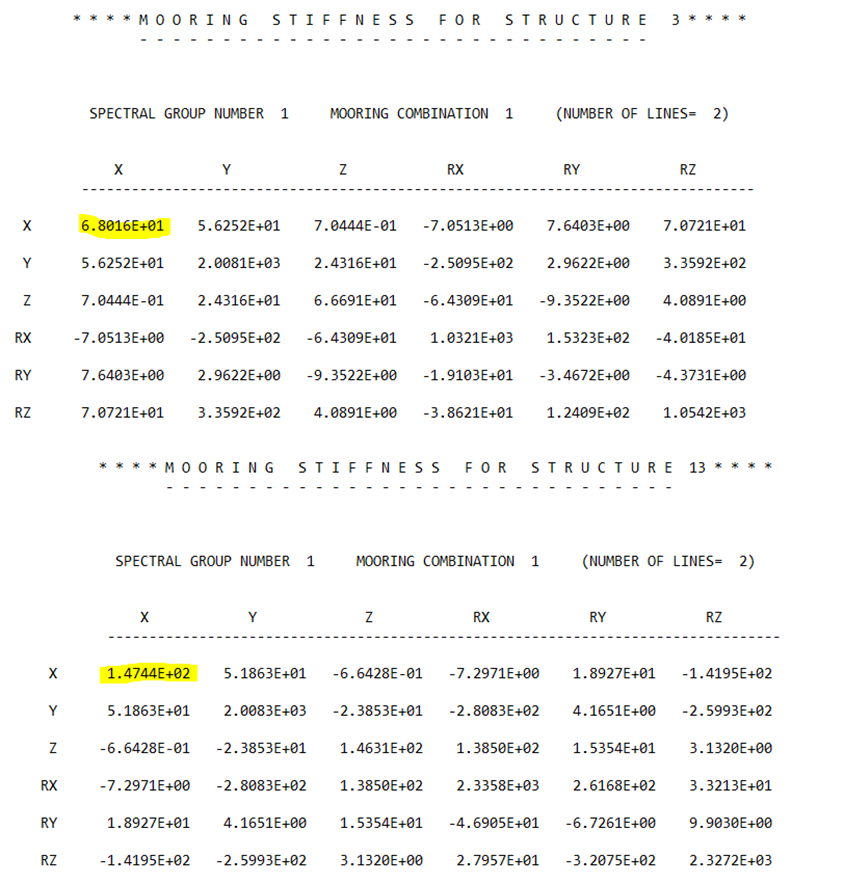

Please check if there is any global mooring stiffness in x-direction, which is the only contribution on the stififness in x-direction as there is no hydrostic stiffness for surge-surge. If not, the critical damping percentage in this direction may not be calculated.

If you find the hydrodynamic responses in frequency statistic analysis agree well with the reference article, the results should be considered to be reliable. Congratulations on your hard work and successful outcomes.

-

November 6, 2024 at 1:28 pm

-

November 6, 2024 at 1:53 pm

Shuangxing Du

Ansys EmployeePlease check the critical damping output. I guess that in your model only Strucre#3 and Structure#13 have mooring stiffness in x-direction. The additional dampings are used always in the program, but the critical damping percentage output of a DOF could be zero for a structure if there is no stiffness in that DOF.

-

November 6, 2024 at 1:58 pm

-

November 6, 2024 at 2:02 pm

Shuangxing Du

Ansys EmployeeOK, it is strange. Can you please show me the data in data category 7 for Structure#3 in the HR (statistic analysis) input data file?

-

November 6, 2024 at 2:05 pm

S.S.S.ShankaVasuki

Subscriber********************************************************************************

********************************************************************************

*********************************** DECK 7 ************************************

********************************************************************************

********************************************************************************

WFS1

SSTF 2 1 84000. 0. 0. 0. 0. 0.

SSTF 2 2 0. 8900. 0. 0. 0. 0.

SSTF 2 3 0. 0. 1500. 0. 0. 0.

SSTF 2 4 0. 0. 0. 1.69997 0. 0.

SSTF 2 5 0. 0. 0. 0. 1.39974 0.

SSTF 2 6 0. 0. 0. 0. 0. 84.0002

SSTF 6 1 84000. 0. 0. 0. 0. 0.

SSTF 6 2 0. 8900. 0. 0. 0. 0.

SSTF 6 3 0. 0. 1500. 0. 0. 0.

SSTF 6 4 0. 0. 0. 1.6999658 0. 0.

SSTF 6 5 0. 0. 0. 0. 1.3997359 0.

SSTF 6 6 0. 0. 0. 0. 0. 84.000196

END

********************************************************************************

********************************************************************************

WFS2

SSTF 3 1 84000. 0. 0. 0. 0. 0.

SSTF 3 2 0. 8900. 0. 0. 0. 0.

SSTF 3 3 0. 0. 1500. 0. 0. 0.

SSTF 3 4 0. 0. 0. 1.69997 0. 0.

SSTF 3 5 0. 0. 0. 0. 1.39974 0.

SSTF 3 6 0. 0. 0. 0. 0. 84.0002

SSTF 7 1 84000. 0. 0. 0. 0. 0.

SSTF 7 2 0. 8900. 0. 0. 0. 0.

SSTF 7 3 0. 0. 1500. 0. 0. 0.

SSTF 7 4 0. 0. 0. 1.6999658 0. 0.

SSTF 7 5 0. 0. 0. 0. 1.3997359 0.

SSTF 7 6 0. 0. 0. 0. 0. 84.000196

END

********************************************************************************

********************************************************************************

WFS3

SSTF 4 1 84000. 0. 0. 0. 0. 0.

SSTF 4 2 0. 8900. 0. 0. 0. 0.

SSTF 4 3 0. 0. 1500. 0. 0. 0.

SSTF 4 4 0. 0. 0. 1.6999658 0. 0.

SSTF 4 5 0. 0. 0. 0. 1.3997359 0.

SSTF 4 6 0. 0. 0. 0. 0. 84.000196

SSTF 8 1 84000. 0. 0. 0. 0. 0.

SSTF 8 2 0. 8900. 0. 0. 0. 0.

SSTF 8 3 0. 0. 1500. 0. 0. 0.

SSTF 8 4 0. 0. 0. 1.6999658 0. 0.

SSTF 8 5 0. 0. 0. 0. 1.3997359 0.

SSTF 8 6 0. 0. 0. 0. 0. 84.000196

SSTF 3 1 206. 0. 0. 0. 0. 0.

SSTF 3 2 0. 4020. 0. 0. 0. 0.

SSTF 3 3 0. 0. 0. 0. 0. 0.

SSTF 3 4 0. 0. 0. 0. 0. 0.

SSTF 3 5 0. 0. 0. 0. 0. 0.

SSTF 3 6 0. 0. 0. 0. 0. 1820.

END

********************************************************************************

********************************************************************************

WFS4

SSTF 5 1 84000. 0. 0. 0. 0. 0.

SSTF 5 2 0. 8900. 0. 0. 0. 0.

SSTF 5 3 0. 0. 1500. 0. 0. 0.

SSTF 5 4 0. 0. 0. 1.6999658 0. 0.

SSTF 5 5 0. 0. 0. 0. 1.3997359 0.

SSTF 5 6 0. 0. 0. 0. 0. 84.000196

SSTF 9 1 84000. 0. 0. 0. 0. 0.

SSTF 9 2 0. 8900. 0. 0. 0. 0.

SSTF 9 3 0. 0. 1500. 0. 0. 0.

SSTF 9 4 0. 0. 0. 1.6999658 0. 0.

SSTF 9 5 0. 0. 0. 0. 1.3997359 0.

SSTF 9 6 0. 0. 0. 0. 0. 84.000196

END

********************************************************************************

********************************************************************************

WFS5

SSTF 10 1 84000. 0. 0. 0. 0. 0.

SSTF 10 2 0. 8900. 0. 0. 0. 0.

SSTF 10 3 0. 0. 1500. 0. 0. 0.

SSTF 10 4 0. 0. 0. 1.6999658 0. 0.

SSTF 10 5 0. 0. 0. 0. 1.3997359 0.

SSTF 10 6 0. 0. 0. 0. 0. 84.000196

END

********************************************************************************

********************************************************************************

WFS6

SSTF 7 1 84000. 0. 0. 0. 0. 0.

SSTF 7 2 0. 8900. 0. 0. 0. 0.

SSTF 7 3 0. 0. 1500. 0. 0. 0.

SSTF 7 4 0. 0. 0. 1.6999658 0. 0.

SSTF 7 5 0. 0. 0. 0. 1.3997359 0.

SSTF 7 6 0. 0. 0. 0. 0. 84.000196

SSTF 11 1 84000. 0. 0. 0. 0. 0.

SSTF 11 2 0. 8900. 0. 0. 0. 0.

SSTF 11 3 0. 0. 1500. 0. 0. 0.

SSTF 11 4 0. 0. 0. 1.6999658 0. 0.

SSTF 11 5 0. 0. 0. 0. 1.3997359 0.

SSTF 11 6 0. 0. 0. 0. 0. 84.000196

END

********************************************************************************

********************************************************************************

WFS7

SSTF 8 1 84000. 0. 0. 0. 0. 0.

SSTF 8 2 0. 8900. 0. 0. 0. 0.

SSTF 8 3 0. 0. 1500. 0. 0. 0.

SSTF 8 4 0. 0. 0. 1.6999658 0. 0.

SSTF 8 5 0. 0. 0. 0. 1.3997359 0.

SSTF 8 6 0. 0. 0. 0. 0. 84.000196

SSTF 12 1 84000. 0. 0. 0. 0. 0.

SSTF 12 2 0. 8900. 0. 0. 0. 0.

SSTF 12 3 0. 0. 1500. 0. 0. 0.

SSTF 12 4 0. 0. 0. 1.6999658 0. 0.

SSTF 12 5 0. 0. 0. 0. 1.3997359 0.

SSTF 12 6 0. 0. 0. 0. 0. 84.000196

END

********************************************************************************

********************************************************************************

WFS8

SSTF 9 1 84000. 0. 0. 0. 0. 0.

SSTF 9 2 0. 8900. 0. 0. 0. 0.

SSTF 9 3 0. 0. 1500. 0. 0. 0.

SSTF 9 4 0. 0. 0. 1.6999658 0. 0.

SSTF 9 5 0. 0. 0. 0. 1.3997359 0.

SSTF 9 6 0. 0. 0. 0. 0. 84.000196

SSTF 13 1 84000. 0. 0. 0. 0. 0.

SSTF 13 2 0. 8900. 0. 0. 0. 0.

SSTF 13 3 0. 0. 1500. 0. 0. 0.

SSTF 13 4 0. 0. 0. 1.6999658 0. 0.

SSTF 13 5 0. 0. 0. 0. 1.3997359 0.

SSTF 13 6 0. 0. 0. 0. 0. 84.000196

END

********************************************************************************

********************************************************************************

WFS9

SSTF 10 1 84000. 0. 0. 0. 0. 0.

SSTF 10 2 0. 8900. 0. 0. 0. 0.

SSTF 10 3 0. 0. 1500. 0. 0. 0.

SSTF 10 4 0. 0. 0. 1.6999658 0. 0.

SSTF 10 5 0. 0. 0. 0. 1.3997359 0.

SSTF 10 6 0. 0. 0. 0. 0. 84.000196

SSTF 14 1 84000. 0. 0. 0. 0. 0.

SSTF 14 2 0. 8900. 0. 0. 0. 0.

SSTF 14 3 0. 0. 1500. 0. 0. 0.

SSTF 14 4 0. 0. 0. 1.6999658 0. 0.

SSTF 14 5 0. 0. 0. 0. 1.3997359 0.

SSTF 14 6 0. 0. 0. 0. 0. 84.000196

END

********************************************************************************

********************************************************************************

WF10

SSTF 15 1 84000. 0. 0. 0. 0. 0.

SSTF 15 2 0. 8900. 0. 0. 0. 0.

SSTF 15 3 0. 0. 1500. 0. 0. 0.

SSTF 15 4 0. 0. 0. 1.6999658 0. 0.

SSTF 15 5 0. 0. 0. 0. 1.3997359 0.

SSTF 15 6 0. 0. 0. 0. 0. 84.000196

END

********************************************************************************

********************************************************************************

WF11

SSTF 12 1 84000. 0. 0. 0. 0. 0.

SSTF 12 2 0. 8900. 0. 0. 0. 0.

SSTF 12 3 0. 0. 1500. 0. 0. 0.

SSTF 12 4 0. 0. 0. 1.6999658 0. 0.

SSTF 12 5 0. 0. 0. 0. 1.3997359 0.

SSTF 12 6 0. 0. 0. 0. 0. 84.000196

END

********************************************************************************

********************************************************************************

WF12

SSTF 13 1 84000. 0. 0. 0. 0. 0.

SSTF 13 2 0. 8900. 0. 0. 0. 0.

SSTF 13 3 0. 0. 1500. 0. 0. 0.

SSTF 13 4 0. 0. 0. 1.6999658 0. 0.

SSTF 13 5 0. 0. 0. 0. 1.3997359 0.

SSTF 13 6 0. 0. 0. 0. 0. 84.000196

END

********************************************************************************

********************************************************************************

WF13

SSTF 14 1 84000. 0. 0. 0. 0. 0.

SSTF 14 2 0. 8900. 0. 0. 0. 0.

SSTF 14 3 0. 0. 1500. 0. 0. 0.

SSTF 14 4 0. 0. 0. 1.6999658 0. 0.

SSTF 14 5 0. 0. 0. 0. 1.3997359 0.

SSTF 14 6 0. 0. 0. 0. 0. 84.000196

SSTF 13 1 206. 0. 0. 0. 0. 0.

SSTF 13 2 0. 4020. 0. 0. 0. 0.

SSTF 13 3 0. 0. 0. 0. 0. 0.

SSTF 13 4 0. 0. 0. 0. 0. 0.

SSTF 13 5 0. 0. 0. 0. 0. 0.

SSTF 13 6 0. 0. 0. 0. 0. 1819.9999

END

********************************************************************************

********************************************************************************

WF14

SSTF 15 1 84000. 0. 0. 0. 0. 0.

SSTF 15 2 0. 8900. 0. 0. 0. 0.

SSTF 15 3 0. 0. 1500. 0. 0. 0.

SSTF 15 4 0. 0. 0. 1.6999658 0. 0.

SSTF 15 5 0. 0. 0. 0. 1.3997359 0.

SSTF 15 6 0. 0. 0. 0. 0. 84.000196

END

********************************************************************************

********************************************************************************

WF15

END

-

- You must be logged in to reply to this topic.

-

5094

-

1830

-

1387

-

1248

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.