-

-

March 16, 2020 at 7:30 pm

Rajasekhar

SubscriberHello All,

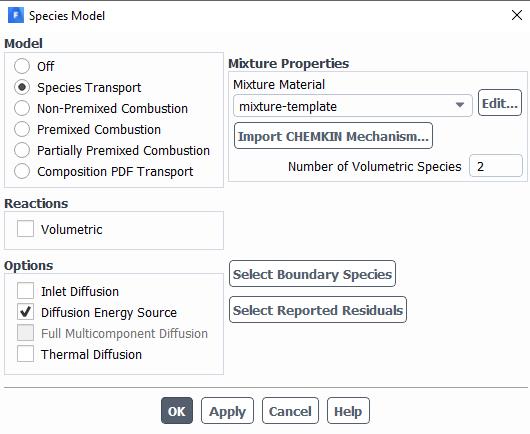

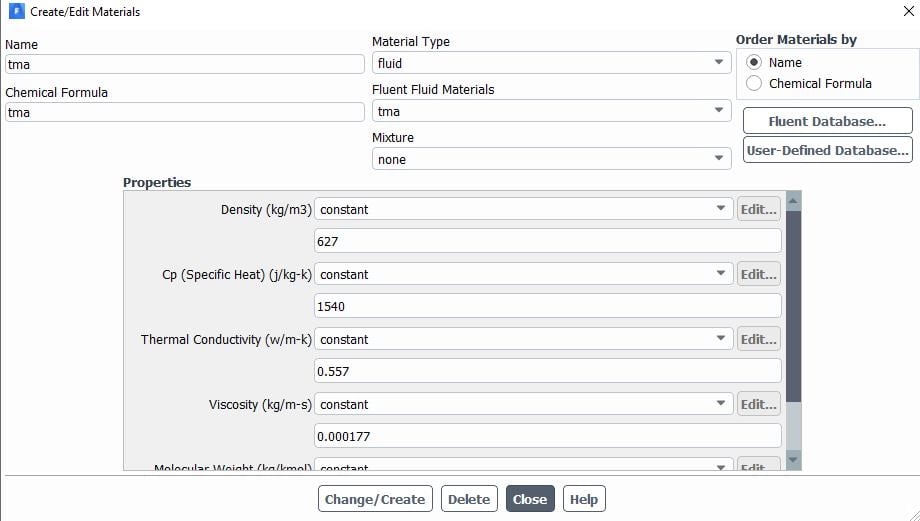

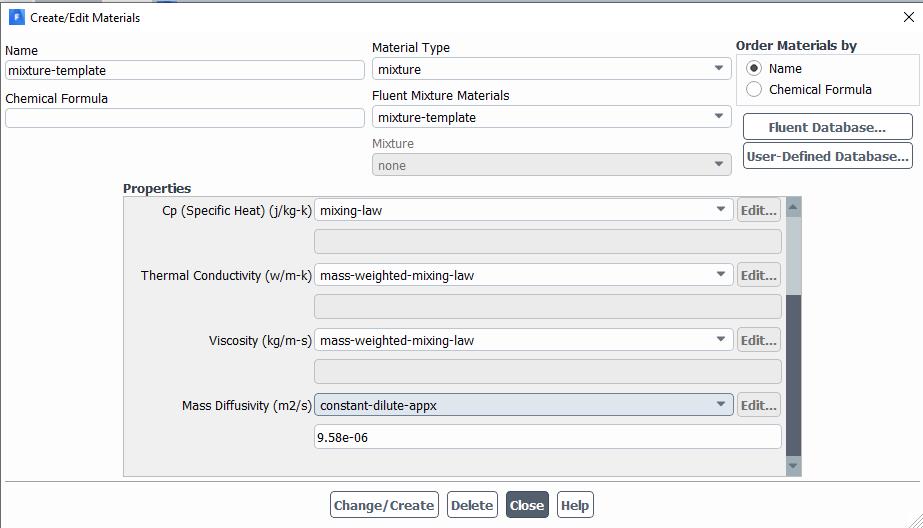

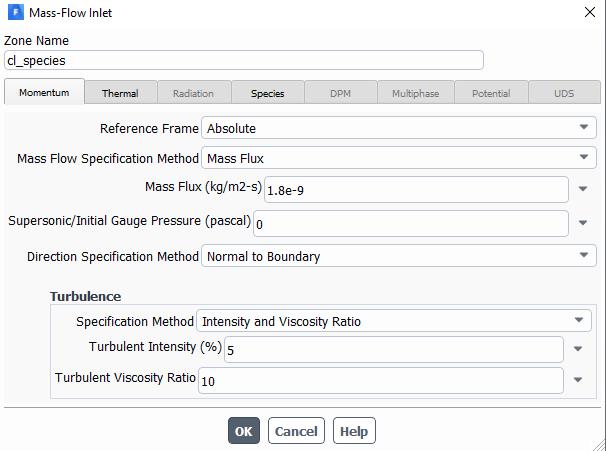

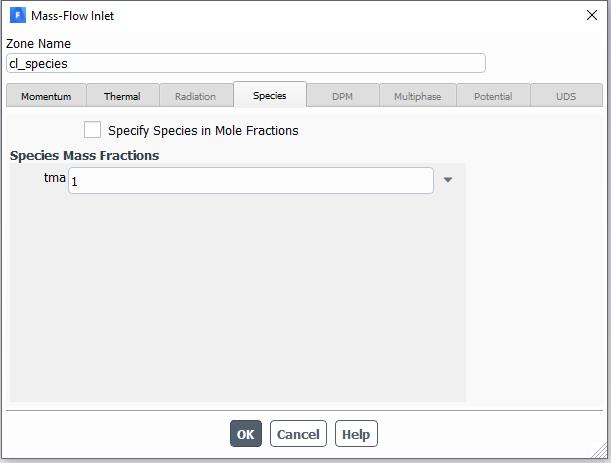

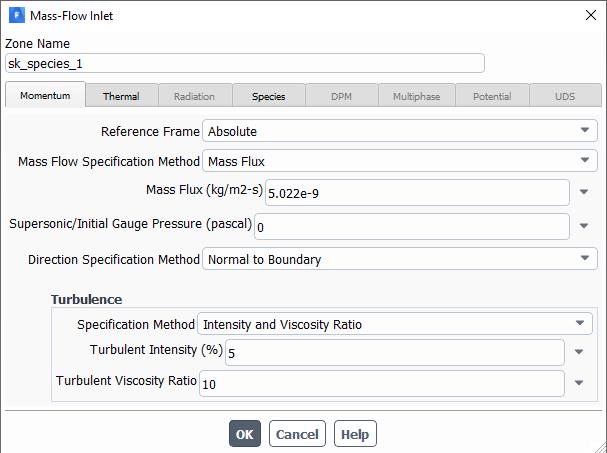

we are simulating a multi species setup in our case. we have a room where the Supply volume flow rate is 10360 L/S. our extract volume flow rate is 9320 L/S. this is a fish selling shop. the main objective of this simulation is the maintain the Fish odor ppm in the desired level such that the people wont feel the fishy smell. we have enabled gravity, we have incorporated air and Trimethylamine as the mixture template in our case. Trimethylamine is the species which is emitted from the fish. this species causes fishy odor as per a lot of articles.

all the inputs related to source generation rate of TMA from fish from each selling Kiosk are provided (KIOSK= at this place the fishes are placed).

all the flow rates are provided in the word document for your reference.

all the geometrical details are also provided in the word document for your reference.

also attaching the case file link here (https://we.tl/t-wVaDGFztFy).

will anyone please check this case file and let us know if we have done anything wrong in this case file.

since the density of TMA is heavy compared to air and since we enabled the gravity in this case. the TMA concentration should not travel much in upward direction. in the current case the TMA is travelling up. will anyone please suggest us any alternatives in terms of design parameters etc. suggestions will be highly appreciated.

Thankyou

Rajasekhar.

-

March 16, 2020 at 9:48 pm

Karthik Remella

AdministratorHello,

As Ansys employees, we are not allowed to open any documents that are attached here on this community. This is where other members of the community can help. Please feel free to help Rajasekhar verify his simulation.

Thank you.

Best Regards,

Karthik

-

March 17, 2020 at 5:46 am

-

March 17, 2020 at 2:42 pm

Rob

Forum ModeratorLooks OK for a species model. I assume you also have pressure bc's and aren't using fixed flow inlets and outlets? Is gravity defined in the correct direction?

For HVAC I prefer Body Force Weighted,

Run the model and then ask questions if the results aren't as expected.

-

March 17, 2020 at 5:52 pm

Karthik Remella

AdministratorHello,

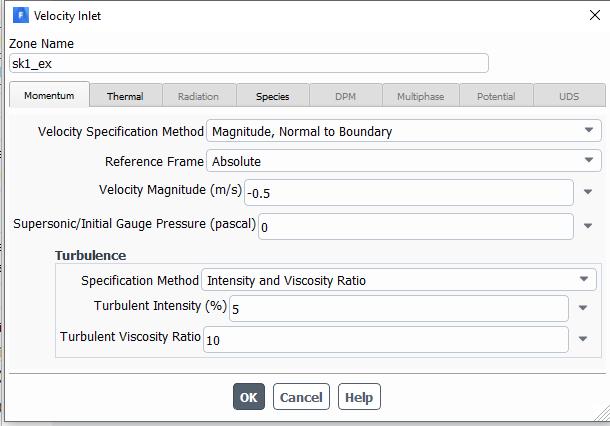

Just to add to what Rob is saying - why are some of your velocities negative normal to the boundary? Is this something intentional? Are you imposing a specific velocity as an outflow?

Thanks.

-

March 18, 2020 at 4:23 am

Rajasekhar

SubscriberHello Rwoolhou and Karthik,

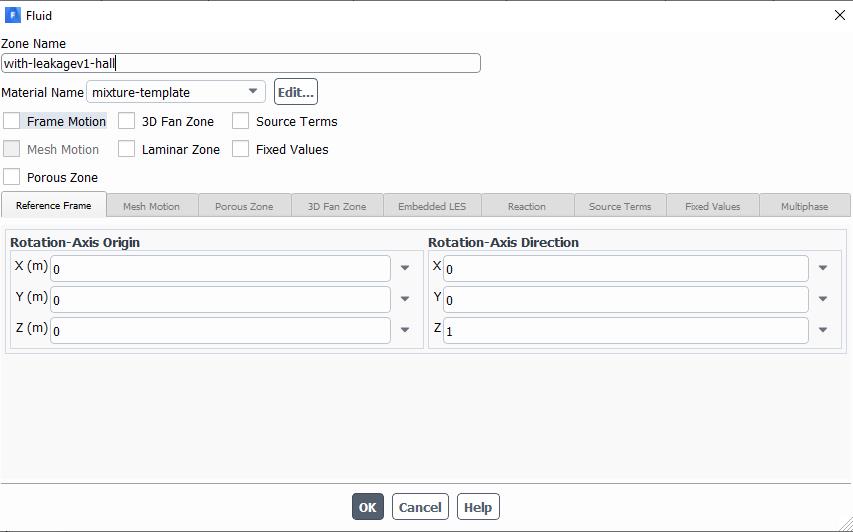

Thankyou for your quick response. as per the initial design from the client there is a mass imbalance in the current case. so in order to maintain mass balance we have considered 3 door openings as leakages for remaining flowrate to go out from the domain. these 3 door openings are considered as pressure outlet boundary conditions in the model.

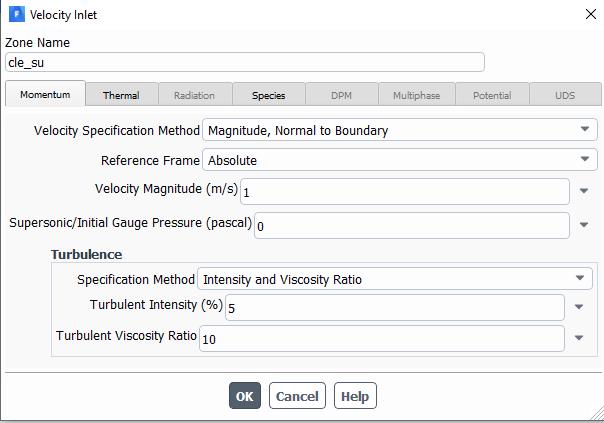

inshort we have velocity inlet boundary condition for volume inflow.

we have velocity inlet with negative sign at velocity outlet boundary condition.

the remaining flowrate is sent out of the domain by using pressure outllet bc along three doors.

please let me know if you need more info on this

i have one more quire. i have attached a molar concentration image in this. please refer that. please find the question in the image itself.

.

Thankyou,

Rajasekhar.

-

March 18, 2020 at 5:18 pm

Karthik Remella

AdministratorHello,

It is fairly unconventional to use negative velocity at the outlet to prescribe a certain mass flow rate at these boundaries. But, if this is something that you need to impose in order to close your problem properly, please go ahead and do that. Since you have more than one outlet, perhaps, it is okay to do what you're doing.

Regarding your other question - do the holes appear as part of your contour plot? Is this an artifact of post-processing? Or is this something that you are intending to model? What is the range of your legend? Is it based on 'Global Range'?

Thanks.

Best Regards,

Karthik

-

March 20, 2020 at 4:35 pm

Rajasekhar

SubscriberHello Karthik,

Thanks a lot for your instant support. in the above problem it self we are supplying a species with total mass flow rate of 1777 mg/hr and my extract system is extracting 649620 mg/hr. will you please tell me what is the underlying physics behind it.

Thankyou,

Reddy.

-

March 20, 2020 at 5:24 pm

Karthik Remella

AdministratorHello,

If you have a closed system and your extraction rate is higher than the feeding rate, you could get into compressibility effects as the air starts to get thin. If your computational domain has opening (similar to your domain) and you are treating the fluid as incompressible, this is a strong possibility that you will get inflow from other boundaries such that your inflow rate matches your outflow.

Again, this is just a speculation based on what I can gather about your problem from the write-ups you have provided. Please feel free to run and analyse your results and let us know if you find anything amiss.

Thank you.

Best,

Karthik -

March 20, 2020 at 6:54 pm

Rajasekhar

SubscriberDear Karthik,

Thanks for your explanation, actually my previous request was to help me to understand why my TMA species is extraction rate is higher compared to my source generation rate.

for instance my source generation (TMA) rate is x kg/s and my tma extraction rate is 10 times of x kg/s. for better understanding please read the below explanation.

I have one question when I analyze the results based on my previous case and data file, I found very strange that the total mass flow rate of TMA species coming from emitting surfaces is 4.9366 e -07 kg/sec (1777.17 mg/hr) which is matching the hand calculation that I defined but when I calculate the mass flow rate of TMA at the extracted surface I got 0.000228 kg/sec (820800 mg/hr), a big difference between the inlet and extract. It seems like the species is generating within the domain. Please find the below snapshots. I am enclosing we transfer link for my case and data file for your reference.

Calculation

Area weighted average (mass fraction of tma) = mass of tma/ mass of air = 0.00002091. see Figure 1

Mass flow rate of tma = 0.00002091* mass flow rate of air (eq 1)

Total mass flow rate from the extracted surfaces = mass flow rate of air + mass flow rate of tma (figure 2)

mass flow rate of air = total mass flow rate - mass flow rate of tma (eq 2)

put value of mass flow rate of air from eq 2 to eq 1

mass flow rate of tma = 0.00002091 * (total mass flow rate – mass flow rate of tma)

mass flow rate of tma = 0.00002091 *(10.907 – mass flow rate of tma)

mass flow rate of tma = 0.000228 kg/sec = 820800 mg/hr

Fig 1

Fig 2

(link for case and data file)

Please have a look, is this because of mesh or any other reason.

Thankyou.

-

March 20, 2020 at 7:02 pm

-

- The topic ‘Ansys fluent Case setup help.’ is closed to new replies.

-

5094

-

1830

-

1387

-

1248

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.