TAGGED: ansys-icepak, udf, udferror

-

-

March 24, 2025 at 9:00 pm

mfaro5

SubscriberHi, I am currently doing a senior design project with a system integrating four fans for cooling. I am trying to attach a UDF to each fan, but I am getting an error saying "more than one curve." In addition, what should I attach within parallel settings specifically for the UDF? Within my code, I feel like the error is caused by having multiple zone IDs in a single UDF. I am fairly new to Icepak and developing UDFs, and I would greatly appreciate it if anyone could help me!

-

March 24, 2025 at 9:02 pm

mfaro5

Subscriber.

-

March 28, 2025 at 7:24 pm

Rabindra Paul

Ansys EmployeeHi Thanks for contacting forum. As the error messsage is saying each fan should have their respective fan curve under non-linear fan curve.

Regarding UDF question. Icepak interface does not allow to attach any external UDF files like fluent. But some Icepak features may use internal UDFs if needed. The option in the network parallel panel is just to turn on the switch to use the shared path for any internal UDFs used by the model. Please let me know if this helps. Please feel free to use support portal to discuss your requirement.

-

April 1, 2025 at 1:01 am

mfaro5

SubscriberThanks for responding! How would I use an internal UDF? I want to use a UDF for each fan to turn on the fans based on a specific temperature threshold assigned within the UDF. Is there a method I can use to simulate this scenario in Icepak?

-

-

April 1, 2025 at 1:56 pm

Rabindra Paul

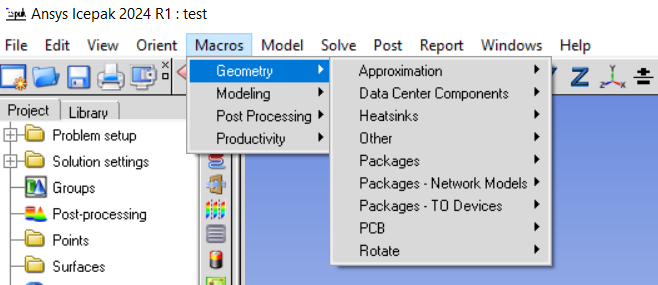

Ansys EmployeeHi- Icepak interface does not support UDF. I guess the best think would be to use Fluent software. Icepak supports macros similar to UDF. You may review avaiable macros to get an idea. But the process you are trying to achieve is not possible through an available macros and will need new macro. Hope this information is of help.

-

April 2, 2025 at 2:51 am

jonk

SubscriberHi Rabindra!

To shift the question a little bit: the necessity is to control the fan as a function of some external temperature or condition in a transient simulation. We are able to set up a transient fan, but what we wish to do is specify a fan curve, or setpoint, as a function of temperature to analyze transient behavior.I cannot find in the documentation how to prepare a macro, as you mentioned. Is this something the user can do? If so, can you point me to where this would be located in the documentation or examples on the portal?

-

-

April 2, 2025 at 4:31 pm

Rabindra Paul

Ansys EmployeeHi - Thanks for your note. I would suggest to contact through customer portal case to discuss the workaround and available options for you. Yes, users can create their macros with special support/consulting. It is not part of usual support and documentation. You may work with your account manager, if needed.

Please let me know any comments.

Regards,

Rabindra

-

- You must be logged in to reply to this topic.

- Three-Phase Voltage Imbalances in dual stator electric generator

- Link the Circuit to 3D Terminals

- Magnetic Dipole moment calculation

- Integration lines or U Axis Line for circular and rectangular ports

- Core Loss in ANSYS MAXWELL Eddy Current solution

- exporting and importing my Netlist for my external circuit

- Error of Metal Fraction in Icepak Classic.

- The unit of theta in Is*sin(2*pi*fre*Time+theta-2*pi/3)

- 2D transient simulation -torque issue

- Two way coupling for Maxwell and thermal problem

-

4618

-

1530

-

1386

-

1209

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.