TAGGED: co-simulation, electromagnetic, thermal, workbench

-

-

February 4, 2020 at 3:37 pm

Ayman

Subscriberhow could i use apdl code to force ansys workbench use these two element type:

1-solid 185 with keyopt (2)=1 for steel columns, beams and flush end plates i used to capture large deformation for trilinear material

2-solid 186 with keyopt (2)=0 for blind bolt i used to capture strain for bilinear material

and should i change any setting to apply them

-

February 4, 2020 at 4:02 pm

peteroznewman

SubscriberThe first point to make is that SOLID185 is a linear element, while SOLID186 is a quadratic element.

When Mechanical makes a mesh, it is either linear or quadratic. You can't force a linear element type onto a quadratic mesh and vice versa.

When you click on Mesh in the outline, you can set the Element Order globally to either Linear or Quadratic.

You can override the global setting on individual bodies by inserting a Mesh Control Method and set the Element Order.

You could try quadratic elements on all bodies initially.

Keyopt(2) = 0 is the default for SOLID186 so you don't need to do anything other than make sure the mesh is quadratic.

-

February 6, 2020 at 7:38 am

Ayman

Subscriberwhen I change the element order as you mentioned for steel columns, beams, and flush end plates I used linear element and for the blind bolt, I used Quadratic element then I get this error:

"An internal solution magnitude limit was exceeded. Please check your Environment for inappropriate load values or insufficient supports. Please see the Troubleshooting section of the Help System for more information."

and inside solver output I found these errors:

*** ERROR *** CP = 83.062 TIME= 23:19:10

The value of UX at node 310032 is 62110597.8. It is greater than the

current limit of 1000000 (which can be reset on the NCNV command).

This generally indicates rigid body motion as a result of an

unconstrained model. Verify that your model is properly constrained.

*** ERROR *** CP = 83.062 TIME= 23:19:10

*** MESSAGE CONTINUATION ---- DIAGNOSTIC INFORMATION ***

If one or more parts of the model are held together only by contact

verify that the contact surfaces are closed. You can use the CNCHECK

command to check the initial contact status in the SOLUTION module.

-

February 6, 2020 at 1:08 pm

peteroznewman

SubscriberThe error says there is insufficient support of UX direction.

Do you have a nonlinear contact in the model?

If so, did you insert a Contact Tool under the Connections folder?

If so, what was the Initial Contact Status? Were all the contacts closed?

Please show a lot more detail about your model.

-

February 6, 2020 at 1:46 pm

-

February 6, 2020 at 2:33 pm

peteroznewman

SubscriberSEKER77, please copy the contents of your post above, and paste them into a New Discussion, then delete the post above. This is not your discussion and your post is not on the topic of this discussion.

-

February 6, 2020 at 4:19 pm

-

February 11, 2020 at 11:25 am

Ayman

SubscriberI checked the contact tool and all my contact are closed and use adjust to touch too

we have already talked about this before in this old discussion I only change the element type for members from program controlled to Quadratic for bolts and linear for other steel members I don't know where is the problem so here is my model link.

-

February 13, 2020 at 6:49 am

Ayman

Subscriber@peteroznewman do you have any suggestions for my problem, sorry for disturb you and thanks in advance.

-

February 17, 2020 at 1:47 am

peteroznewman

SubscriberAyman,

I downloaded your bolted cross assembly of tubes. I can't see any obvious errors.

One simple check is to add a Modal analysis to the Model cell and drag down the supports. That allows you to see if any parts are not properly connected. Frictional contacts are automatically converted to Bonded Contact during the Modal analysis.

Another suggestion is to create a 1/4 symmetry model. Open DesignModeler and insert a Symmetry object with 2 planes of symmetry: XY and YZ on the full model. You will be left with a 1/4 model. This will be 4 times easier to debug.

-

March 1, 2020 at 9:05 pm

Ayman

SubscriberPeter,

Thank you for your attention. i tried to solve the many times with different setting until i found the error, my problem was with the mesh so i tried the following:

-remeshed the model all over again to ensure the quality of mesh.

-I used a contact sizing to refine the mesh between the nuts and endplate Which I think that cause the problem.

-I change the element control to manual in the geometry details and for each body, I change the brick integration scheme to reduced to save more time.

-I change the mesh detail setting: 1-Under defaults physics preference to mechanical instead of NL mech.

2-Under sizing transition to slow.

3- Under sizing span angle centre to fine.

4-under quality error limits to aggressive mech.

5-under quality smoothing to fine.

after that the model have been solved but it takes a long time and compare the result between my model and expermintal result in the research and i found the following:

1-The force-displacement chart looks to be close I think it's acceptable.

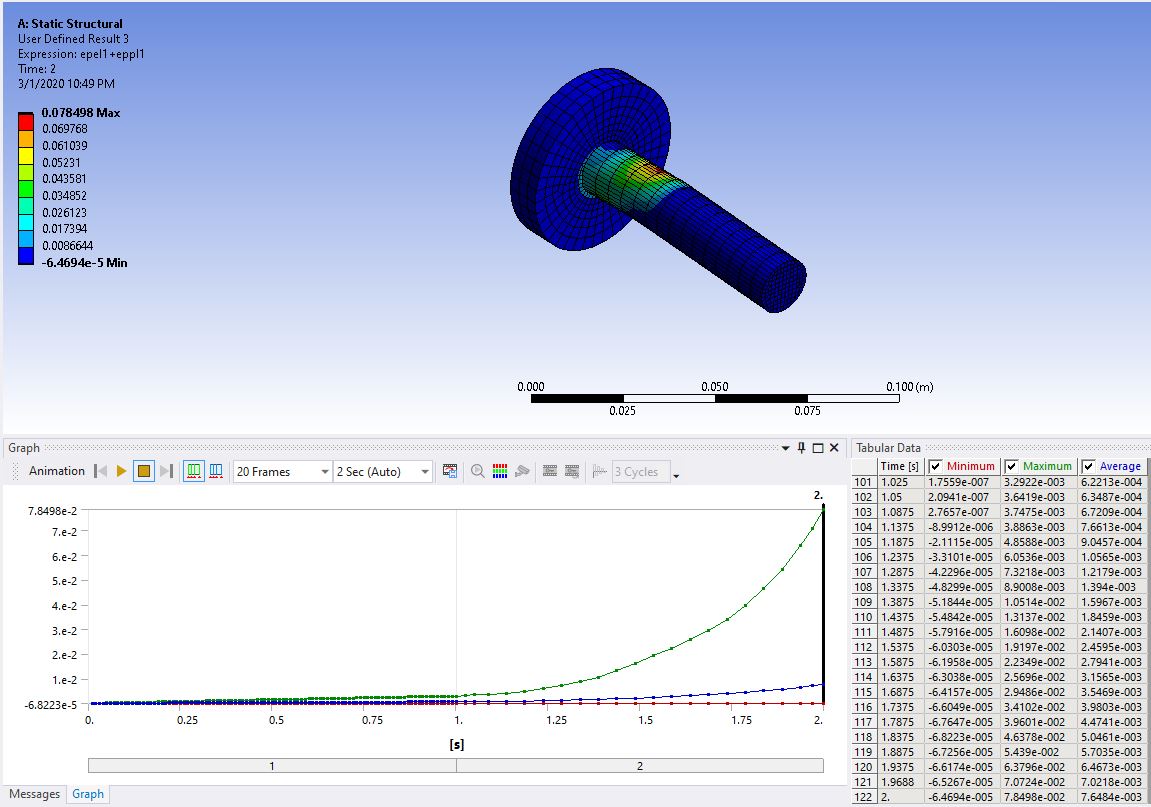

2-The force-strain chart for bolts looks to be so far from the research results like the following

a-for B1&B2 in the research:

B-for B1&B2 in my model:

B1:

B2:

so I have redone the work as you suggest with the 1/4 model and start to check the result again and found the following:

1-The force-displacement chart looks to be close I think it's acceptable too.

2-The force-strain chart for bolts looks to be so far too but it have been changed from the full model and the research results like the following:

a-for B1&B2 in the research:

B-for B1&B2 in my 1/4 model:

B1:

B2:

I don't know how to reach to the ecact results i have tried every thing i have attached the 1/4 model if you have more suggestions

Download link for 1/4 model: https://we.tl/t-QzaM2e9qHm

Download link for full model: https://we.tl/t-oPxFTCxjGn

and I am searching for trilinear material charts for the bolts if you have any data or if you can tell me where to find.

sorry for taking much of your time and thanks a lot for all you do for me.

-

- The topic ‘Ansys workbench’ is closed to new replies.

-

5149

-

1831

-

1387

-

1248

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.