TAGGED: #fsi-#transient, ansys-cfx, anys-mechanical, coupling

-

-

September 2, 2024 at 1:53 pm

ashishkumar.gupta

SubscriberHello,

It is very frustationg to understand the different error I am encountering.

My Transient Strtcutral and Fluent runs perfectly well if simulated alone, whereas on system coupling, I get various errors. I have tried to develop fine mesh, adopt to better mesh style and restrict rigid motion but nothing helped. Are there any proper tutorials to deal with this?

Please help me out!!

-

September 3, 2024 at 1:01 pm

Rahul

Ansys EmployeeHello Ashish,

Please share the errors from the log files of the participants and system coupling.

You can find it at:

Fluent transcript: progress_files > DP0 > FFF > Fluent > solution.trn

Mechanical output file: DP0 > SYS > MECH > solution.out

SyC log file: DP0 > SC > SC > SyC > scLog.scl

-

September 3, 2024 at 1:10 pm

Rahul

Ansys Employee- What Dynamic Mesh settings are being used in Fluent? Try Tetra-hedral cells to enable remeshing with the Unified Remeshing methods.

- I guess you are using liquid as working fluid. Make sure your material is set as a compressible liquid. An incompressible fluid will have infinite sound speed, which in cases with deforming fluids can lead to pressure spikes at the FSI interfaces resulting in excessive deformation. If you still experience high pressure oscillations at the FSI interface, consider using Solution Stabilization 12.6.9.8 Solution Stabilization for Dynamic Meshes Boundary Zones (ansys.com)

-

September 3, 2024 at 1:41 pm

ashishkumar.gupta

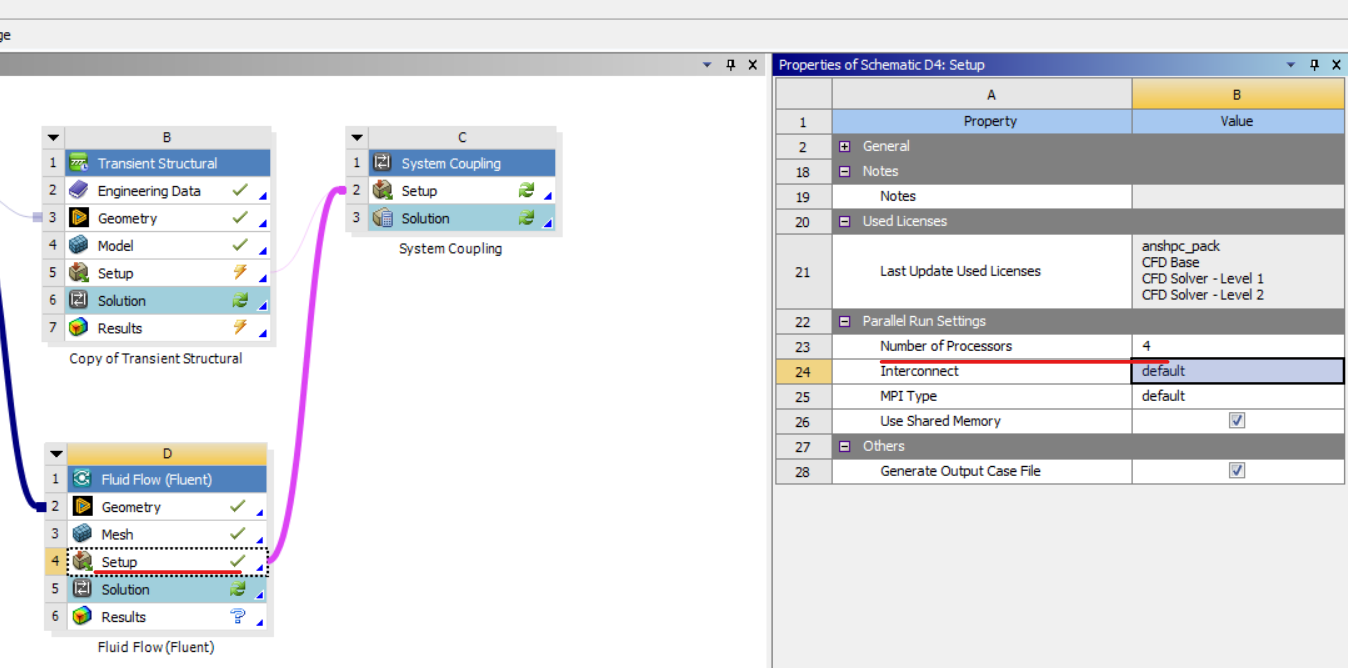

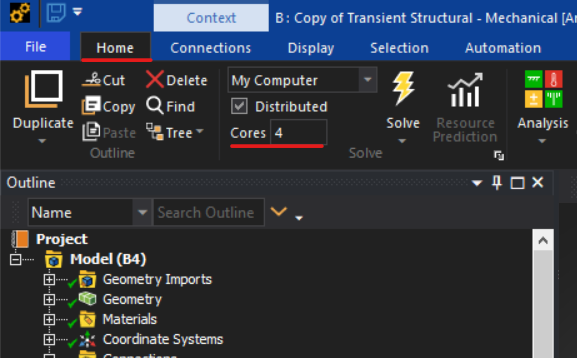

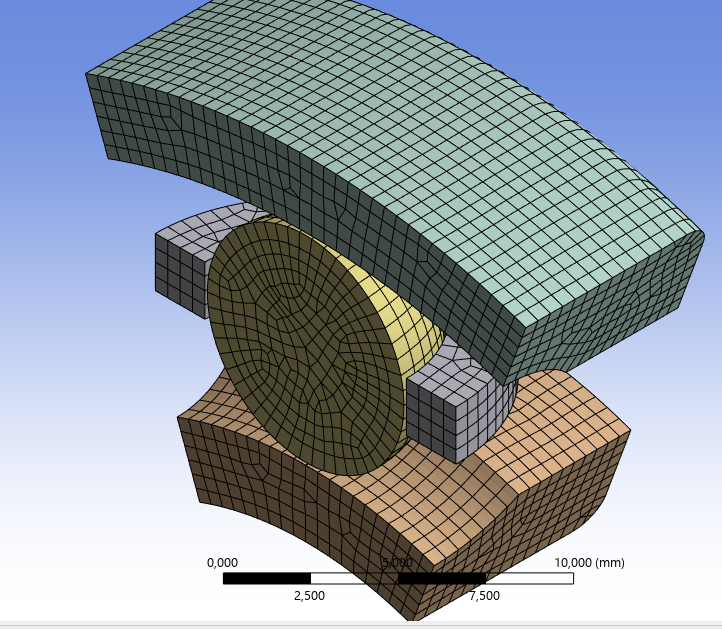

SubscriberHi Rahul, for the 2 way FSI, my mapping problem has been resolved. I am running with the hex-dominant method (mesh size 2 mm for whole bodx and 1mm for FSI). I have 4 parallel cores. But I think the solution is runnig very slow. Also, can u give me quick tips/tools from which I can know to solve solution quickly and efficiently?

-

September 3, 2024 at 1:41 pm

ashishkumar.gupta

SubscriberHi Rahul, for the 2 way FSI, my mapping problem has been resolved. I am running with the hex-dominant method (mesh size 2 mm for whole bodx and 1mm for FSI). I have 4 parallel cores. But I think the solution is runnig very slow. Also, can u give me quick tips/tools from which I can know to solve solution quickly and efficiently?

-

September 3, 2024 at 1:48 pm

-

September 3, 2024 at 1:58 pm

ashishkumar.gupta

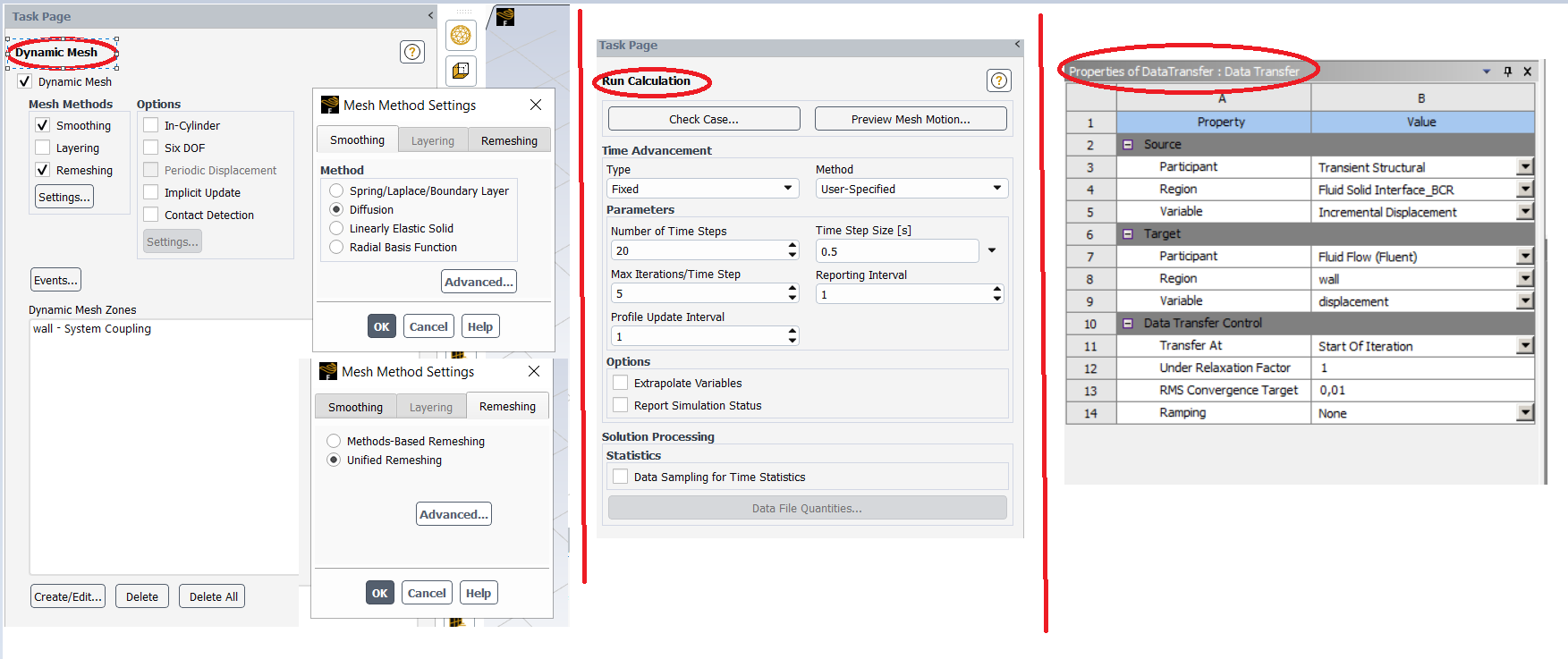

SubscriberI am using 4 parralel cores. In addition, Dynamic meshing has been set up with unified meshing. Still the solution was slow. It is very complicated to understading the converging and simulation time in FSI. The documents are helpful but too difficult to interpret sometimes.

-

September 3, 2024 at 2:31 pm

Rahul

Ansys Employee -

September 5, 2024 at 12:27 pm

ashishkumar.gupta

SubscriberHi Rahul,

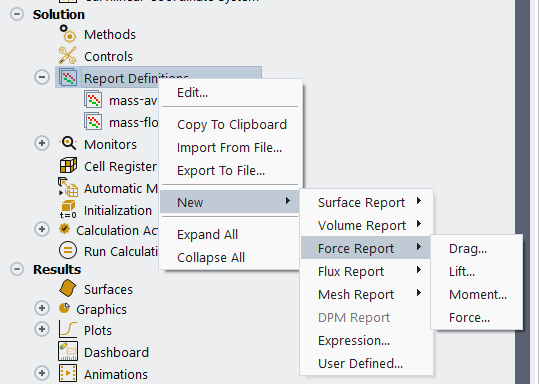

I did not find this oiptzion in Ansys Fluent: "monitor force/heat flux, etc with report definitions in Fluent. Do not use too many Fluent iterations per coupling step, this will help you to improve the solution time."

Could you send me the SS of where exactly I can find it? Also, how many Fluent iterations per coupling step is recommened or how can I find the optimised value?

In addition, I have an additional doubt which I have attached below:

Thank you!!!

Regards,

Ashish

-

September 5, 2024 at 1:54 pm

Rahul

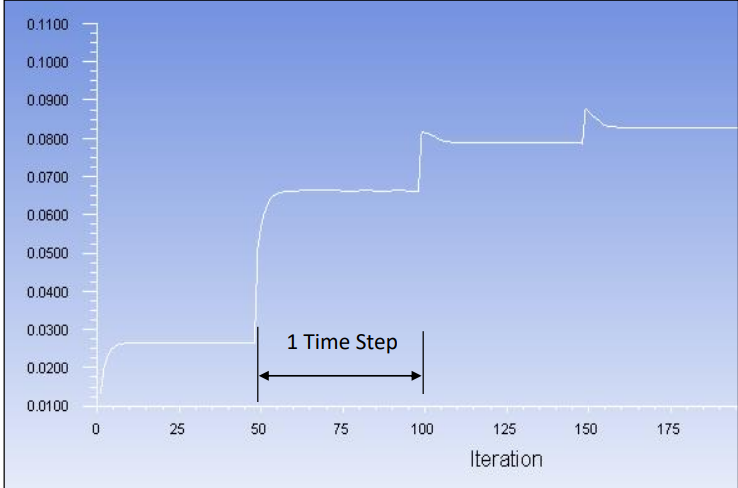

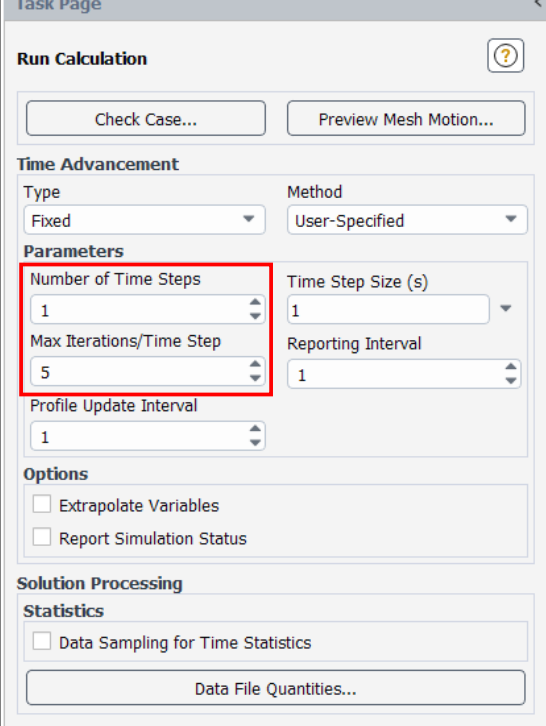

Ansys EmployeeMax Iterations/Time Step ‐ Interpreted in SyC as Fluent iterations per Coupling Iteration.

Use fewer iterations than a normal transient case

‐ Rough guide is:

• ~5 iterations for cases with initial fluid solution

• ~10 iterations for cases without initial solutionAim to converge the Fluent by end of Coupling Step.

-

September 6, 2024 at 6:15 am

ashishkumar.gupta

SubscriberThaqnk you Rahul for the detailed info. Could you also help me out with the 'additional doubt ' with the pic attached above? TIA

-

September 6, 2024 at 7:26 am

Rahul

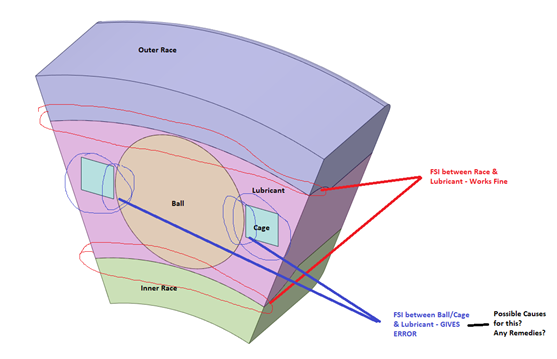

Ansys EmployeeI assume you are having two interfaces there: 1: Lubricant-Cage 2. Lubricant-Ball.

How is the mesh in that narrow passage there?

Could you please share the error message that you are getting?

-

September 6, 2024 at 8:19 am

-

September 6, 2024 at 8:29 am

Rahul

Ansys EmployeeThe error is from Mechanical participant that solution is not converging. Check if the material properties, boundary conditions are set correctly. Also, try refining the mesh in the MAPDL.

-

September 6, 2024 at 12:09 pm

ashishkumar.gupta

SubscriberAs I said, the meshing, B.C. and material were unchanged. So u want to say just by refining mesh, the problem could be solved? and what is MAPDL?

-

September 6, 2024 at 12:16 pm

Rahul

Ansys Employeeokay. Then try refining mesh in Mechanical Particpant and see if it helps.

Also, check .out file for more information about the error.You can find Mechanical output file in folder: DP0 > SYS > MECH > solution.out

-

September 8, 2024 at 7:28 am

ashishkumar.gupta

SubscriberHi, I gave 'Tetrahedral MEsh' to all the bodies in Mech and Fluent with mesh size as fine as 0.2 mm as contrast to 0.5 mm the last time. Still gave an error.

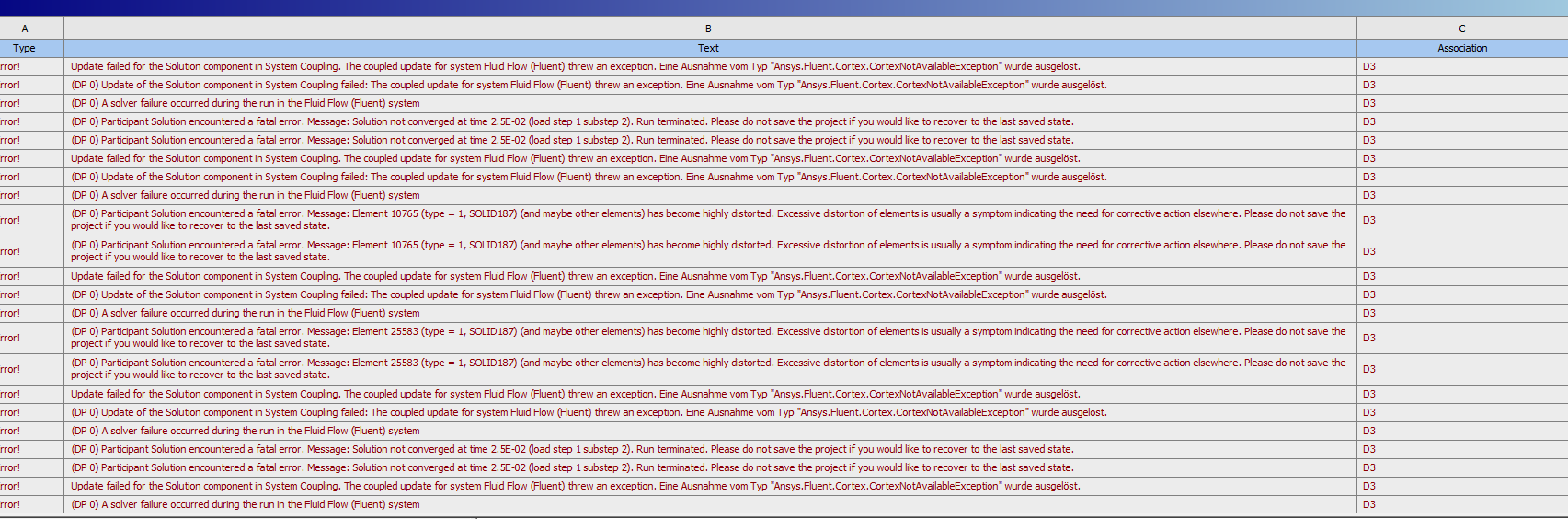

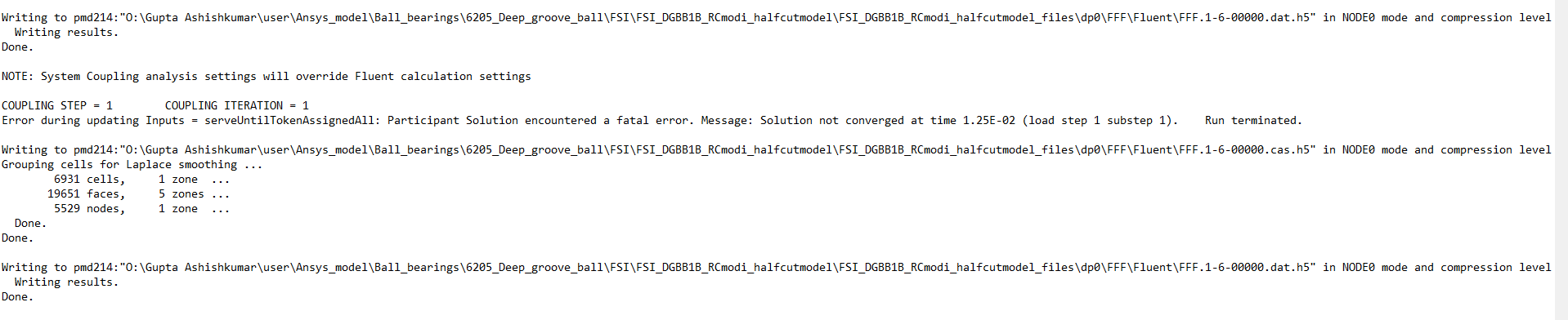

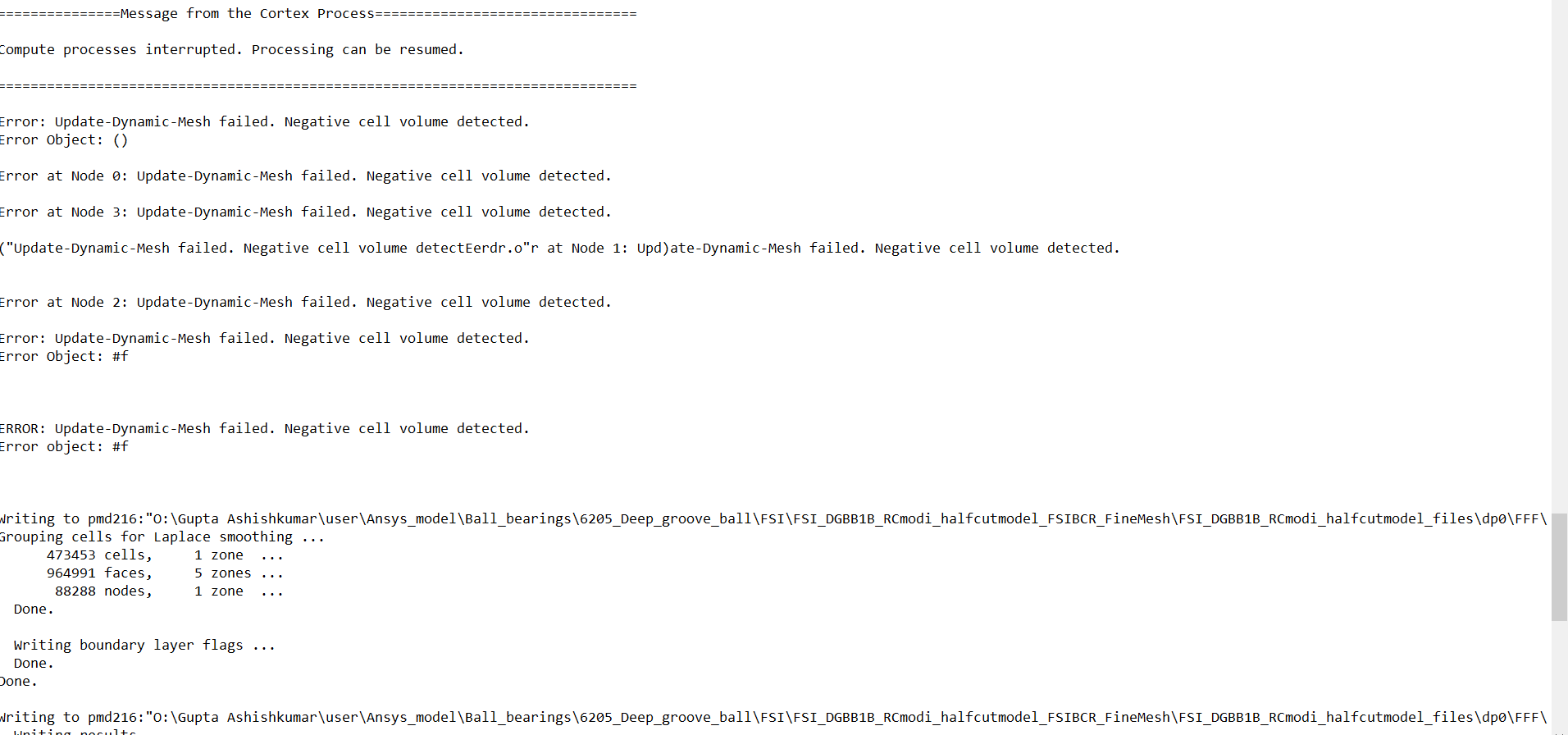

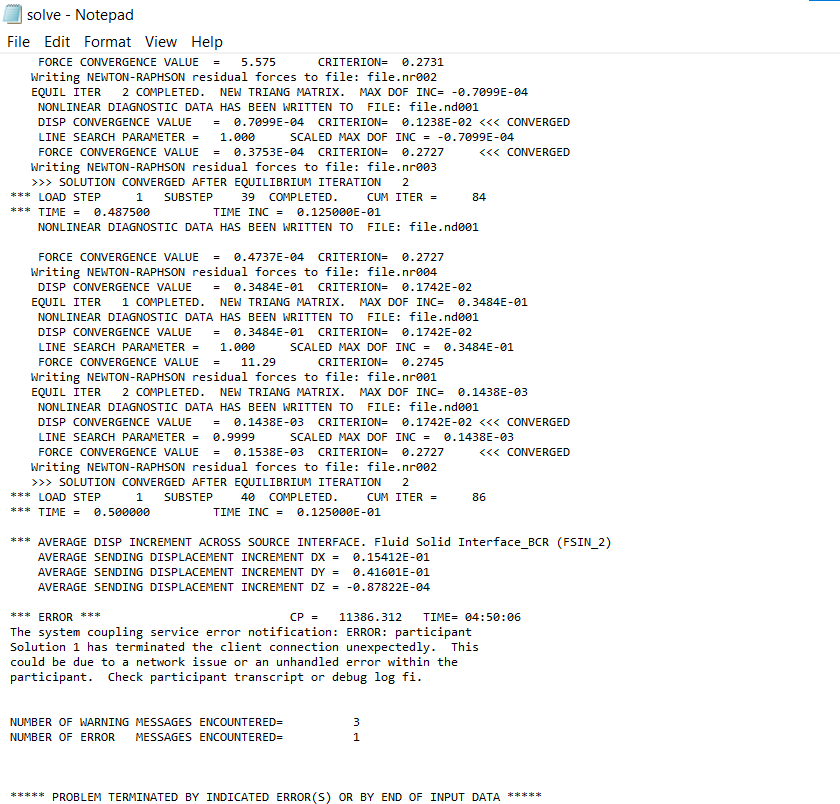

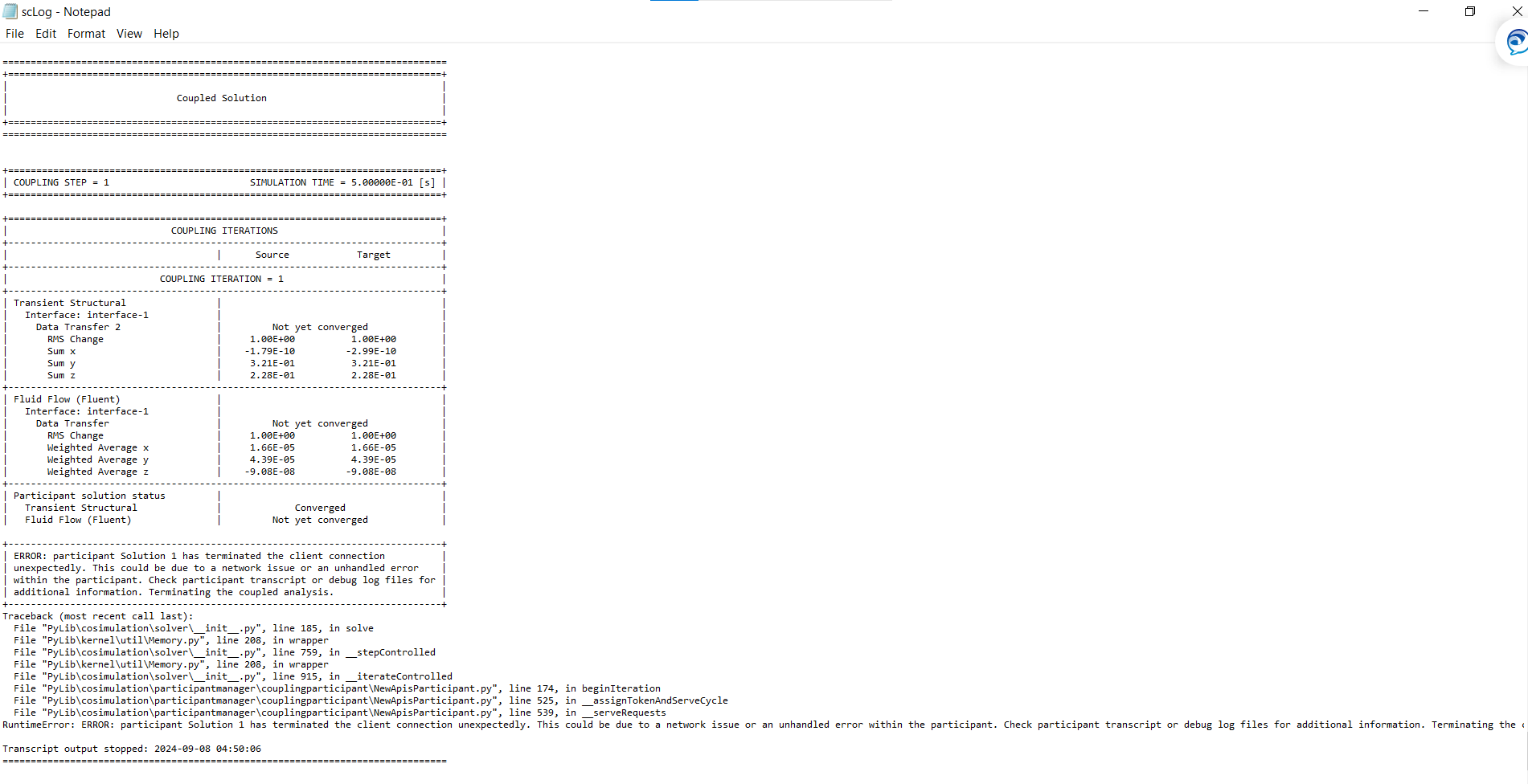

The error in Fluent file:

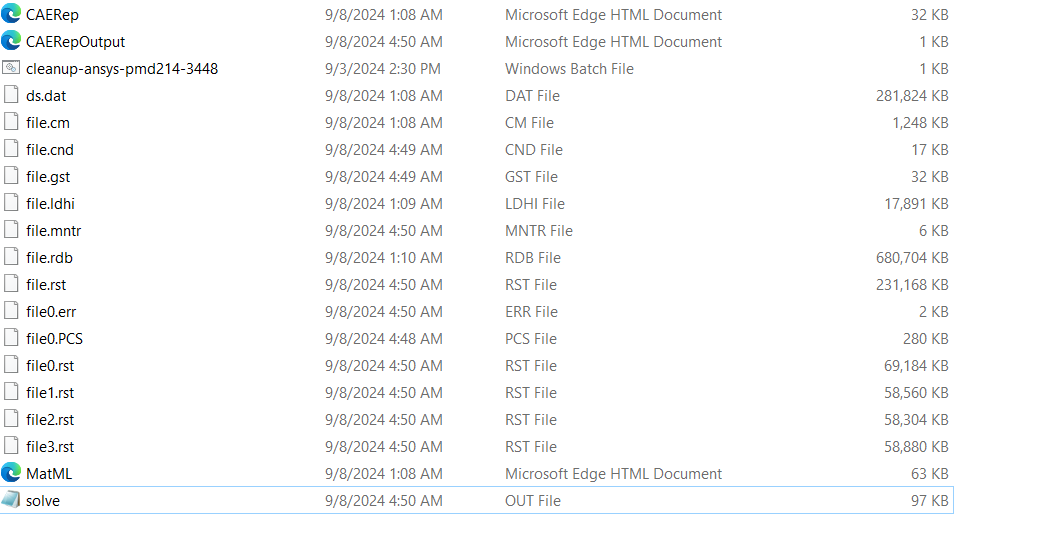

the error in Mech file: (Thre is no Solution.out file in the folder; I guess it is solve.out file)

System Coupling file:

So I do not really think it is the meshing which is causing an error. Could you please help me out here as I am working on the same issue since a week now.

Thank you and hope to hear from u soon!!!

-

September 9, 2024 at 6:56 am

Rahul

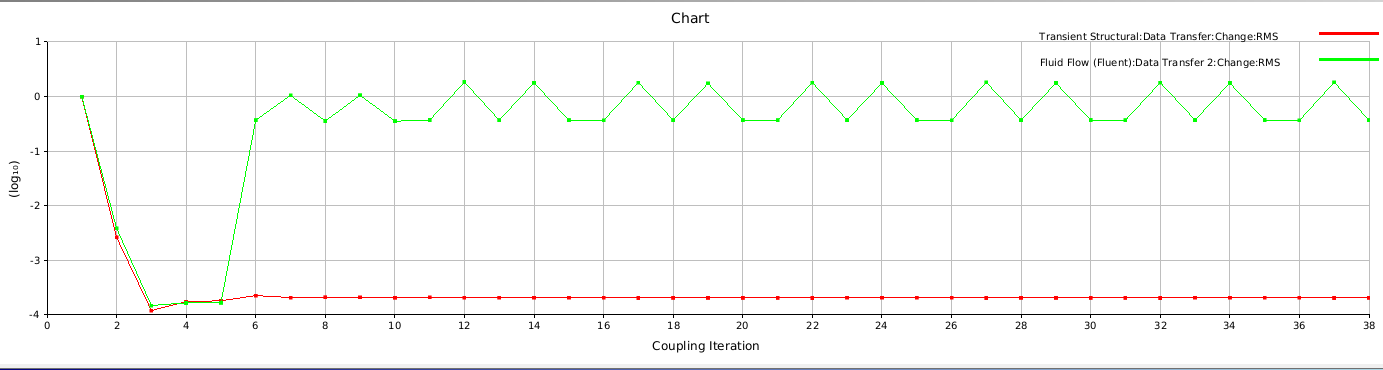

Ansys EmployeeThis time it failed in Fluent with negative mesh error. When this happens, it is often because unreasonable displacements were received by Fluent. Since the Fluent mesh collapsed, you should check if the incremental displacement sent to Fluent was reasonable.

It is important to ask here is why are the forces/displacements oscillating with increasing magnitude? If the problem here is due to unstable coupling between the force and displacement on the interface and the displacements calculated are over-shooting the correct position, resulting in an collapsed mesh.

Have you tried

- reducing time step?

- Use under-relaxation of data transfer?

Share the dynamic mesh settings being used for this case.

-

September 9, 2024 at 7:06 am

-

September 9, 2024 at 7:06 am

-

September 9, 2024 at 7:16 am

Rahul

Ansys EmployeeChange the time step setting under 'Analysis Settings' in system coupling and not in Fluent.

Using under relaxation of data transfer will make the solution more stable at the expense of more COUPLING ITERATIONS to reach convergence. So, if you reduce the URF, consider increasing the max coupling iterations

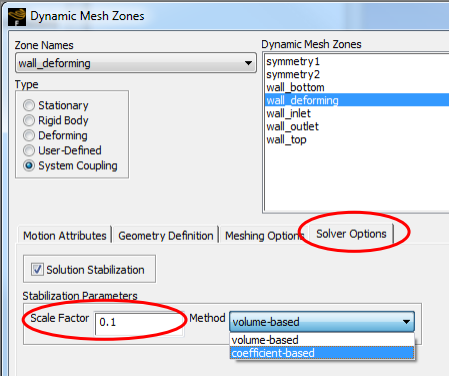

according.Note that some cases can remain unstable even when under-relaxation is used; to stabilize these types of cases Solution Stabilization is available in Fluent in the Dynamic Mesh settings on the Solver Options panel.

-

September 9, 2024 at 7:20 am

ashishkumar.gupta

Subscriberok...could you recommend some ideal values for time step, URF, & max coupling iterations ? The Scale Factor should be kept at 0.1 for coeff. based?

-

September 9, 2024 at 7:32 am

Rahul

Ansys EmployeeMost of the time these values are case dependent. try changing it and see what works for your case.

Initially you could try using URF = 0.8 and decrease further if needed.

for scale factor start with smaller values ( e.g.1e-3 ) and then increase. coefficient-based method has been shown to be more robust than the volume based method so it is recommended.

-

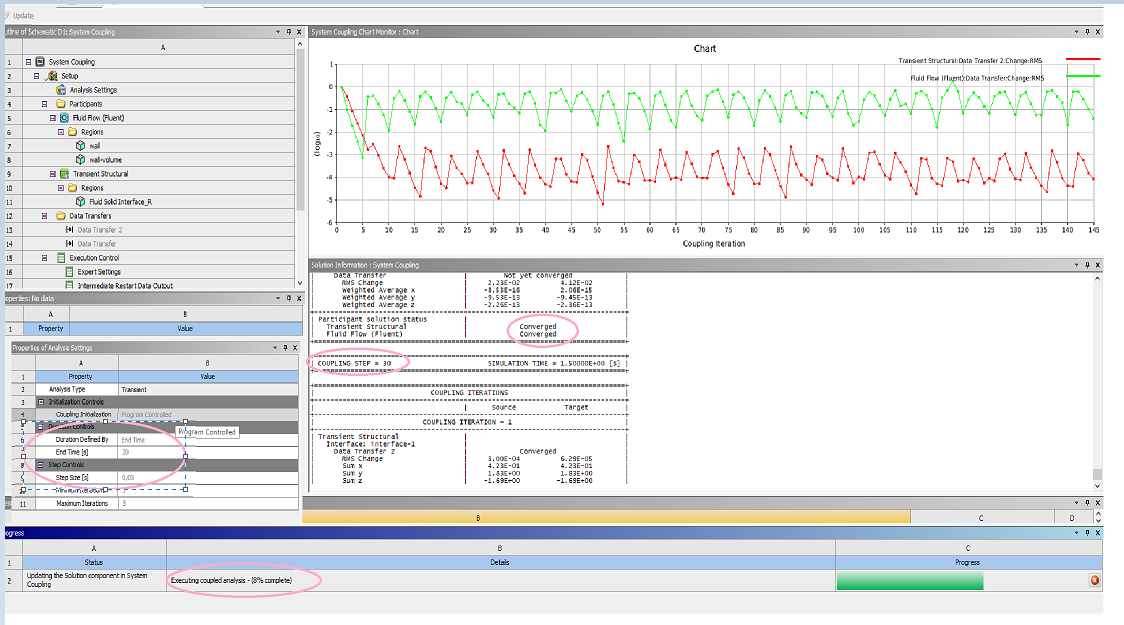

September 11, 2024 at 11:54 am

-

September 11, 2024 at 12:04 pm

Rahul

Ansys EmployeeAs discussed earlier, monitor the convergence of coupling participants and decide the number of Fluent iteration to be used per coupling iteration (here the goal is to converge the fluent at the end of coupling step and not every coupling iteration) to optimize the solve time or use machine with higher processes and memory.

I recommend that you build up to the final two-way analysis incrementally, progressively adding complexity with each step. You can find the recommended steps for building any coupled analysis here: Building Up to a Coupled Analysis (ansys.com)

-

- You must be logged in to reply to this topic.

-

4939

-

1639

-

1386

-

1242

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.