-

-

July 8, 2024 at 3:39 pm

Saeed

SubscriberHello,

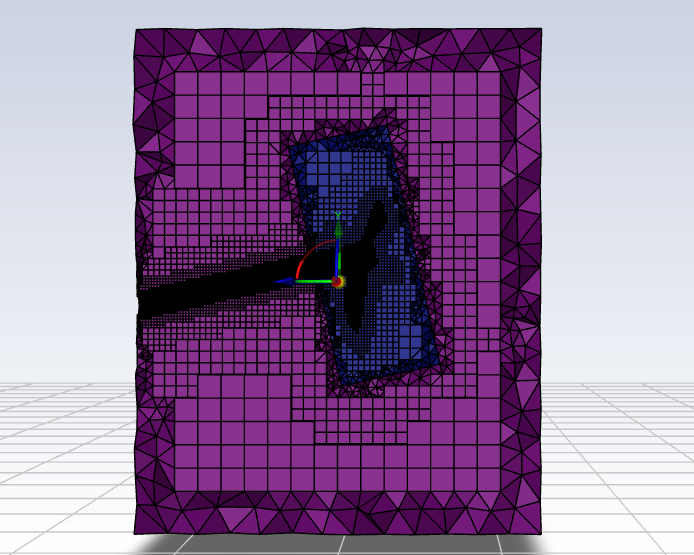

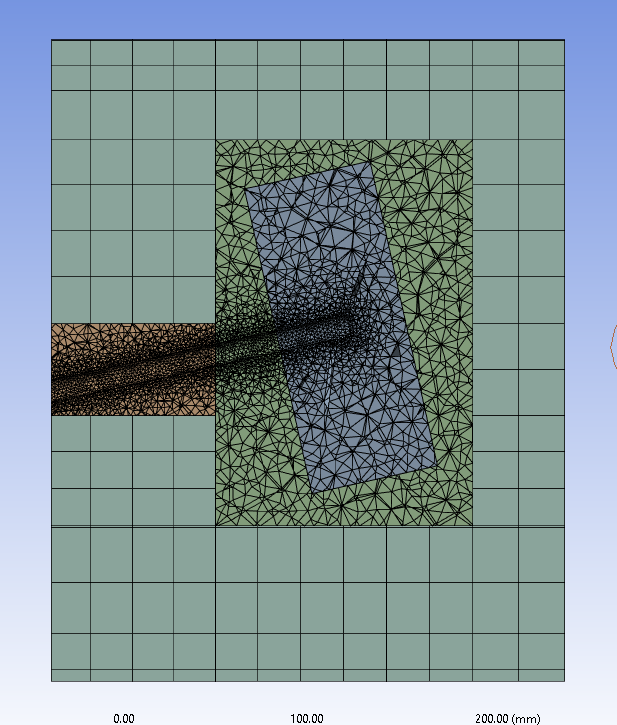

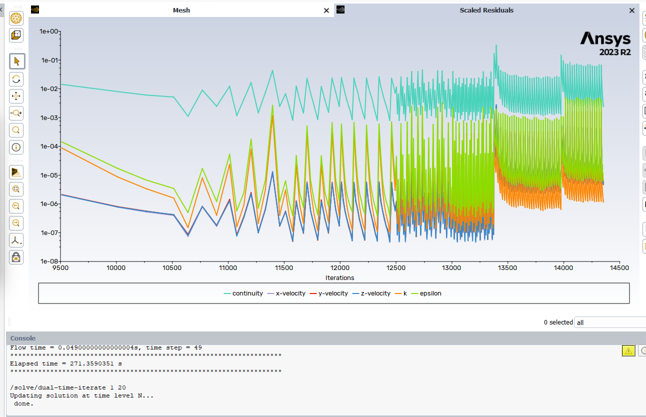

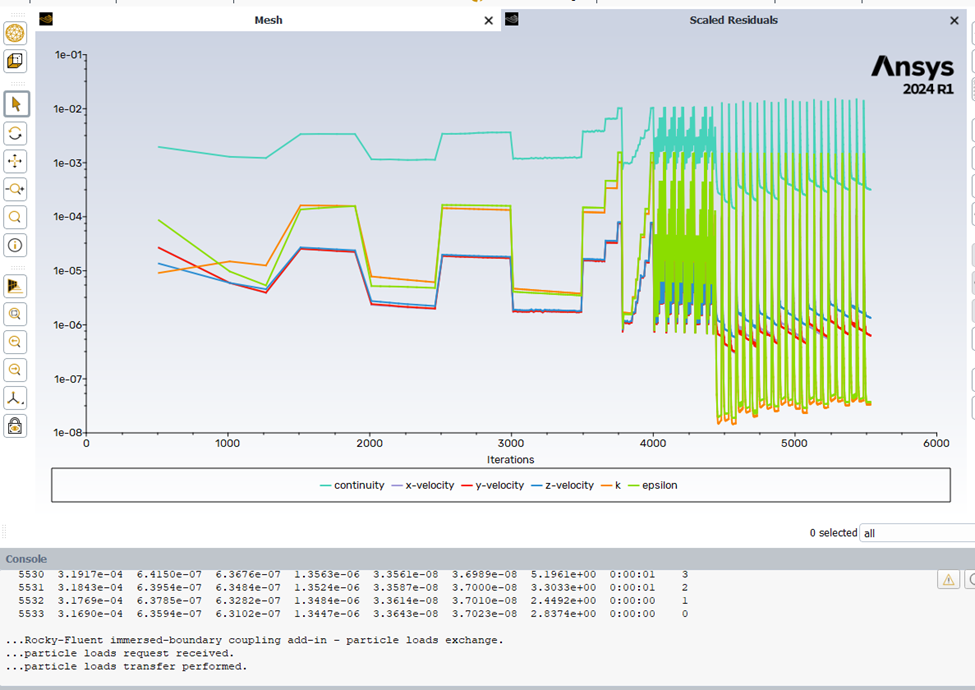

I am running CFD-DEM simulation with two different meshes and I have some questions. I have generated volume mesh and a regular mesh . with the volume mesh Rocky gives me the attached error. But with the regular mesh simulation runs but in fluent iterations, when the simulation startes continuity goes up suddenly and also it does not converge any more. also that rise happens almost every 500 iterations but the simulation runs.

1- Can you please let me know how can I solve the volume mesh error in Rocky ?

2- For the regular mesh I would be grateful if you have any sugustions for improving it.

3- Regarding the convergence , for coupling simulation does the convergence of the iterations still matters when Rocky starts ? If so can you please let me know how can I fix that?

Thanks

-

July 9, 2024 at 11:19 am

Rob

Forum ModeratorYou didn't post the poly-hexcore error.

Re convergence, how does the flow field look? How fast are the particles moving relative to the Fluent solver time step and cell size near the impellor?

-

July 9, 2024 at 2:05 pm

Saeed

SubscriberDear Rob,

Thank you for your response.

this is the poly-hexacore error:

Fluent time step is 0.001s and Rocky is 4.6e-6 s.

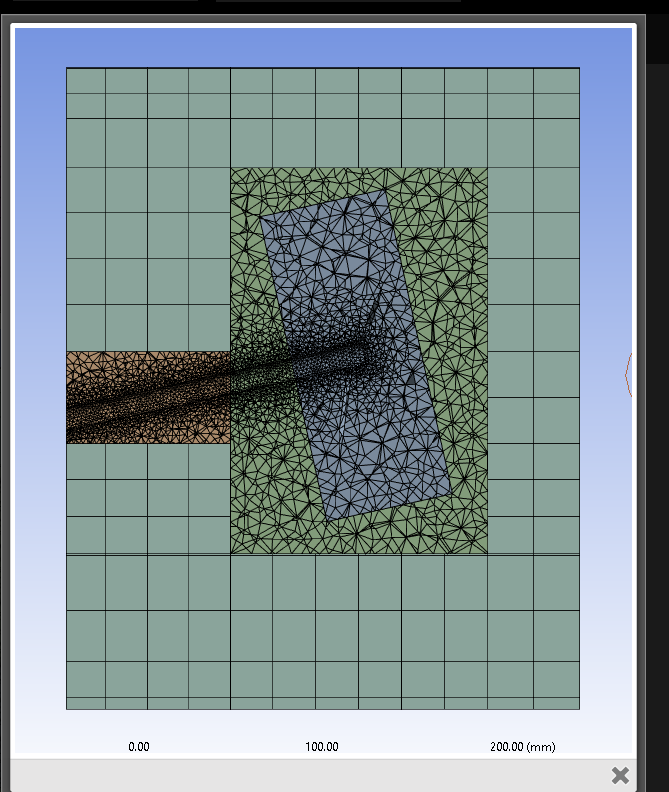

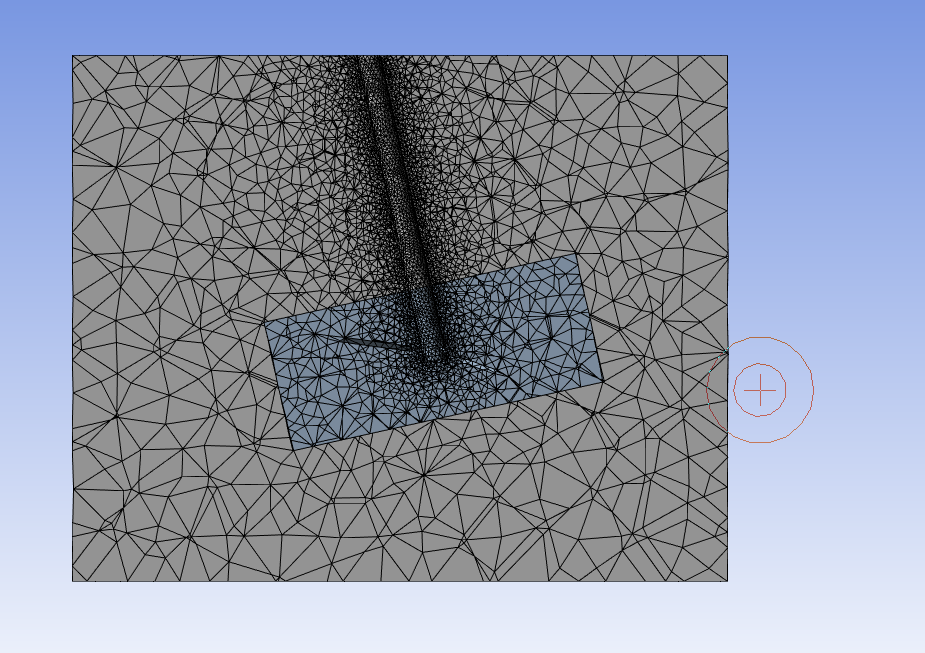

near the impeller cell size: for volume mesh I have 1mm face size on the impeller wall and 8mm cell size in the impeller region. for the regular mesh is 6mm impeller wall cell size and the impelle region is 10 mm.

Thanks

-

July 9, 2024 at 3:38 pm

Rob

Forum ModeratorAnd the flow transit time for a cell relative to the CFD timestep?

-

July 10, 2024 at 1:33 am

Saeed

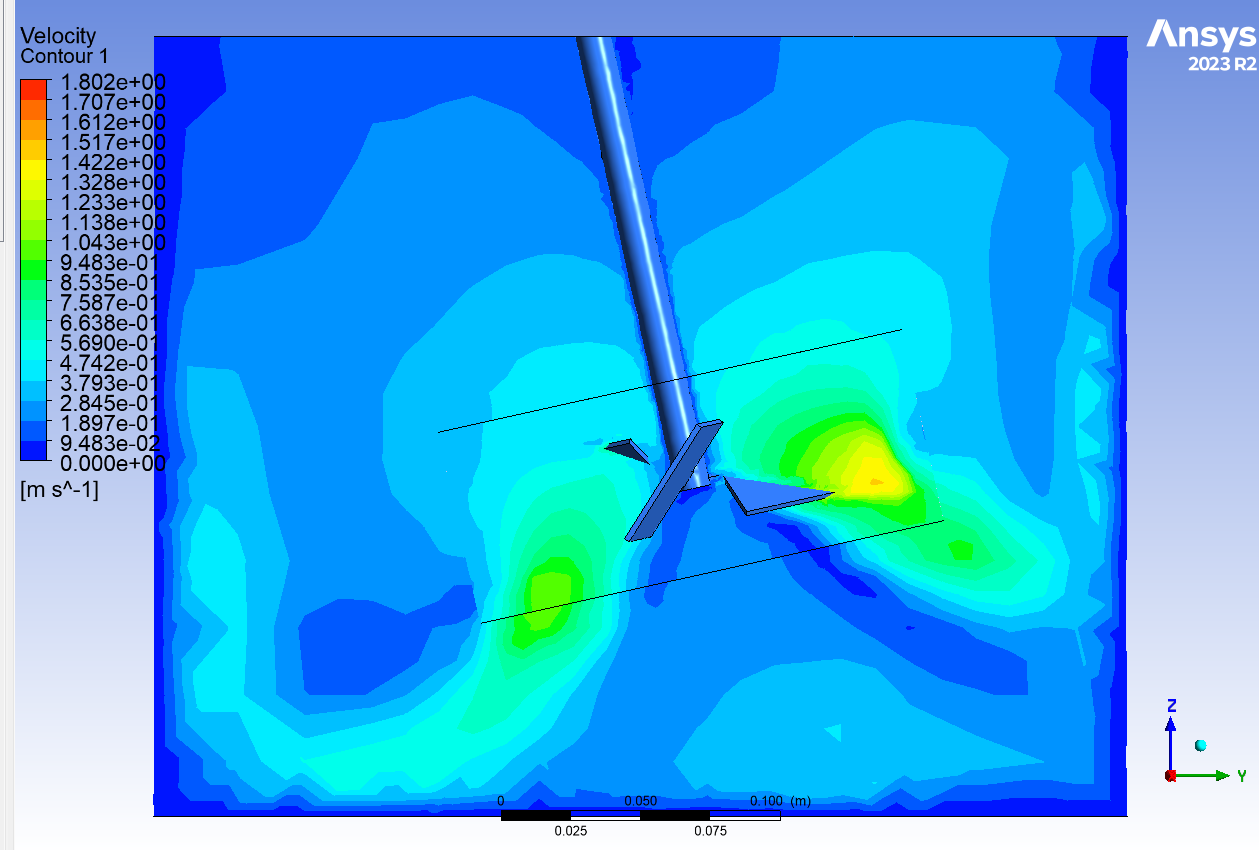

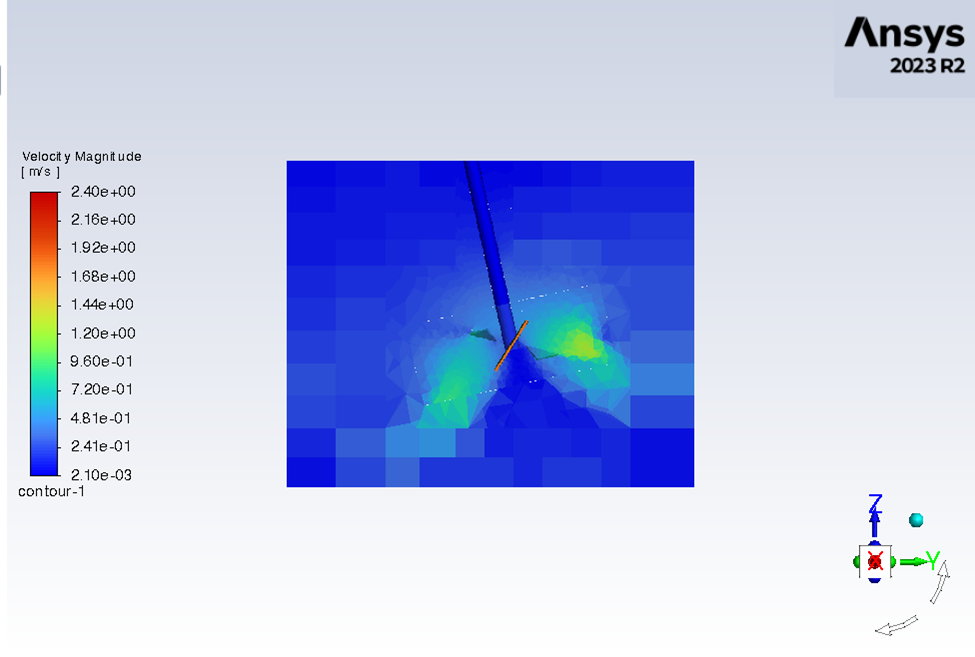

Subscriber1- The characteristic length of the cell at the tim of the impeller is about 2 mm and the velocity there is about 1.4 m/s so the transiet time should be 0.0014 s. (contour plot attached)

2- can you please also discuss about the other mesh too. what do you think about that ? is it a good mesh or not ? BTW the cfd-dem runs in that want and do not give the error in the volume mesh.

-

July 10, 2024 at 10:30 am

Rob

Forum ModeratorSo try dropping the time step in Fluent to make sure it's low enough.

To check the mesh replot the above with node values off - you need to do that in Fluent's post processing. You're then looking to see how well resolved the velocity gradients are.

-

July 10, 2024 at 10:13 pm

Saeed

SubscriberThanks I will try that.

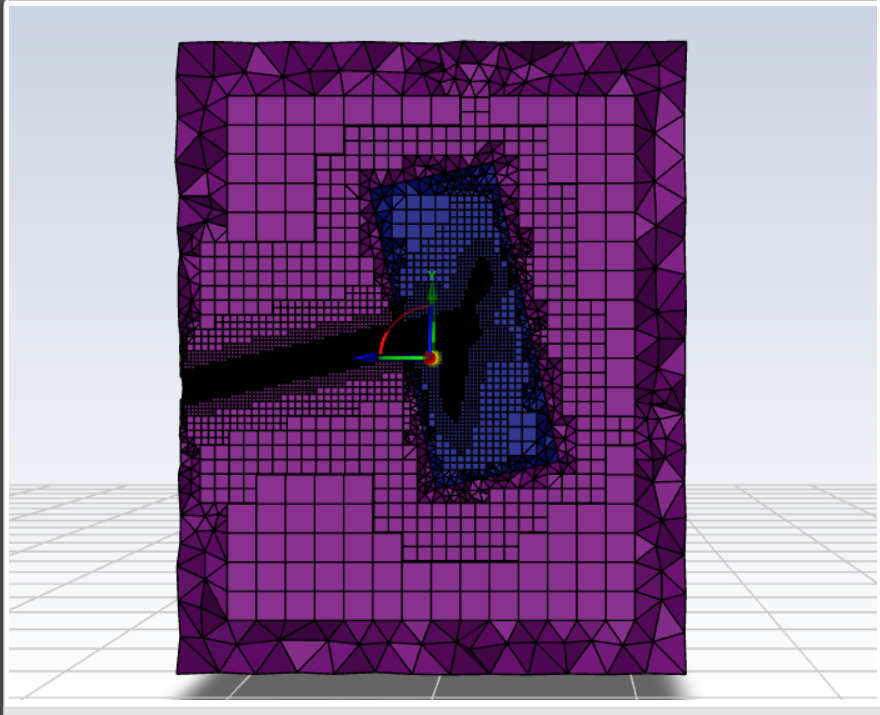

1- About the mesh I meant more about the different regions I have designed or my mesh methods.

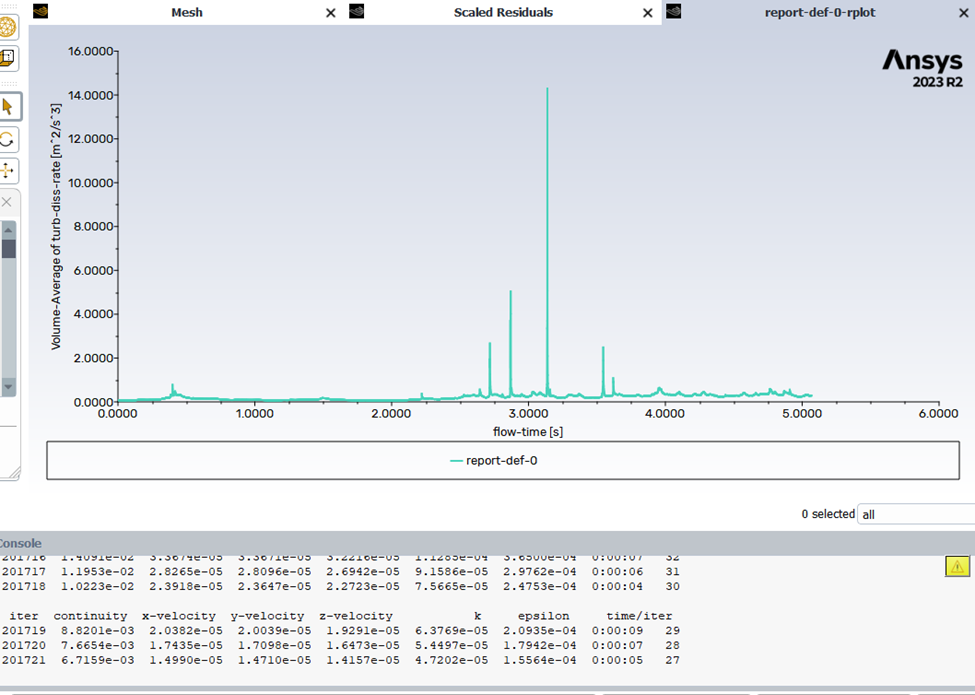

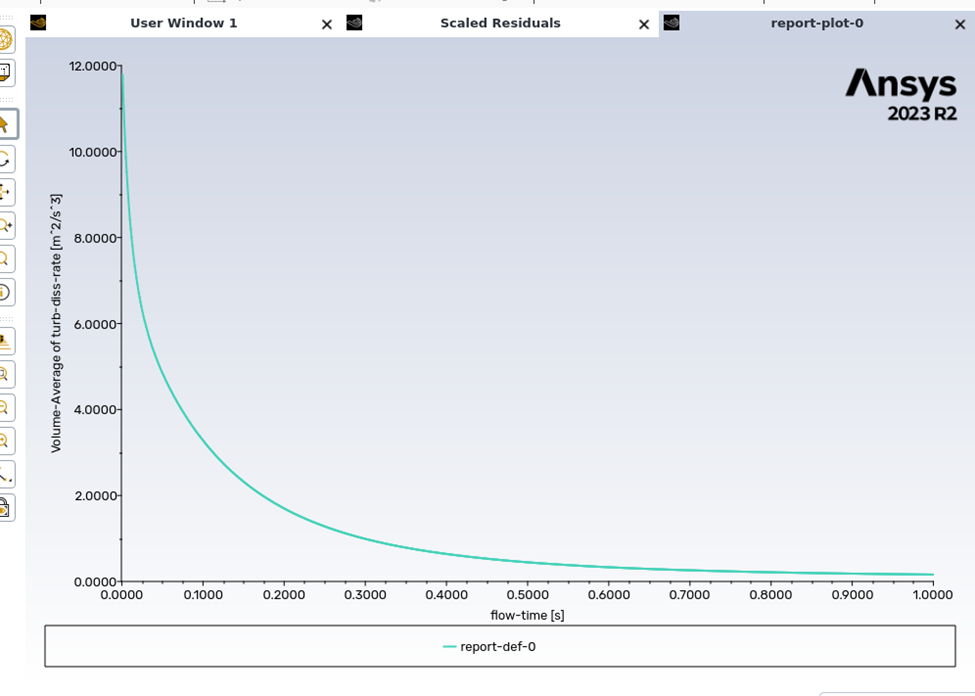

2- I did another simulation with the mesh that coupled simulation can be run, but this time I increased the number of iterations to 40 from 20 and also activated porudction limiter in my k-epsilone model. In the first few time step it did not converge but slowly started to converge after 30 iterations, however, after a few seconds it needed more iterations to converge. could you please help me with that ? I have also plotted a report definitoin. Based on thay do you think the results are reliable or they are not correct ?

-

July 12, 2024 at 2:04 pm

Rob

Forum ModeratorThat sounds like the solution is evolving with time, and may require the time step to be altered to cope.

-

July 12, 2024 at 2:53 pm

-

July 15, 2024 at 9:23 am

Rob

Forum ModeratorNot easily. There are ways to import multiple meshes into Fluent, (look up Append) so you could mesh as two parts and tet around the baffles. Or just tet the whole lot and don't try to use poly or poly-hexcore.

As a general comment, I tend to avoid poly-hexcore for any multiphase models as the sudden jump in cell size doesn't work well if there's a large phase gradient in the same area.

-

July 16, 2024 at 8:58 pm

Saeed

SubscriberThank you for your reply and help.

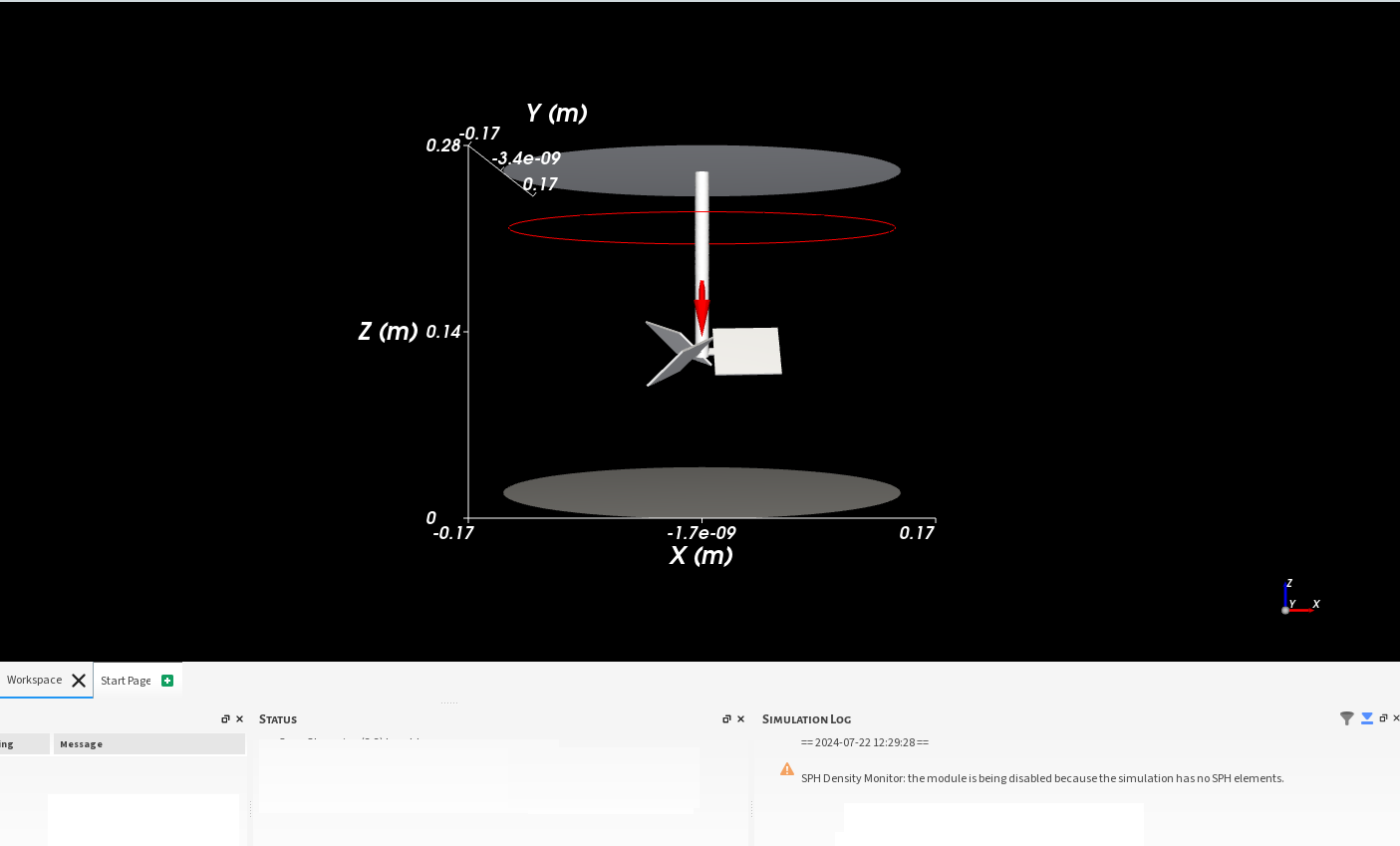

my case is a mixing tank with no baffeles and a tilted impeller which then I will use it as my case file for Rocky. Attached is the mesh and the the velocity contour with node values off as you mentioned in the previous messages.

can you please let me know what do you think about the mesh and the velocity gradients? Do you think the simulation results are acceptable ?

I have also attached a report definition of the epsilone volume average. (these are results before transfering to Rocky)

-

July 18, 2024 at 10:03 am

Rob

Forum ModeratorThe jump in cell size is too high - otherwise it looks to be working.

-

July 18, 2024 at 2:25 pm

Saeed

SubscriberThe reason that I have chosen this cell size is that my particles in Rocky are 20mm so I need to have mesh size larger than particle size which I tried to satisfy that in hexa cells. Now , I want to ask in geometries like a mixing tank which we can not have a structured mesh and for example near the impeller we need a finer mesh , what should I do to have reliable results ?

Thanks

-

July 19, 2024 at 4:35 pm

Rob

Forum ModeratorThe particles are that big relative to the mixer? Have a look at the semi-resolved model options in Rocky.

-

July 21, 2024 at 5:58 pm

Saeed

Subscribermy shaft has 2.74cm charectristic length and my partciles have 2cm diameter.

I actually ran a simulation with that too. and these are the questions I have.

1- in 2-way unresolved there are multiple tabs that in one of them you can choose the drag law or... but in semi-resolved there is not and there is just one tab related to fluent processors and etc. even tho I have turned on drag force statistics in modules the drag force of particles showed is 0 when i post process after simulation.

2- In the fluent there was a pi-control added next to the parameters which were iterating , which never converged even it values went up and down and fluctuated. can you please explain what is pi-control and how can i help it converge ?

3- my first sinulation had 0.01s time step which proceeded with no issue. i dropped down the time step size to 0.001s and it goes for a few time steps in fluent and then does not change at all , iterations does not change with no errors or warning, even after 24hrs no changes was made. can you please help me with it.

Thanks

-

July 22, 2024 at 1:21 pm

Vinicius Daroz

Ansys EmployeeHello Saeed,

I see you are using 23R2 so semi-resolved is not a good option in this case, since it does not support turbulent flows. The reason why you don't see a drag law selection option is because there isn't one. The semi-resolved approach does not rely on any correlations for computing the drag force. On top of that, you would need a super fine mesh.

The error you are getting, the "DEM explicit time step" one, is raised when the DEM time step is too large to handle the drag force. Since the drag force is computed explicitly, if the time step is too large, the solution diverges. Try to lower Rocky's timestep and check how it goes. Also, keep the ratio between Fluent and Rocky time steps below 1e3. Finally, as pointed out by Rob, smooth out the transition between the cell zones. My final suggestion is to keep the impeller still as a first test, without the sliding mesh, just the bare minimum. Try to isolate the issue.

Since particles are big, have you checked Rocky's SPH approach?

-

July 22, 2024 at 4:55 pm

Saeed

SubscriberDear Rob and Vinicius,

Thank you for your suggustions.

1- about the semi-resolved so basically i can not use semi-resolved if i want to measure the drag force and it can just be used for particles distribution . Correct ?

I have done simulation with 24R1 too with a fine mesh and 0.001s time step and same issue comes up that simulation does not proceed.

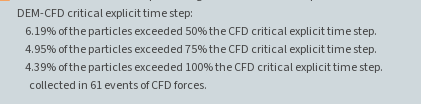

2- Before Rob mentioned that he suggusts that instead of using a tetra/hexa combination just use tetra with lower time step. I ran a simulation with 0.001 and 0.0005 time steps and 4.67e-6 DEM time step with the attached mesh. the one with 0.001s crashed and gave the follwing error and simulation stopped before even 0.1s of simulation output :

DEM-CFD critical explicit time step:

6.19% of the particles exceeded 50% the CFD critical explicit time step.

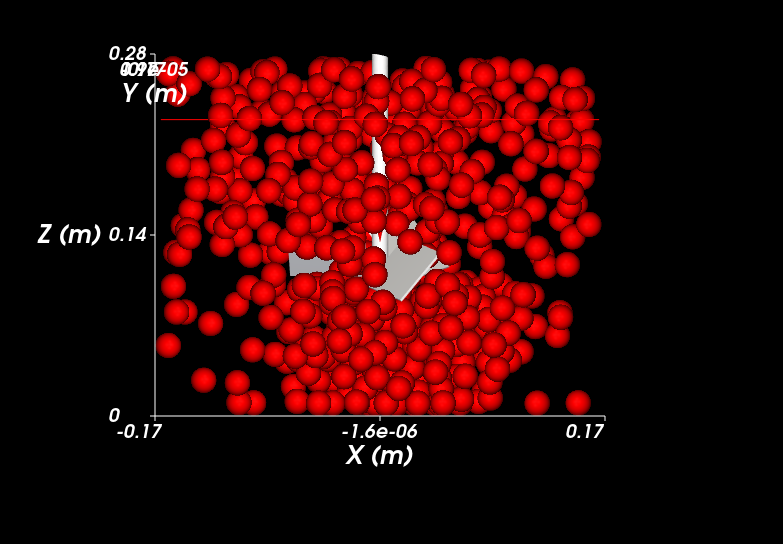

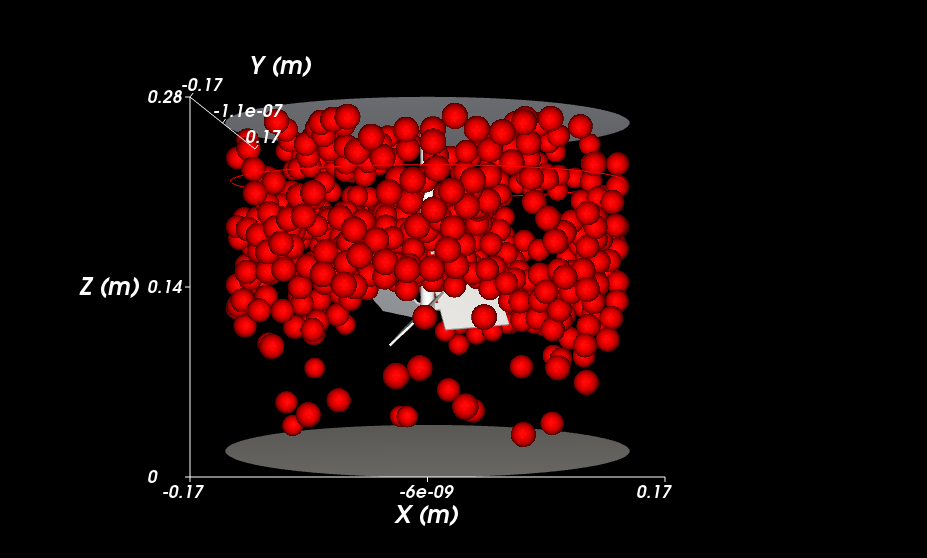

3.23% of the particles exceeded 75% the CFD critical explicit time step.The one with 0.0005s time step , went to 9s and gave the following error and particles agglomorated (picture attached )but the simulation were still running:

DEM-CFD critical explicit time step:

0.183% of the particles exceeded 50% the CFD critical explicit time step.

0.0913% of the particles exceeded 75% the CFD critical explicit time step.

0.0913% of the particles exceeded 100% the CFD critical explicit time step. collected in 11 events of CFD forces.I want to know why it took the simulation 9s to give the error and suddenly got unstable , if there is a problem why it did not gave the error begining of the simulation ?

3- i ran one or two with SPH and particles agglomorated , i will try again SPH and with lower time step of DEM and let you know.

Thanks

-

July 23, 2024 at 4:40 pm

Vinicius Daroz

Ansys EmployeeHi Saeed,

- In the semi-resolved method, there is a total force scalar stored on each particle. This is the only information you have.

- The Explicit timestep error is related to the DEM timestep, not the Fluent timestep.

- Sounds good.

-

July 23, 2024 at 9:49 pm

Saeed

SubscriberHello,

I did a SPH simulation, all the sph settings are default I just changed the element size to 0.005 msince my particle size 0.02m. the problem is after the particles are added , they do not change their position anymore and do not move. it seems like they are fixed and just vibrate in their place. in the attached figure all the particles have not moved in the past 3s of the simulation.

Can you please help me with that ?

Thanks

-

July 25, 2024 at 6:31 pm

Saeed

Subscriber -

July 29, 2024 at 10:35 am

Rob

Forum ModeratorDid not change? What does the Rocky screen look like?

-

July 29, 2024 at 12:34 pm

-

- The topic ‘ANSYS fluent – Rocky DEM coupling’ is closed to new replies.

-

4979

-

1650

-

1386

-

1242

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.